Synthesis method of diesel fuel depressant

A technology of diesel oil point depressant and synthesis method, which is applied in the field of additives, can solve the problems such as difficult to reduce the cold filter point of diesel oil with relatively high wax content, and achieve the effect of excellent cold filter point reduction performance, mild reaction conditions, and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

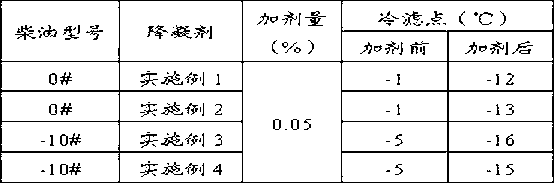

Embodiment 1

[0029] A synthetic method of diesel pour point depressant, the concrete steps include:

[0030] In a reactor with a stirring device, add 90 mL of toluene and 90 mL of S150 solvent, stir, control the temperature of the water bath to 95 ° C, pass nitrogen, the nitrogen pressure is 0.1 MPa, add 200 g of cetyl alcohol ester and 100 g of acrylamide, divide into two The initiator was added dropwise, and the mixed raw material liquid composed of vinyl acetate and styrene was added dropwise; the initiator was composed of 0.73g tert-butyl peroxide-2-ethylhexanoate and 0.073g azobisisobutyric acid. The mixed raw material liquid is composed of 100 g vinyl acetate and 100 g styrene; 8 g of the initiator is added dropwise for the first time, and 100 g of the mixed raw material liquid composed of vinyl acetate and styrene is added dropwise, and the reaction is carried out for 0.5 hours. The mixed raw material liquid composed of the remaining initiator, vinyl acetate and styrene is then adde...

Embodiment 2

[0033] A synthetic method of diesel pour point depressant, the concrete steps include:

[0034] In a reactor with a stirring device, add 303.0 mL of toluene and 151.5 mL of S150 solvent, stir, control the temperature of the water bath to 60 ° C, pass nitrogen, the nitrogen pressure is 0.05 MPa, add 200 g of behenyl ester and 100 g of diethylene Triamine, add the initiator dropwise twice, and dropwise add the mixed raw material liquid composed of vinyl acetate and styrene at the same time; the initiator is composed of 4g tert-butyl peroxide-2-ethylhexanoate and 2g azodicarbonate It is composed of dimethyl isobutyrate, and the mixed raw material liquid is composed of 100 g of vinyl acetate and 200 g of styrene; for the first time, 4.8 g of an initiator is added dropwise, and 60 g of a mixed raw material liquid composed of vinyl acetate and styrene is added dropwise. , after the reaction for 2 hours, the mixed raw material liquid composed of the remaining initiator, vinyl acetate...

Embodiment 3

[0037]A synthetic method of diesel pour point depressant, the concrete steps include:

[0038] In a reactor with a stirring device, add 95.5 mL of toluene and 63.6 mL of S150 solvent, stir, control the temperature of the water bath to 80 ° C, pass nitrogen, the nitrogen pressure is 0.2 MPa, add 100 g of stearyl alcohol ester and 120 g of triethylene tetrakis Amine, add the initiator dropwise twice, and dropwise add the mixed raw material liquid composed of vinyl acetate and styrene at the same time; the initiator is composed of 3.85g tert-butyl peroxide-2-ethylhexanoate and 1.15g azo Dimethyl diisobutyrate consists of 120g vinyl acetate and 80g styrene; 3.75g of initiator is added dropwise for the first time, and a mixed raw material solution consisting of vinyl acetate and styrene is added dropwise at the same time 50g, after the reaction for 4 hours, the mixed raw material liquid composed of the remaining initiator, vinyl acetate and styrene was added dropwise; the copolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com