Low-temperature fluidity improver for diesel oil

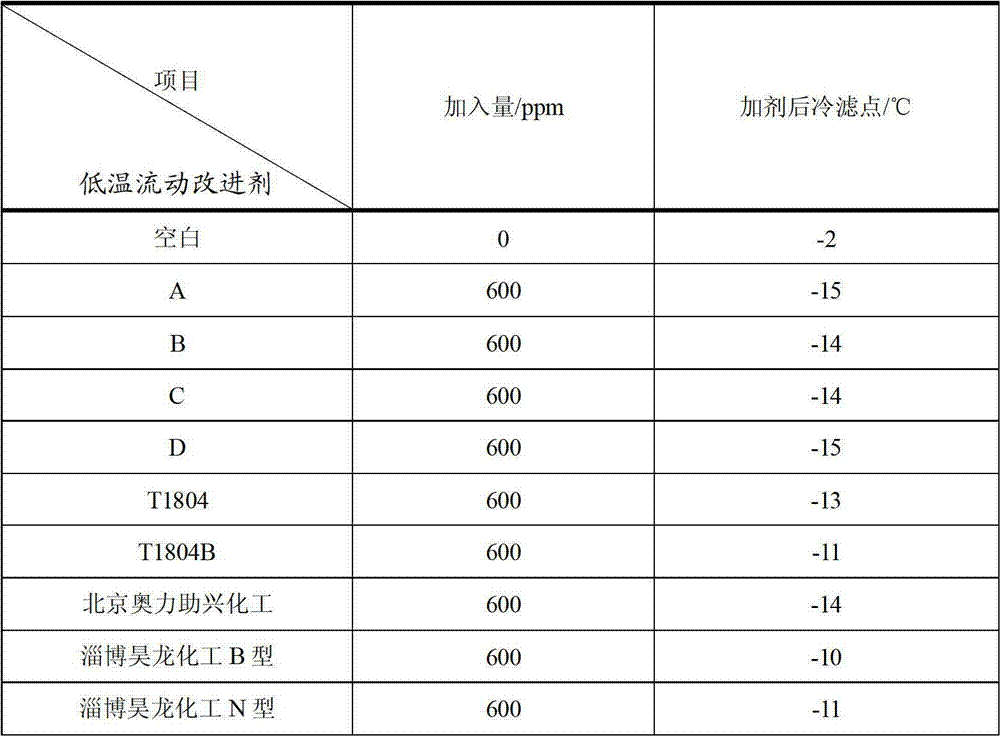

A technology of low temperature fluidity and flow improver, applied in the field of low temperature fluidity improver and diesel fuel additive, can solve the problem of reducing diesel cold filter point, etc., and achieve the effect of improving susceptibility and pour point reducing effect, simple preparation and good market value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific component distribution ratio of the low-temperature fluidity improver is: 75g of T1804B low-temperature flow improver, 8g of aromatic compound-toluene, 15g of non-ionic surfactant Span-Span 80, 6g of another non-ionic surfactant Agent Tween-Tween 81, 3g ester compound-ethyl acetate, 5g polar nitrogen-containing compound-triethanolamine.

[0024] The specific preparation process is: first add T1804 series low-temperature flow improver, then sequentially add non-ionic surfactant Span, Tween, polar nitrogen-containing compound, ester compound, and finally add aromatic compound to the prescription amount, stir and mix thoroughly to obtain compound product.

Embodiment 2

[0026] The specific component distribution ratio of the slow-release antiscalant is: 60g of T1804 low-temperature flow improver, 1g of aromatic compound-xylene, 5g of non-ionic surfactant Span-Span 85, 1g of another non-ionic surface active agent Active agent Tween—Tween 80, 0.5g ester compound—butyl acetate, 0.5g polar nitrogen compound—triethylenetetramine.

[0027] The specific preparation process is: first add T1804 series low-temperature flow improver, then sequentially add non-ionic surfactant Span, Tween, polar nitrogen-containing compound, ester compound, and finally add aromatic compound to the prescription amount, stir and mix thoroughly to obtain compound product.

Embodiment 3

[0029] The specific component distribution ratio of the slow-release antiscalant is: 90g of T1804 low-temperature flow improver, 10g of aromatic compound-cyclohexane, 20g of non-ionic surfactant Span-Span 80, 10g of another non-ionic Surfactant Tween—Tween 81, 5g ester compound—isobutyl acetate, 8g polar nitrogen compound—tetraethylenepentamine.

[0030] The specific preparation process is: first add T1804 series low-temperature flow improver, then sequentially add non-ionic surfactant Span, Tween, polar nitrogen-containing compounds, and organic esters, and finally add aromatic compounds to the prescription amount, and fully stir and mix to obtain compound product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com