Surfactant compounded pour point depressant and preparation method and application thereof

A technique for surfactants and pour point depressants, which is applied in the field of compounded pour point depressants with surfactants and its preparation, can solve problems such as unsatisfactory pour point depressants, improve the pour point depressant effect, and the preparation method is simple and easy to improve The effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The measurement method of cold filter point in the present invention is carried out according to "SH / T0248-2006 Determination method of cold filter point of diesel oil and civil heating oil", and the measurement method of condensation point is carried out according to "GB510-83 Determination of freezing point of petroleum products".

[0030] Raw materials used in the following examples:

[0031]

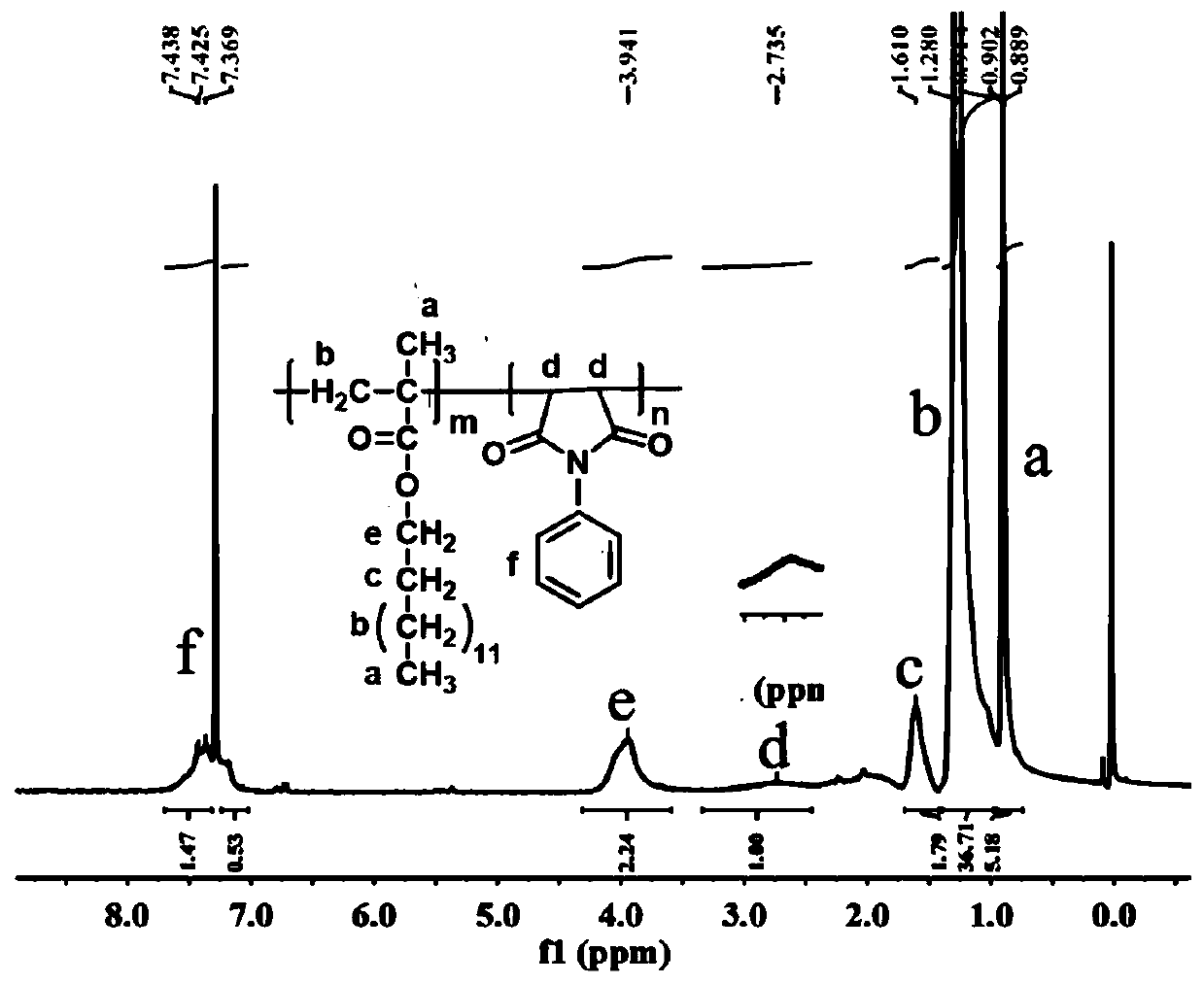

[0032] The preparation method of polybenzyl methacrylate-maleic anhydride tetradecylamine used in the following examples comprises: 2g tetradecyl methacrylate-maleic anhydride binary copolymer is dissolved in 25ml toluene solvent, adds 3.8g aniline, The catalyst is 0.0464g of p-toluenesulfonic acid, the temperature is gradually raised to 110-120°C, and the amination reaction is carried out for 10 hours to obtain polytetradecyl methacrylate-maleic anhydride-aniline. The molecular Mw of polymer tested by GPC is 73542g / mol, and Mn is 45364g / mol, and Mw / Mn is 1.621, and product...

Embodiment 2

[0039] The surfactant compound pour point depressant in this embodiment is made up of the following components by weight percentage:

[0040]

[0041] The preparation method of the above-mentioned diesel oil surfactant composite pour point depressant is as follows: tetradecyl methacrylate-maleic anhydride-aniline, Span 80, Tween 60 and 1-methylnaphthalene are mixed in proportion at 25-40°C Mix and stir evenly at a certain temperature, and ultrasonically disperse for 15 minutes to obtain a surfactant compound pour point depressant.

[0042] The application of the above-mentioned surfactant compound pour point depressant in diesel oil pour point depressant, the ratio of surfactant compound pour point depressant: diesel oil, calculated by mass ratio, is preferably 1:200, and the diesel surfactant compound depressant Add the coagulant to the diesel oil at 40°C, mix and stir evenly, and disperse ultrasonically for 25 minutes to obtain the diesel oil containing the diesel surfact...

Embodiment 3

[0045] The surfactant compound pour point depressant in this embodiment is made up of the following components by weight percentage:

[0046]

[0047] The preparation method of the above-mentioned surfactant composite pour point depressant is as follows: tetradecyl methacrylate-maleic anhydride-aniline, Span 80, Tween 60 and 1-methylnaphthalene are mixed in proportion at 25-40°C Mix and stir evenly at high temperature, and ultrasonically disperse for 15 minutes to obtain the diesel pour point depressant composition.

[0048] The application of the above-mentioned surfactant compounded pour point depressant in diesel oil pour point depressant, the proportion of surfactant compounded pour point depressant: diesel oil, calculated by mass ratio, is preferably 1:200, and the surfactant compounded with diesel oil Add the pour point depressant to the diesel oil at a temperature of 40°C, mix and stir evenly, and disperse ultrasonically for 25 minutes to obtain the diesel oil contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com