Diesel pour point depressant and preparation method thereof

A technology of diesel pour point depressant and active agent, applied in the field of diesel pour point depressant and its preparation, can solve the problems of small limitation, reduce diesel cold filter point and freezing point, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

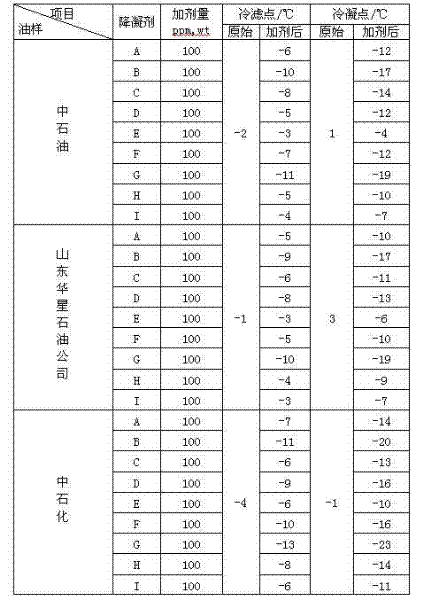

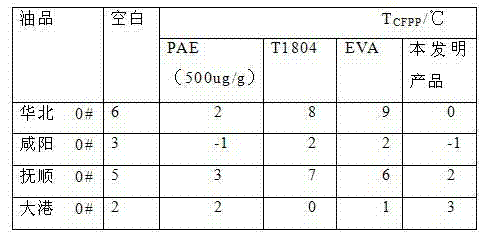

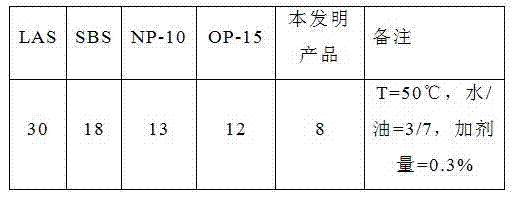

Image

Examples

Embodiment 1

[0034] 1. Preparation of ethylene-vinyl acetate

[0035] Put vinyl acetate and ethylene into the autoclave according to the molar ratio of 1:2, control the pressure at 10Mpa, temperature 180°C, use 1wt% initiator azobisisobutyronitrile, and polymerize for 3 hours to obtain ethylene- Vinyl acetate copolymer.

[0036] 2. Preparation of Styrene-Stearyl Maleate Copolymer

[0037] (1) Add styrene and maleic anhydride to the reactor at a molar ratio of 1:2, use dibenzamide peroxide as the initiator, and use toluene as the solvent, heat up to 110°C under constant stirring, and react for 4 hours. That is, a styrene-maleic anhydride copolymer was obtained.

[0038] (2) Add stearyl alcohol which is equimolar to maleic anhydride, and use p-toluenesulfonic acid as a catalyst to perform esterification at 150°C to obtain a styrene-stearyl maleate copolymer.

[0039] 3. Preparation of polymethacrylate

[0040] (1) Add methacrylic acid, pentanol, hexanol, heptanol, octanol, lauryl alcohol...

Embodiment 2

[0050] 1. Preparation of ethylene-vinyl acetate

[0051] Put vinyl acetate and ethylene into the autoclave according to the molar ratio of 1:2.2, the pressure is controlled at 12Mpa, the temperature is 190°C, and 1wt% initiator azobisisobutyronitrile is used for polymerization reaction for 3 hours to obtain ethylene- Vinyl acetate copolymer.

[0052] 2. Preparation of Styrene-Stearyl Maleate Copolymer

[0053] (1) Add styrene and maleic anhydride to the reactor at a molar ratio of 1:2, use dibenzamide peroxide as the initiator, and use toluene as the solvent, heat up to 120°C under constant stirring, and react for 4 hours. That is, a styrene-maleic anhydride copolymer was obtained.

[0054] (2) Add stearyl alcohol which is equimolar to maleic anhydride, and use p-toluenesulfonic acid as a catalyst to perform esterification at 150°C to obtain a styrene-stearyl maleate copolymer.

[0055] 3. Preparation of polymethacrylate

[0056] (1) Add methacrylic acid, pentanol, hexanol...

Embodiment 3

[0061] 1. Preparation of ethylene-vinyl acetate

[0062] Put vinyl acetate and ethylene into the autoclave at a molar ratio of 1:2.2, control the pressure at 12Mpa, temperature 190°C, use 1wt% initiator benzoyl peroxide, and polymerize for 3 hours to obtain ethylene-acetic acid vinyl ester copolymer.

[0063] 2. Preparation of Styrene-Stearyl Maleate Copolymer

[0064] (1) Add styrene and maleic anhydride to the reactor at a molar ratio of 1:2.2, use dibenzamide peroxide as the initiator, and use toluene as the solvent, heat up to 120°C under constant stirring, and react for 4 hours. That is, a styrene-maleic anhydride copolymer was obtained.

[0065] (2) Add stearyl alcohol which is equimolar to maleic anhydride, and use p-toluenesulfonic acid as a catalyst to perform esterification at 150°C to obtain a styrene-stearyl maleate copolymer.

[0066] 3. Preparation of polymethacrylate

[0067] (1) Add methacrylic acid, amyl alcohol, hexanol, heptanol, octanol, lauryl alcohol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com