Borehole stabilizer for drilling fluid, preparation method and applications thereof

A wellbore stabilizer and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance, high cost, limited use, etc., to achieve good temperature resistance, low cost, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

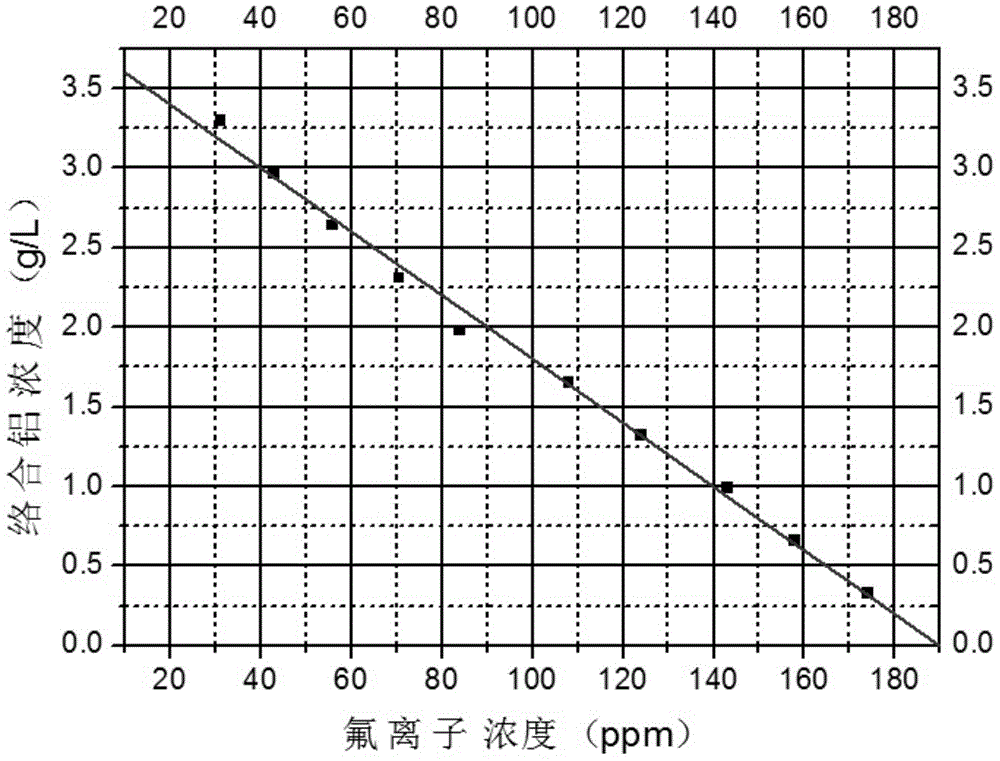

Image

Examples

Embodiment 1

[0032] Weigh 36.0Kg of deionized water into the reactor, turn on the stirring device, add 1.0Kg of sodium hydroxide into the reactor, stir fully to dissolve the alkali completely; weigh 5.0Kg of sodium humate and 25.0Kg of phenolic resin Add in the reaction kettle one by one, stir to make it mix evenly, and control the temperature between 30~40°C at the same time; prepare 0.1Kg of tartaric acid into an aqueous solution with a mass fraction of 56%, add the aqueous solution of tartaric acid into the reaction kettle, and fully stir for 10 Minutes, keep the reaction temperature between 30-40°C; then weigh 5.0Kg of aluminum sulfate and slowly add it into the reaction kettle, stir rapidly, control the temperature at 60-70°C, and react at constant temperature for 2.0 hours. After the reaction is complete, the product is dried and pulverized at 100°C to obtain the product.

Embodiment 2

[0034] Weigh 59.0Kg of deionized water into the reactor, turn on the stirring device, add 3.0Kg of potassium hydroxide into the reactor, stir fully to dissolve the alkali completely; weigh 25.0Kg of potassium humate and 5.0Kg of sulfonated Add the sulfonated phenolic resin from the tannin extract to the reaction kettle in turn, stir to make it evenly mixed, and at the same time control the temperature between 40 and 50°C; prepare 0.5Kg of sodium pyrosulfite into an aqueous solution with a mass fraction of 54% and add it to the reaction kettle. Fully stir for 20 minutes, keep the reaction temperature between 40-50°C; then weigh 15.0Kg of aluminum sulfate and slowly add it into the reaction kettle, stir rapidly, control the temperature at 60-70°C, and react at constant temperature for 3.0 hours. After the reaction is complete, the product is dried and pulverized at 100°C to obtain the product.

Embodiment 3

[0036] Weigh 42.0Kg of deionized water into the reaction kettle, turn on the stirring device, add 2.0Kg of potassium hydroxide into the reaction kettle, stir fully to dissolve the alkali completely; weigh 15.0Kg of ammonium humate and 15.0Kg of sulfonated Add lignin sulfonated phenolic resin into the reaction kettle in turn, stir to make it evenly mixed, and control the temperature between 40 and 50°C at the same time; prepare 0.3Kg sodium citrate into an aqueous solution with a mass fraction of 59% and add it to the reaction kettle , fully stirred for 30 minutes, and kept the reaction temperature between 40-50°C; then weighed 15.0Kg of aluminum chloride and slowly added it to the reaction kettle, stirred rapidly, controlled the temperature at 70-80°C, and reacted at constant temperature for 2.0 hours. After the reaction is complete, the product is dried and pulverized at 100°C to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com