Method for preparing diesel depressant

A technology of diesel pour point depressant and solvent, which is applied in the field of preparation of diesel pour point depressant, which can solve the problems of high power consumption, inability to transport, and high viscosity in crude oil transportation, and achieve reduced energy consumption, excellent cooling filter point and pour point depressant Point Performance, Single and Yield High Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

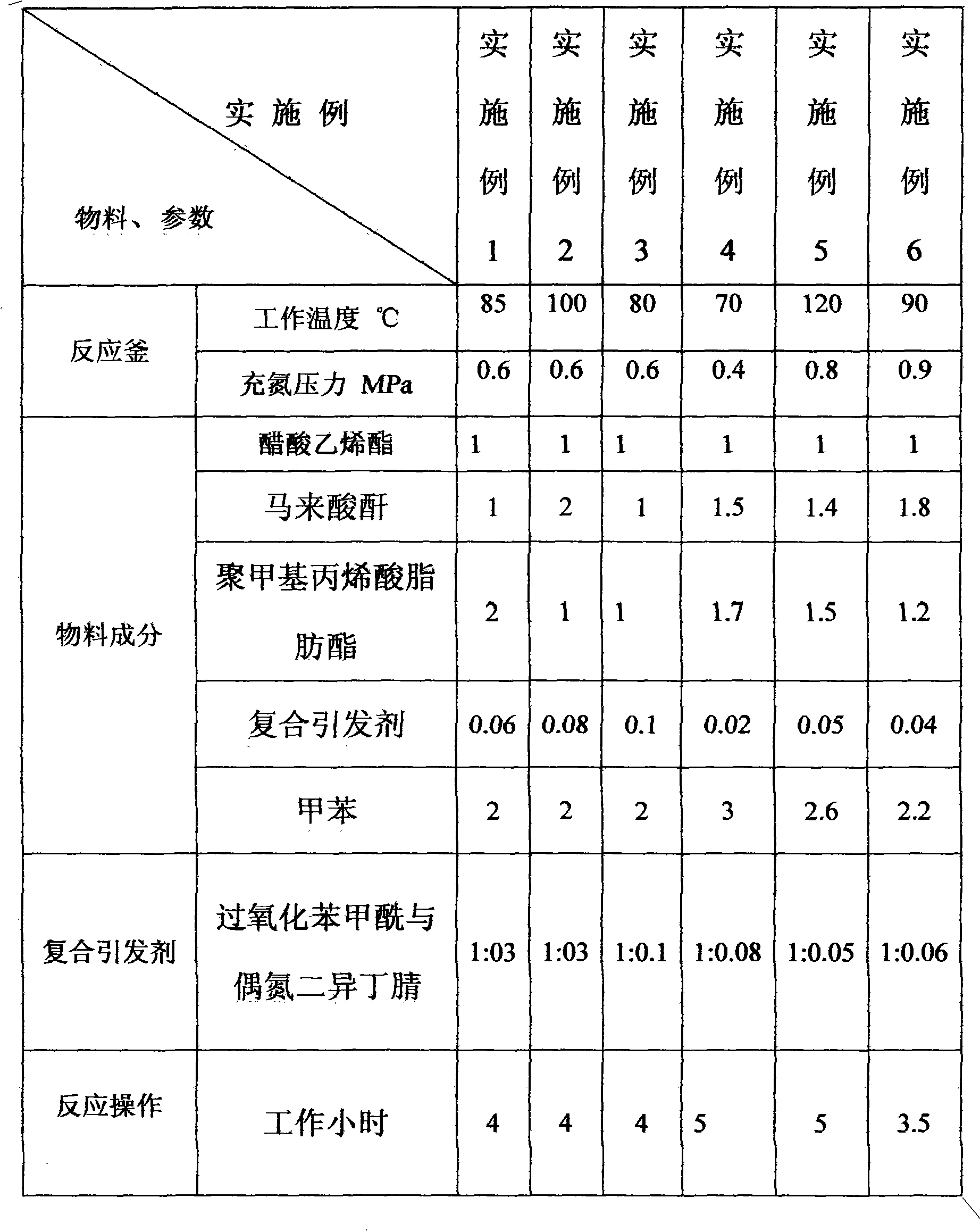

Embodiment 1

[0013] In the reactor with stirring, put part of toluene, stir, raise the temperature to 85°C and keep the temperature constant, and at the same time, fill the reactor with nitrogen to 0.6MPa, and keep this pressure all the time. Prepare vinyl acetate, maleic anhydride, polymethacrylate fatty ester and toluene, according to the ratio of mass ratio 1:1.0:2.0:2.0, use the metering pump to transport the uniformly mixed preparation solution into the reaction kettle, and inject the composite initiator , to carry out the polymerization reaction. Here, vinyl acetate: composite initiator is by mass ratio 1: 0.06, and composite initiator is benzoyl peroxide and azodiisobutyronitrile, forms by the ratio of mass ratio 1: 0.05, and reaction mass is in After reacting in the reactor for 4 hours, put the discharged material into the still, and distill off the unreacted monomer and solvent, and the residue is the terpolymer.

Embodiment 2

[0015] In a stirred reactor, put some toluene, stir, raise the temperature to 100°C and keep the temperature constant, and at the same time, fill the reactor with nitrogen to 0.6MPa, and keep this pressure all the time. Prepare vinyl acetate, maleic anhydride, polymethacrylic fatty ester and toluene, and use a metering pump to transport the uniformly mixed preparation solution to the reaction kettle according to the mass ratio of 1:2.0:1.0:2.0, and add the composite initiator dropwise , to carry out the polymerization reaction. Here, vinyl acetate: composite initiator is by mass ratio 1: 0.08, and composite initiator is benzoyl peroxide and azodiisobutyronitrile, forms by the ratio of mass ratio 1: 0.08, and reaction mass is in After reacting in the reactor for 4 hours, put the discharged material into the still, and distill off the unreacted monomer and solvent, and the residue is the terpolymer.

Embodiment 3

[0017] In the reactor with stirring, put part of toluene, stir, raise the temperature to 80°C and keep the temperature constant, and at the same time, fill the reactor with nitrogen to 0.6MPa, and keep this pressure all the time. Prepare vinyl acetate, maleic anhydride, polymethacrylic fatty ester and toluene, according to the ratio of mass ratio 1: 1.0: 1.0: 2.0, use a metering pump to transport the uniformly mixed preparation solution to the reactor, and add the composite initiator dropwise , to carry out the polymerization reaction. Here, vinyl acetate: composite initiator is by mass ratio 1: 0.1, and composite initiator is benzoyl peroxide and azodiisobutyronitrile, forms by the ratio of mass ratio 1: 0.1, and reaction mass is in After reacting in the reactor for 4 hours, put the discharged material into the still, and distill off the unreacted monomer and solvent, and the residue is the terpolymer.

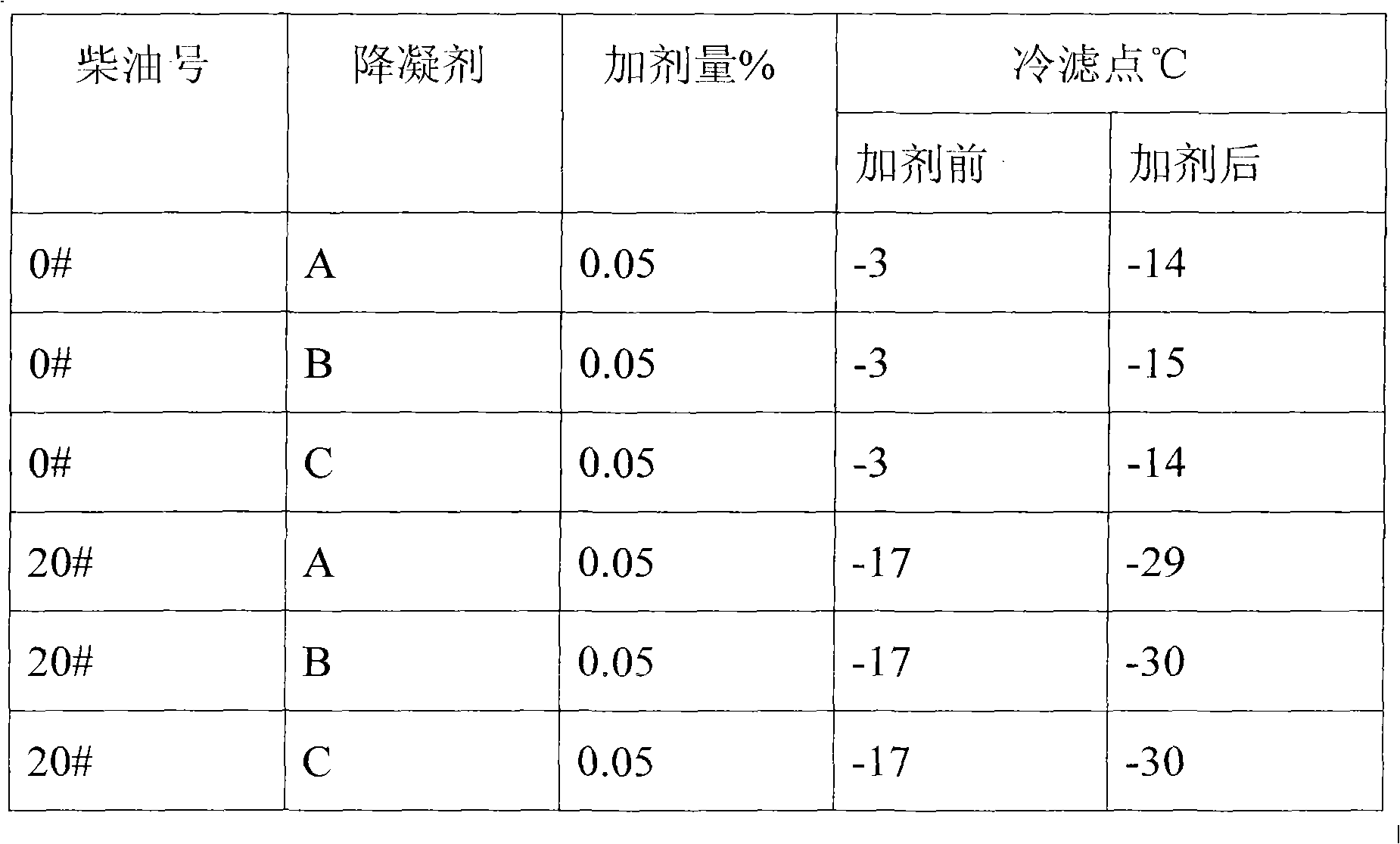

[0018] 0.6 grams of the above-mentioned terpolymer dry agent and 0.2 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com