Nanometer compound binary polymer pour point reducer and preparation method thereof

A nano-composite and polymer technology, used in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of the engine not working properly, blocking the engine oil pipeline and filter, etc., to achieve excellent pour point reduction effect, low temperature flow Sexual improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

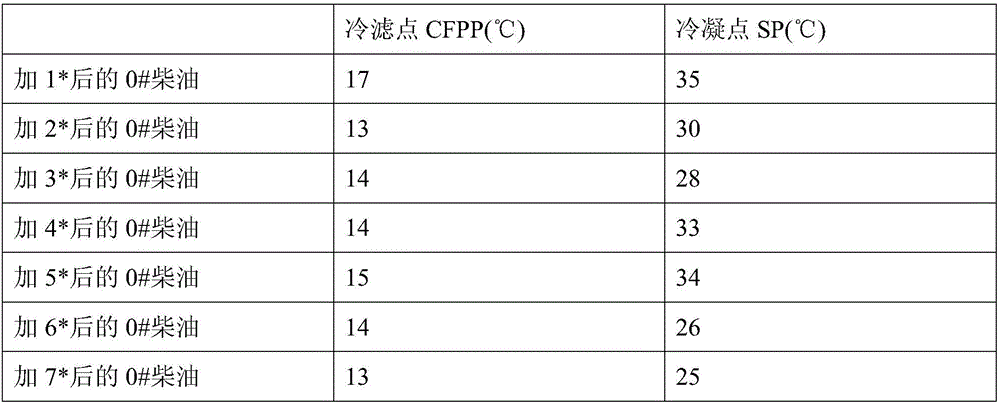

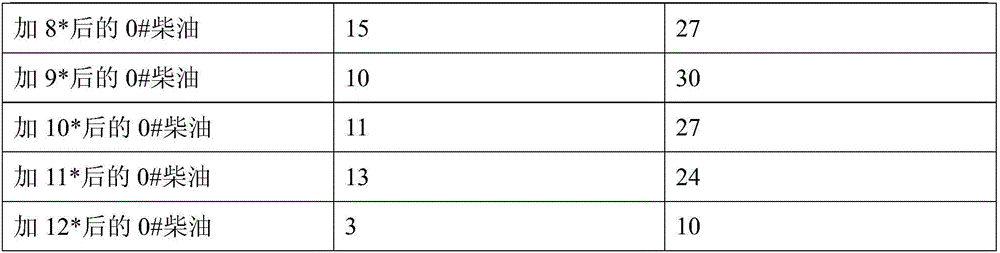

Examples

Embodiment 1

[0022] A novel nanocomposite binary polymer pour point depressant, which is prepared by a method comprising the following steps:

[0023] (1) By adding nano-SiO 2 Under the action of silane coupling agent KH570, the modification reaction is carried out at a temperature of 60-70°C to obtain modified nano-SiO 2 ;

[0024] The nano-SiO used in the above reaction 2 , the amount of silane coupling agent KH570, calculated by mass ratio, that is, nano-SiO 2 : silane coupling agent KH570 is 1:0.7;

[0025] (2) The modified nano-SiO 2 Put it in a flask with binary polymer pour point depressant, and react at 120°C for 5 hours by solvent blending method to obtain a new type of nanocomposite binary polymer pour point depressant;

[0026] The modified nano-SiO used in the above reaction 2 , the amount of methacrylate maleic anhydride binary copolymer, calculated by mass ratio, that is, modified nano-SiO 2 : methacrylic acid maleic anhydride binary copolymer is 1:4;

[0027] The use...

Embodiment 2

[0038] The difference from Example 1 is that the mol ratio of methacrylic acid and myristyl alcohol used in the preparation step (1) of the binary polymer pour point depressant is 1.2:1, and the amount of the catalyst p-toluenesulfonic acid is methyl 1.0% of the total mass of acrylic acid and higher alcohols, the amount of inhibitor hydroquinone is 0.3% of the total mass of methacrylic acid and higher alcohols;

[0039] The amount of methacrylate used in step (2), maleic anhydride is calculated by molar ratio, i.e. methacrylate: maleic anhydride is 1:0.8, and the amount of initiator benzoyl peroxide is methacrylic acid and 0.5% of the total mass of maleic anhydride;

[0040] Others are the same as in Example 1.

Embodiment 3

[0042] The difference from Example 1 is that the mol ratio of methacrylic acid and myristyl alcohol used in the preparation step (1) of the binary polymer pour point depressant is 1.8:1, and the amount of the catalyst p-toluenesulfonic acid is methyl 1.7% of the total mass of acrylic acid and higher alcohols, the amount of inhibitor hydroquinone is 1.0% of the total mass of methacrylic acid and higher alcohols;

[0043] The amount of methacrylic acid ester used in step (2), maleic anhydride is calculated by molar ratio, i.e. methacrylic acid ester: maleic anhydride is 1:1.2, and the amount of initiator benzoyl peroxide is methacrylic acid and 0.9% of the total mass of maleic anhydride;

[0044] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com