Filling method and system of coal mine goaf

A technology for gobs and coal mines, which is applied to filling materials, mining equipment, and earthwork drilling and mining, and can solve problems such as shortage of filling materials, achieve the effects of reducing filling production costs, good flow performance, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

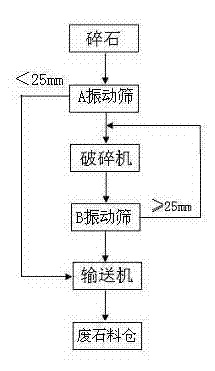

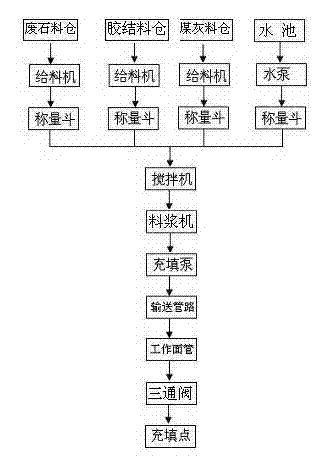

[0019] Coal mine goaf filling system of the present invention such as figure 1 As shown, including waste rock silo, cement silo, coal ash silo, pool, feeder, weighing hopper, mixer, slurry machine, filling pump, conveying pipeline, working face pipe and tee pipe, conveying pipe The road includes surface pipes, drill pipes and downhole pipes, and the surface pipes, borehole pipes and downhole pipes are connected in sequence. The waste rock silo, the cemented silo and the coal ash silo are respectively connected to their respective weighing hoppers through their respective feeders, and the water pool is connected to their respective weighing hoppers through a water pump. Each weighing bucket is connected to the inlet of the mixer respectively, the outlet of the mixer is connected to the inlet of the filling pump through the slurry machine, the outlet of the filling pump is connected to the surface pipe, the drilling pipe and the downhole pipe in turn, the downhole pipe is co...

Embodiment 2

[0024] Another embodiment of the present invention is that the waste rock is stripped covering soil, surrounding rock and gangue without industrial value, and the cementing material is water-quenched slag. Use fly ash as fine aggregate, add waste rock, water-quenched slag and water into the mixer and stir evenly to make a slurry with a mass concentration of 81%. Waste rock, water-quenched slag, and fly ash are contained in each cubic slurry The ratio of water and water is 1086kg: 100 kg: 400 kg: 372 kg. The slurry is sent to the inlet of the filling pump through the slurry machine. Other steps of the goaf filling system and filling process of this embodiment are the same as those of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com