Method for preparing ceramic material by process steps of powder green body dipping and precursor cracking

A technology of ceramic precursors and ceramic materials, which is applied in the field of ceramic material powder green body impregnation-precursor cracking preparation, which can solve the problems of high cost of inorganic fibers and weaving, difficult selection of composition, and high cost of material manufacturing, etc., to achieve uniformity of products Excellent performance, lower sintering temperature, and lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

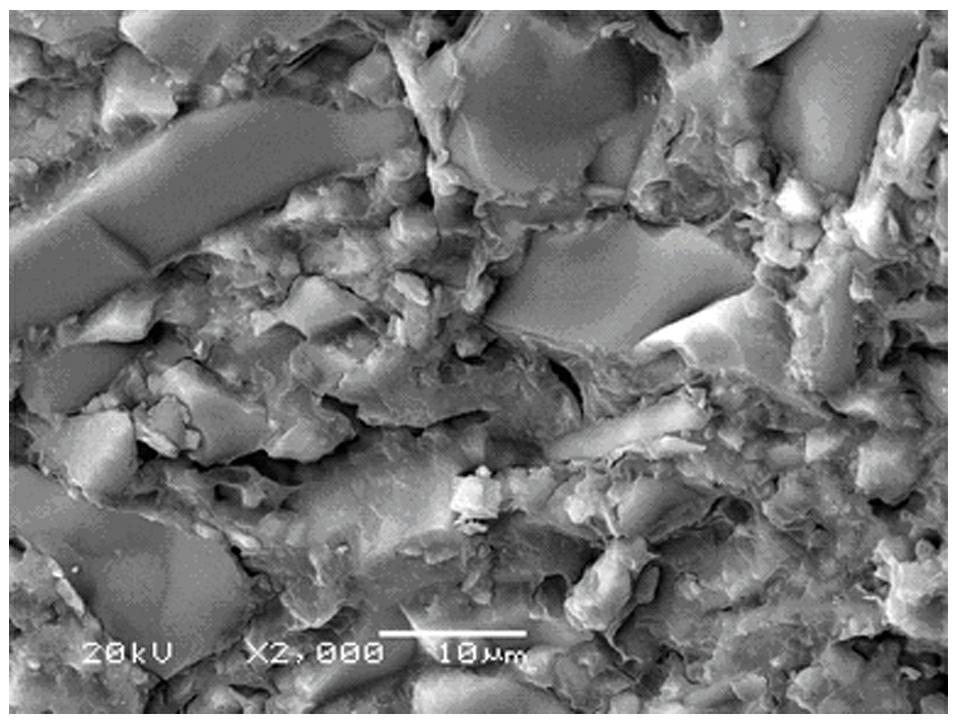

Image

Examples

Embodiment 1

[0031] (1) Mix α-type silicon nitride ceramic powder and paraffin in a weight ratio of 85:15, and then press it (the traditional method of powder molding such as isostatic pressing, gel injection molding or grouting molding can also be used) Molding) method to prepare a blank with a size of 100mm×100mm×10mm, and the molding pressure is 20MPa;

[0032] (2) Put the α-type silicon nitride ceramic powder body obtained in step (1) in a high-temperature oven, and bake at 500°C for 2 hours to remove paraffin wax and make the body form pores required for impregnation;

[0033] (3) Place the green body treated in step (2) in a closed container containing the precursor borazane, and immerse it in a vacuum for 1 hour to allow the borazane to enter the pores of the green body;

[0034] (4) Put the body containing the precursor borazane in the pores in a closed autoclave, fill it with nitrogen, increase the pressure to 5MPa, heat to 70°C, and hold for 50 hours to solidify the precursor borazane a...

Embodiment 2

[0040] (1) The silicon carbide powder and paraffin are mixed in a weight ratio of 80:20, and then molded by molding (the traditional methods of powder molding such as isostatic pressing, gel injection molding or grouting molding can also be used). A blank with a size of 100mm×100mm×10mm is formed, and the molding pressure is 20MPa;

[0041] (2) Put the green body prepared in step (1) in an oven and bake it at 400°C for 3 hours to remove paraffin and make the green body form pores required for impregnation;

[0042] (3) Place the green body treated in step (2) in a closed container containing the precursor borazane, and immerse it in a vacuum for 1 hour to allow the borazane to enter the pores of the green body;

[0043] (4) Place the green body containing the precursor borazane in the pores in a closed autoclave, fill it with nitrogen, increase the pressure to 5MPa, heat to 70°C, and hold for 50 hours to solidify the borazane and cool it out;

[0044] (5) Put the solidified body of th...

Embodiment 3

[0049] (1) The silicon carbide ceramic powder and paraffin wax are mixed in a weight ratio of 80:20, and then molded by molding (the traditional method of powder molding such as isostatic pressing, gel injection molding or grouting molding can also be used) method Prepared into a blank with a size of 70mm×30mm×10mm, and the molding pressure is 25MPa;

[0050] (2) Put the body prepared in step (1) in an oven and bake at 500°C for 2 hours to remove paraffin and make the body form pores required for impregnation;

[0051] (3) Dissolve polycarbosilane in toluene, prepare a solution with a concentration of 50wt%, and add it to a sealable container; place the body treated in step (2) in a container containing polycarbosilane solution, Close the container, vacuum, and immerse for 1 hour to make the polycarbosilane solution enter the pores of the green body;

[0052] (4) Place the green body containing the precursor polycarbosilane solution in the pores in an open container, slowly heat it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com