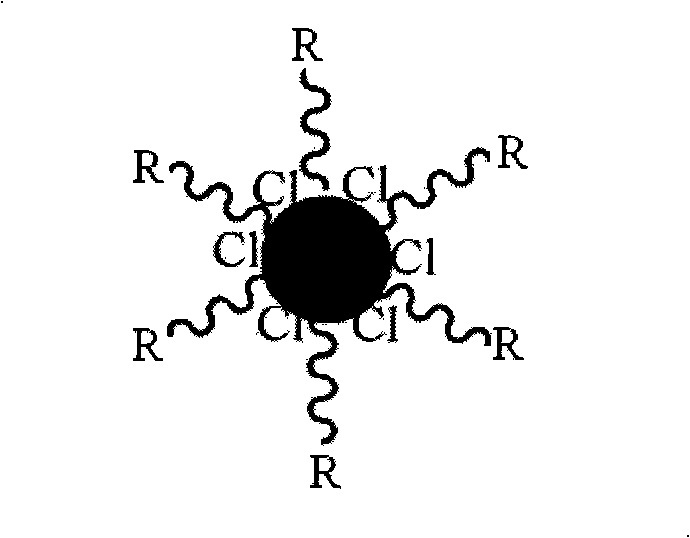

Star poly-(methyl)acrylate long-chain ester polymer and preparation method thereof

A technology of long-chain acrylic acid ester and polymer, which is applied in the field of star-shaped polyacrylic acid long-chain ester polymer and its preparation, can solve the problems of complex polymerization method and process, and achieves improved low-temperature fluidity, high molecular weight and low vitrification Effect of transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

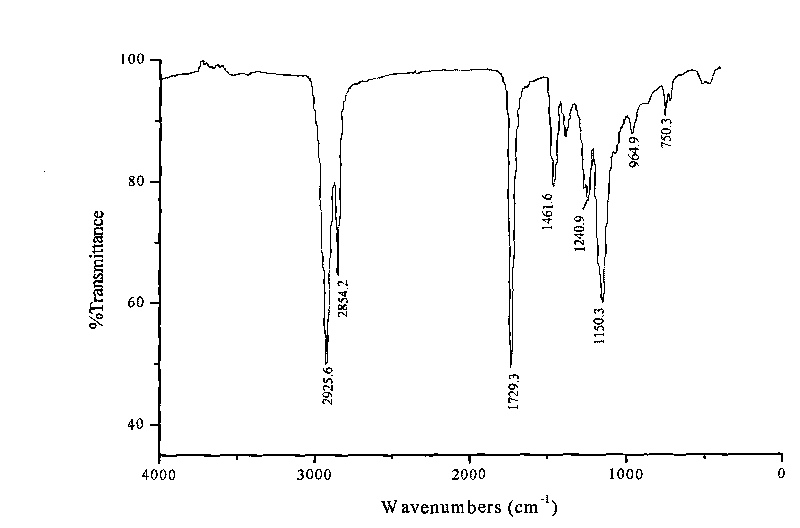

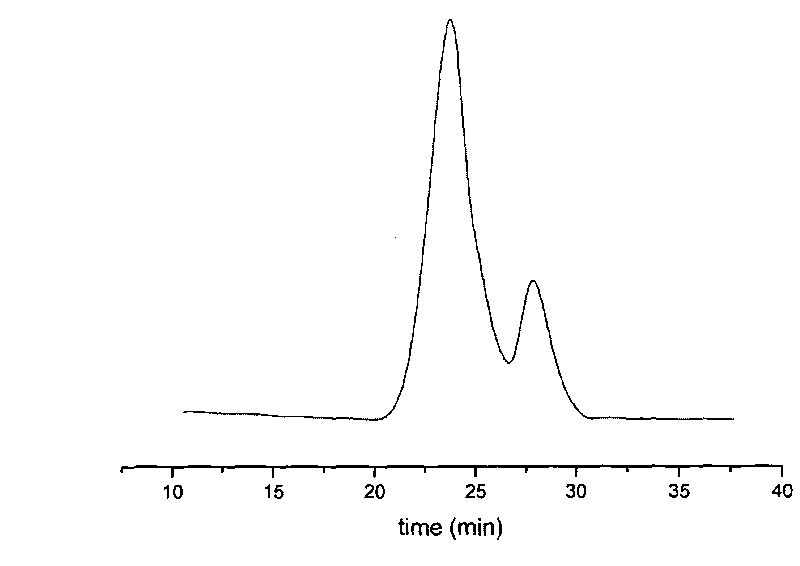

Image

Examples

Embodiment 1

[0036] In a refluxed 100ml three-necked flask, nitrogen was introduced to replace oxygen, and 5.1g of lauryl methacrylate and 12.4ml of cyclohexanone were added. After bubbling with high-purity nitrogen for 30 minutes, 65.2 mg CuCl and 124.8 μL PMDETA were added. And continue to stir, after the ligand is fully complexed with cuprous chloride, add 3.26mgCuCl 2 . Continue to feed nitrogen into the system and start heating. When the temperature rises to the reaction temperature of 60° C., add 97.8 μL of initiator EBriB. After reacting for 1.5 hours, 1.2 mL of EGDMA was added, the temperature was raised to 90° C., the reaction was carried out in a nitrogen atmosphere for 9 hours, and the reaction was stopped by rapid cooling. After adding 120ml of tetrahydrofuran to dissolve the reaction product, pass through 110g of alumina to remove copper ions, add to a large amount of methanol precipitant to precipitate the product, repeat twice and vacuum dry to constant weight to obtain th...

Embodiment 2

[0042] In Example 1, the temperature was raised to 60° C., the initiator EBriB was added and reacted for 2 hours, and then EGDMA was added, and the rest were the same as Example 1.

Embodiment 3

[0044] In Example 1, after adding EGDMA and raising the temperature to 90° C., the reaction was carried out in a nitrogen atmosphere for 6 hours, and the rest were the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com