Novel concrete base safety guard device

A technology of safety guardrail and concrete base, which is applied to road safety devices, roads, roads, etc., can solve problems such as the inability to meet the needs of road maintenance, and achieve the effects of reducing operation time, simple production and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

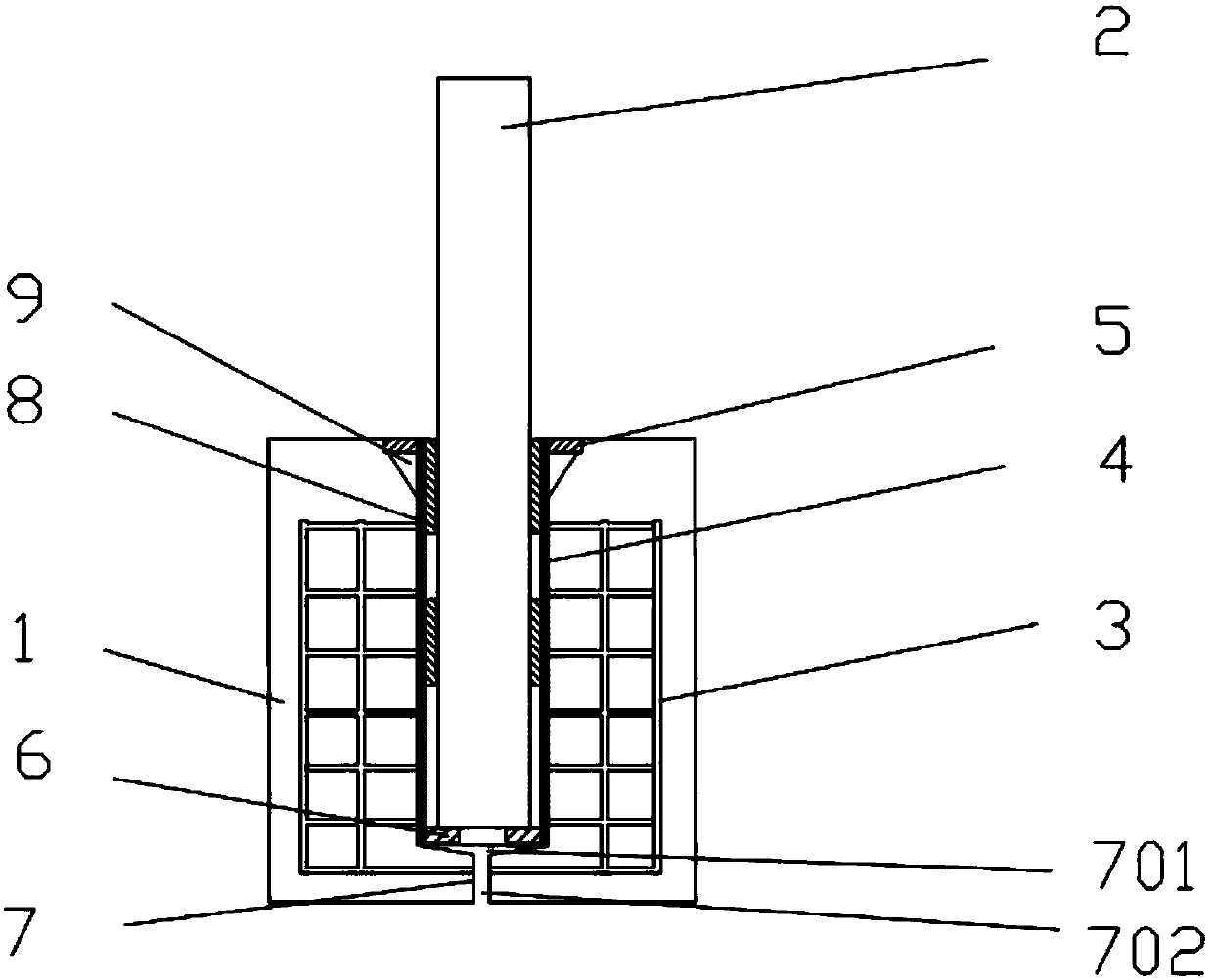

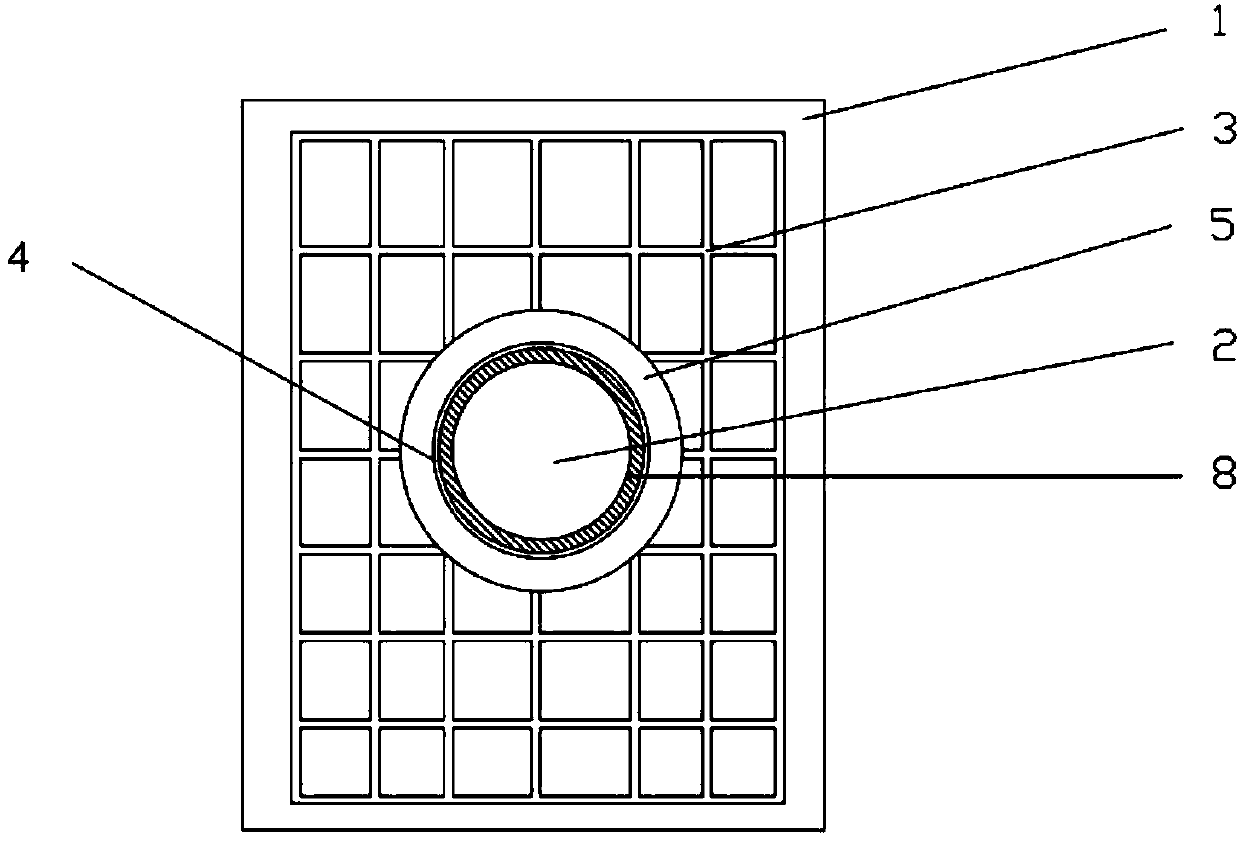

[0049] combined with Figure 1-3 , a new type of concrete base safety guardrail device, including a base 1 and a column 2 arranged in the base 1, the base 1 is made of concrete cast-in-place or factory prefabricated, and the base 1 is integrated with the roadbed One;

[0050] A reinforcing cage 3 is pre-embedded in the base 1, and a column cavity is provided in the base 1, and a column cover 4 is preset on the inner side of the column cavity, and the column cover 4 is fixedly connected with the reinforcing cage 3, The outer ring of the upper edge of the column cover 4 is fixedly connected with a reinforcing plate 5, and the lower edge is provided with a drainage channel 7 downward, and several limit blocks 6 are fixedly connected to the inner wall of the column cover 4;

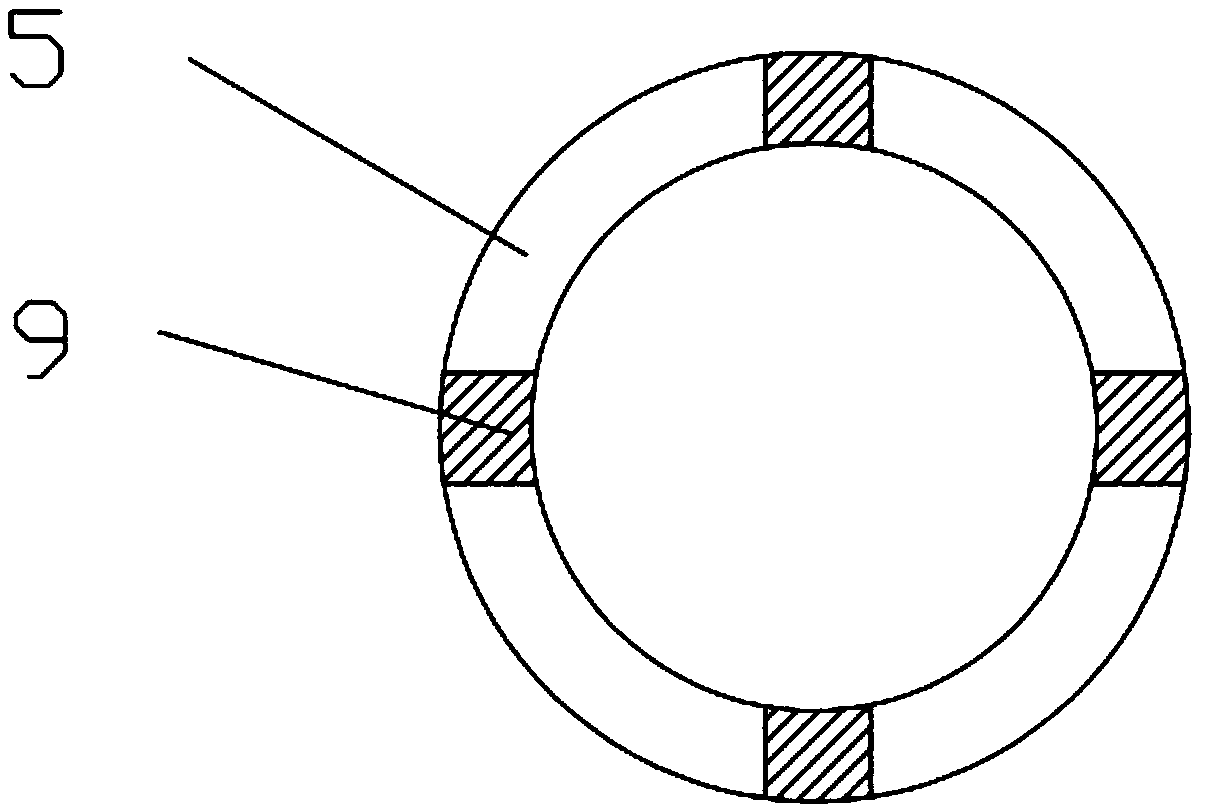

[0051] Between the inner wall of the column cover 4 and the column 2, several shock-absorbing blocking parts 8 are arranged from top to bottom.

[0052] As a preferred implementation of this embodiment, one...

Embodiment 2

[0069] combined with Figure 3-5 , a new type of concrete base safety guardrail device, including a base 1 and a column 2 arranged in the base 1, the base 1 is made of concrete cast-in-place or factory prefabricated, and the base 1 is integrated with the roadbed One;

[0070] A reinforcing cage 3 is pre-embedded in the base 1, and a column cavity is provided in the base 1, and a column cover 4 is preset on the inner side of the column cavity, and the column cover 4 is fixedly connected with the reinforcing cage 3, The outer ring of the upper edge of the column cover 4 is fixedly connected with a reinforcing plate 5, and the lower edge is provided with a drainage channel 7 downward, and several limit blocks 6 are fixedly connected to the inner wall of the column cover 4;

[0071] Between the inner wall of the column cover 4 and the column 2, several shock-absorbing blocking parts 8 are arranged from top to bottom.

[0072] As a preferred implementation of this embodiment, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com