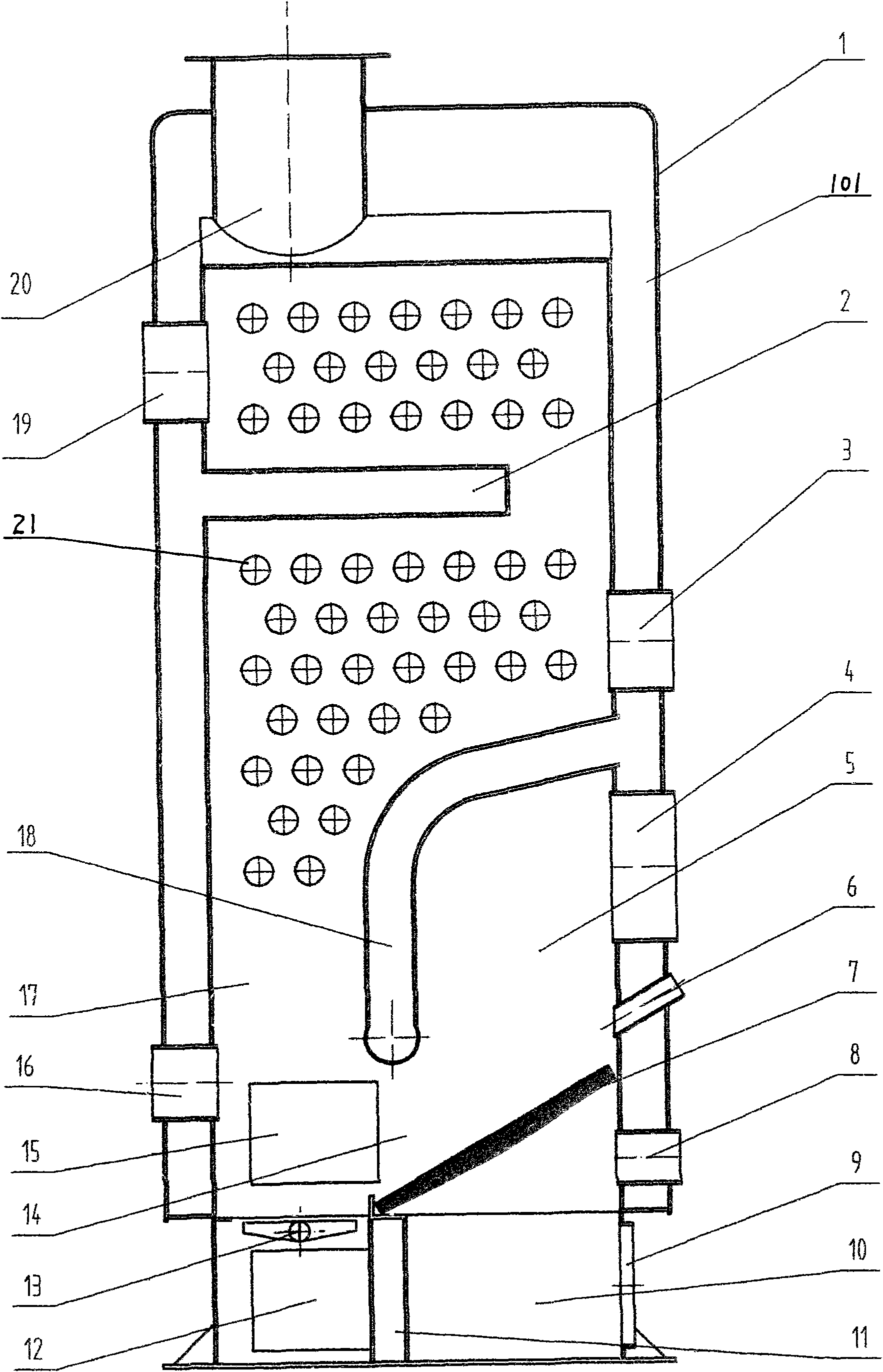

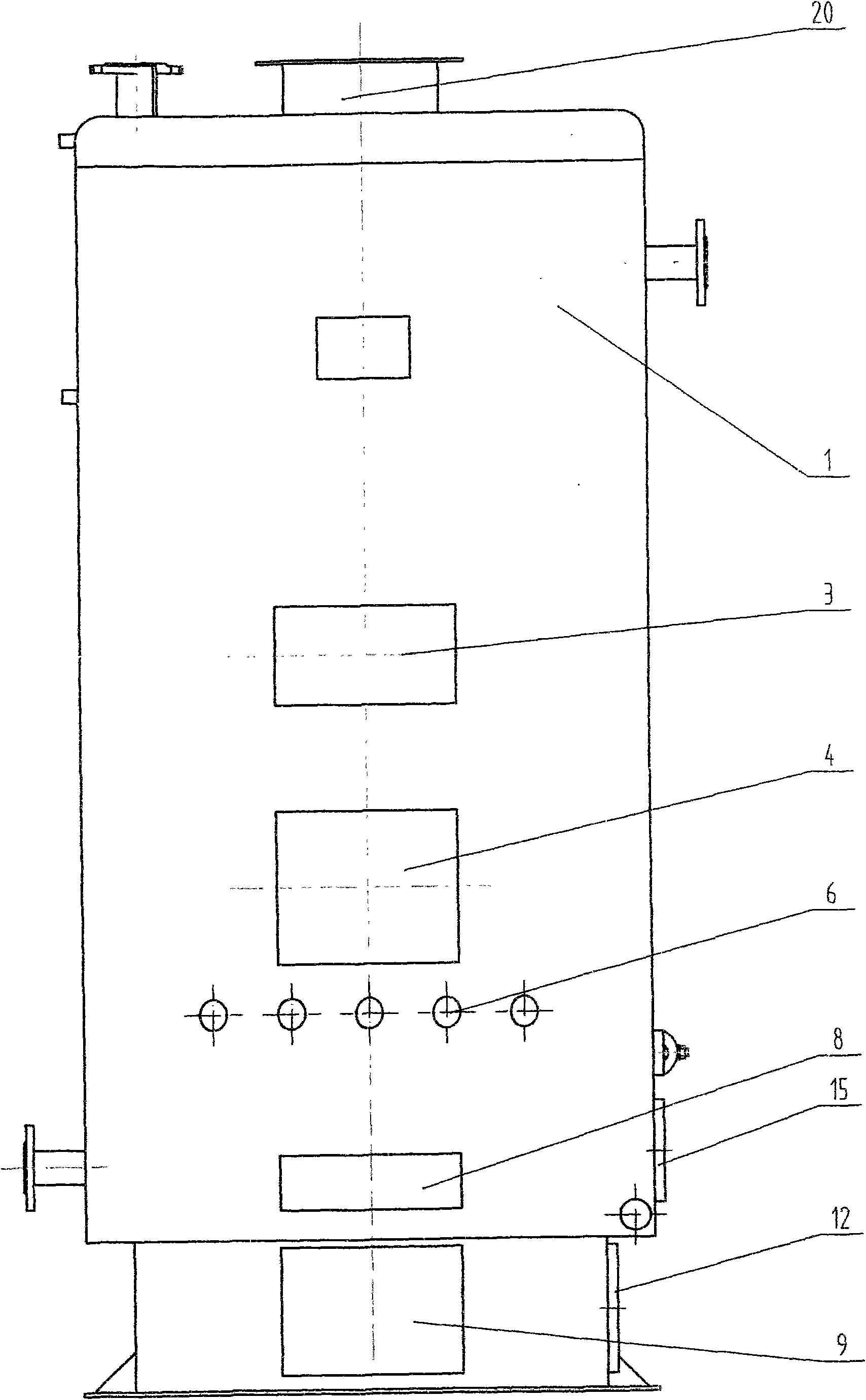

Downdraft gasification coal-fired boiler

A gasification boiler, downdraft technology, applied in the field of coal-fired boilers, can solve the problems of complicated operation, black smoke, weak gas output and purity, etc., and achieve the effect of sufficient pyrolysis, simple operation, continuous and stable flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] As shown in the figure, the downdraft coal-fired gasification boiler has a furnace body 1 with an interlayer water jacket 101 inside, and water inlets and water outlets are arranged on both sides of the outer wall of the furnace body 1. The furnace body 1 sits on On the base 10, a combined fire grate is arranged under the body of heater 1 on the base 10. Boiler body 1 bottom is provided with vertical clapboard 18, and vertical clapboard 18 can be arc-shaped, and vertical clapboard 18 is located on the inner wall of heater body 1 and communicates with interlayer water jacket 101 and vertical clapboard 18 lower ends are positioned at grate top, The furnace body is divided into a gasification chamber 5 and a combustion chamber 17 by a vertical partition 18 , and the connection between the combustion chamber 17 and the gasification chamber 5 is a gas outlet 14 . The combined fire grate is composed of an inclined fixed fire grate 7 below the gasification chamber 5 and a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com