Patents

Literature

37results about How to "Won't bring out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

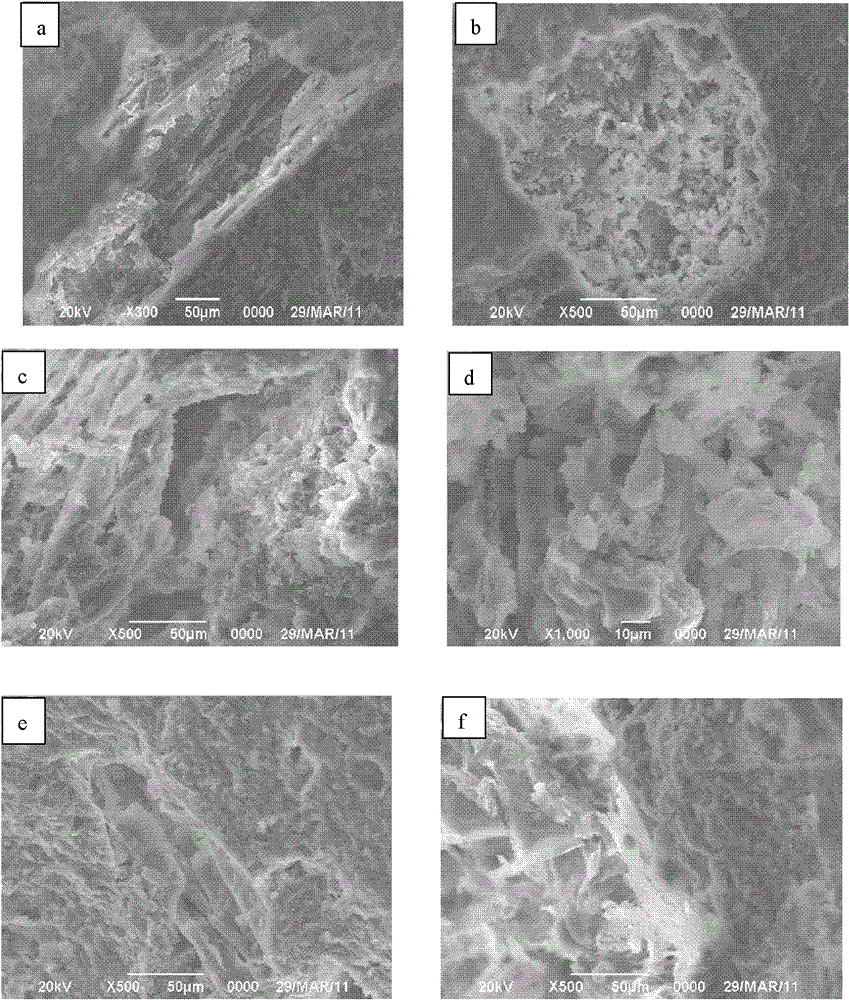

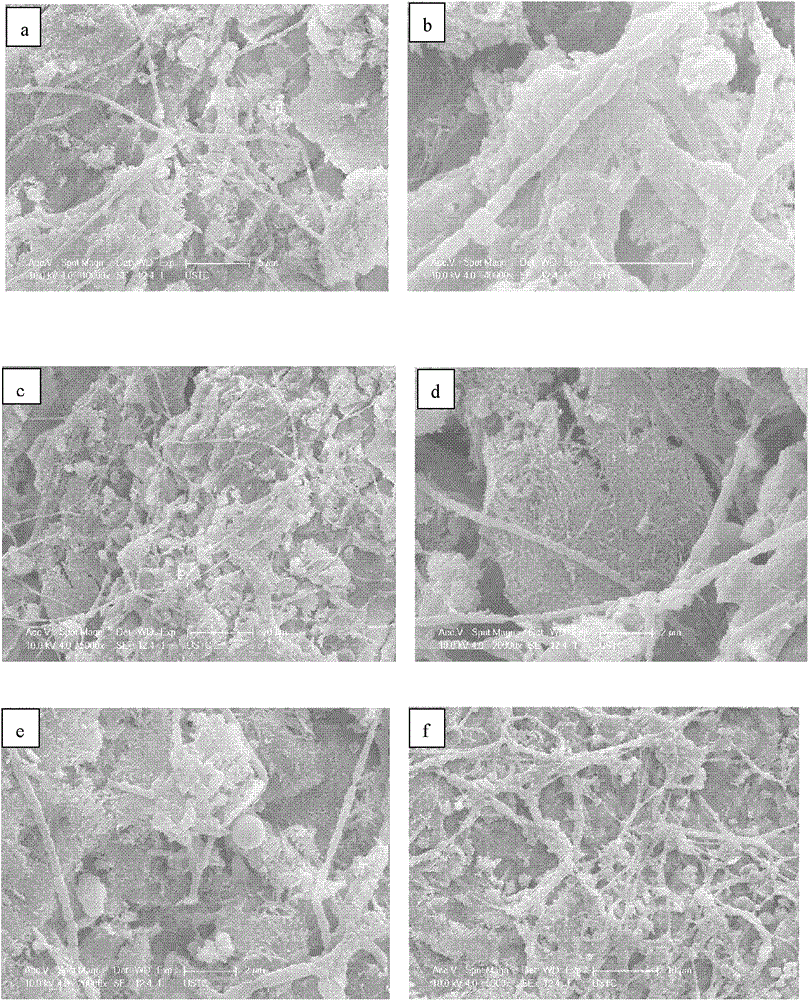

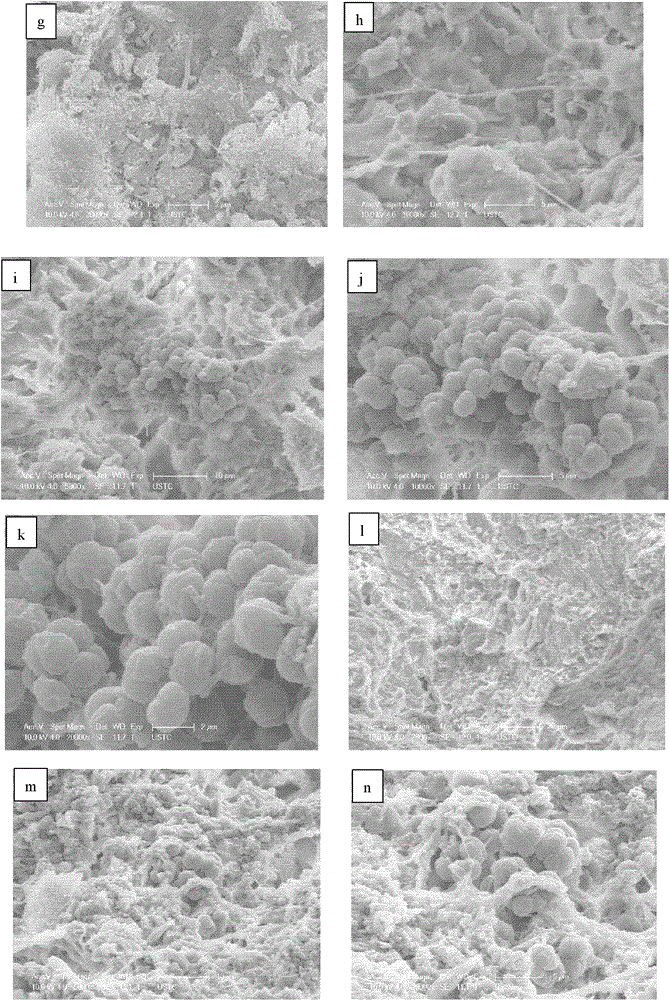

Attapulgite clay porous ceramsite, and preparation method and purpose thereof

ActiveCN102225870AWide variety of sourcesLow priceCatalyst carriersTreatment with aerobic and anaerobic processesWater resistancePorosity

The invention discloses an attapulgite clay porous porous ceramsite, a preparation method of the ceramsite, and a purpose of the ceramsite. The ceramsite is prepared from raw materials of attapulgite clay and biomass, and a binder of industrial soluble glass. The ceramsite is prepared through calcining and oxidizing. The attapulgite clay porous ceramsite prepared by the present invention has advantages of high porosity, large specific surface area, high strength, strong water resistance, high water absorption, high catalytic activity, and the like. The porous ceramsite prepared by the presentinvention can be applied as a carrier for a catalyst, and a filling material for an aerated biological filter.

Owner:HEFEI UNIV OF TECH

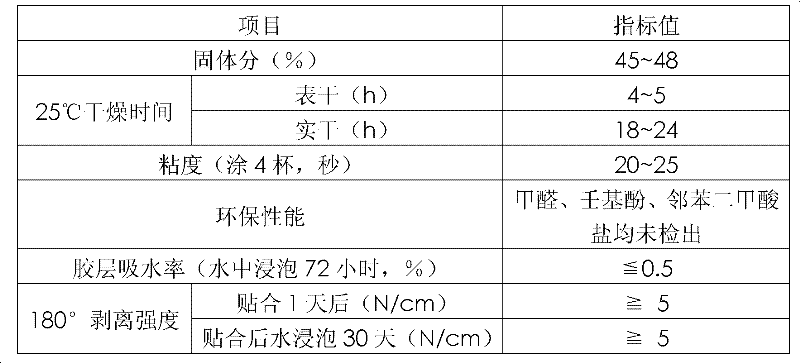

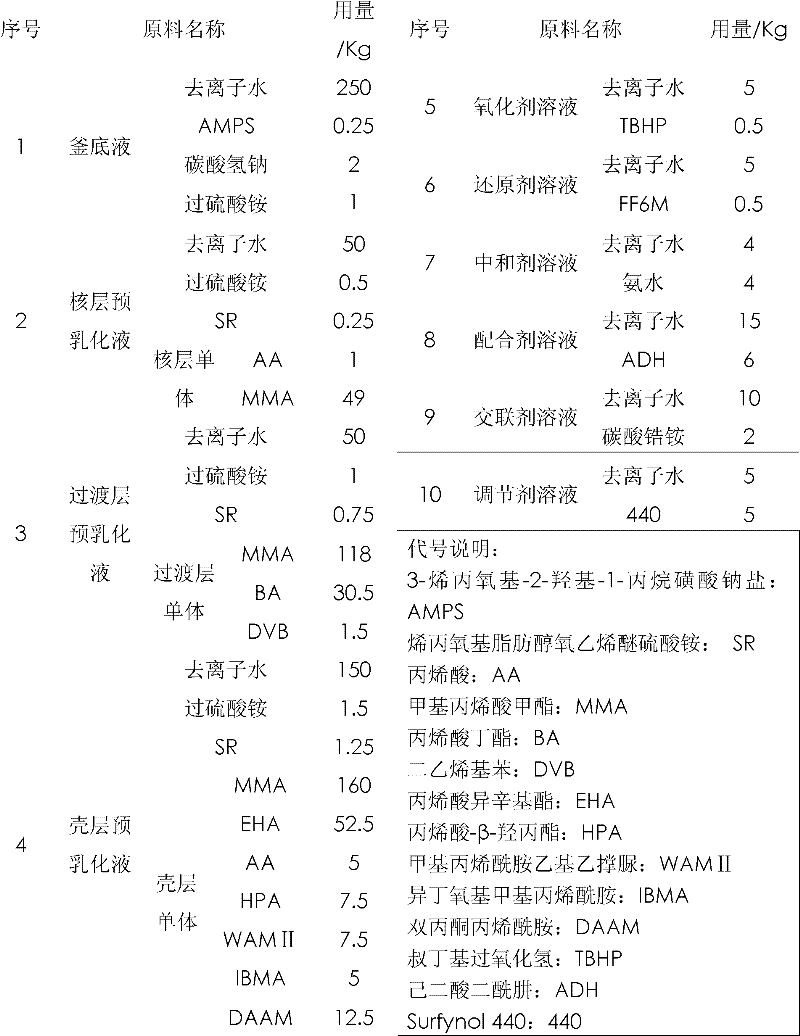

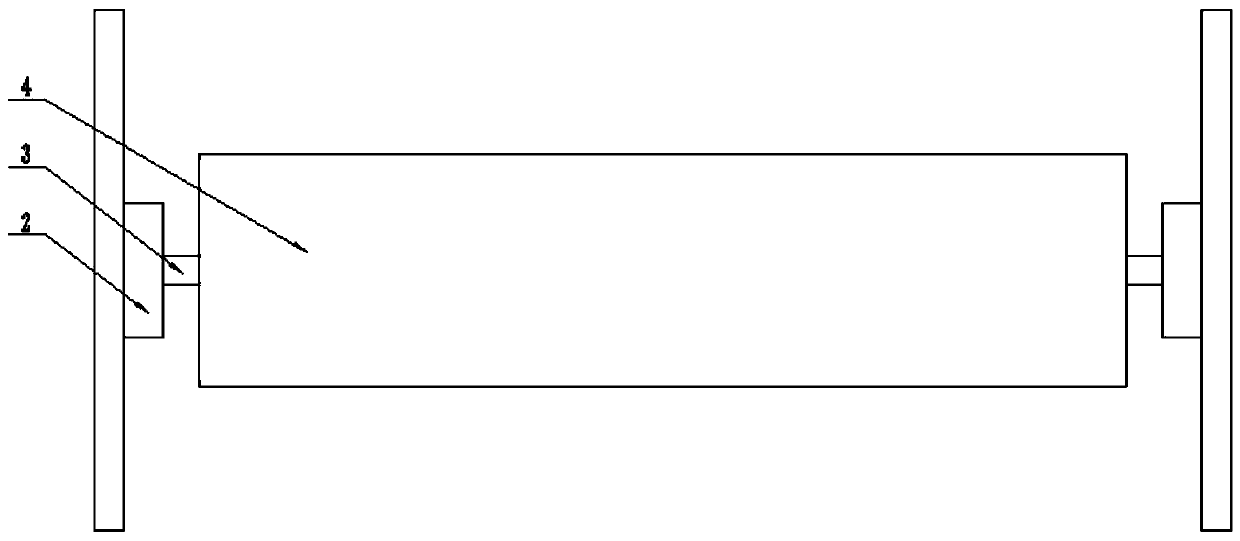

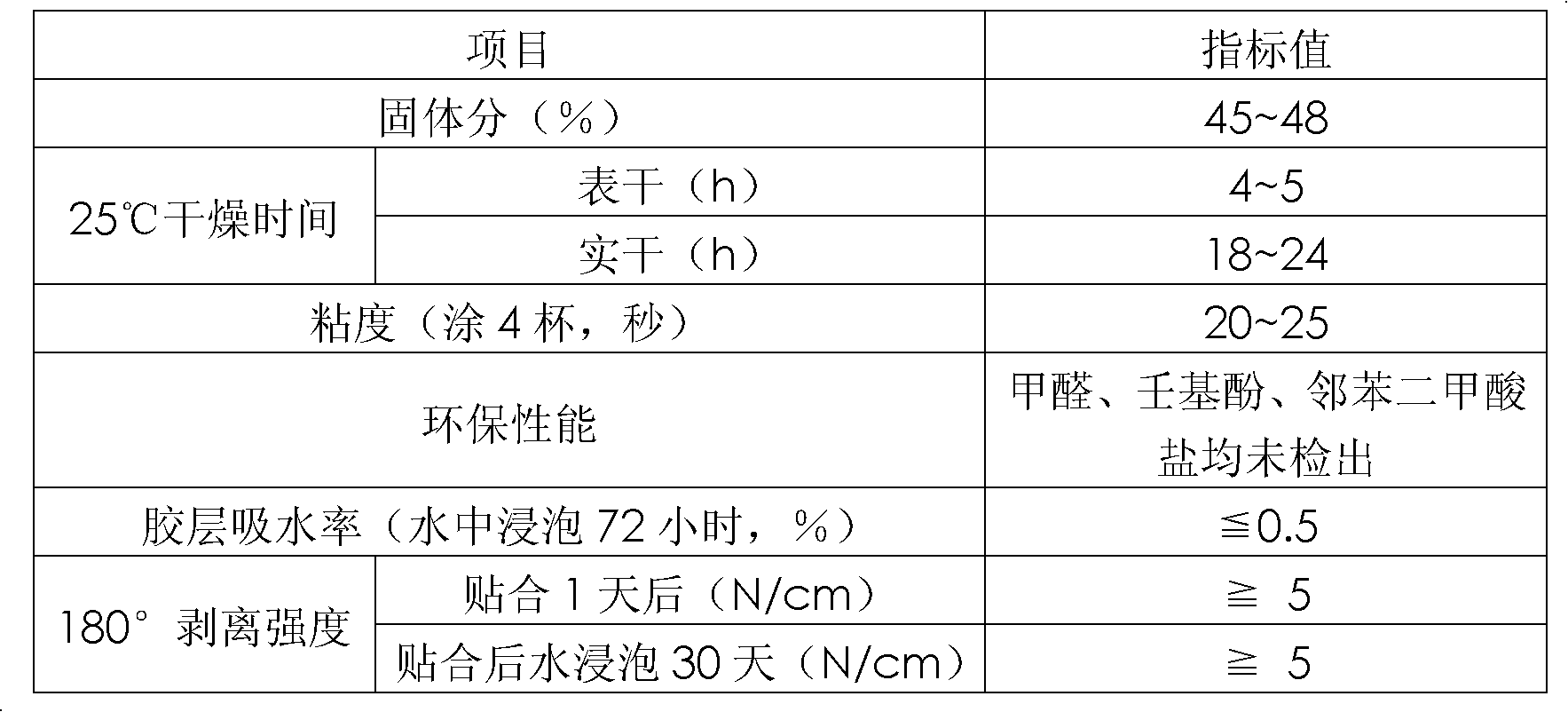

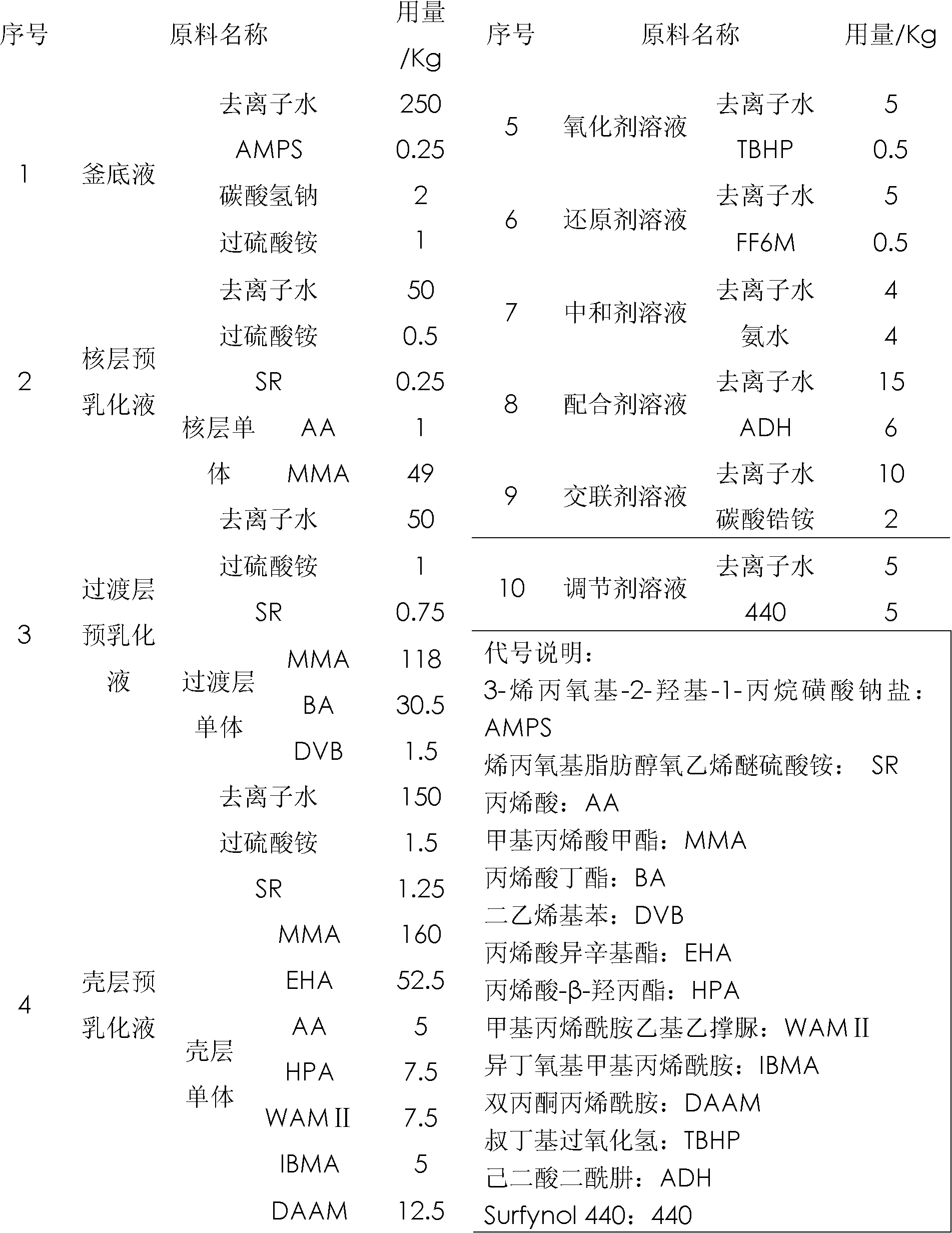

Single-component water-based adhesive for evaporative cooling wet curtain and preparation method thereof

ActiveCN102516904AAvoid performance conflictsImprove wetting and levelingNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedAdhesive

The invention discloses a single-component water-based adhesive for an evaporative cooling wet curtain and a preparation method thereof. The method comprises the following steps of: firstly preparing kettle bottom liquid and adding into a polymerization reaction kettle; then respectively preparing nuclear layer pre-emulsion, transition layer pre-emulsion and shell layer pre-emulsion; removing possibly-caused free formaldehyde through carrying out nuclear layer-transition layer-shell layer gradient emulsion polymerization, by adopting an environmentally-friendly and highly-efficient reactive emulsifier and through replacing hydroxymethyl acrylamide with a novel self-crosslinking monomer and replacing sodium formaldehyde sulphoxylate with a macromolecule polymerization type reducing agent; and introducing carbamido or nitrogen heterocycle into an acrylate structure to provide a higher intermolecular hydrogen bond and an intermolecular acting force and improve the wet adhesive force and the scrub resistance of an adhesive layer. The invention has the beneficial effects that the adhesive force and the water resistance of the adhesive layer are ensured through ion crosslinking and in cooperation with diacetone acrylamide / adipic dihydrazide crosslinking; and by adopting an adjusting agent with the super-strong defoaming and wetting functions, the adhesive is ensured to satisfy higher coating rate in the gluing process and not to generate tiny bubble residues.

Owner:DONGGUAN STAR COSM POLYMER

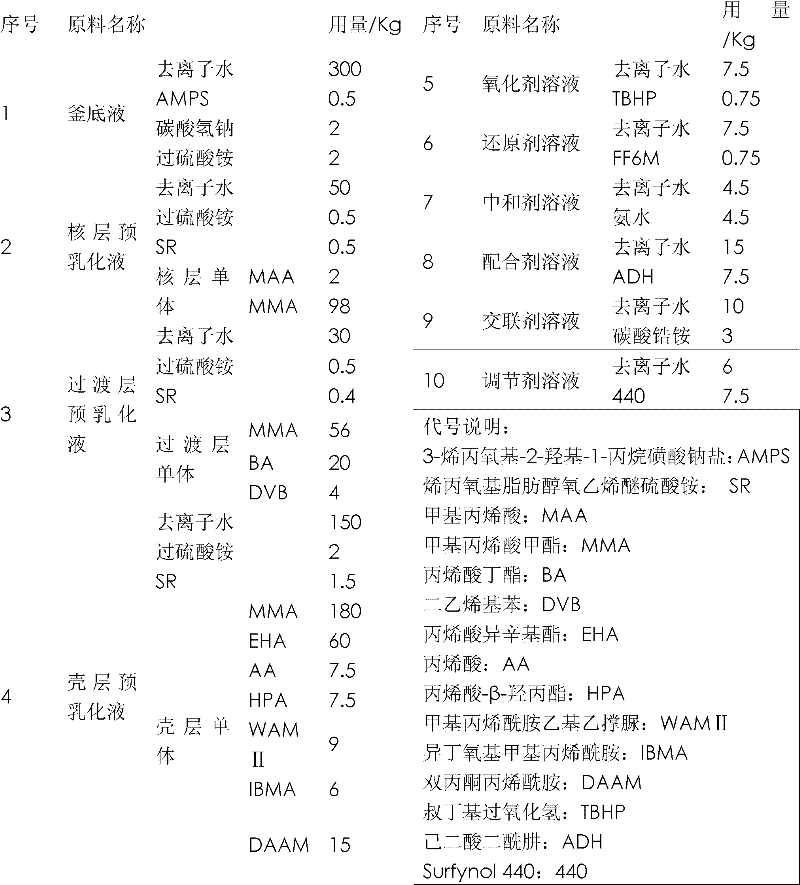

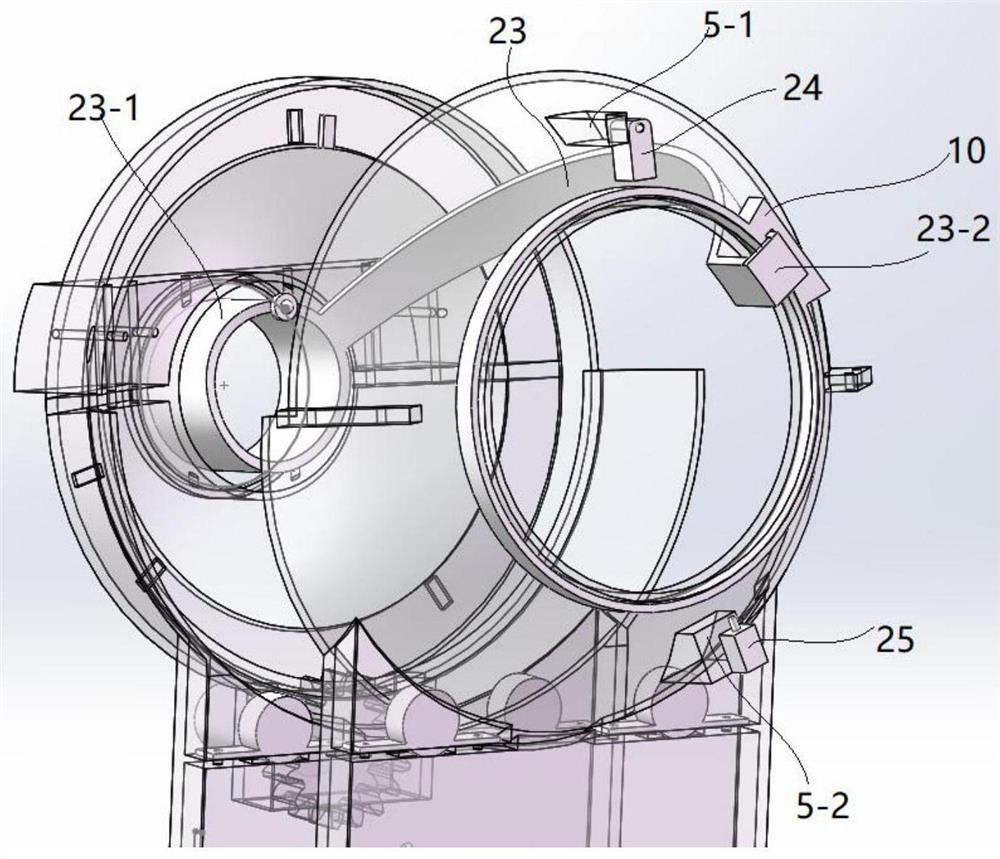

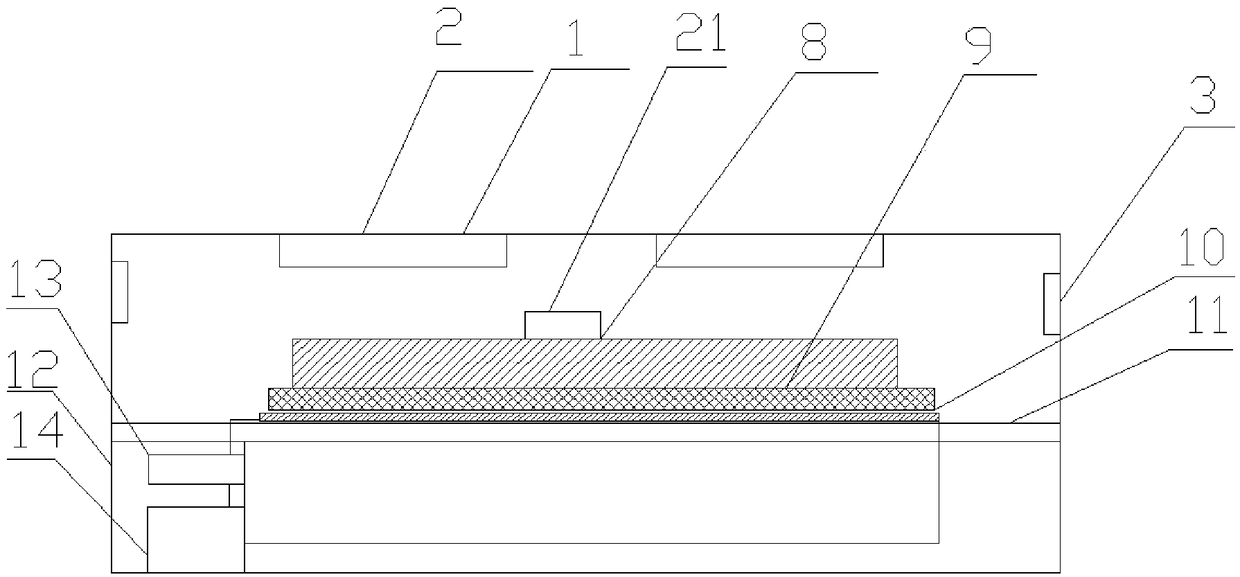

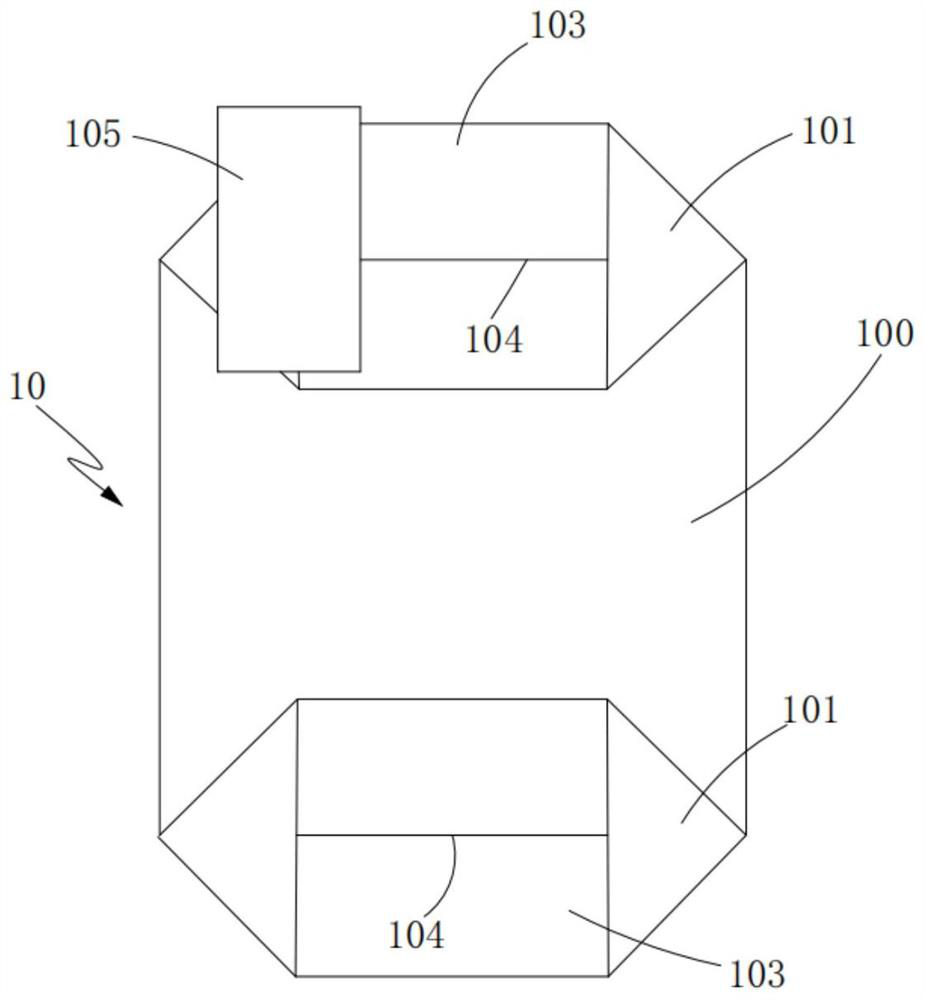

Intelligent cat litter basin

PendingCN111802256ADo not need to add frequentlyWon't bring outAnimal housingElectronic systemsLitter

The invention discloses an intelligent cat litter basin, and belongs to the technical field of pet equipment. The intelligent cat litter basin comprises a shell with a long hollow channel, an ellipsoid self-cleaning cabin, a storing and discharging module, a litter filtering plate, a sticking removing plate module, an electronic system module, a motor transmission module, a smashing and discharging module and a litter collecting box. The cat litter basin has the advantages that caked cat litter after cat defecation can be automatically cleaned, and caked cat litter adhering to the wall can beautomatically shoveled away; a system monitors the amount of cat litter in the self-cleaning cabin, and the cat litter is automatically supplemented when the amount is small, so that the trouble of frequently adding the cat litter is avoided; the long hollow channel can solve the problem of cat litter leakage; potential safety hazards of cats are eliminated through single-layer defecation holes; sand can be buried in cat excrement in a self-cleaning process, so that cat excrement can be fully attached to the cat litter; and waste sand enters the smashing and discharging module and then is flushed into a sewer with water, so that the trouble of manual garbage dumping is avoided, and the real full-automatic self-cleaning function is achieved.

Owner:林英豪

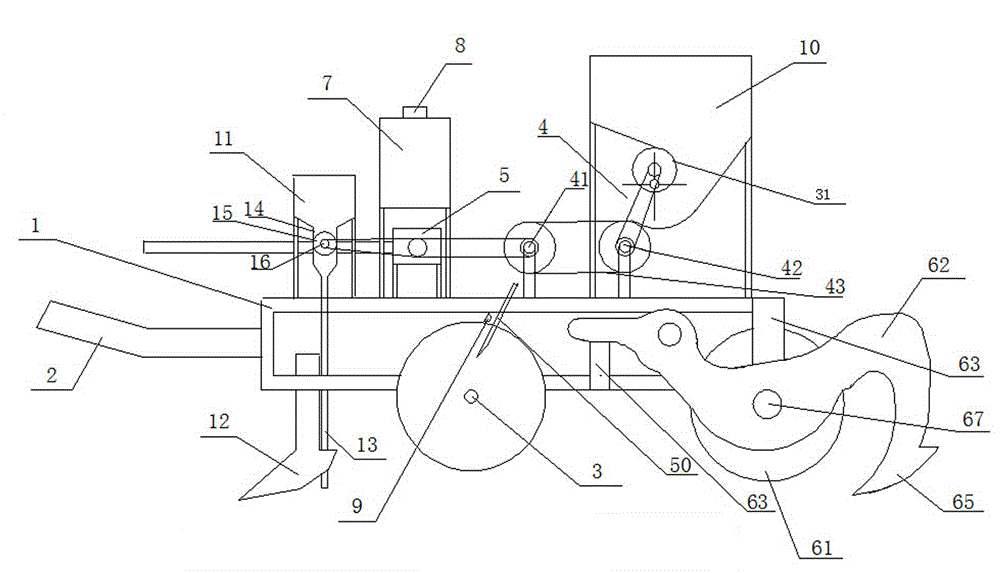

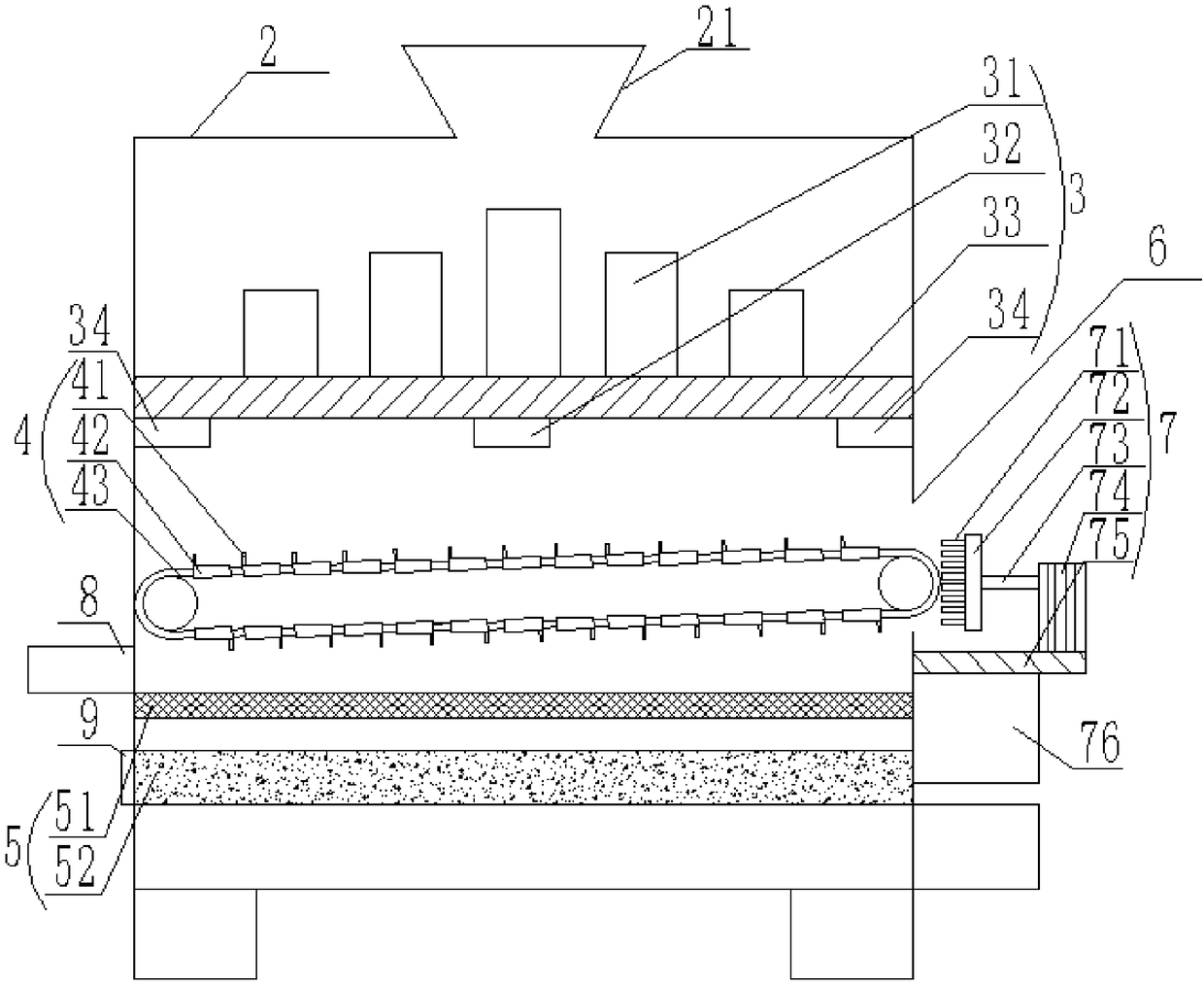

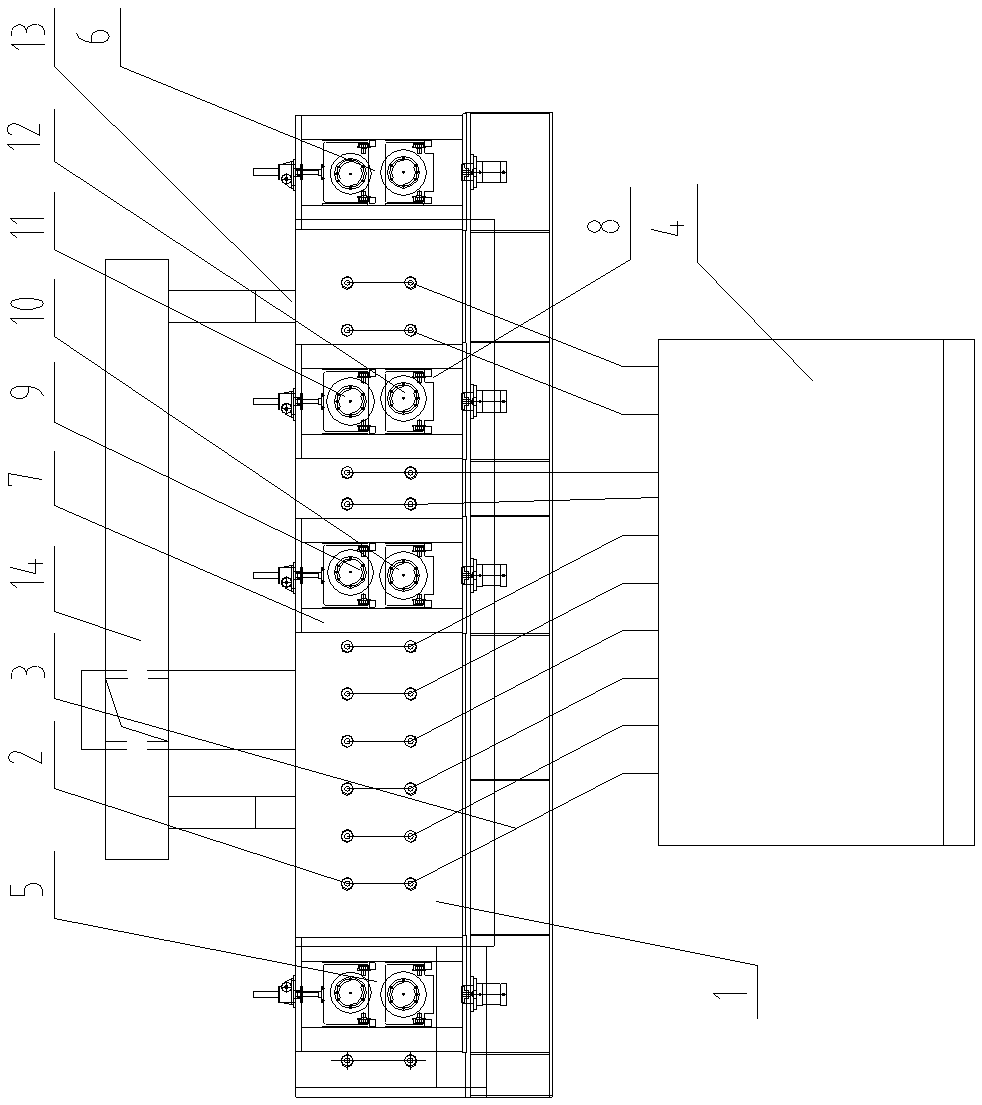

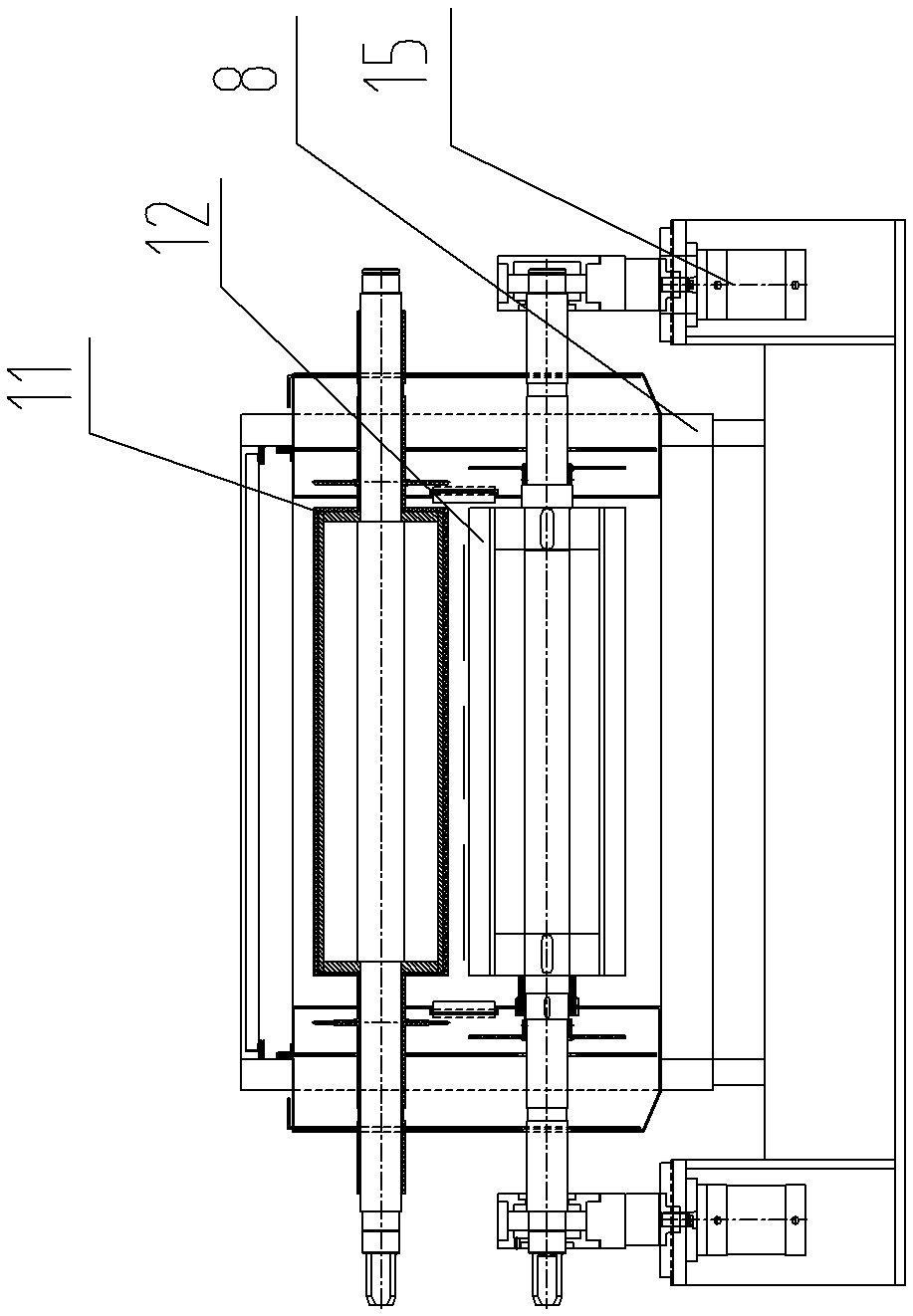

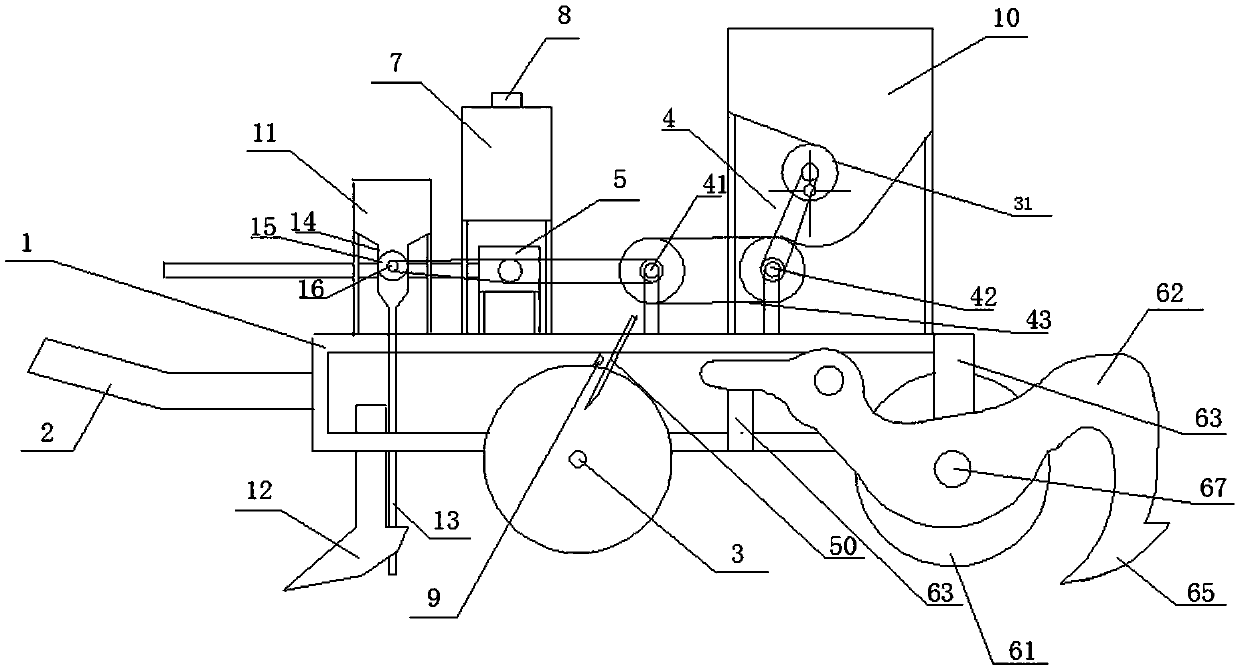

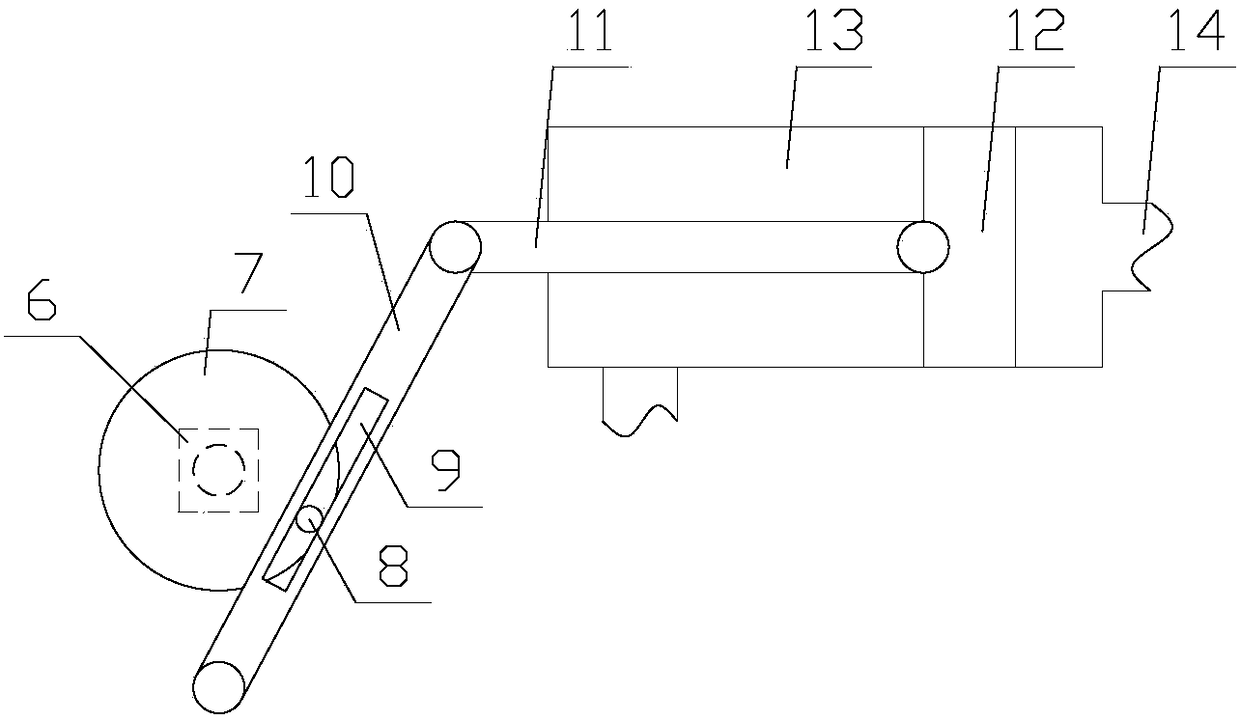

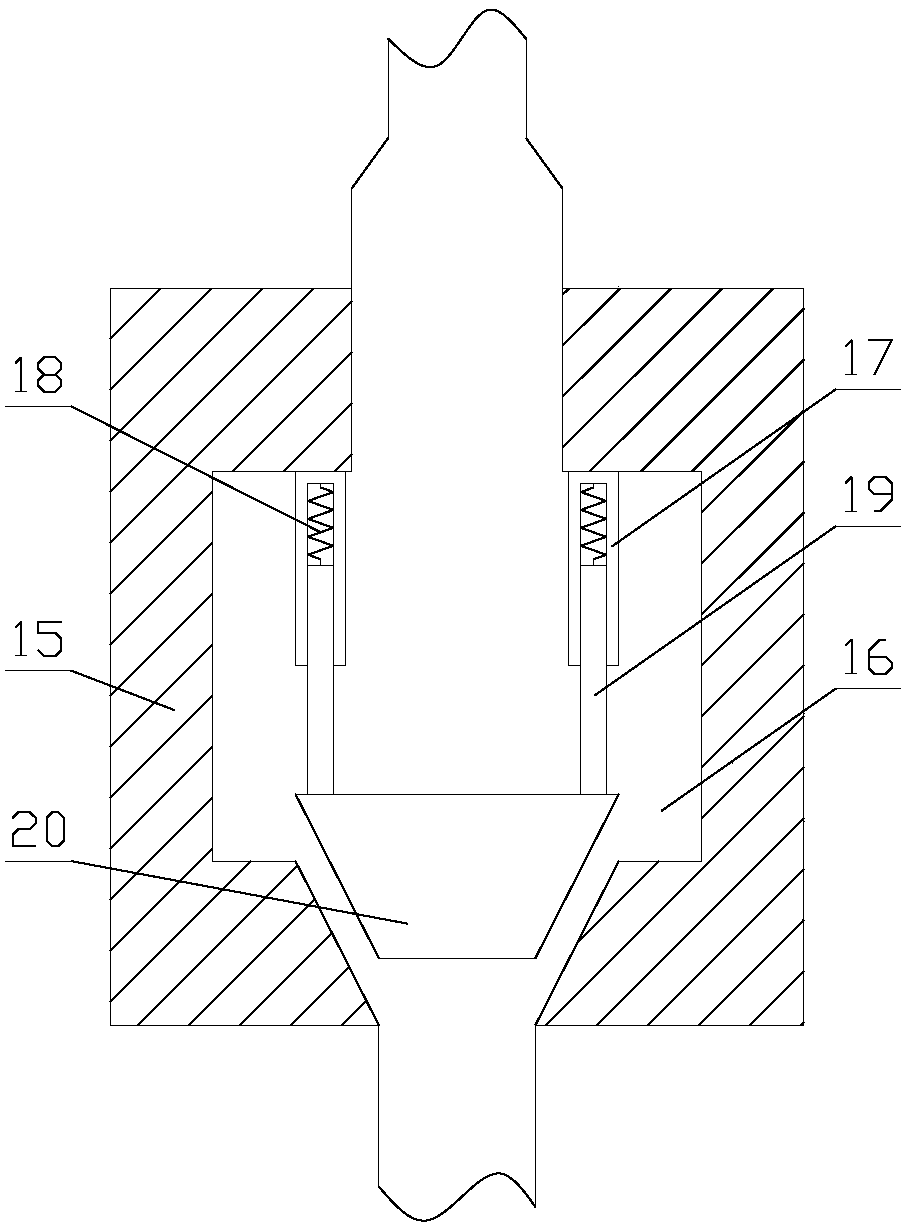

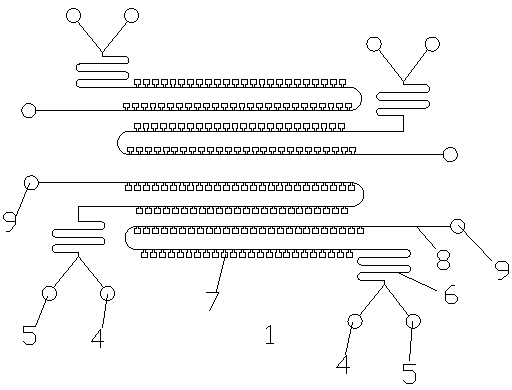

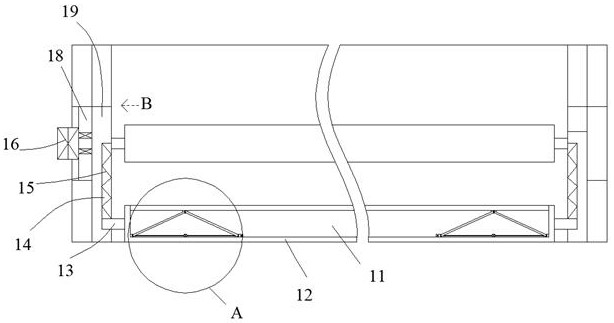

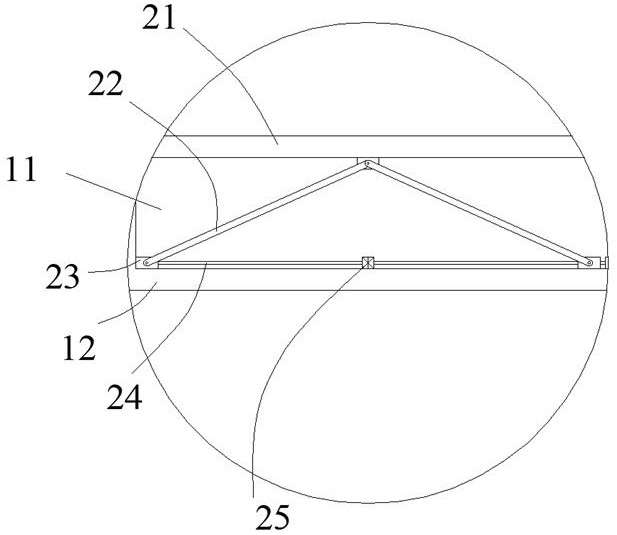

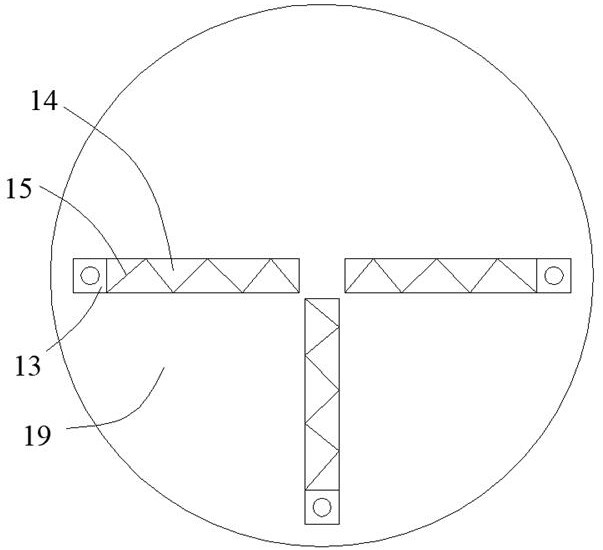

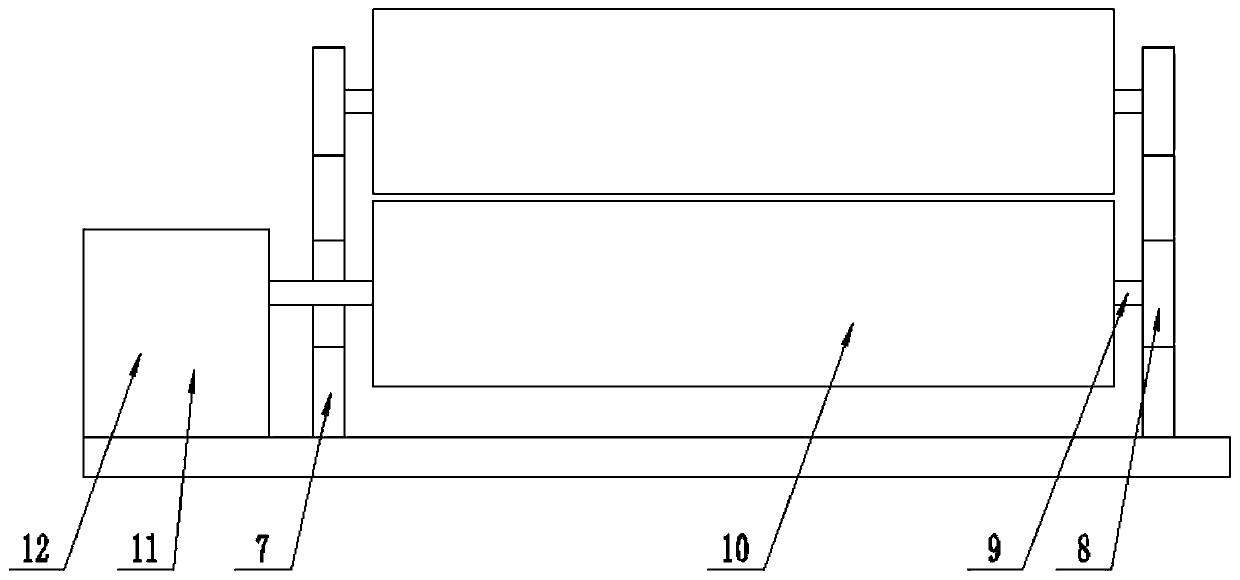

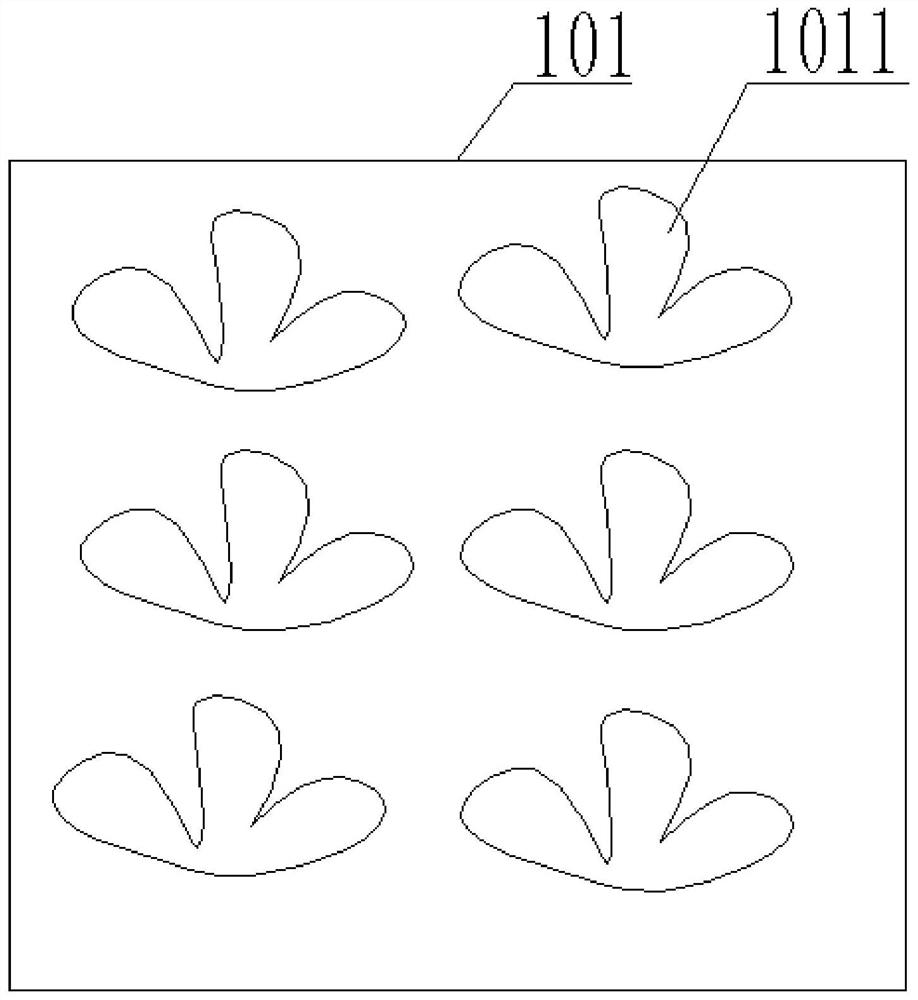

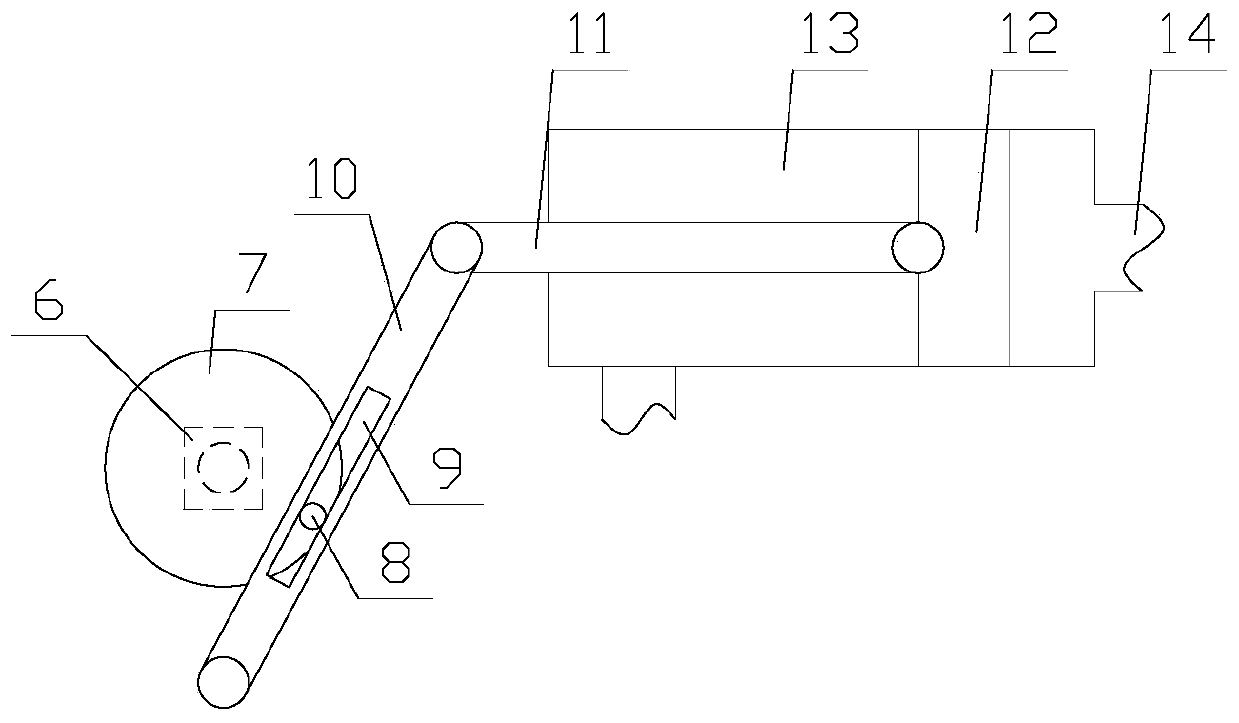

Comprehensive operation machine for desert planting

ActiveCN104081918AImprove work efficiencyEasy to sendPlantingWatering devicesDrive shaftTraction frame

The invention relates to the agricultural cultivation field, and in particular relates to a comprehensive operation machine integrating sowing, grass mulching and water spraying for ecological planting of deserts. The comprehensive operation machine comprises a rack, a traction frame arranged at the front end of the rack and a land wheel arranged at the middle part of the rack by a land axle; and the comprehensive operation machine is characterized in that the comprehensive operation machine also comprises a sowing mechanism, a water replenishing mechanism, a grass mulching mechanism, a grass dividing mechanism, a grass delivery mechanism, a grass moving mechanism, a grass container, a grass pressing wheel and a sand covering plow, wherein a speed changer is arranged on the rack, the front end of speed changer is connected with external power by a cross-shaped universal drive shaft, and two sides of the speed changer are provided with a first power output shaft and a second power output shaft respectively, and the speed changer provides power for the whole machine. The comprehensive operation machine has multiple functions, can perform sowing, grass mulching, water spraying and sand covering at one time, can be adjusted according to the specific circumstance of the deserts and is improved in the operation efficiency.

Owner:景泰绿地农机装备有限公司

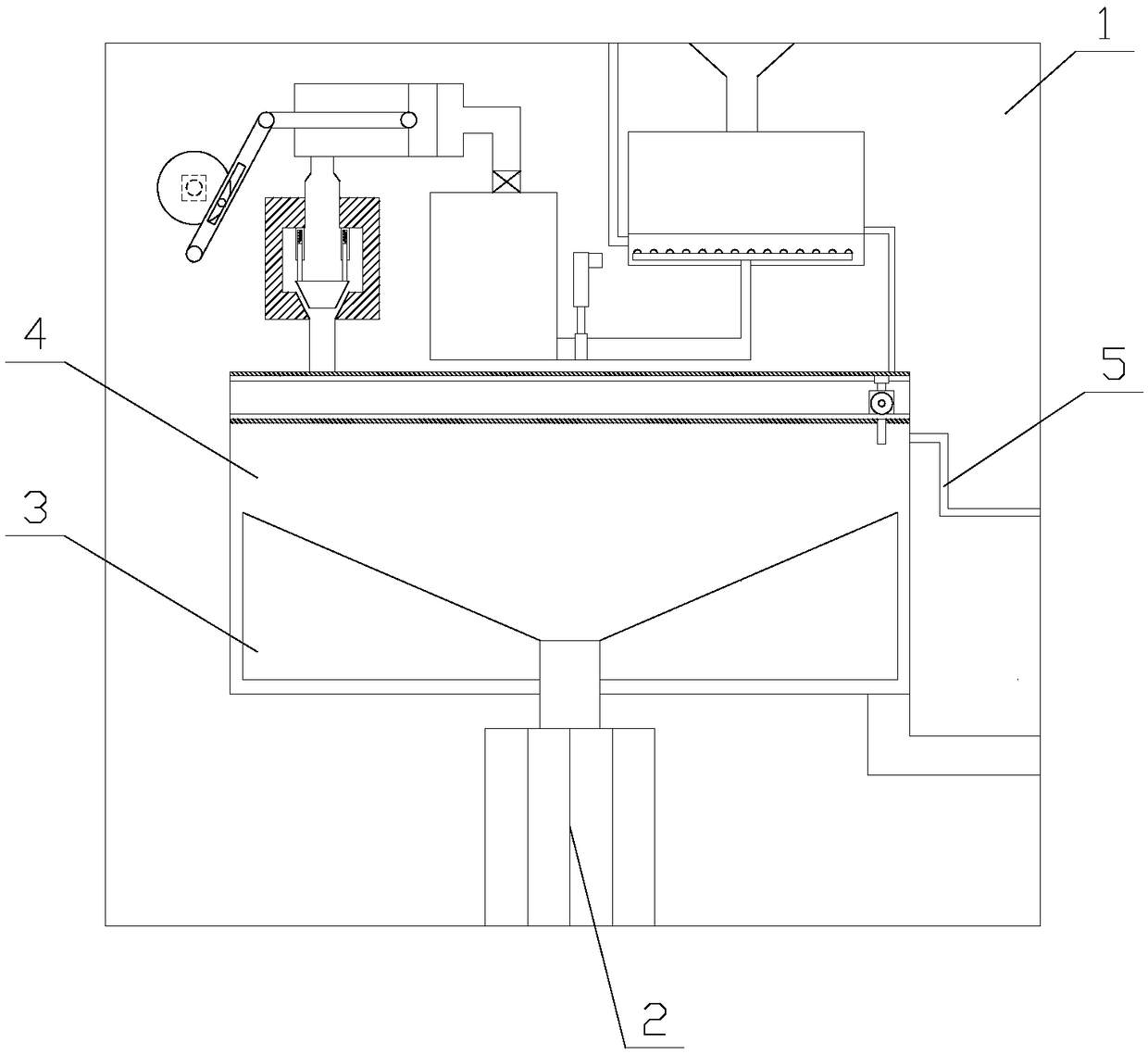

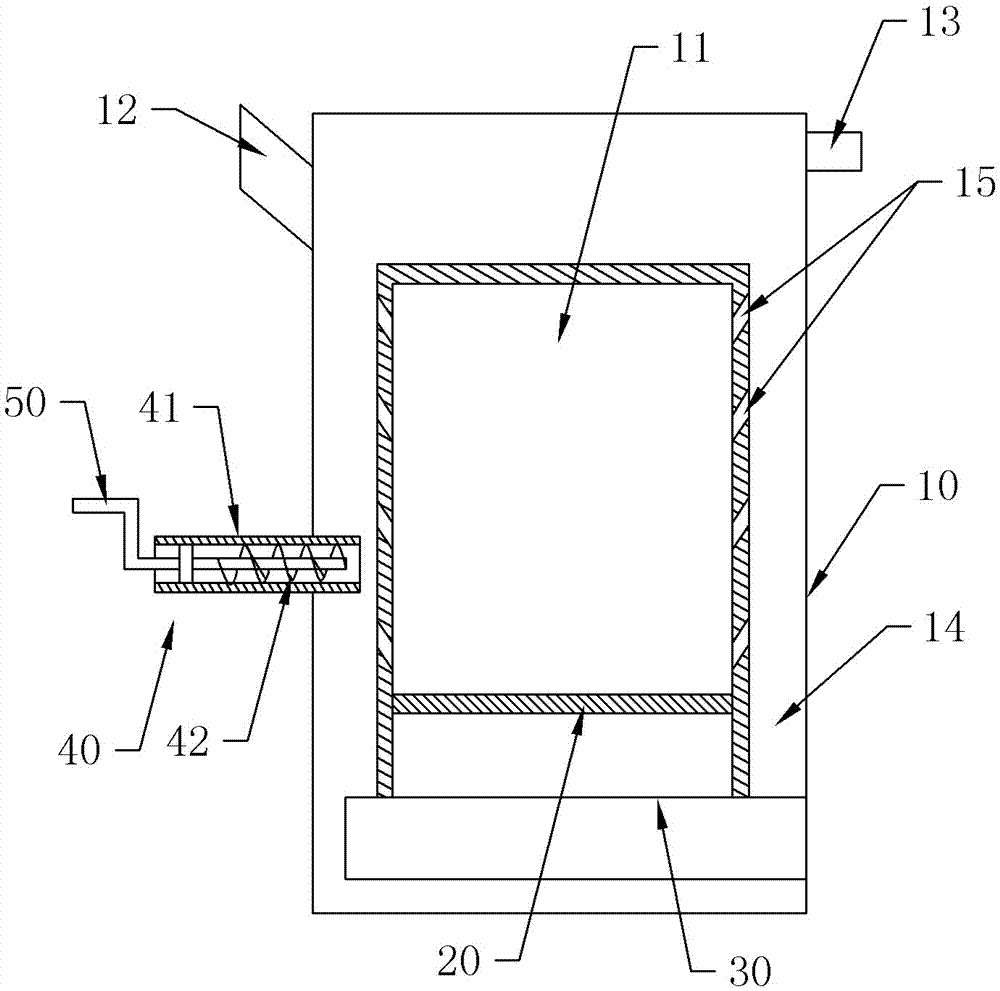

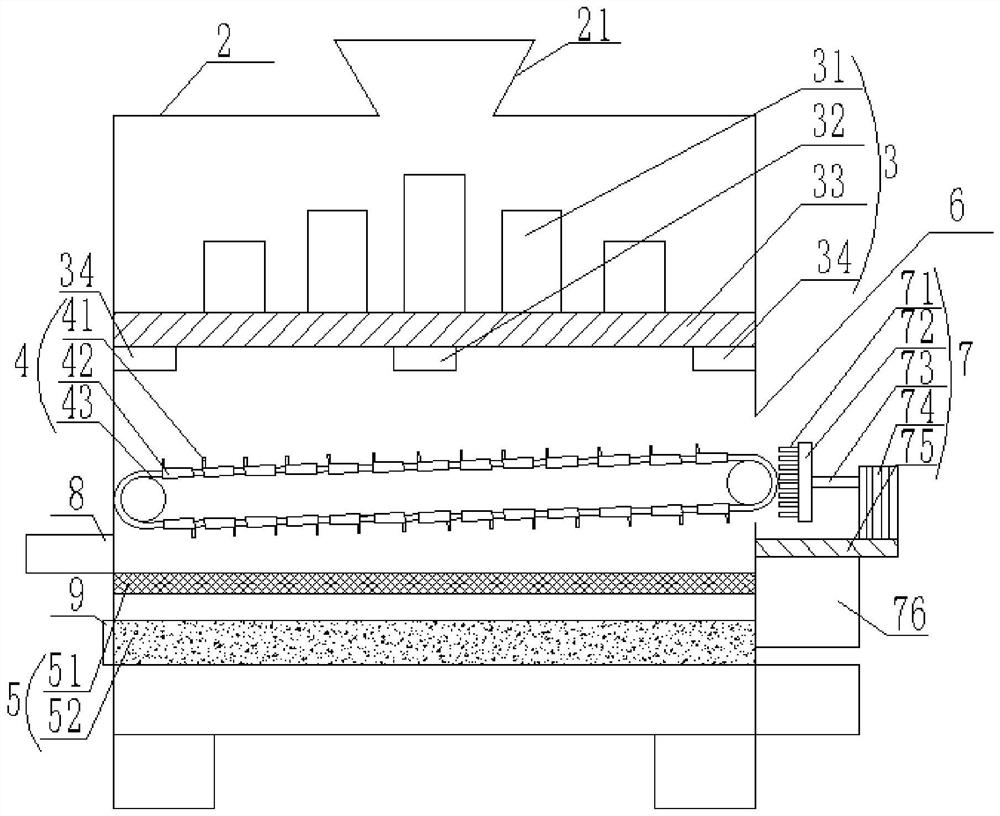

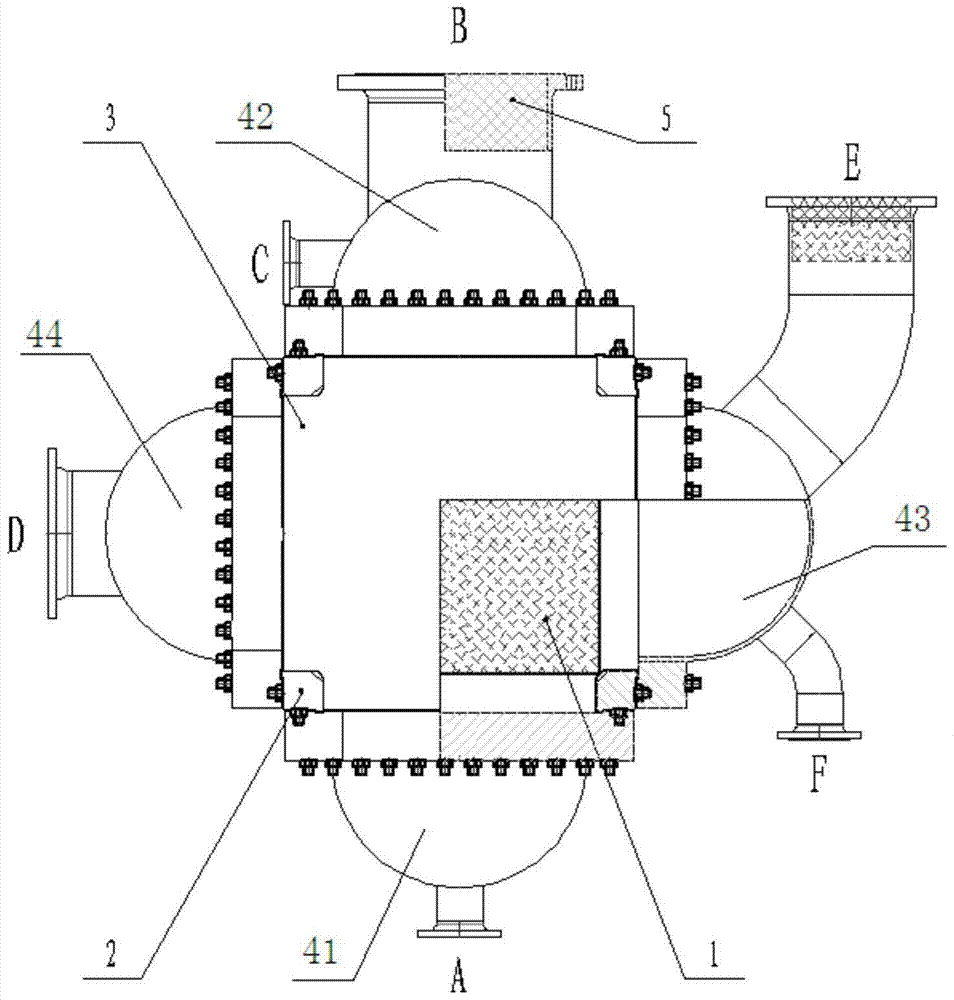

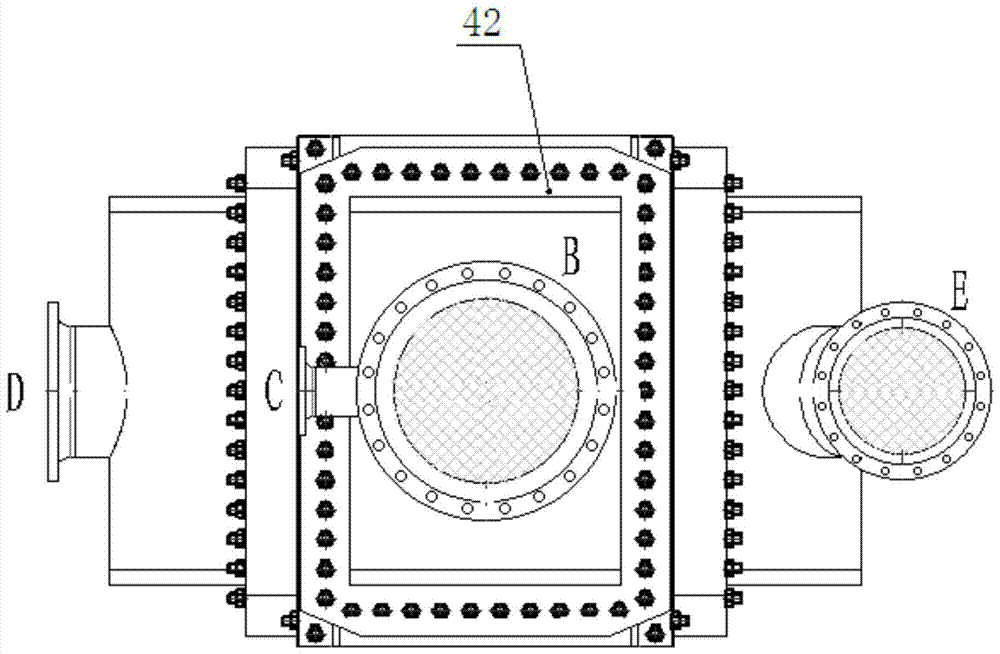

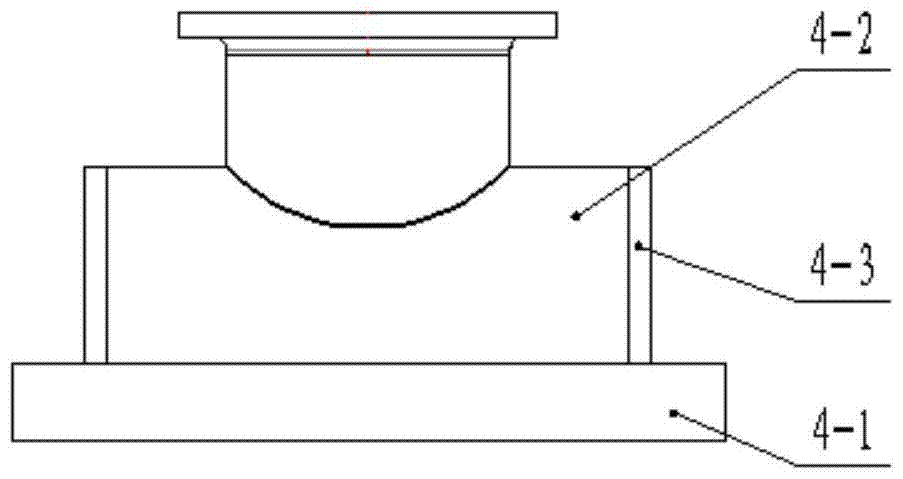

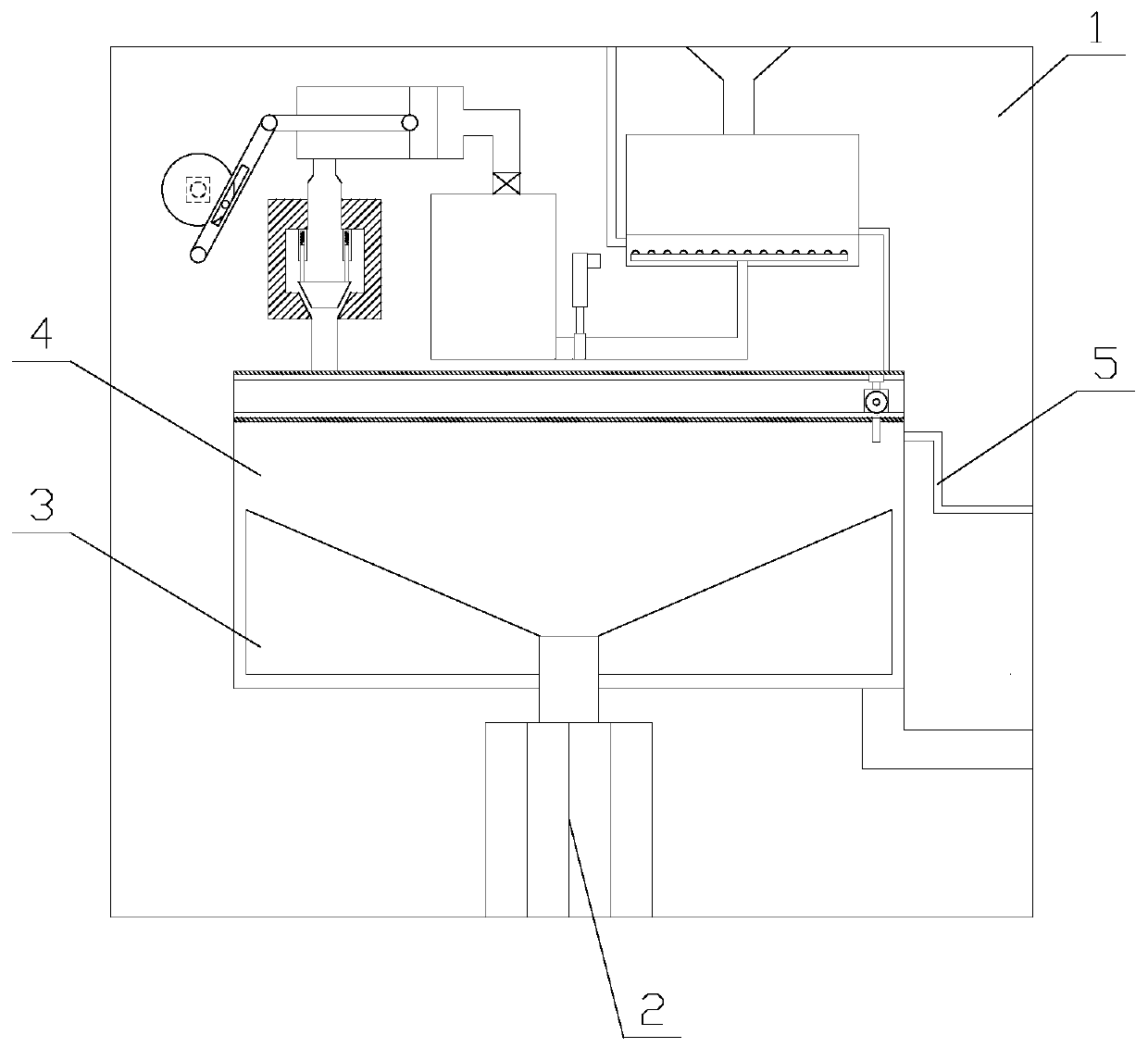

Township integrated sewage treatment system

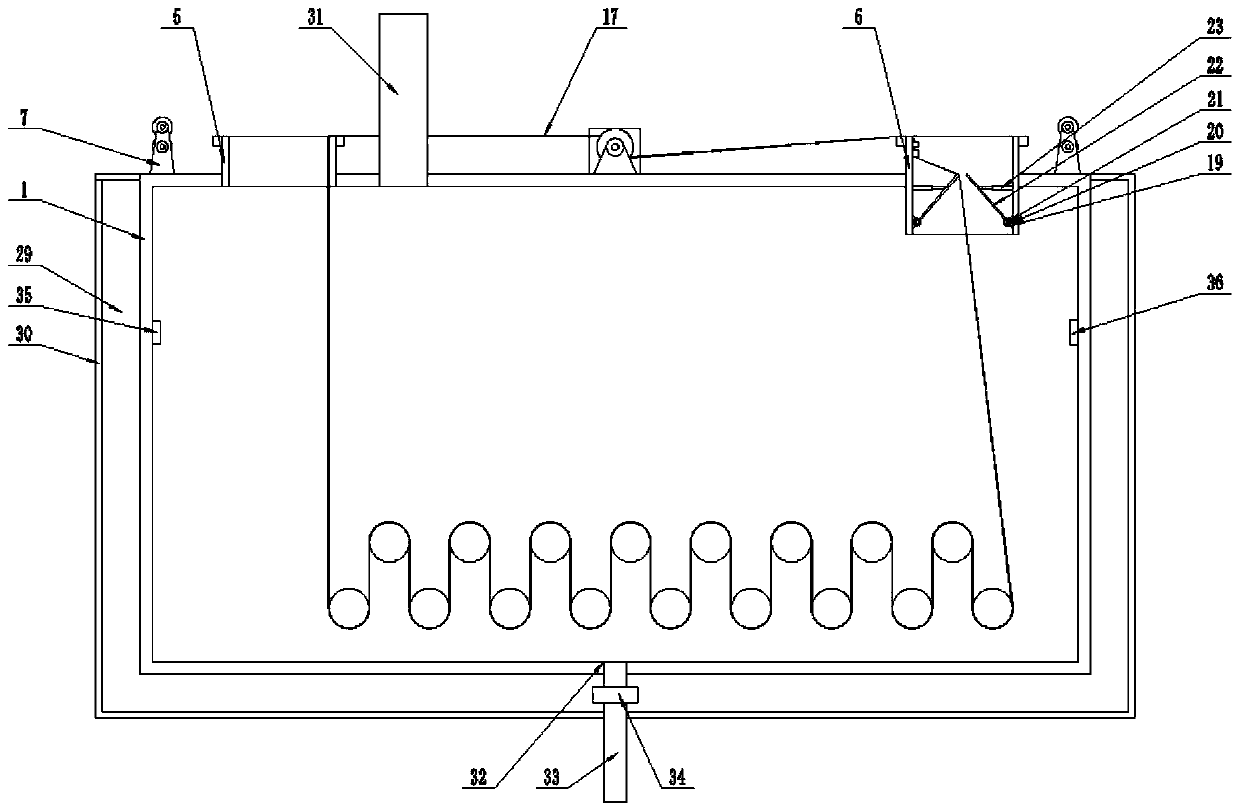

ActiveCN108439713AEffective absorptionPurifyWater/sewage treatment by irradiationWater contaminantsShunt DeviceSewage

The invention discloses a township integrated sewage treatment system and belongs to the technical field of sewage filter equipment. The township integrated sewage treatment system is used for solvingthe problems that existing sewage treatment equipment is poor in treatment effect and does not classify impurities basically for maximum utilization of resources in the sewage treatment process. Thesystem comprises a filter pool, a water purification pool and a storage pool which are connected in sequence, wherein the filter pool comprises a box, a water inlet is formed in the top of the box, and a shunting device, a conveying device and a filter device are arranged in the box from top to bottom in sequence; the shunting device comprises a support plate, flow guide columns, vibrators and a vibration power supply, the support plate is arranged on the inner wall of the box, the flow guide columns are arranged on the support plate, the vibration power supply and the vibrators are arranged at the lower part of the support plate, and the vibration power supply is connected with the vibrators; the water purification pool comprises a pool body, and water purification plants for water purification are planted in the pool body.

Owner:SICHUAN STONG EURO & AMERICA ENVIRONMENT ENG

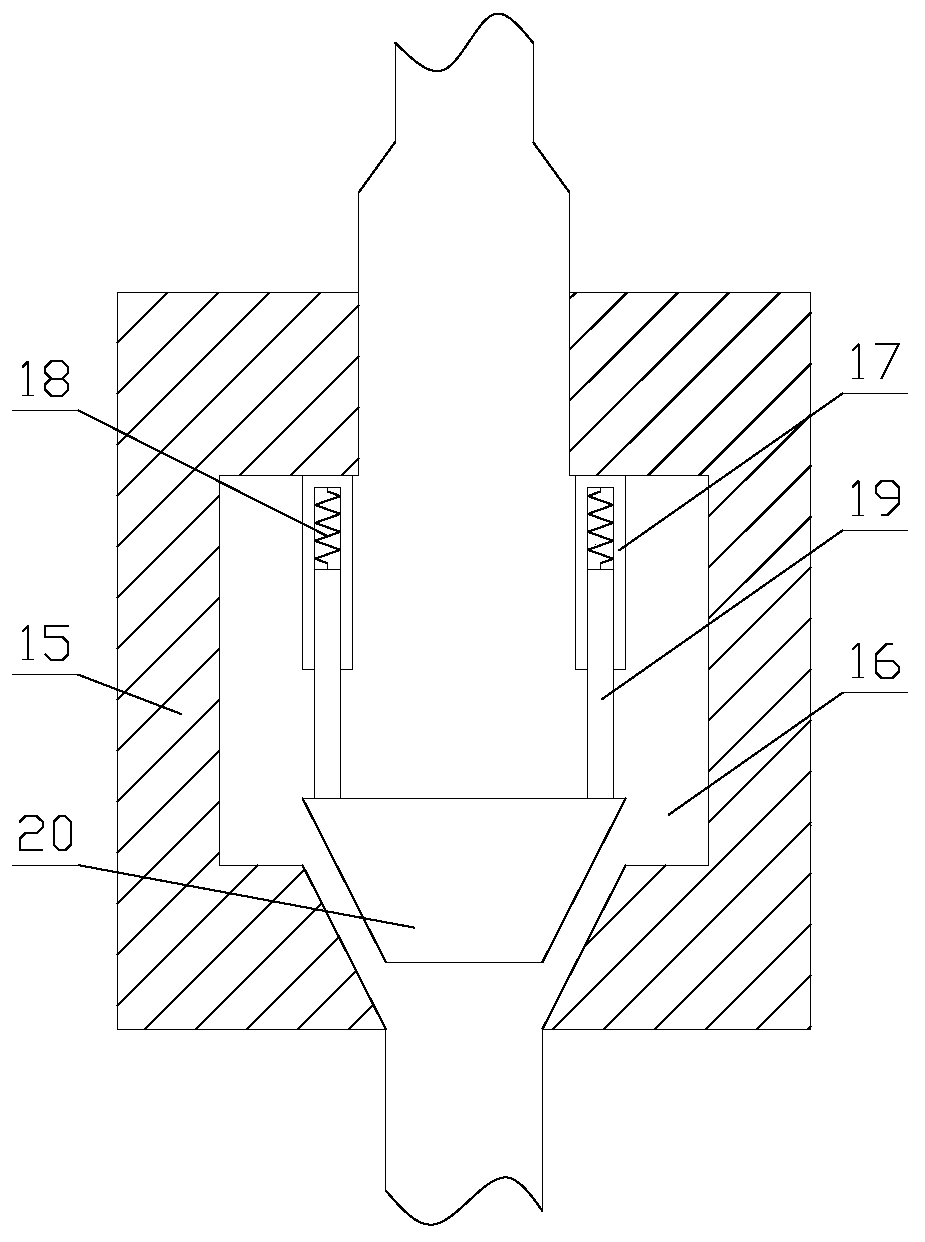

Metal packaging tin forming machining machine and machining method

InactiveCN113231527AAvoid replacementImprove processing efficiencyHollow articlesChanging equipmentPackaging Tank

The invention relates to a metal packaging tin forming machining machine and machining method. The metal packaging tin forming machining machine comprises a working bottom plate, an intermittent driving device, a blanking device, a mounting plate and mounting bases, the working bottom plate is provided with the intermittent driving device, the blanking device is arranged above the intermittent driving device, and the blanking device is mounted on the mounting plate. The mounting bases are symmetrically connected to the left and right ends of the mounting plate. The following problems can be solved that when a traditional metal packaging tin is subjected to forming machining, only a metal plate with the fixed length can be cut, when metal tins with different diameters need to be manufactured, equipment needs to be replaced for machining, the working time is wasted, the machining efficiency of the whole device is reduced, and after blanking is completed, and when a blanking knife moves upwards, the metal coiled material is easily brought out, the tensioning degree of the metal coiled material is damaged, the whole working process is possibly interfered, and the blanking position is changed.

Owner:义乌市伟硕包装科技有限公司

Energy-saving process and energy-saving device for utilization of kiln waste

InactiveCN102589309AWon't bring outCause damageCombustion processIndirect carbon-dioxide mitigationCold airBrick

The invention belongs to the technical field of ceramic industrial kilns, and particularly relates to an energy-saving process and an energy-saving device for utilization of kiln waste. The process includes steps: firstly, heat exchange, namely using a quench fan to send cold air into a pipeline of a kiln quench zone, and allowing the cold air passing through the pipeline of the quench zone to exchange heat with the quench zone; and secondly, heat utilization, namely mixing acquired hot air with air conveyed by a combustion fan into a combustion pipeline to raise the temperature of the combustion air to 600-800 DEG C. The energy-saving process and the energy-saving device for utilization of kiln waste have the advantages that the cold air is sent into the pipeline for heat exchange with the quench zone and then recycled, and the cold air only flows in the pipeline with no direct reaction with the interior of the industrial kiln and the surfaces of bricks, so that damage of brick blank is avoided, and the bricks are safer, more reliable and more environment-friendly in use. Moreover, the quench zone can be effectively cooled while the temperature of the combustion zone is raised by raising the temperature and improving the oxygen content of the combustion air.

Owner:ZIBO HUIJIU AUTOMATION TECH

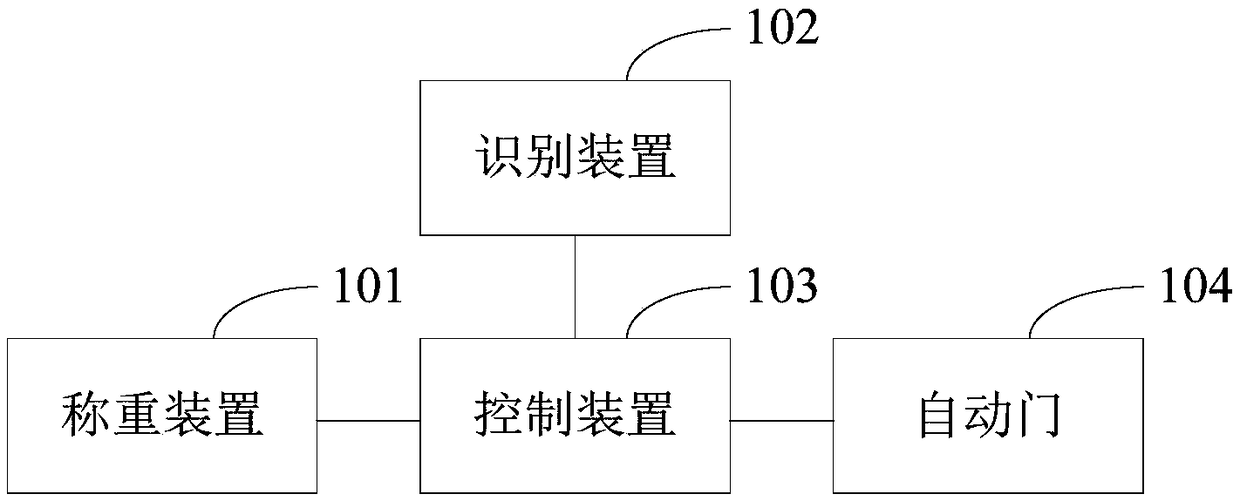

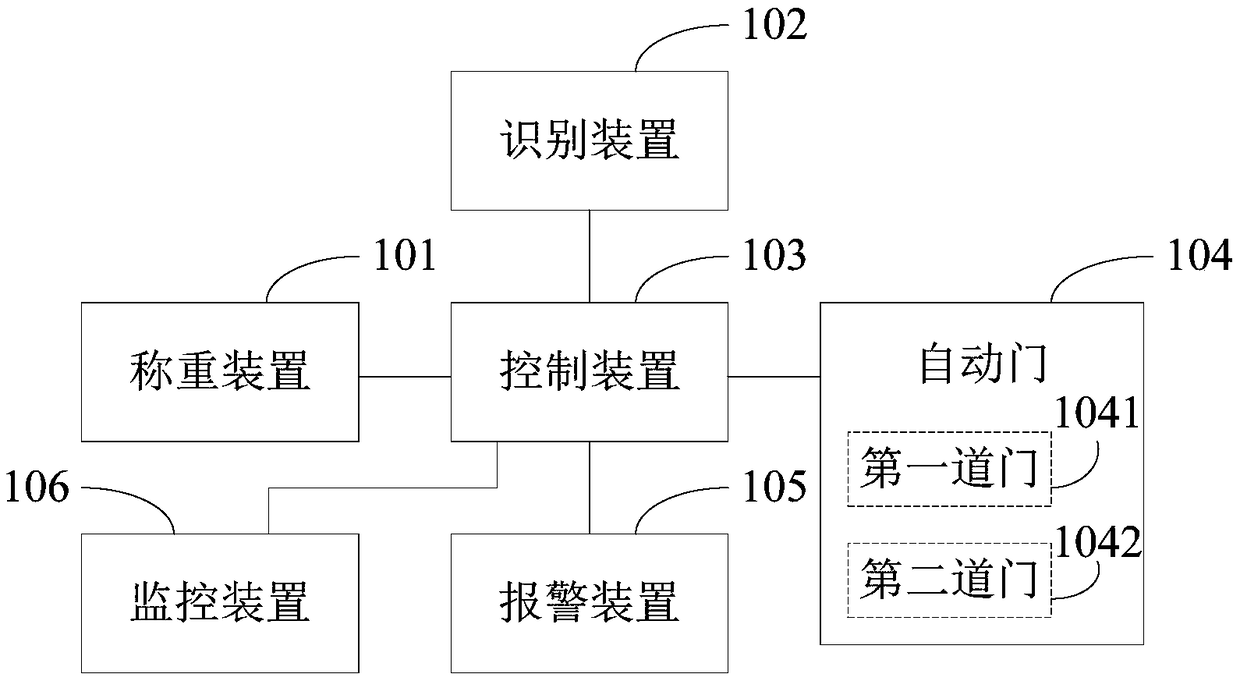

Unmanned supermarket access control system

InactiveCN109326026AImprove securityWon't bring outOptical detectionIndividual entry/exit registersControl systemIdentification device

The invention is suitable for the technical field of unmanned supermarket systems, and provides an unmanned supermarket access control system. The system comprises a weighing device, an identificationdevice, a control device and an automatic door; the weighing device is used for obtaining weight information of customers entering and leaving a supermarket and transmitting the weight information tothe control device; the identification device is used for acquiring identity information of the customers entering and leaving the supermarket and transmitting the identity information to the controldevice; the control device is used for sending an output signal to the automatic door according to the acquired weight information and identity information, wherein the output signal includes a dooropening allowing signal and a door opening forbidding signal; and the automatic door is used for controlling a door body to be in an opened or closed state according to the acquired output signal. Bythe adoption of the access control system, the opening and closing of the automatic door can be controlled according to the weight and identity information of the customers entering and leaving the supermarket, so that the safety of the unmanned supermarket is improved.

Owner:河北戴斯特尼科技有限公司

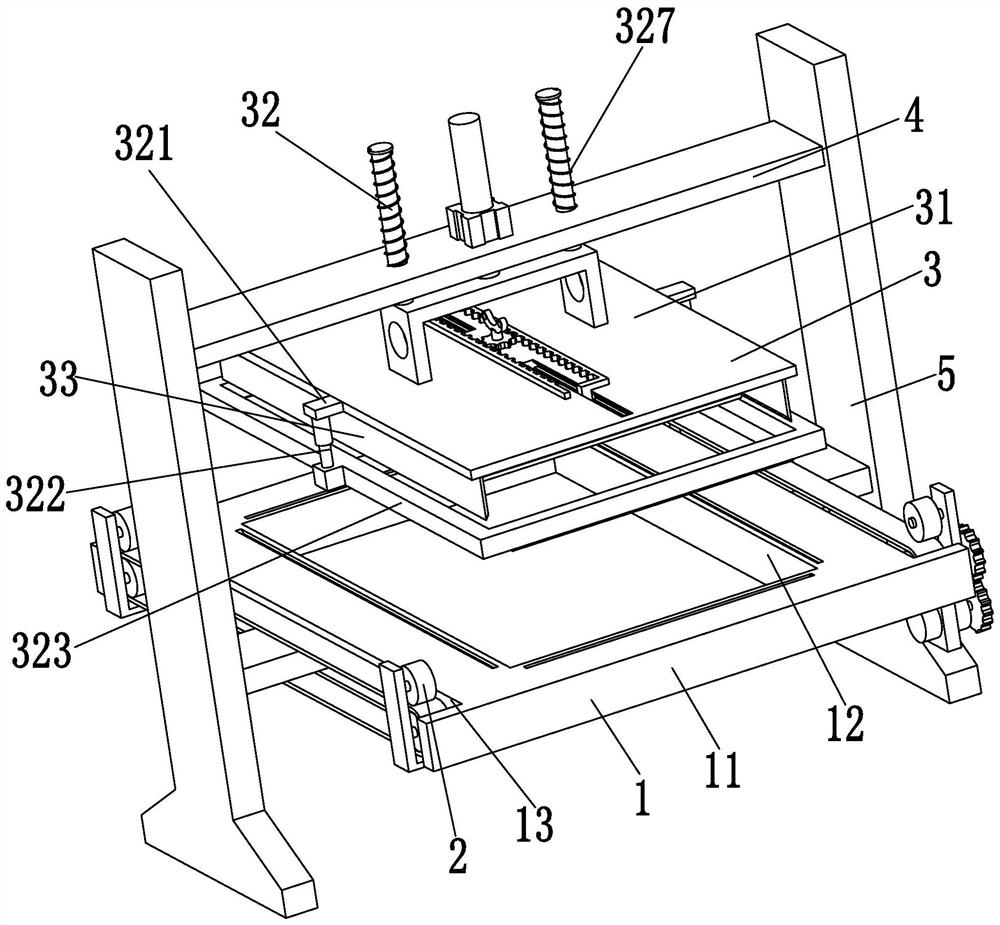

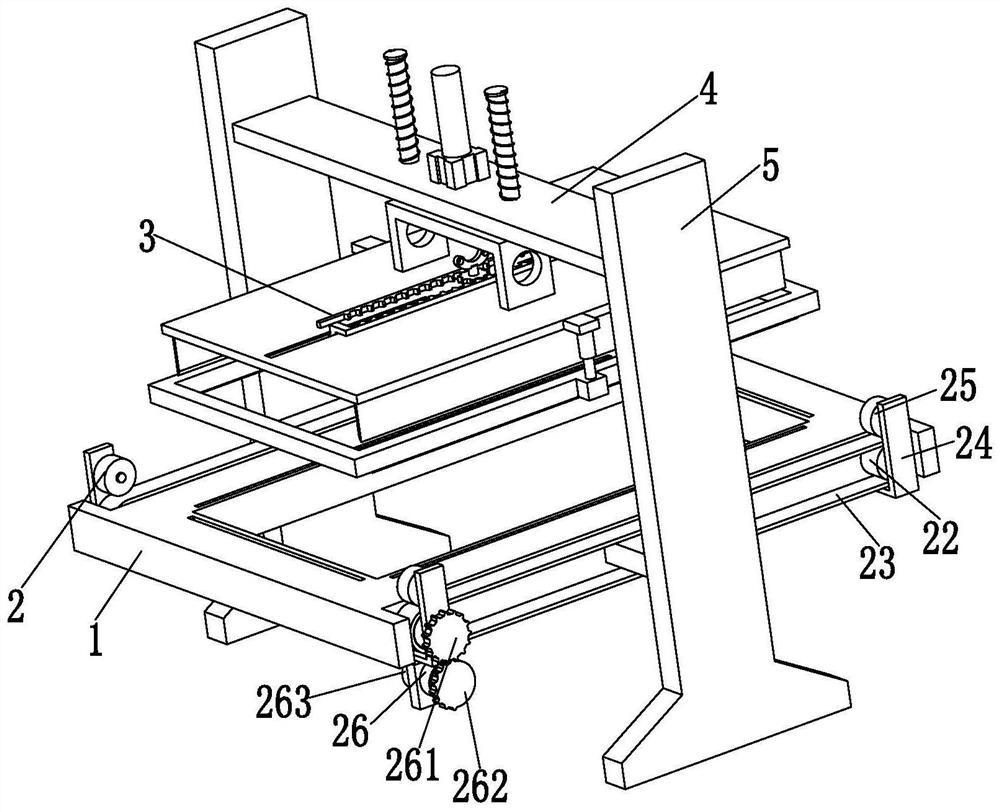

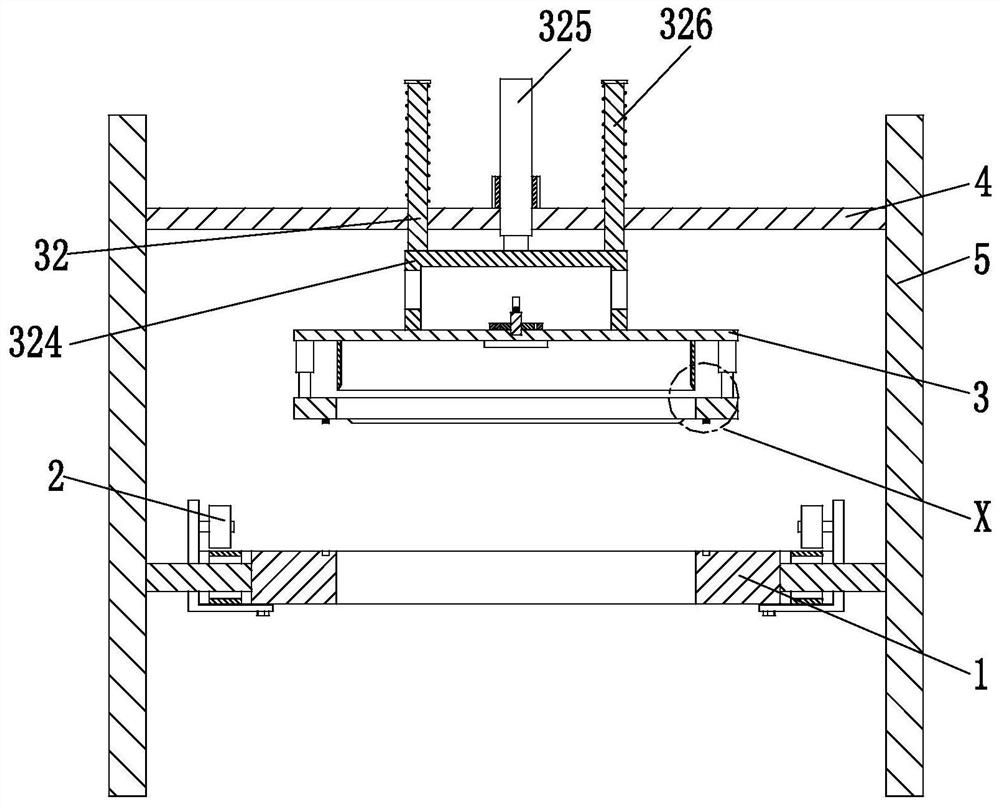

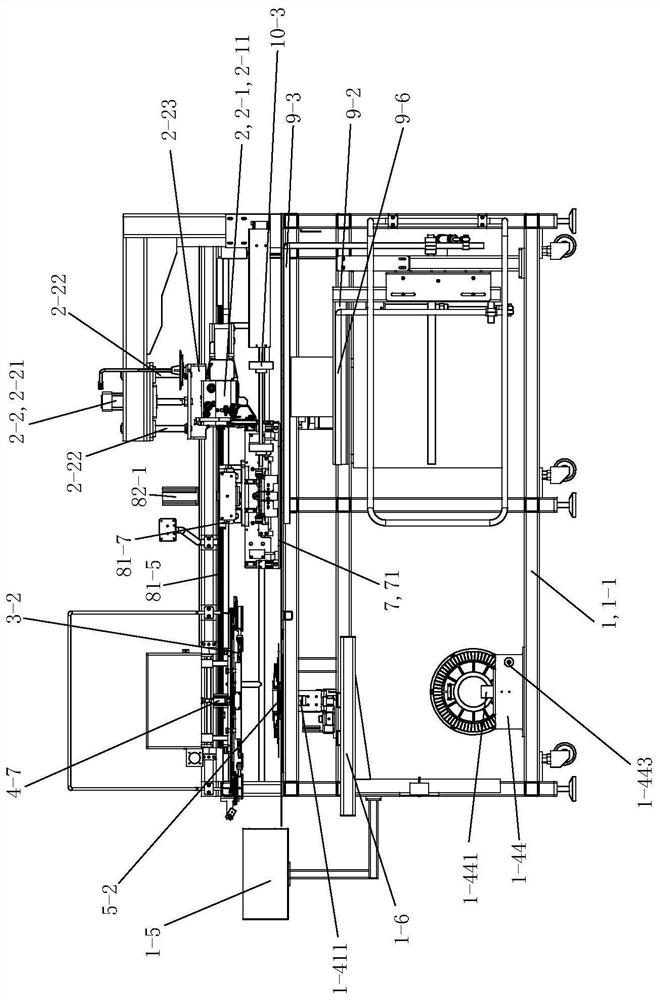

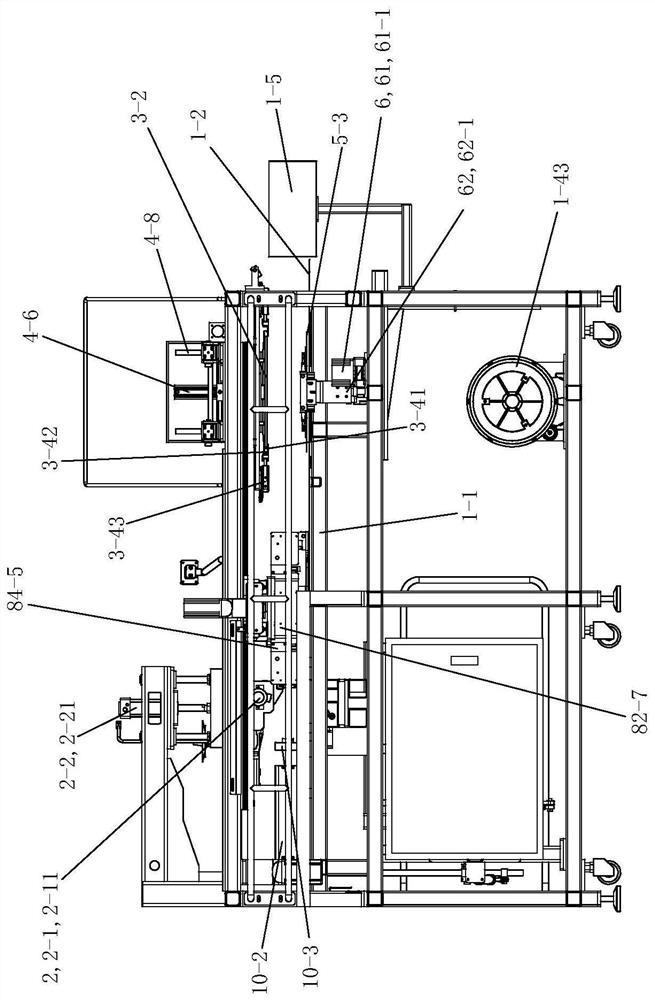

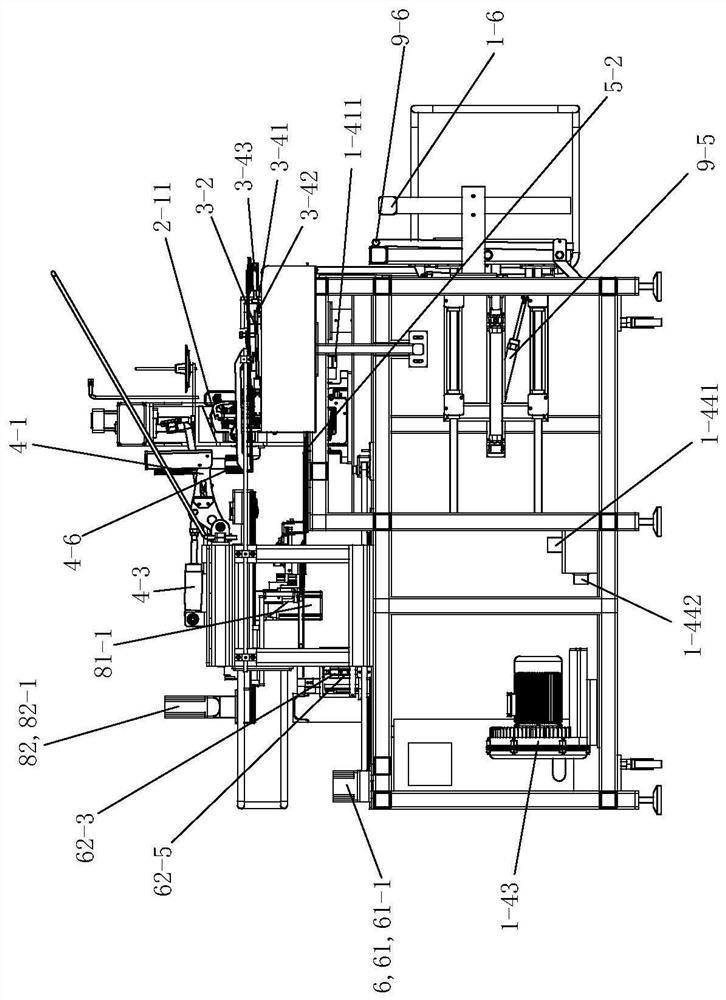

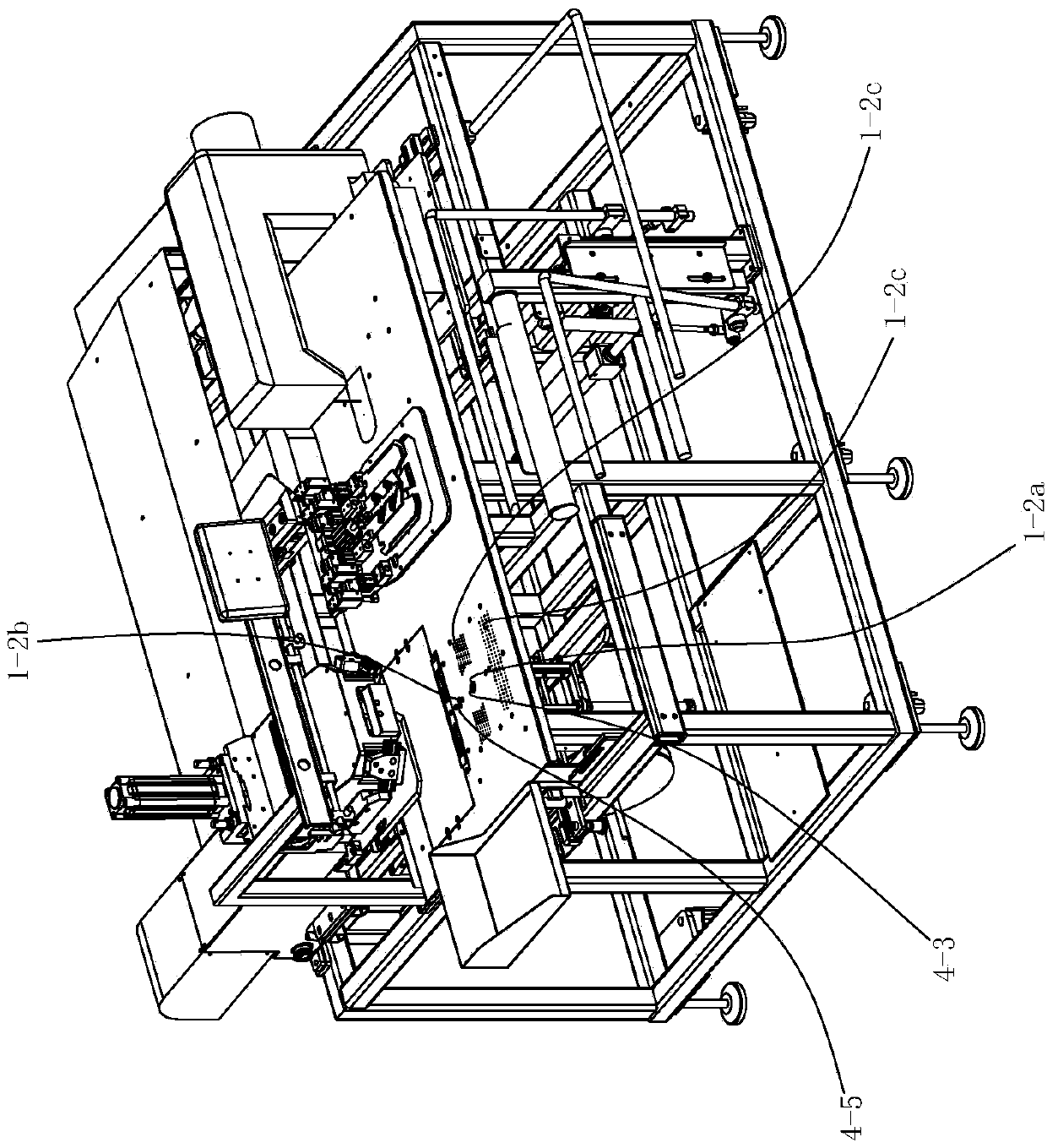

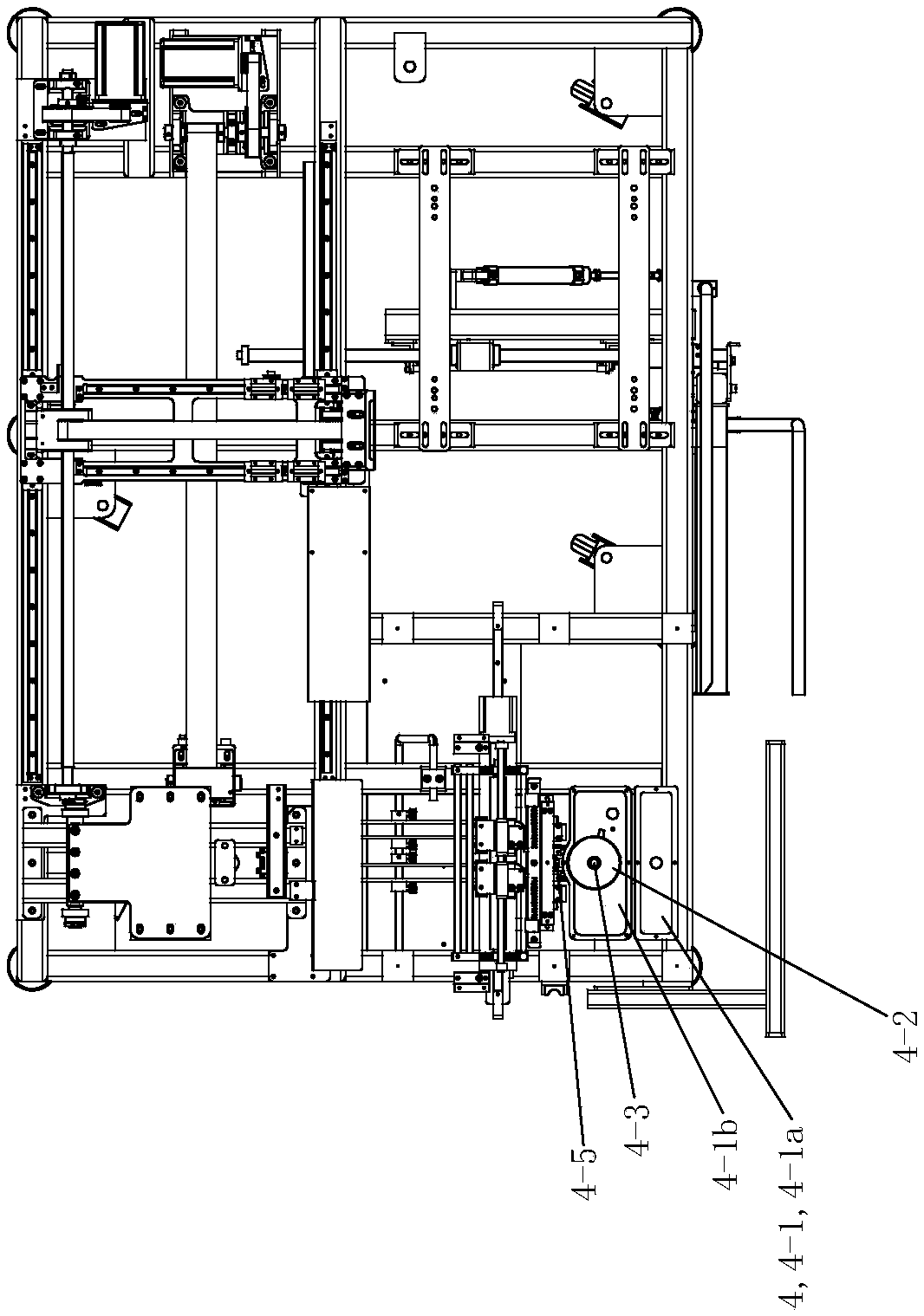

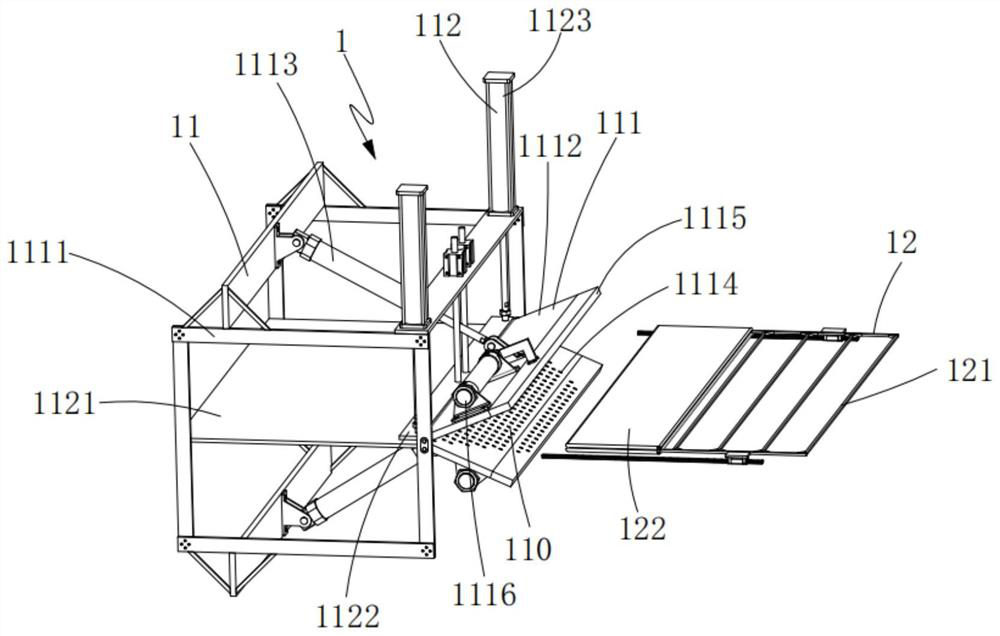

Kangaroo pocket sewing equipment

PendingCN111826820ASimple structureHigh degree of automationWork-feeding meansSewing-machine control devicesMechanical engineering

The invention discloses kangaroo pocket sewing equipment. The kangaroo pocket sewing equipment comprises a workbench assembly and a sewing assembly. The workbench assembly comprises a rack and a workbench plate. The workbench plate is horizontally and fixedly arranged on the rack. The sewing assembly is arranged on the right portion of the rack. The kangaroo pocket sewing equipment is characterized by further comprising an edge folding assembly, an edge folding driving device, a pocket-shaped plate assembly, a pocket-shaped plate driving device, a frame pressing device and a frame pressing driving device. The edge folding assembly cooperates with the pocket-shaped plate assembly to fold the edge of pocket cloth. The edge folding driving device drives the edge folding assembly to move up and down, and the pocket-shaped plate driving device drives the pocket-shaped plate assembly to move up and down and back and forth. The frame pressing device is used for conveying the folded pocket cloth and bodice cloth to the sewing assembly for sewing, and the frame pressing driving device drives the frame pressing device to move up and down, front and back and left and right.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

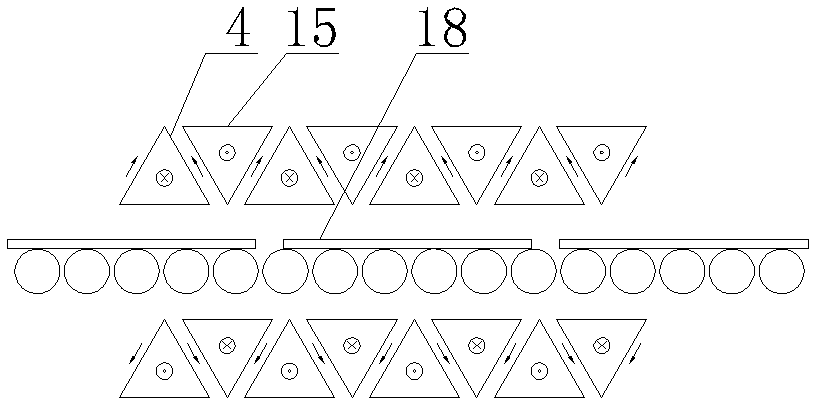

Degreasing device

PendingCN108301010AEasy to realize scrubbingGuaranteed degreasing effectCleaning using toolsSteel beltEngineering

The invention relates to the technical field of steep strip machining, in particular to a degreasing device, which can effectively guarantee the degreasing effect. The degreasing device comprises a degreasing box; and a spraying head is mounted in the degreasing box, and is connected with an alkali liquid box through a liquid inlet pipeline. The degreasing device is characterized in that the degreasing box is provided with a feeding rubber roller pair at an inlet end and a water stop rubber roller pair at an outlet end; a brushing roller mechanism is mounted in the degreasing box, and comprises a front bracket and a back bracket; upper brushing rollers and lower rubber rollers are mounted on the front bracket in a staggered manner; and upper rubber rollers and lower brushing rollers are mounted on the back bracket in a staggered manner.

Owner:WUXI CITY XIDONG RUBBER & PLASTICS MACHINERY

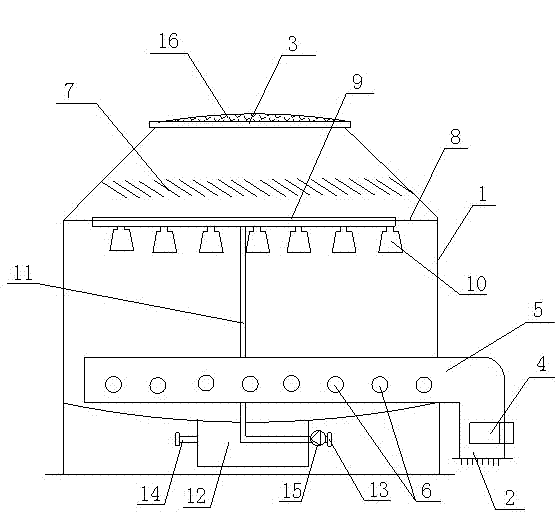

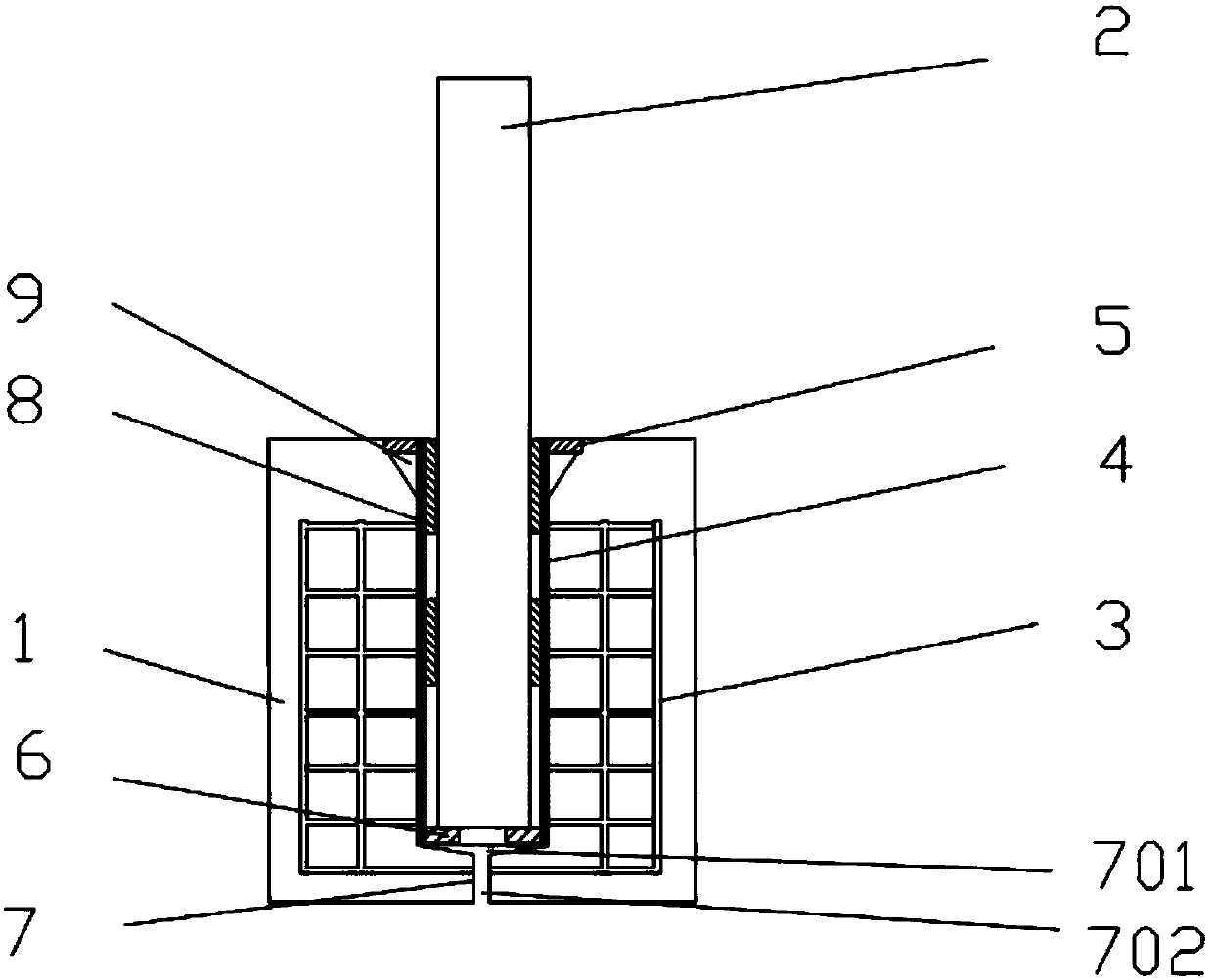

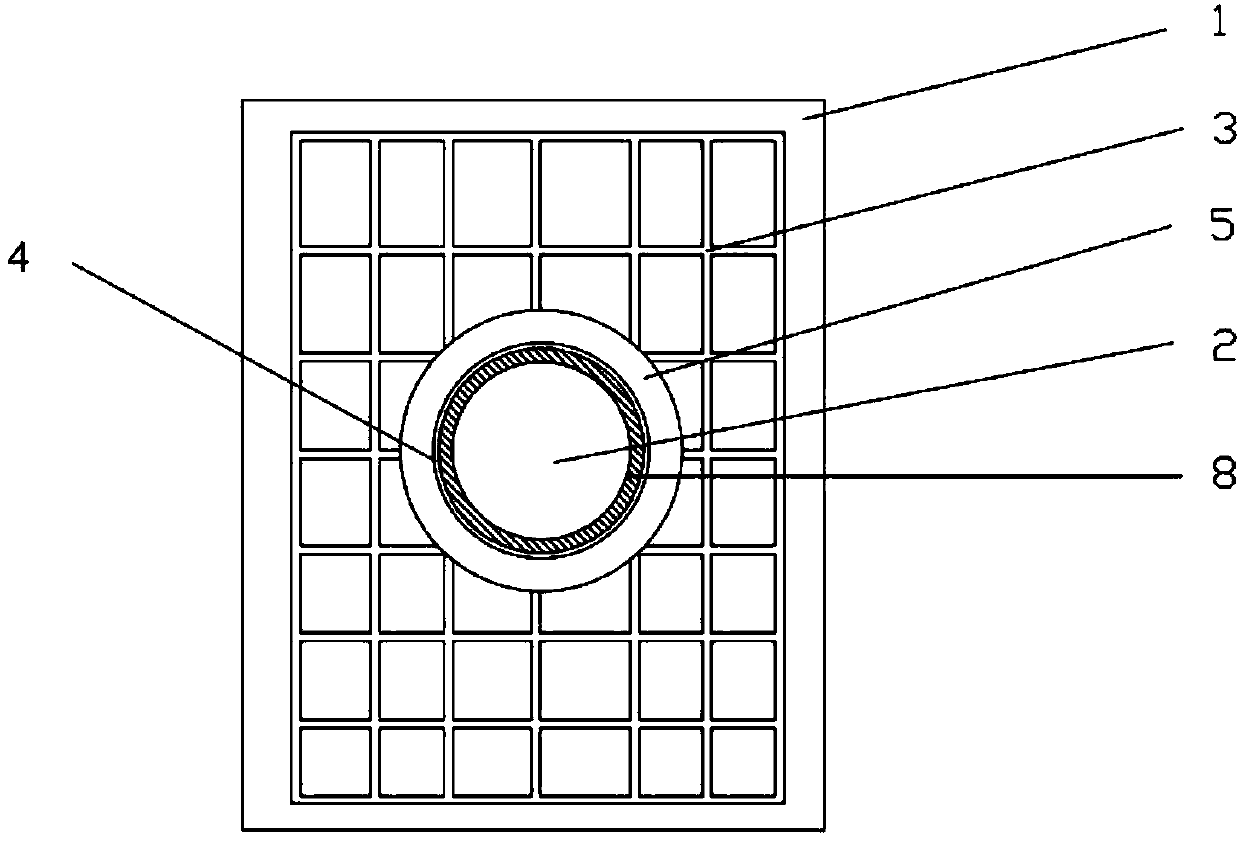

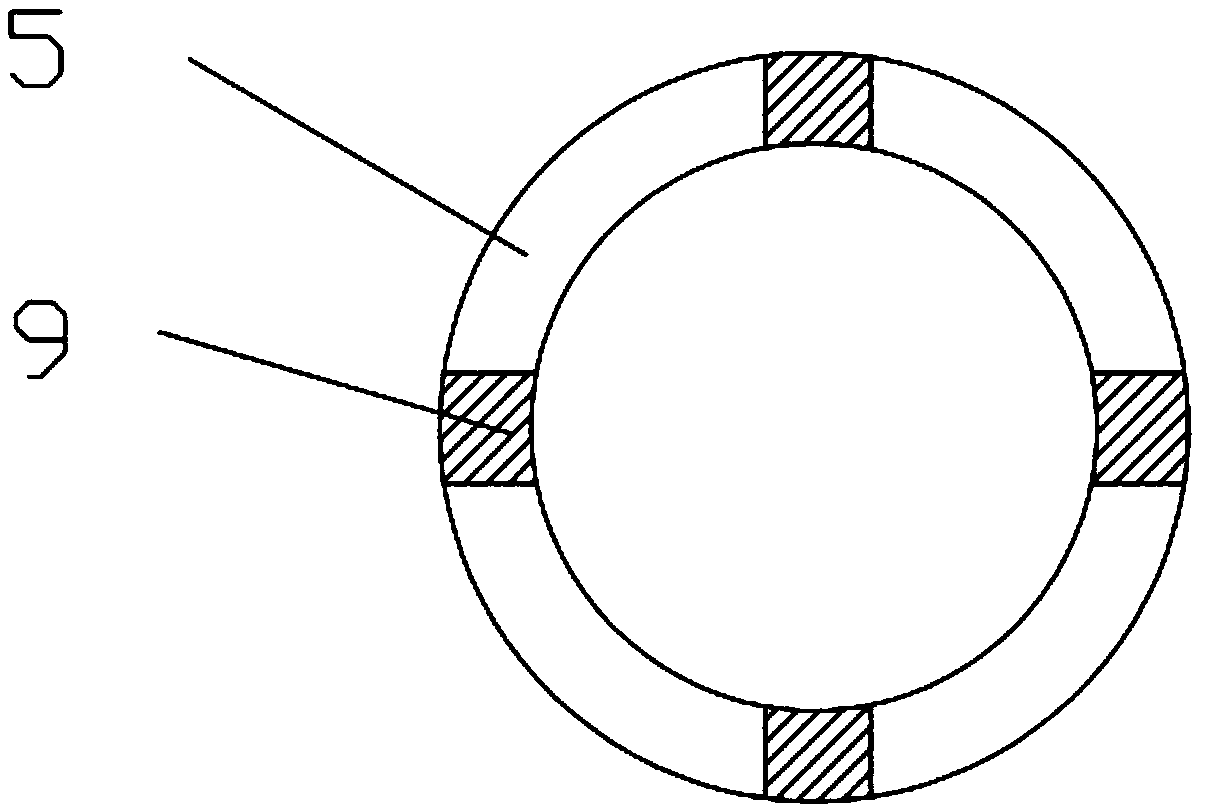

Energy-saving cooling tower

The invention discloses an energy-saving cooling tower. The tower comprises a tower body, a cold air inlet and a cold air outlet, the cold air inlet is arranged on the side surface of the bottom of the tower body, an induced draft fan is arranged at the cold air inlet, the cold air inlet is connected with a cold air inlet tube, the cold air inlet tube is uniformly provided with a plurality of air inlet apertures, the cold air outlet is arranged at the top of the tower body, a water blocking plate is arranged at the cold air outlet, a support is fixed at the upper portion of the tower body, a water spray tube is fixed on the support, atomization spray nozzles are uniformly distributed below the water spray tube, the middle of the water spray tube is connected with a water tube, a circulation water tank is arranged at the bottom of the tower body, the lower end of the water tube stretches to the inside of the circulation water tank, the tail end of the water tube is connected with a circulation water inlet, the circulation water inlet is arranged at one side of the circulation water tank, and a circulation water outlet is arranged at the other side of the circulation water tank. According to the invention, the cold air inlet tube absorbs underground cold air, so the temperature difference is large, the cooling effect is good, and environmental protection is realized; and a gas in the tower body has a small flow velocity and cannot take out water mist, and the water blocking plate is arranged at the cold air outlet, so the take-out of the water mist is further prevented without the arrangement of a water collection device.

Owner:HAIMEN DASHENG WATER TREATMENT EQUIP PLANT

Novel concrete base safety guard device

The invention discloses a novel concrete base safety guard device, comprising a base and a vertical post arranged in the base; the base is made of cast-in-place concrete or pre-made in a factory; thebase is integrated to a subgrade; a reinforcing cage is embedded in the base; a post cavity is arranged in the base; a post sleeve is pre-arranged on the inner periphery of the post cavity and is fixedly connected with the reinforcing cage; the upper peripheral rig of the post sleeve is fixedly connected with a reinforcing disc, the lower peripheral edge of the post sleeve is provided with a drainpassage, a plurality of limiting blocks are fixed to the inner wall of the post sleeve, and a plurality of damping seal rings are arranged between the inner wall of the post sleeve and the vertical post from top to bottom. The novel concrete base safety guard device has the advantages that the damaged vertical post is quick to change so that operating time is effectively shortened for construction staff; the novel concrete base safety guard device is well compatible with current standard facilities and is highly applicable; materials selected herein are common, the novel concrete base safetyguard device is simple to manufacture and widely applicable, and the vertical post in a vertical tube can be protected from damage so that reusing is achieved; the novel concrete base safety guard device is solid, durable, economical and reliable, and low in cost.

Owner:张玉建

Desert planting comprehensive operating machine

ActiveCN104081918BImprove work efficiencyEasy to sendPlantingWatering devicesDrive shaftAgricultural engineering

The invention relates to the agricultural cultivation field, and in particular relates to a comprehensive operation machine integrating sowing, grass mulching and water spraying for ecological planting of deserts. The comprehensive operation machine comprises a rack, a traction frame arranged at the front end of the rack and a land wheel arranged at the middle part of the rack by a land axle; and the comprehensive operation machine is characterized in that the comprehensive operation machine also comprises a sowing mechanism, a water replenishing mechanism, a grass mulching mechanism, a grass dividing mechanism, a grass delivery mechanism, a grass moving mechanism, a grass container, a grass pressing wheel and a sand covering plow, wherein a speed changer is arranged on the rack, the front end of speed changer is connected with external power by a cross-shaped universal drive shaft, and two sides of the speed changer are provided with a first power output shaft and a second power output shaft respectively, and the speed changer provides power for the whole machine. The comprehensive operation machine has multiple functions, can perform sowing, grass mulching, water spraying and sand covering at one time, can be adjusted according to the specific circumstance of the deserts and is improved in the operation efficiency.

Owner:景泰绿地农机装备有限公司

Special aluminum alloy production equipment with high production precision

The invention relates to special aluminum alloy production equipment with high production precision. The special aluminum alloy production equipment with high production precision comprises a shell; afirst motor, a stirring pool, a drain pipe, a hydrogen removing mechanism, a scraping mechanism and a plurality of paddles are arranged inside the shell; the hydrogen removing mechanism comprises anair exhaust unit, a non-return unit and a combustion unit; the scraping mechanism comprises a cross beam; and a moving groove, a limiting groove, a limiting block, a third motor, a drive wheel, a guide rail and a scraper blade are arranged inside the cross beam. According to the special aluminum alloy production equipment with high production precision, a large amount of hydrogen generated in theproduction process of an aluminum alloy can be removed through the hydrogen removing mechanism, the hydrogen is prevented from being adsorbed by the molten aluminum, certain mechanical properties of the aluminum alloy are prevented from being lost, the special aluminum alloy production equipment with high production precision can remove a stable oxide film formed on the surface of the melt of thealuminum alloy through the scraping mechanism, and oxide is prevented from forming shrink holes and gas holes in the melt of the aluminum alloy.

Owner:扬州地标金属制品有限公司

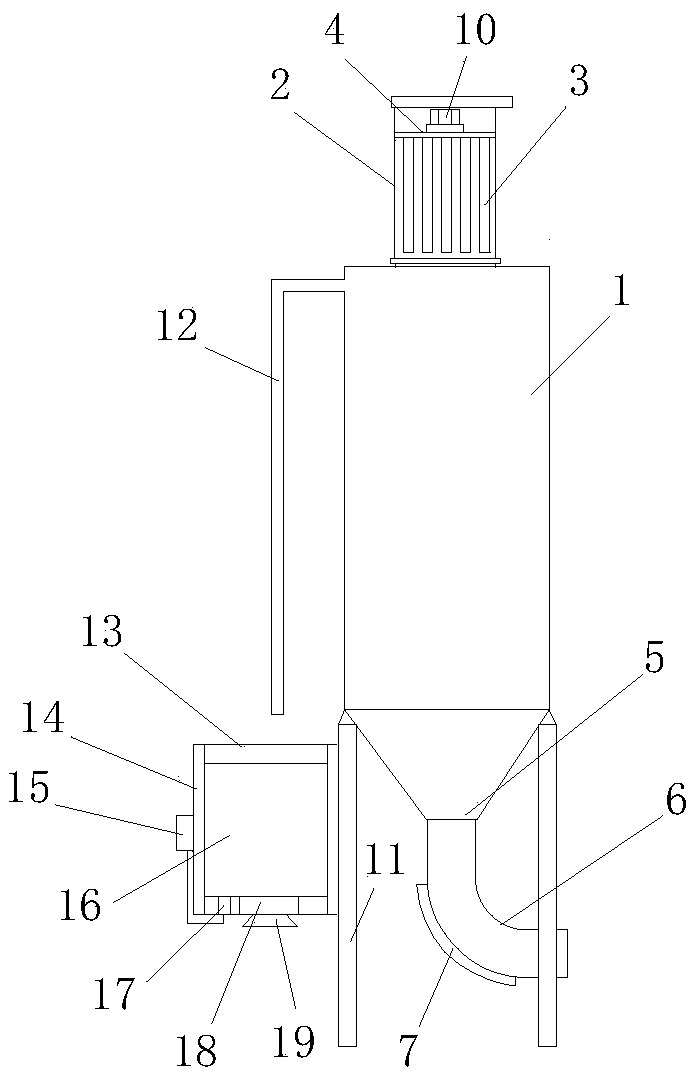

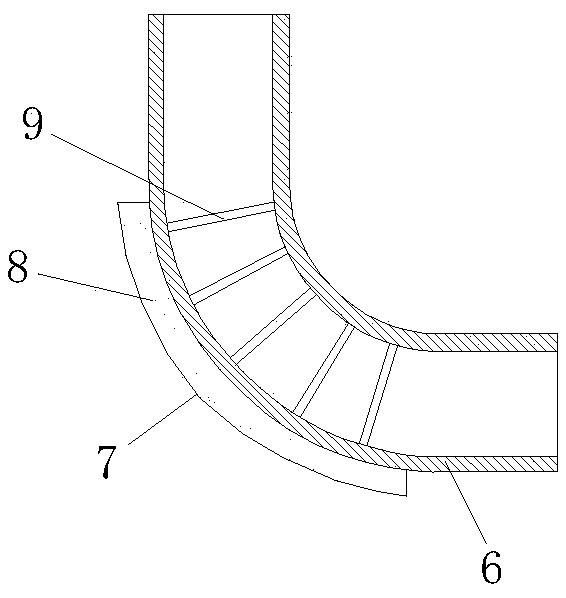

Cement bin with overflow device

InactiveCN105501730AWear-resistantImpact resistantProtective foundationLarge containersEngineeringCement

The invention discloses a cement bin with an overflow device. The cement bin comprises a bin body, a dust collector, an anti-abrasion elbow pipe connected with a discharging opening of the bin body and supporting legs which are arranged at the bottom of the bin body, wherein an overflow bucket is installed on the supporting legs, an overflow opening is formed in the top of one side of the bin body, the overflow opening is connected with the overflow bucket by virtue of overflow pipes, slide rails are correspondingly arranged at the left side and the right side in the overflow bucket, each slide rail is provided with a movable bucket, a red light spring-type switch and a sound spring-type switch are respectively arranged at the left side and the right side in the overflow bucket, the anti-abrasion elbow pipe comprises an elbow and a shell arranged outside the elbow, and the dust collector comprises a dust collector barrel which is vertically fixed on the top of the bin body. By adopting the cement bin, cement is prevented from overflowing out of the cement bin, so that the environmental pollution and product waste can be avoided, the dust removal efficiency is high, and the replacement frequency of the anti-abrasion elbow pipe is reduced.

Owner:GUANGXI JINHONG CONCRETE CO LTD

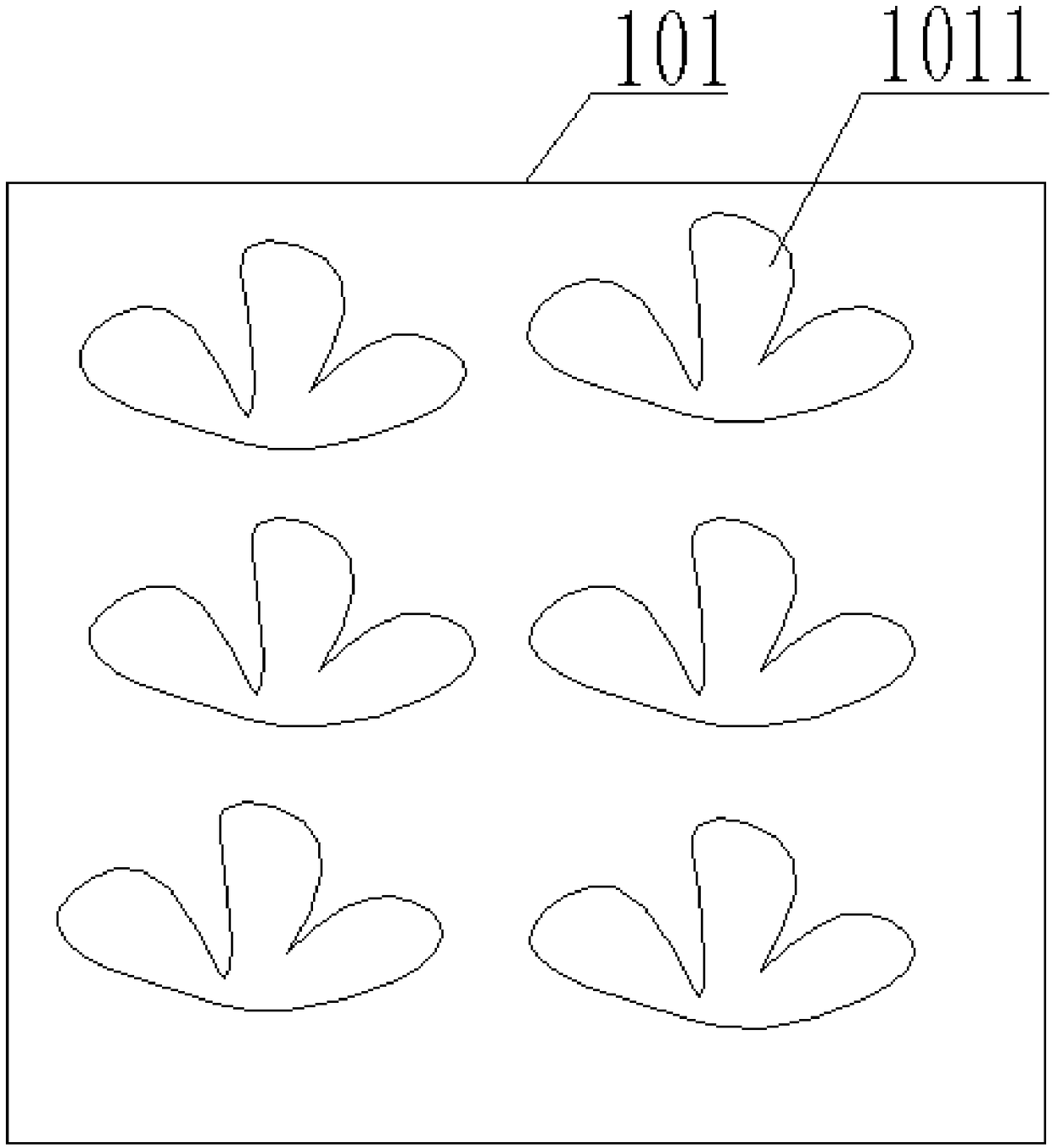

Fixing device for super-resolution imaging of red blood cell and use method

PendingCN109580485AEasy to observeSolve the requirement of sticking to the wallMaterial analysis by optical meansTotal internal reflectionMedicine

The invention discloses a fixing device for super-resolution imaging of a red blood cell and a use method, and belongs to the technical field of interaction of micromachining technology and biologicalimaging. According to the fixing device for super-resolution imaging of the red blood cell, the red blood cell is fixed to and attached to the surface of glass, physical fixation of the red blood cell with a smooth surface is realized, total internal reflection super-resolution imaging observation is convenient, and the requirements for sample wall-attaching in the total internal reflection super-resolution imaging process are met. The device does not need to be chemically modified or processed, the use is simple and convenient, and the manufacturing cost is low. The size of each red blood cell fixing chamber is small, a plurality of repetitive units can be arranged on the fixing device with the area less than the area of a one-yuan coin, a plurality of red blood cells can be subjected tosuper-resolution shooting synchronously, in addition, a plurality of micro-channels can be arranged on one fixing device, that is, red blood cells in blood samples of different sources can be subjected to super-resolution imaging synchronously on one fixing device, and the experiment throughput is greatly improved.

Owner:DALIAN UNIV OF TECH

Clean-type biomass burning device

InactiveCN105444209AWon't bring outAvoid dischargeDomestic stoves or rangesLighting and heating apparatusHelical bladeDischarge rate

The invention discloses a clean-type biomass burning device. The clean-type biomass burning device comprises furnace body, a supporting bottom plate, an ash storage box and a burning hearth arranged inside the furnace body, wherein the supporting bottom plate is positioned at the lower part of the burning hearth, the ash storage box is positioned below the supporting bottom plate, a feeding port and an air outlet are further formed in the furnace body, an air-intake structure is further arranged, the air-intake structure comprises an air intake pipeline and a helical blade, the helical blade is connected into the interior of the air intake pipeline in a rotating manner, an air storage cavity is arranged inside the furnace body, the air storage cavity is positioned on the periphery of the burning hearth, a plurality of air inlets communicated with the burning hearth are further formed in a side wall of the air storage cavity, and the air intake pipeline is communicated with the air storage cavity. The discharge rate of the ash inside the hearth of the burning device is less, therefore, the cleaning is convenient.

Owner:CHONGQING XUPENG ECOLOGICAL AGRI DEV CO LTD

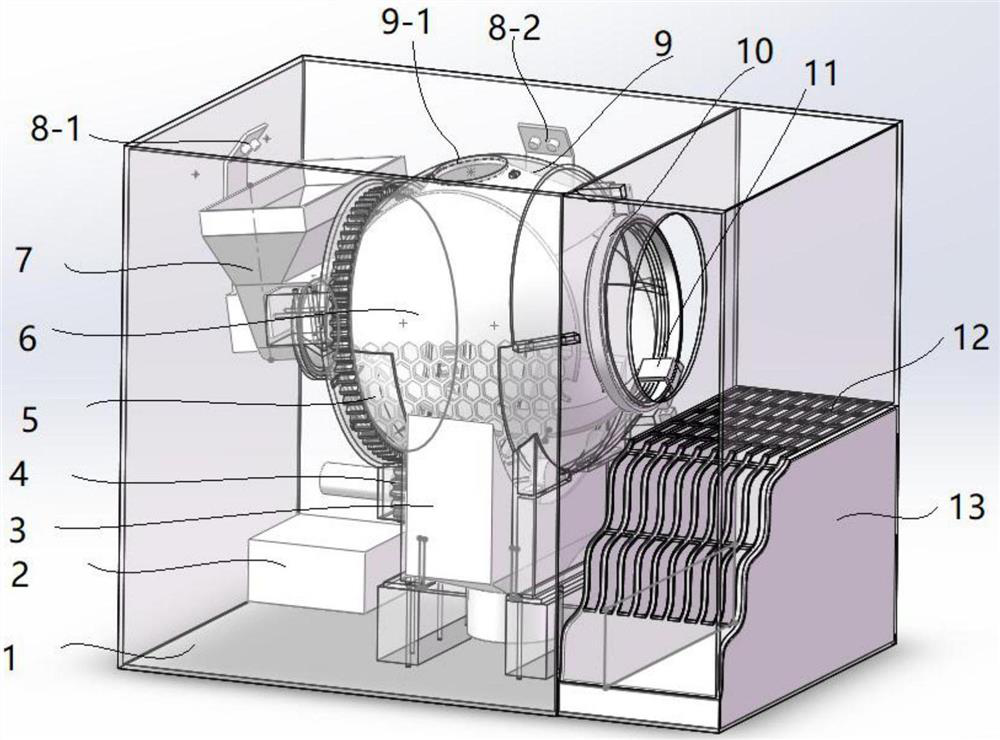

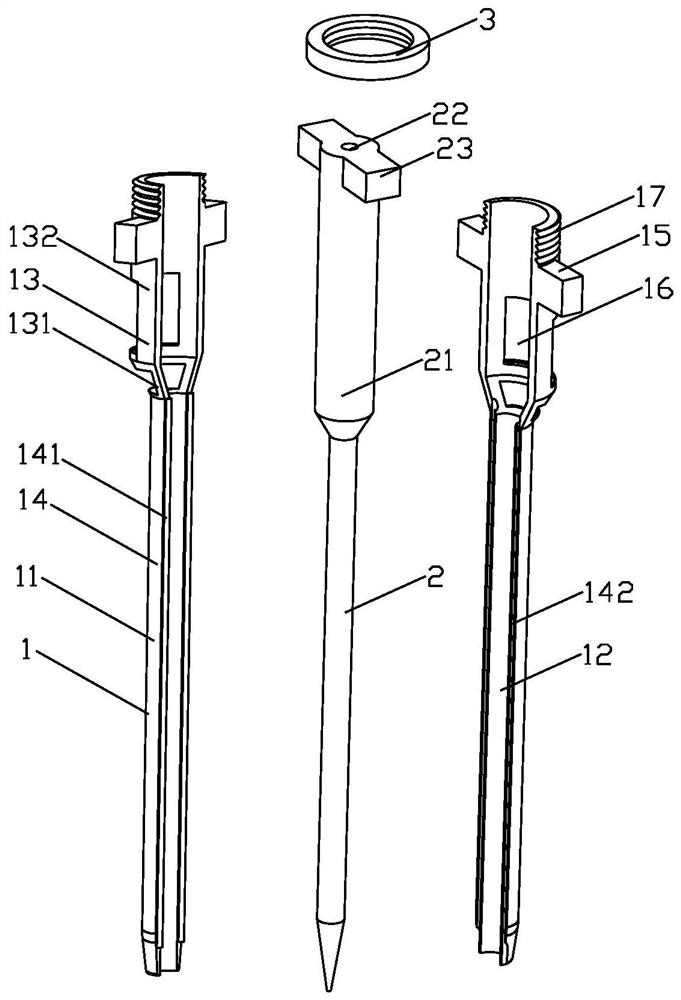

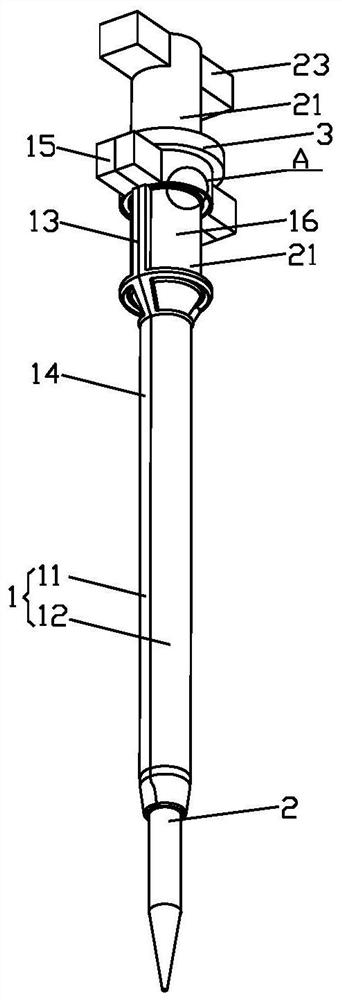

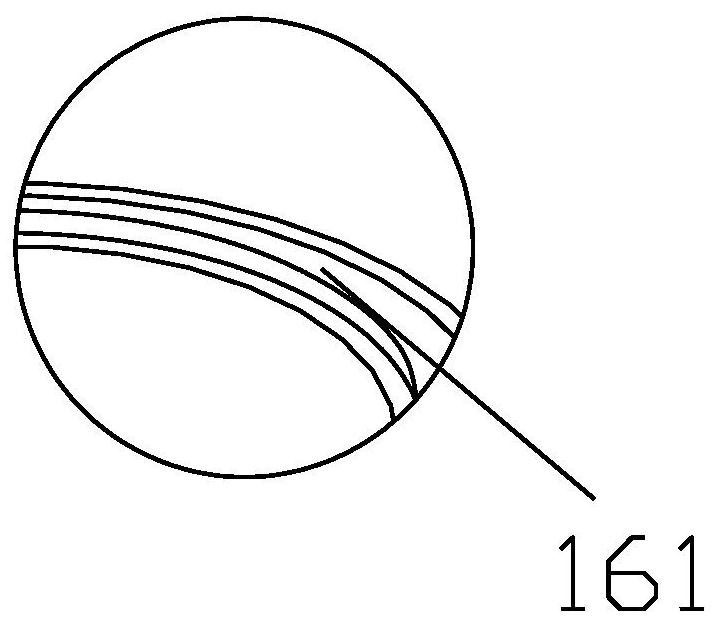

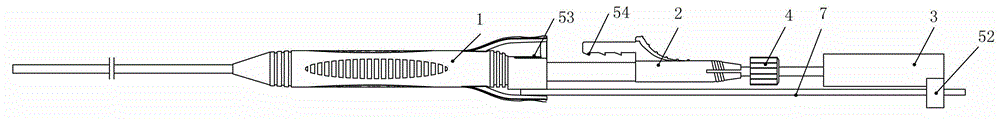

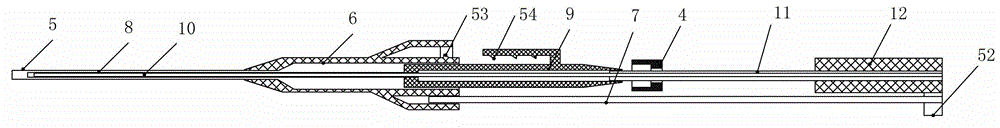

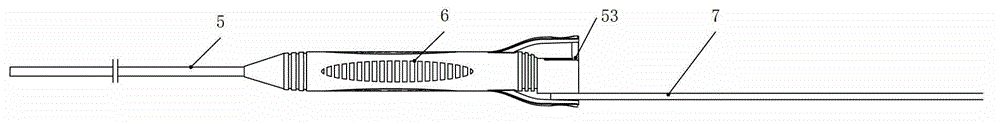

Two-half type visual dilator special for peritoneal dialysis catheter

PendingCN112755290AAccurate placementWon't bring outCatheterPeritoneal dialysisPeritoneal dialysis catheterDilator

The invention provides a two-half type visual dilator special for a peritoneal dialysis catheter. The two-half type visual dilator comprises a sheath made of stainless steel and a guide core nested in the sheath; the sheath comprises a left sheath and a right sheath, and the left sheath and the right sheath are matched with each other and each comprise a sheath body, a rod body and a first handle rod which are integrally formed; the front end of each sheath body is designed to be a circular truncated cone, and the rear end of the sheath body is designed to be a column body; the two rod bodies are provided with an arc-shaped protruding column and an arc-shaped inner groove which are matched with each other correspondingly; the two sides of the outer wall of each column body are symmetrically connected with corresponding first handle rods; the circular truncated cones and the column bodies are provided with visual windows, and transparent glass or plastic is installed on the visual windows; the top of the front end of the guide core is designed to be in a sharp shape, the rear end of the guide core is designed to be a blocking body matched with the sheath bodies, and a through hole is formed in the middle of the guide core. Money is saved for a patient, burden is relieved for national medical insurance, and an inner polyester sleeve can still be placed in an accurate position and cannot be taken out under the condition that a color Doppler ultrasound instrument is not used.

Owner:谢小街

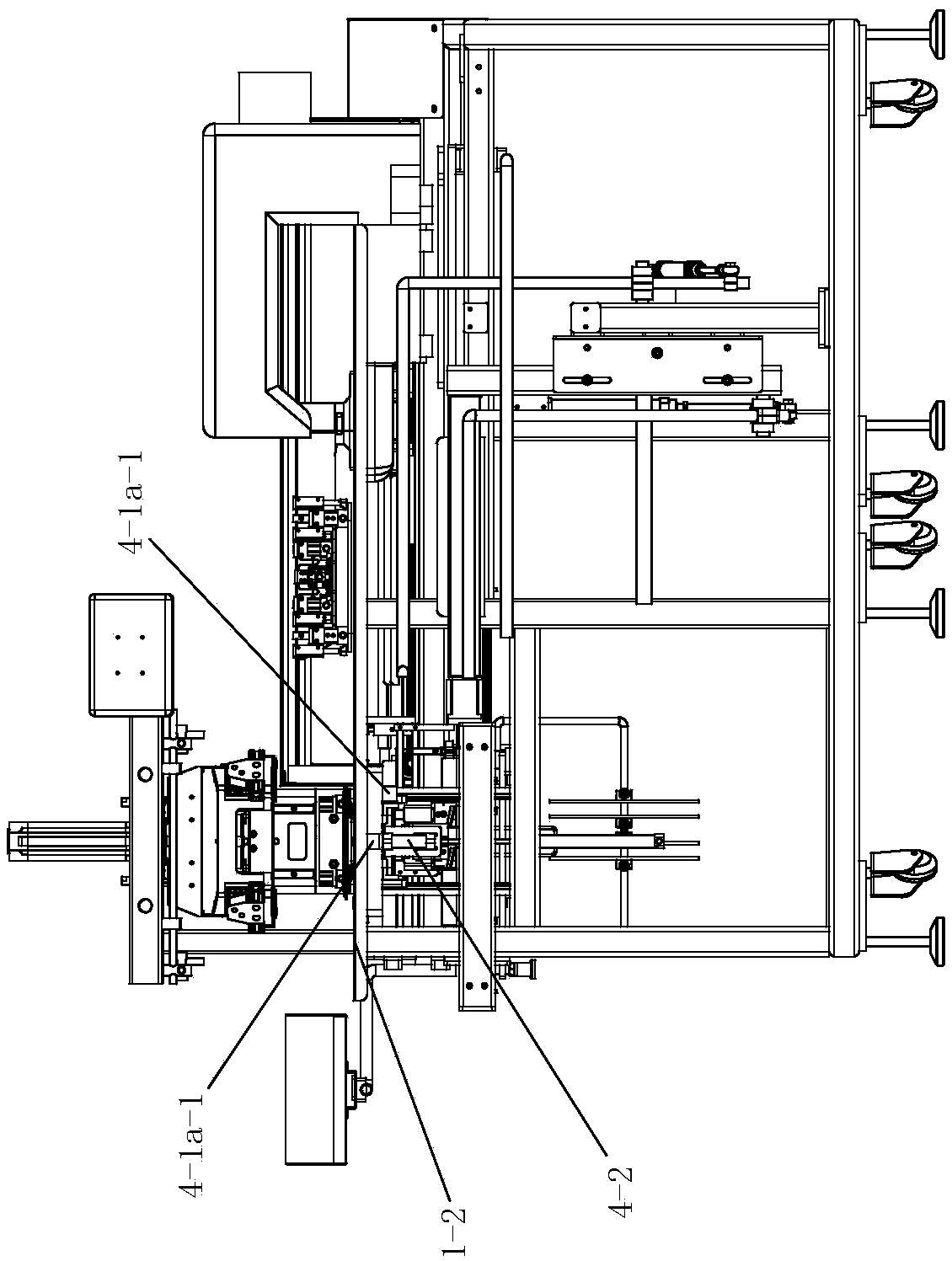

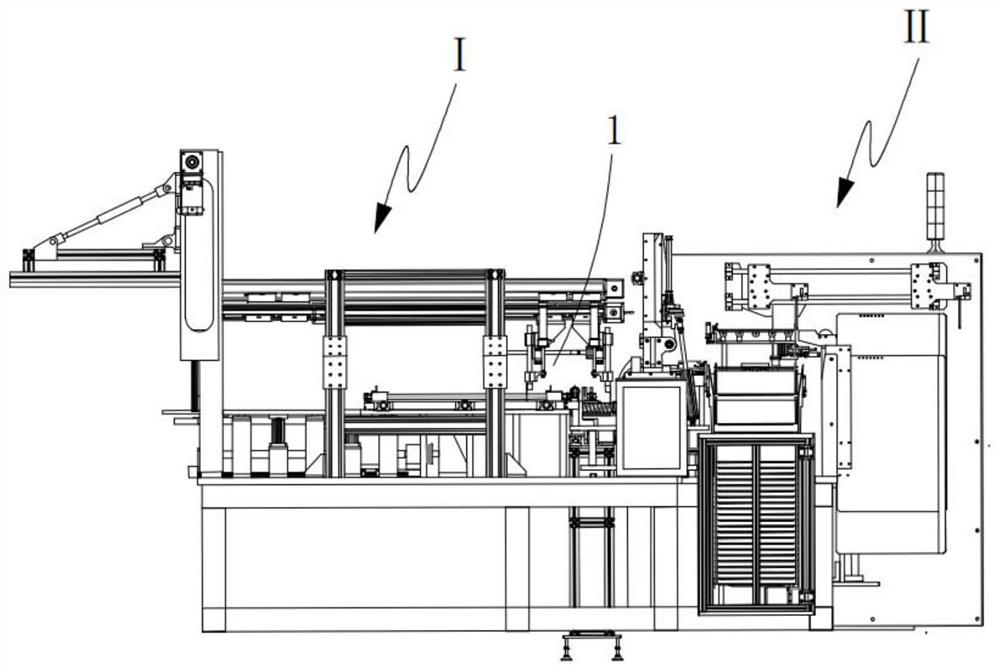

Auxiliary positioning adjusting device of full-automatic cold-folding bagging machine

PendingCN110306296AQuality improvementWon't bring outWork-feeding meansElectromagnetPulp and paper industry

The invention discloses an auxiliary positioning adjusting device of a full-automatic cold-folding bagging machine. The auxiliary positioning adjusting device of the full-automatic cold-folding bagging machine is characterized by comprising air suction boxes, an electromagnet, a first auxiliary ejector rod, a first auxiliary ejector rod driving device, a second auxiliary ejector rod, a second auxiliary ejector rod driving device and an air suction fan. The second auxiliary ejector rod lifts up large-body cloth, so that the middle part of the large-body cloth is arched up and a little margin isgenerated; the two air suction boxes suck air through air suction holes of the workbench plate, so that negative pressure is generated on the surface of the workbench plate; the large-body cloth is adsorbed and fixed, the large-body cloth is maintained in an arched state, when folded pocket cloth is downwards pressed on the workbench plate by an edge folding device of the full-automatic cold-folding bagging machine, a little margin is reserved in the large-body cloth, after being washed with water, the large-body cloth shrinks and then is flatly attached to the pocket cloth, and the quality and grade of clothes are further improved.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

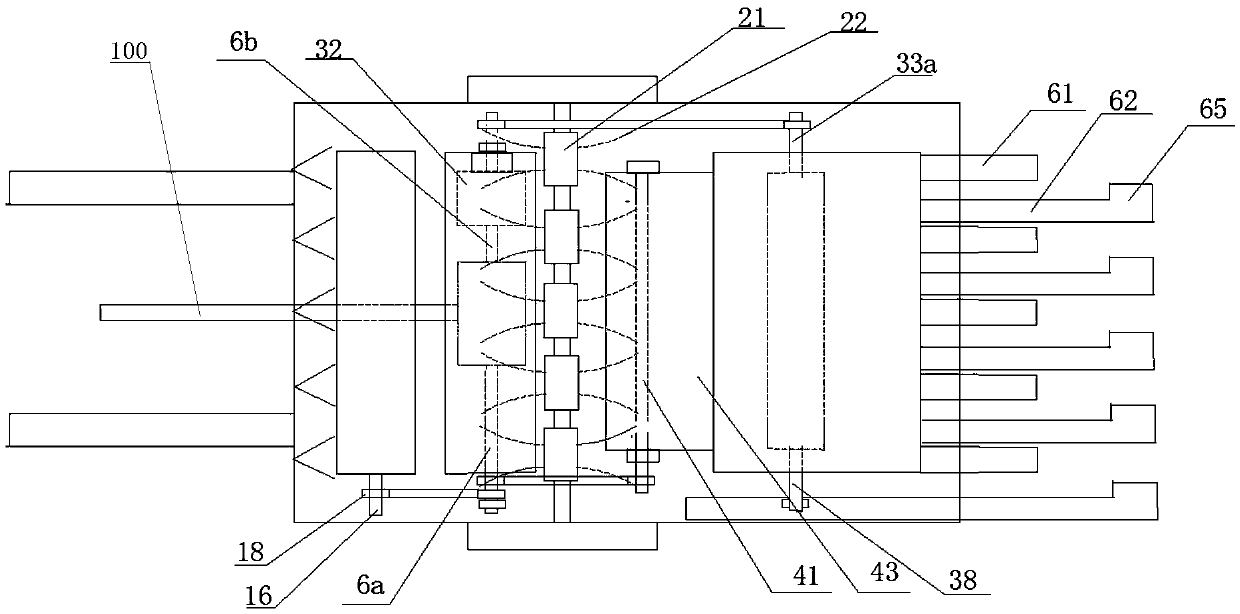

Medical particle implantation device

InactiveCN103007429BRelieve painReduce the risk of contaminationRadiation therapyBiomedical engineeringCaliber

The invention discloses a medical particle implantation device. The medical particle implantation device comprises a front handle component, a rear handle component and a push component which are connected with one another in sequence, as well as an elastic nut used for allowing the rear handle component to be connected and fixed with the push component, wherein the front handle component comprises an outer tube and a front handle which are connected with each other; the rear handle component comprises an inner tube and a rear handle which are connected with each other, wherein the inner tube is embedded in the outer tube, and the rear handle is partially embedded in the front handle; the push component comprises an inner core, a boosting tube and a tail handle which are connected in sequence; the inner core penetrates the inner tube, the boosting tube and the rear handle in sequence; the inner tube comprises a needle head, an elastic connecting tube and an inner tube body which are connected in sequence; the caliber of the elastic connecting tube is smaller than that of the needle head and the inner tube body, so as to place the particles; and an elastic claw type structure is arranged at the tail end of the rear handle, and an external thread matched with the elastic nut is arranged outside the claw type structure.

Owner:吴伟 +1

Mine blasting explosive placing equipment

The invention discloses mine blasting explosive placing equipment. The equipment comprises an outer box body, wherein an inner box body is arranged in the outer box body, a side driving motor is arranged in the outer box body, an output shaft of the side driving motor is fixed to the inner box body, one side of the inner box body is provided with a loading device which can be used for loading explosive cartridges with different specifications, and the equipment further comprises an ignition device which is used for collecting explosive cartridge leads and conveniently enabling all the explosive cartridge leads to be efficiently and rapidly ignited, and openings are formed in the inner box body and the outer box body. The equipment can be put into holes drilled in advance to release the explosive cartridges, and then the leads of the explosive cartridges can be collected in a centralized mode and fully ignited to prevent dud bullets from happening.

Owner:钱国臣

A kind of dyeing tube device which can save dye for fabric dyeing

ActiveCN108660649BWon't bring outFully contactedTextile treatment containersTextile treatment carriersElectric machineryHeat conservation

The invention discloses a dye-saving dyeing cylinder device for fabric dyeing. The device comprises a dyeing cylinder, the dyeing cylinder is fixedly placed on the ground, and a fabric rolling deviceis arranged in the dyeing cylinder; a fabric dragging device is arranged in the dyeing cylinder, a fabric extrusion filter device is arranged at a fabric outlet, and a heat preservation device is arranged on the exterior of the dyeing cylinder; a controller is arranged at the exterior of the dyeing cylinder, and a power output end of the controller is electrically connected with a low-speed rotation motor, a small low-speed rotation motor and an electric retractable rod. The dye-saving dyeing cylinder device for fabric dyeing has the advantages of being simple in structure and high in practicability.

Owner:东阳市新意工业产品设计有限公司

Single-component water-based adhesive for evaporative cooling wet curtain and preparation method thereof

ActiveCN102516904BAvoid Performance ConflictsImprove wetting and levelingNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedAdhesive

Owner:DONGGUAN STAR COSM POLYMER

An integrated sewage treatment system for villages and towns

ActiveCN108439713BEffective absorptionServe as ornamentalWater/sewage treatment by irradiationWater contaminantsFiltrationSewage

The invention discloses a township integrated sewage treatment system, which belongs to the technical field of sewage filtering equipment and is used to solve the problem that the existing sewage treatment equipment has poor treatment effect, and basically does not classify impurities in the process of sewage treatment to achieve The problem of maximizing the utilization of resources. It includes a filter tank, a water purification tank and a storage tank connected in sequence, the filter tank includes a box body, the top of the box body is provided with a water inlet, and the box body is sequentially provided with a flow diversion device, a transmission device and a filter device from top to bottom; The diversion device includes a support plate, a diversion column, a vibrator and a vibration power supply, the support plate is arranged on the inner wall of the box, the flow guide column is arranged on the support plate, and the vibration power supply and the vibrator are arranged on the support The lower part of the plate is connected to the vibration power supply and the vibrator; the water purification pool includes a pool body, and water purification plants for water purification are planted in the pool body.

Owner:SICHUAN STONG EURO & AMERICA ENVIRONMENT ENG

Attapulgite clay porous ceramsite, and preparation method and purpose thereof

ActiveCN102225870BQuick purificationFast filtrationCatalyst carriersTreatment with aerobic and anaerobic processesPorositySoluble glass

The invention discloses an attapulgite clay porous porous ceramsite, a preparation method of the ceramsite, and a purpose of the ceramsite. The ceramsite is prepared from raw materials of attapulgite clay and biomass, and a binder of industrial soluble glass. The ceramsite is prepared through calcining and oxidizing. The attapulgite clay porous ceramsite prepared by the present invention has advantages of high porosity, large specific surface area, high strength, strong water resistance, high water absorption, high catalytic activity, and the like. The porous ceramsite prepared by the presentinvention can be applied as a carrier for a catalyst, and a filling material for an aerated biological filter.

Owner:HEFEI UNIV OF TECH

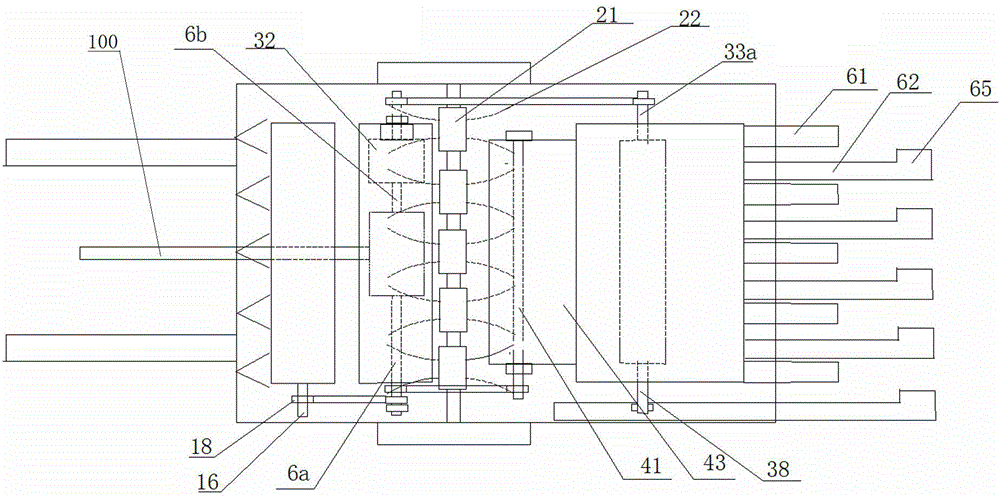

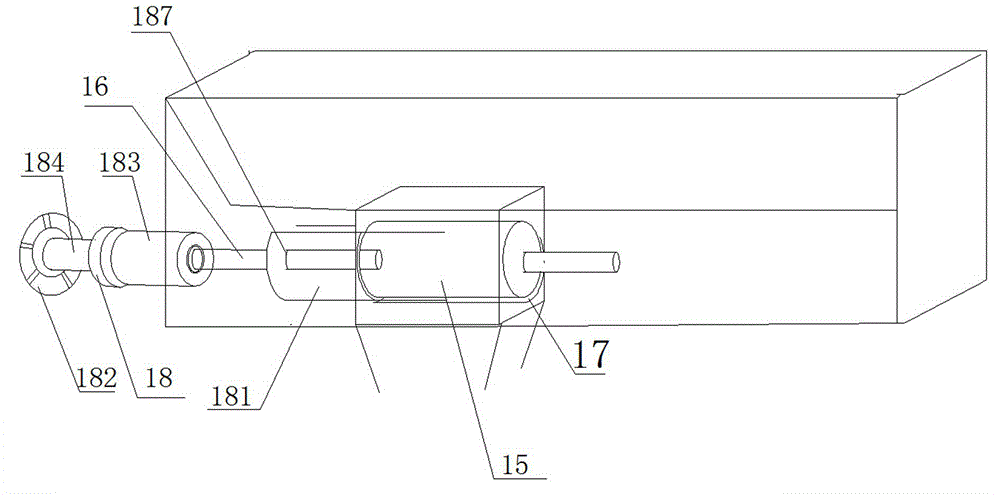

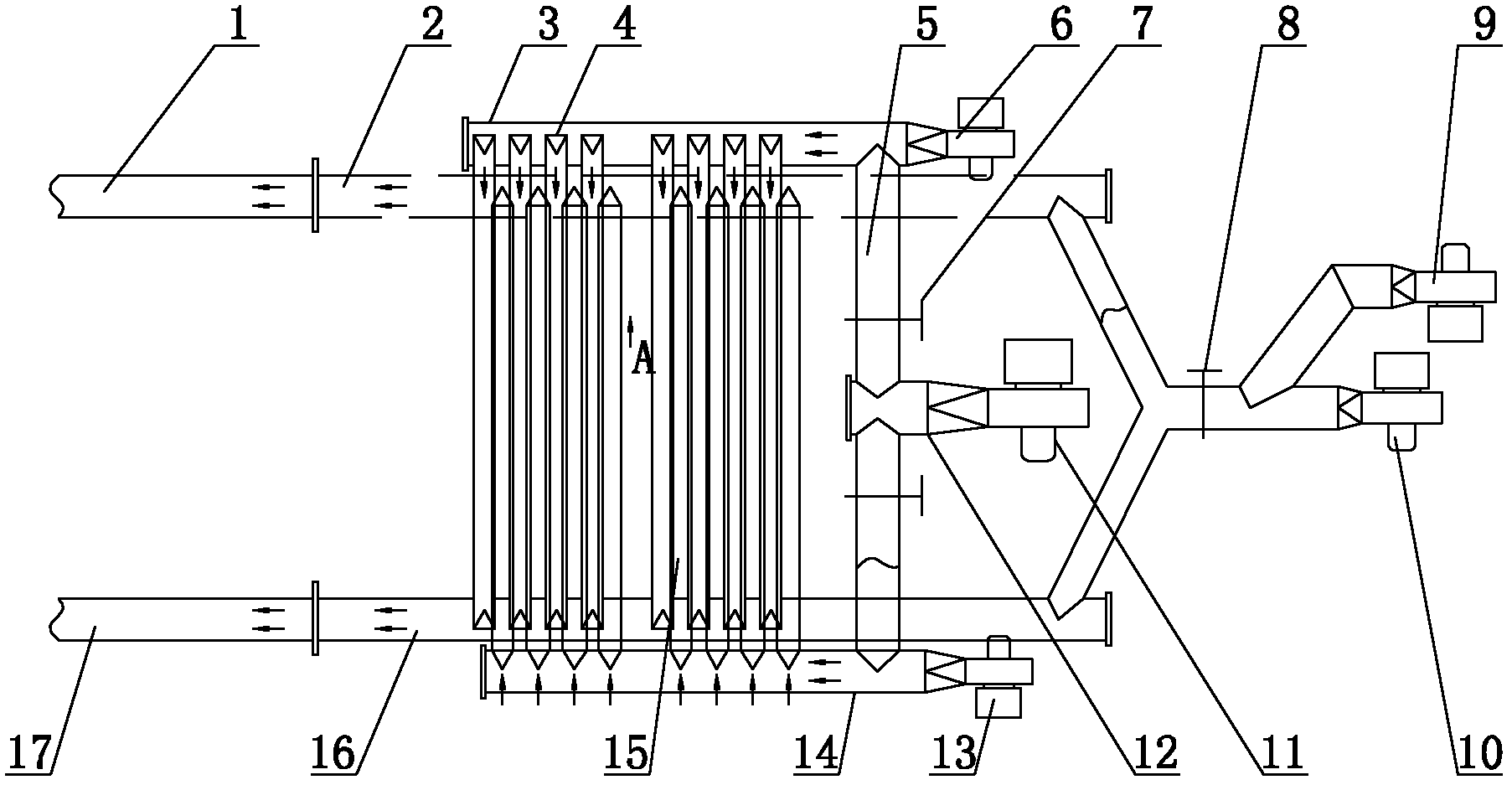

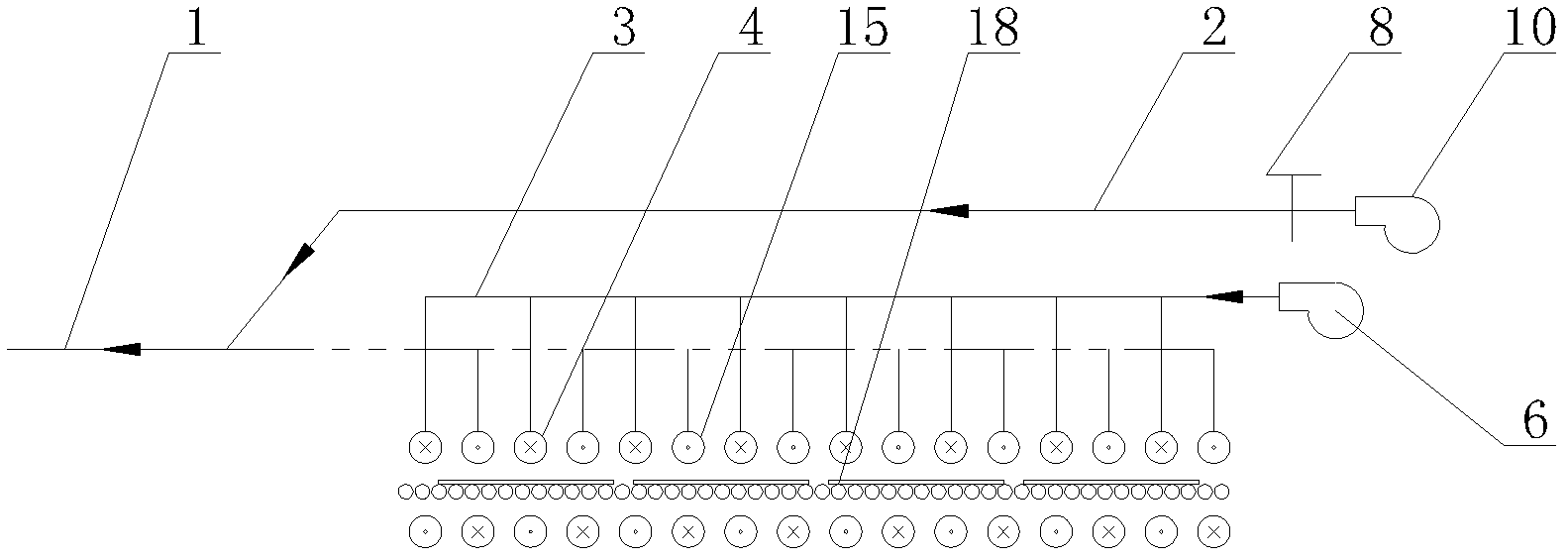

A fully welded plate heat exchanger

ActiveCN105651085BWon't bring outNo dead endsIce removalStationary plate conduit assembliesPlate heat exchangerEngineering

Owner:睿能太宇(沈阳)能源技术有限公司

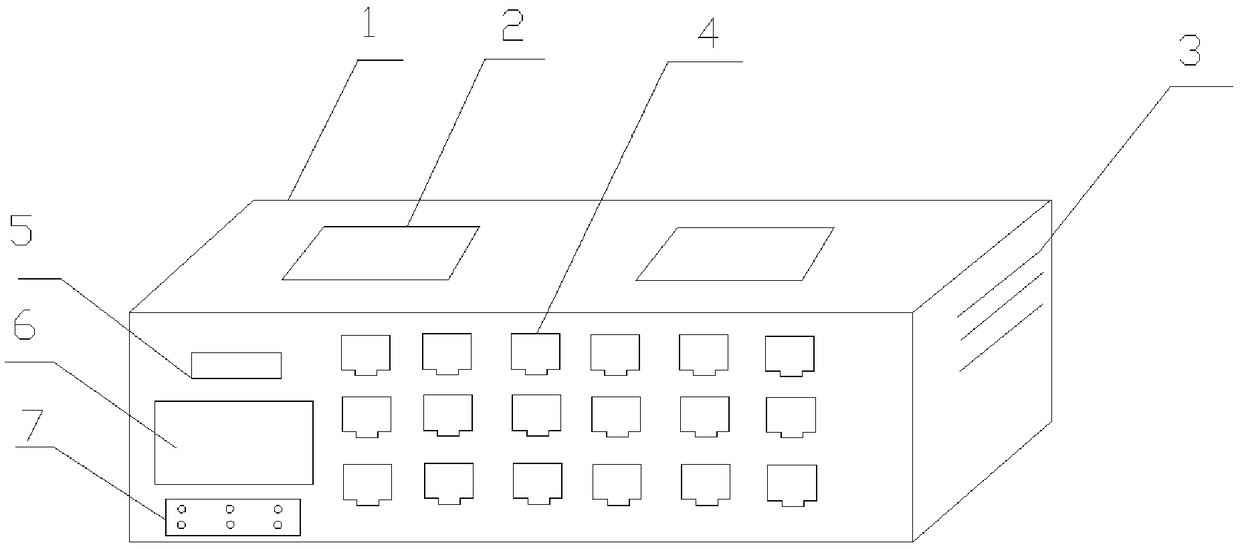

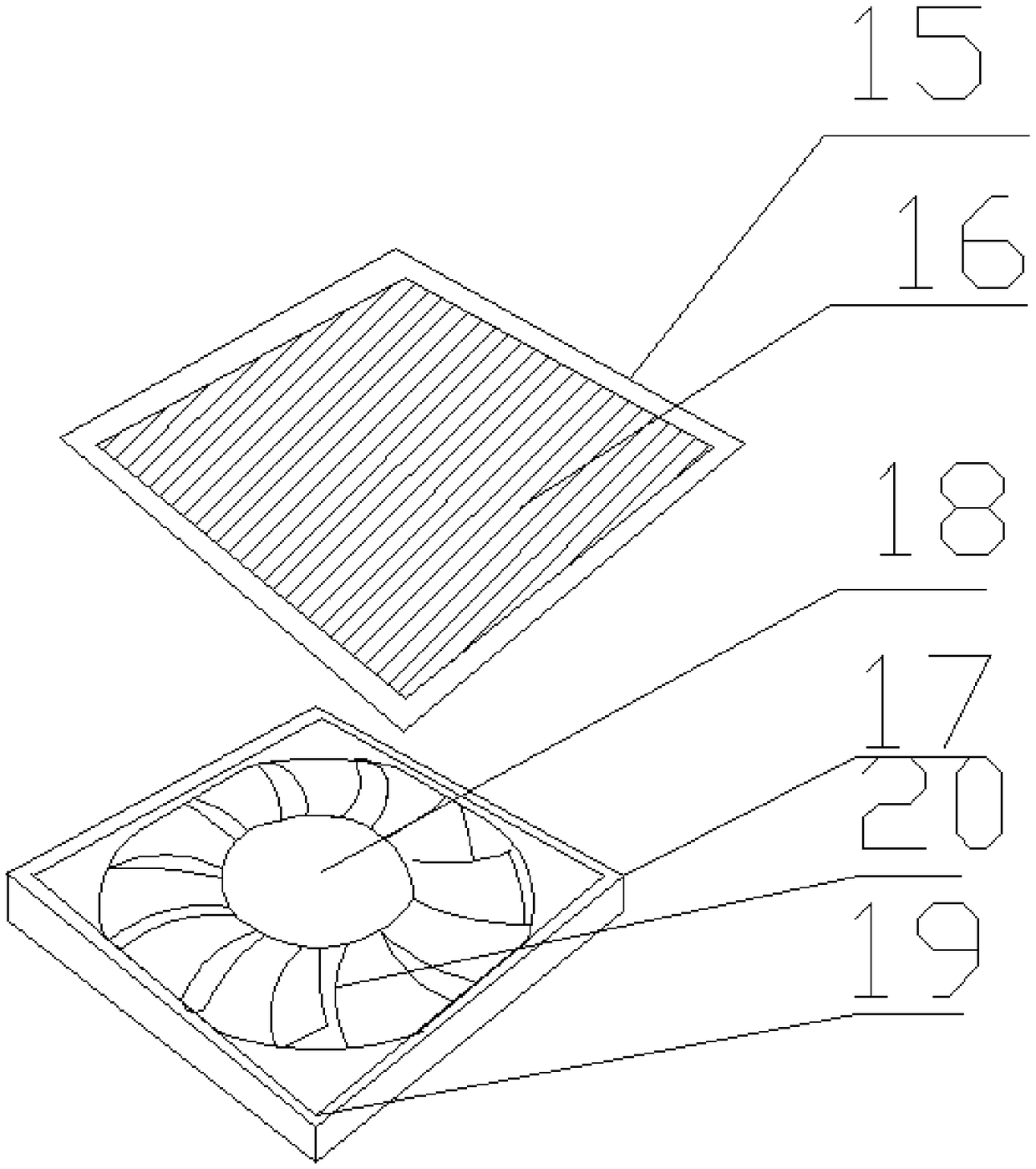

A heat dissipation dustproof switch

InactiveCN109104848AImprove cooling effectHigh trafficCooling/ventilation/heating modificationsCooling effectMotherboard

The invention discloses a heat dissipation dustproof switch, which comprises a housing, an air inlet, a display screen, a control panel, a condensing box and an air outlet, wherein the air inlet is provided with a filter core and a fan, the lower end of the air inlet is provided with a temperature sensor, a main board, a heat conductive medium, a heat switch tube and a support plate at a time, a condensing box is arranged below the support plate, and a compressor and a condenser are arranged inside the condensing box. By adopting compressor cooling system, the cooling effect of the switch is obvious. The temperature sensor added to the motherboard can detect the real-time temperature of the motherboard; the control panel is used to to control the compressor and set the temperature to reduce the temperature intelligently. The air inlet is provided with an integrated filter screen and a fan, thereby increasing the air flow rate and improving the cleanliness. The fan and the cooling system are used for cooling on both sides of the main board, and the air flow on both sides of the main board is small. The fan will not take the air lowered by the cooling system out of the switch, thus greatly improving the cooling effect.

Owner:郑州莱兹电子科技有限公司

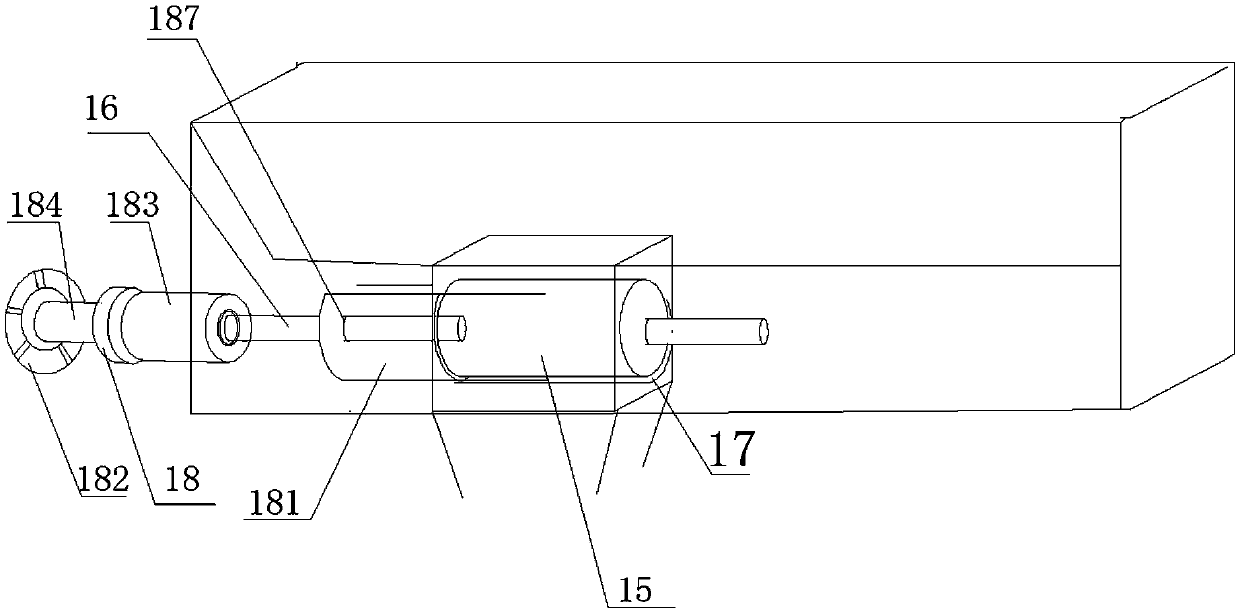

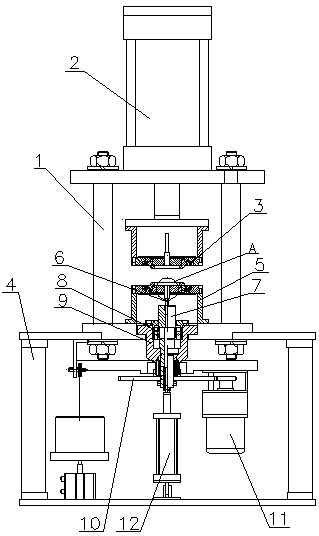

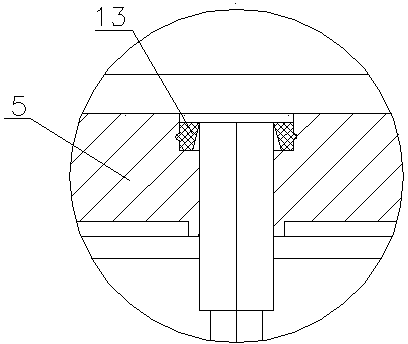

Mooney viscometer

InactiveCN104297106AAvoid enteringReduce frictional resistanceFlow propertiesEngineeringMechanical engineering

The invention relates to a mooney viscometer. The mooney viscometer comprises a lifting cylinder, which is mounted at the upper end of a machine frame, wherein a piston rod of the lifting cylinder is connected with an upper mold in the machine frame; a lower mold frame is arranged at the lower end of the machine frame; a lower mold corresponding to the upper mold is arranged at the upper end of the lower mold frame; a rotor is arranged in an inner hole of the lower mold; the rotor is sleeved with a spindle; the spindle is mounted in a bearing seat at the upper end of the lower mold frame via a bearing; a driving gear is arranged at the lower end of the spindle and located in the lower mold frame; a motor is arranged in the lower mold frame; the output end of the motor is connected with the driving gear; a cylinder is arranged at the lower end of the spindle and mounted on the lower mold frame; the piston rod of the cylinder is in contact with the lower end of the rotor; a sealing ring is arranged between the rotor and the lower mold body; the inner hole of the sealing ring is tapered. The mooney viscometer is simple in structure, and the sealing ring with the tapered inner hole is additionally arranged between the rotor and the lower mold, as a result, fused rubber can be effectively prevented from entering a gap between the rotor and the lower mold, and the fractional resistance of the rotor against the sealing ring is reduced.

Owner:江苏新真威试验机械有限公司

High-strength and high-toughness heat-sealing bottom-pasting bag folding and mouth pasting device

ActiveCN113290940AImprove yield rateGuaranteed firmnessBag making operationsPaper-makingPhysicsEngineering

The invention relates to a high-strength and high-toughness heat-sealing bottom-pasting bag folding and mouth pasting device, which comprises a folding station and a bottom pasting station which are arranged in sequence; a folding device is arranged at the folding station; the folding device comprises a turnover assembly, an angle folding assembly and an air blowing assembly; the turnover assembly comprises two sets of turnover mechanisms which are symmetrically and rotationally arranged up and down and form a woven bag containing space; the turnover mechanisms are used for opening and closing bag mouths of woven bags; after extending to the junction of the two sets of turnover mechanisms, the angle folding assembly moves outwards and is matched with the turnover mechanisms to smoothen the transverse folding wing positions on the two sides of the bag mouth and press the wrap angle position of the bag mouth at the same time; the air blowing assembly is arranged on the contact face of the angle folding assembly and the woven bag; the bag mouth is closed by the turnover mechanisms; and the air blowing assembly blows air, so that the angle folding assembly is separated from the woven bag. According to the invention, the technical problem that the bottom pasting deviation occurs due to the fact that the folding assembly is easily taken out of the wrap angle when being pulled out is solved.

Owner:浙江埃芮克环保科技有限公司

A special aluminum alloy production equipment with high production precision

The invention relates to special aluminum alloy production equipment with high production precision. The special aluminum alloy production equipment with high production precision comprises a shell; afirst motor, a stirring pool, a drain pipe, a hydrogen removing mechanism, a scraping mechanism and a plurality of paddles are arranged inside the shell; the hydrogen removing mechanism comprises anair exhaust unit, a non-return unit and a combustion unit; the scraping mechanism comprises a cross beam; and a moving groove, a limiting groove, a limiting block, a third motor, a drive wheel, a guide rail and a scraper blade are arranged inside the cross beam. According to the special aluminum alloy production equipment with high production precision, a large amount of hydrogen generated in theproduction process of an aluminum alloy can be removed through the hydrogen removing mechanism, the hydrogen is prevented from being adsorbed by the molten aluminum, certain mechanical properties of the aluminum alloy are prevented from being lost, the special aluminum alloy production equipment with high production precision can remove a stable oxide film formed on the surface of the melt of thealuminum alloy through the scraping mechanism, and oxide is prevented from forming shrink holes and gas holes in the melt of the aluminum alloy.

Owner:扬州地标金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com