Diesel oil blend component and production method thereof

A production method and diesel technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of failing to meet the new Beijing V standard for vehicle diesel and high sulfur content in diesel fuel, and achieve low cost, easy operation, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

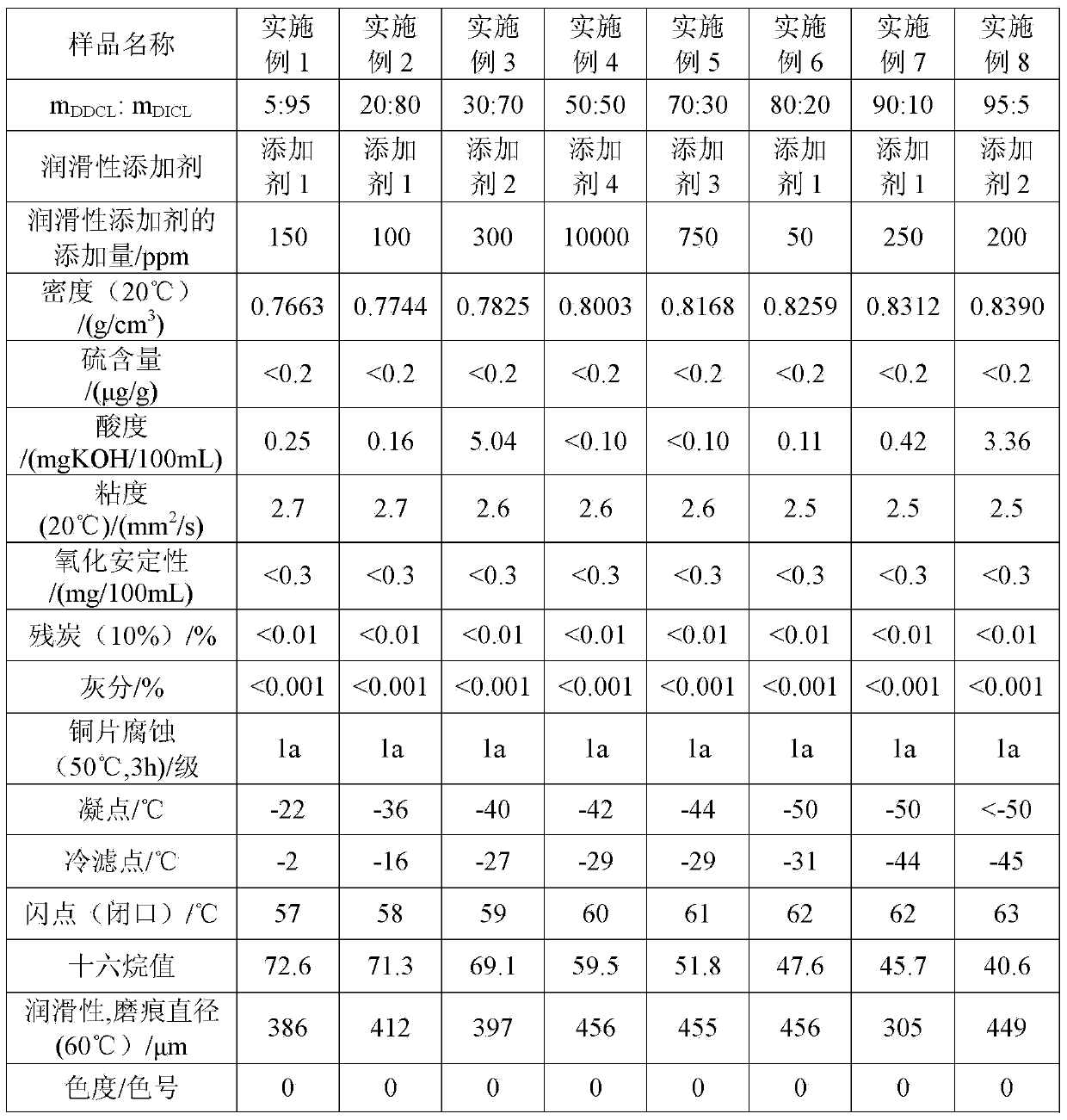

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

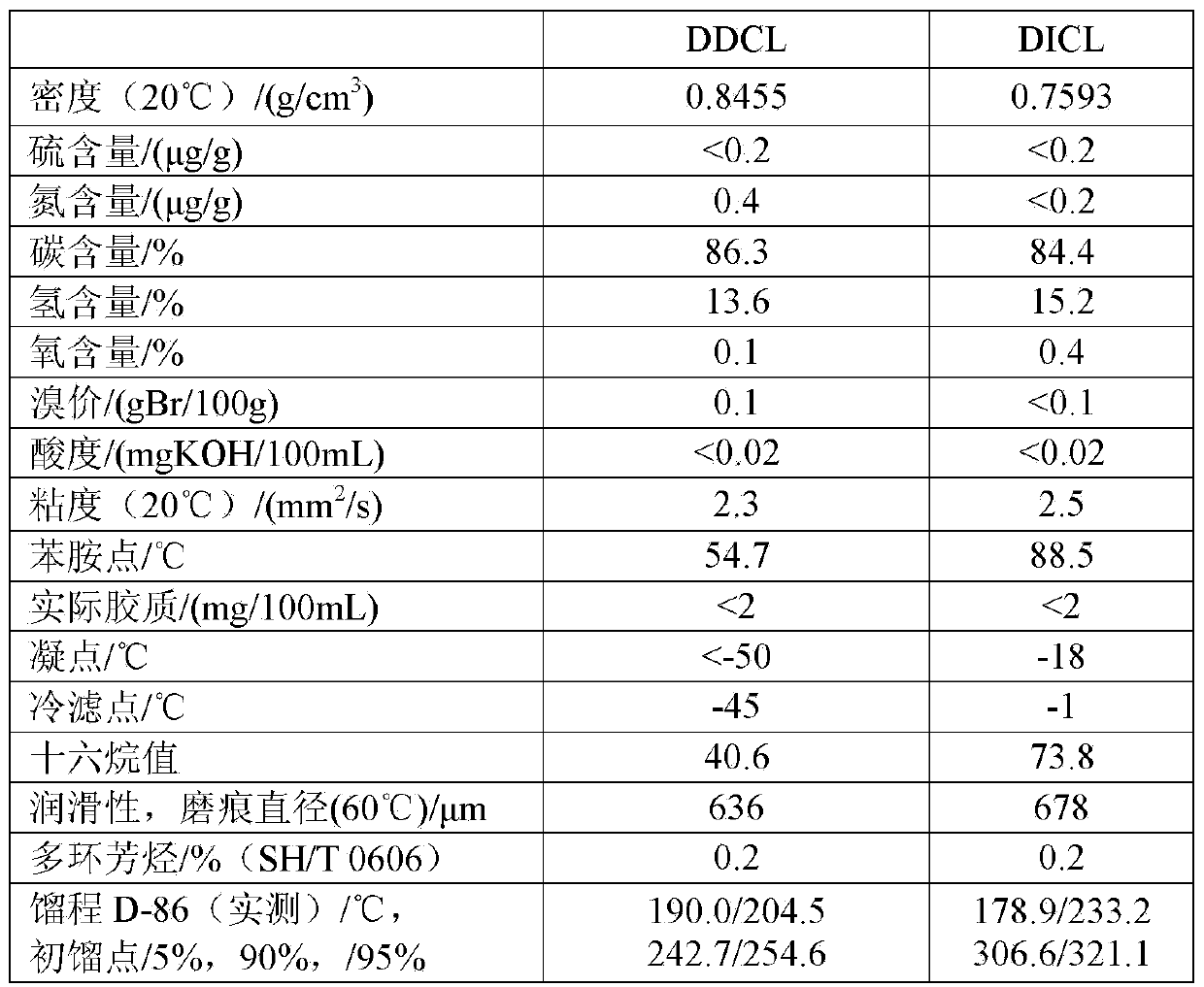

[0022] Generally, according to the liquefaction process of coal-based liquefied fuel oil, it can be divided into two types: Diesel of Direct Coal Liquefaction (hereinafter referred to as DDCL) and coal indirect liquefied diesel (Diesel of Indirect Coal Liquefaction, hereinafter referred to as DICL). With the mandatory implementation of national III, IV, and V diesel standards, the production of vehicle diesel that meets the new standards is also fully implemented. The new standards put forward stricter requirements for sulfur content. Compared with petroleum-based diesel, DICL has low aromatics content and almost no sulfur and nitrogen content. The cetane number of diesel oil can reach more than 70-80. Among them, low aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com