Hydrogenation, modification and pour point depression method by consideration of product quality of diesel oil

A technology for hydrotreating and improving product quality, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problem of diesel fraction freezing point, cold filter point property improvement not obvious, diesel fraction cetane number loss , limited effect and other problems, to achieve the effects of excellent selective ring opening cracking, improved low temperature fluidity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

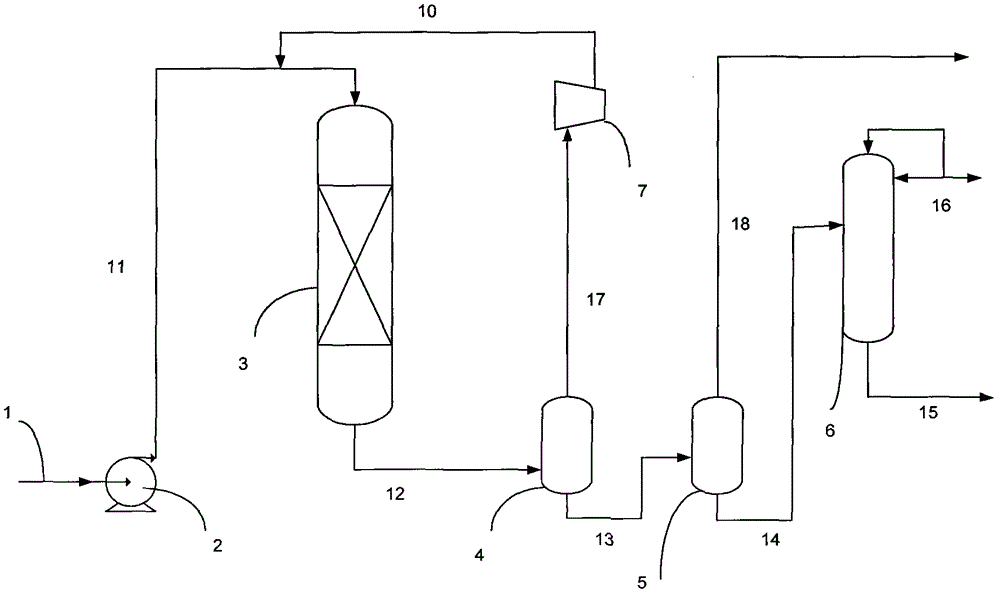

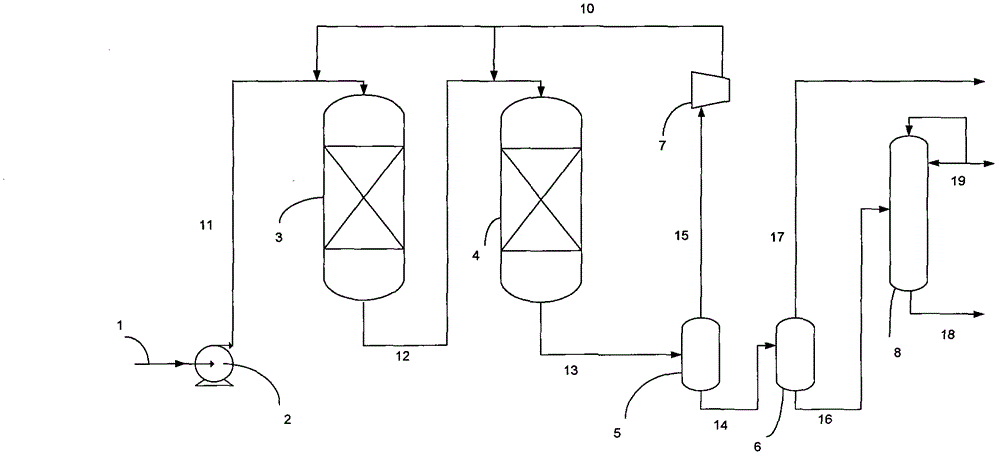

Method used

Image

Examples

Embodiment 1

[0054]The raw material oil A enters the hydrogenation reactor together with the hydrogen, and successively reacts with the hydrofining catalyst and the hydrogenation upgrading catalyst. The effluent after the reaction enters the high-pressure separator and the low-pressure separator without any intermediate separation, and is cooled and separated. The hydrogen-rich gas is recycled, and the liquid product enters the fractionation system to be separated into naphtha fraction and diesel fraction. The reaction conditions are shown in Table 2, and the product yield and properties are shown in Table 3.

[0055] It can be seen from Table 3 that both the freezing point and cold filtration point of diesel oil meet the requirements of -35 low-condensation diesel oil, the sulfur content is less than 10 μg / g, the freezing point is -47°C, the cold filtration point is -34°C, and the cetane number is 53.3. Compared with diesel feedstock, cetane number increased by 5.9 units.

Embodiment 2

[0057] The raw material oil A enters the hydrogenation reactor together with the hydrogen, and successively reacts with the hydrofining catalyst and the hydrogenation upgrading catalyst. The effluent after the reaction enters the high-pressure separator and the low-pressure separator without any intermediate separation, and is cooled and separated. The hydrogen-rich gas is recycled, and the liquid product enters the fractionation system to be separated into naphtha fraction and diesel fraction. The reaction conditions are shown in Table 2, and the product yield and properties are shown in Table 3.

[0058] It can be seen from Table 3 that the sulfur content of diesel oil is less than 10 μg / g, the freezing point is -27°C, the cold filter point is -10°C, and the cetane number is 57.5. Compared with diesel raw materials, the cetane number is increased by 10.1 units.

Embodiment 3

[0060] The raw material oil A enters the hydrogenation reactor together with the hydrogen, and successively reacts with the hydrofining catalyst and the hydrogenation upgrading catalyst. The effluent after the reaction enters the high-pressure separator and the low-pressure separator without any intermediate separation, and is cooled and separated. The hydrogen-rich gas is recycled, and the liquid product enters the fractionation system to be separated into naphtha fraction and diesel fraction. The reaction conditions are shown in Table 2, and the product yield and properties are shown in Table 3.

[0061] It can be seen from Table 3 that the freezing point and cold filtration point of diesel oil meet the requirements of -20 low-condensation diesel oil, the sulfur content is less than 10 μg / g, the freezing point is -36°C, the cold filtration point is -21°C, and the cetane number is 52.4. Compared with diesel feedstock, cetane number increased by 5.0 units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com