Method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil

A technology for hydrocracking tail oil and lubricating base oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of low base oil yield, achieve high activity, increase selectivity, and improve The effect of low temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

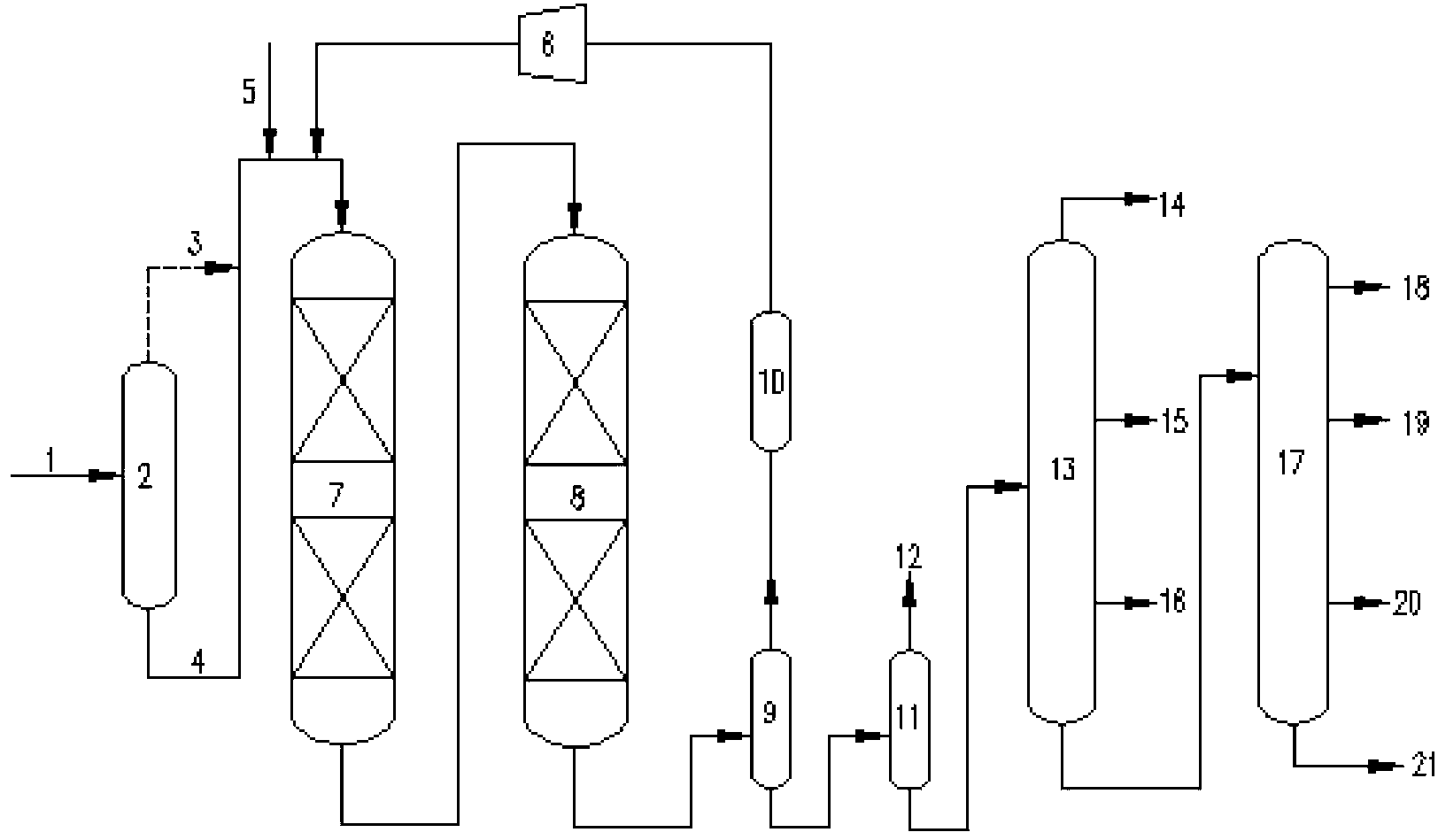

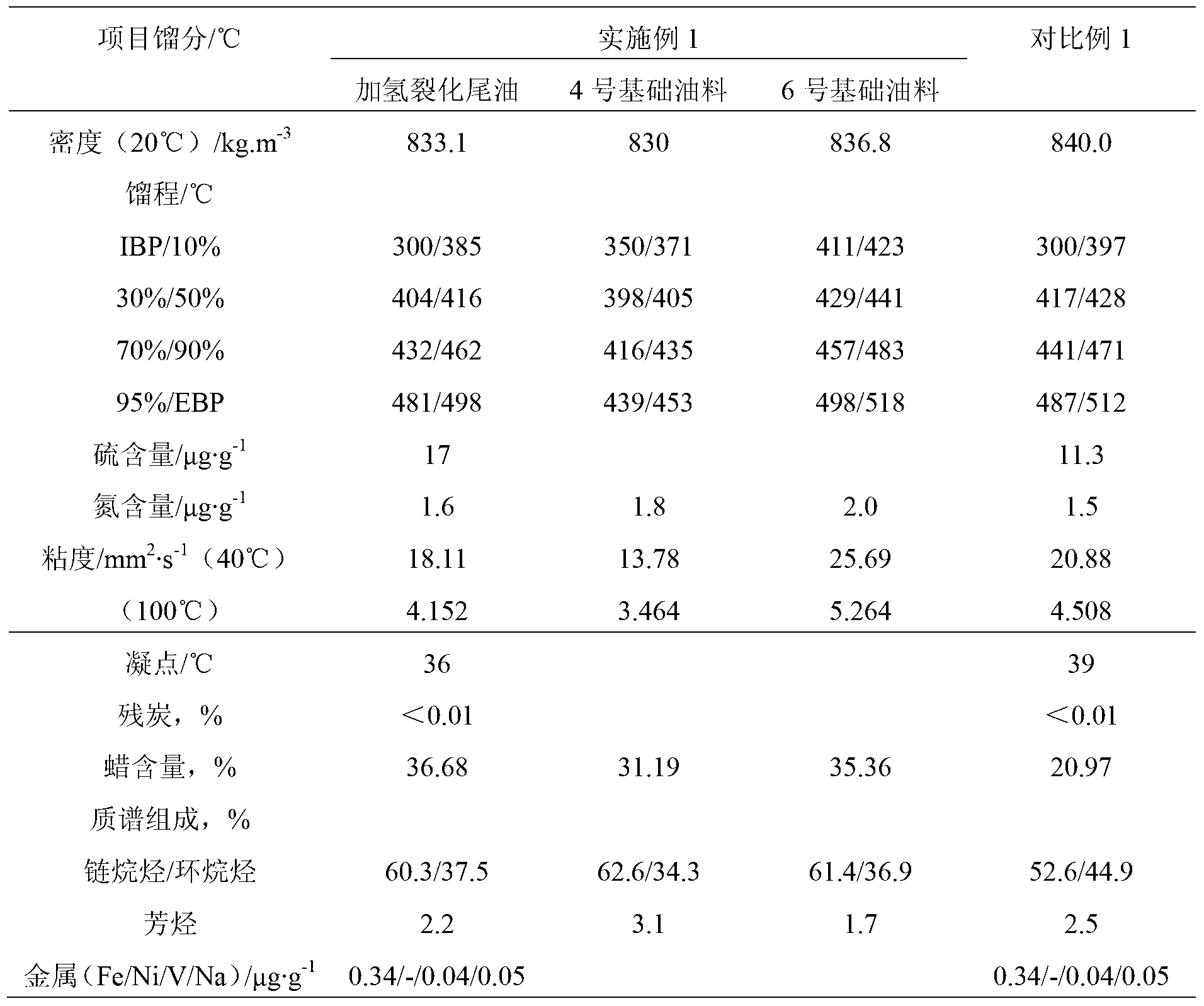

[0038] First, the hydrocracking tail oil (see Table 2 for properties) enters the vacuum pre-fractionator for vacuum fractionation. The cut point of vacuum fractionation is 430°C, and the light fraction of hydrocracking tail oil with an end boiling point ≤ 430°C is taken as No. 4 As the base oil, the heavy fraction of hydrocracking tail oil with an initial boiling point > 430°C was used as the No. 6 base oil (see Table 2 for properties). The base oil is mixed with new hydrogen and the circulating hydrogen boosted by the circulating hydrogen compressor, and then enters the isomerization dewaxing and supplementary refining reactor in turn (see Table 3 for the catalyst used); the reaction is separated from the gas and liquid, and the gas is desulfurized and then compressed The machine pressurization is mixed with fresh hydrogen as the raw material of the isomerization dewaxing-supplementary refining reactor, and the liquid product is often distilled under reduced pressure to obtain...

Embodiment 2

[0040] The raw material that adopts, technological process and corresponding catalyzer are identical with embodiment 1, and what differ with embodiment 1 is the technological condition selected, and reaction technological condition is shown in Table 4, and the result and the property of the lubricating base oil product of generation are shown in Table 5 and Table 7. Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com