Vertical multistage vacuum low-temperature immersed pump

A vacuum low temperature, submersible pump technology, applied in non-displacement pumps, non-variable volume pumps, pumps, etc., can solve the problems of difficult manufacturing and testing, high product prices, high operating costs, short start-up time, hydraulic pressure Symmetry is perfect, the effect of reducing maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

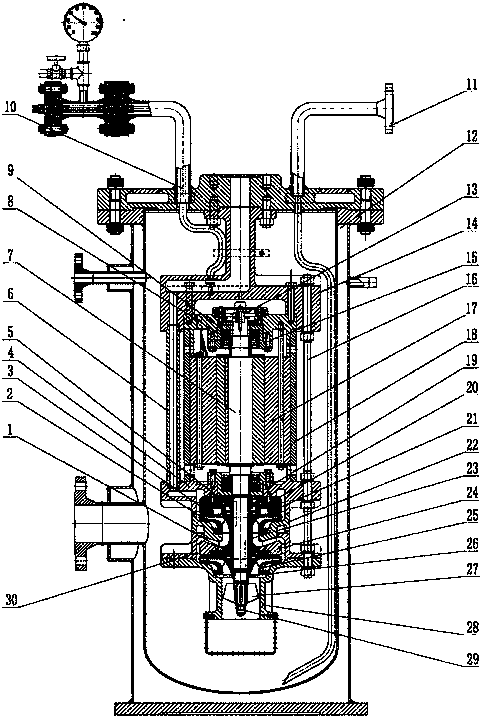

[0013] In the accompanying drawings, the vertical multi-stage vacuum cryogenic submersible pump of the present invention is mainly composed of a motor part, a pump head part, a rotor shaft, a bearing seat, a piercing rod, and a pump pool; the bearing seat 19 supports the rotor shaft 7 through a bearing, and the rotor The upper end of the shaft 7 is equipped with a motor part, and the lower end is equipped with a pump head part. The piercing rod 16 connects the motor part and the pump head part as a whole and places it in the closed pump pool 12.

[0014] The motor part includes motor assembly 17, rotor shaft 7, motor housing 18, motor upper cover 15, motor displacement sensor 13, bearing retaining ring 8, butterfly spring 9, upper cover 14, lower cover 4; Motor assembly 17 is housed in 18, motor upper cover 15 is equipped with on the upper end of motor housing 18, and bushing bearing seat 19 is connected in motor upper cover 15, and the bearing in bearing seat 19 supports rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com