Patents

Literature

147results about How to "Meet delivery requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

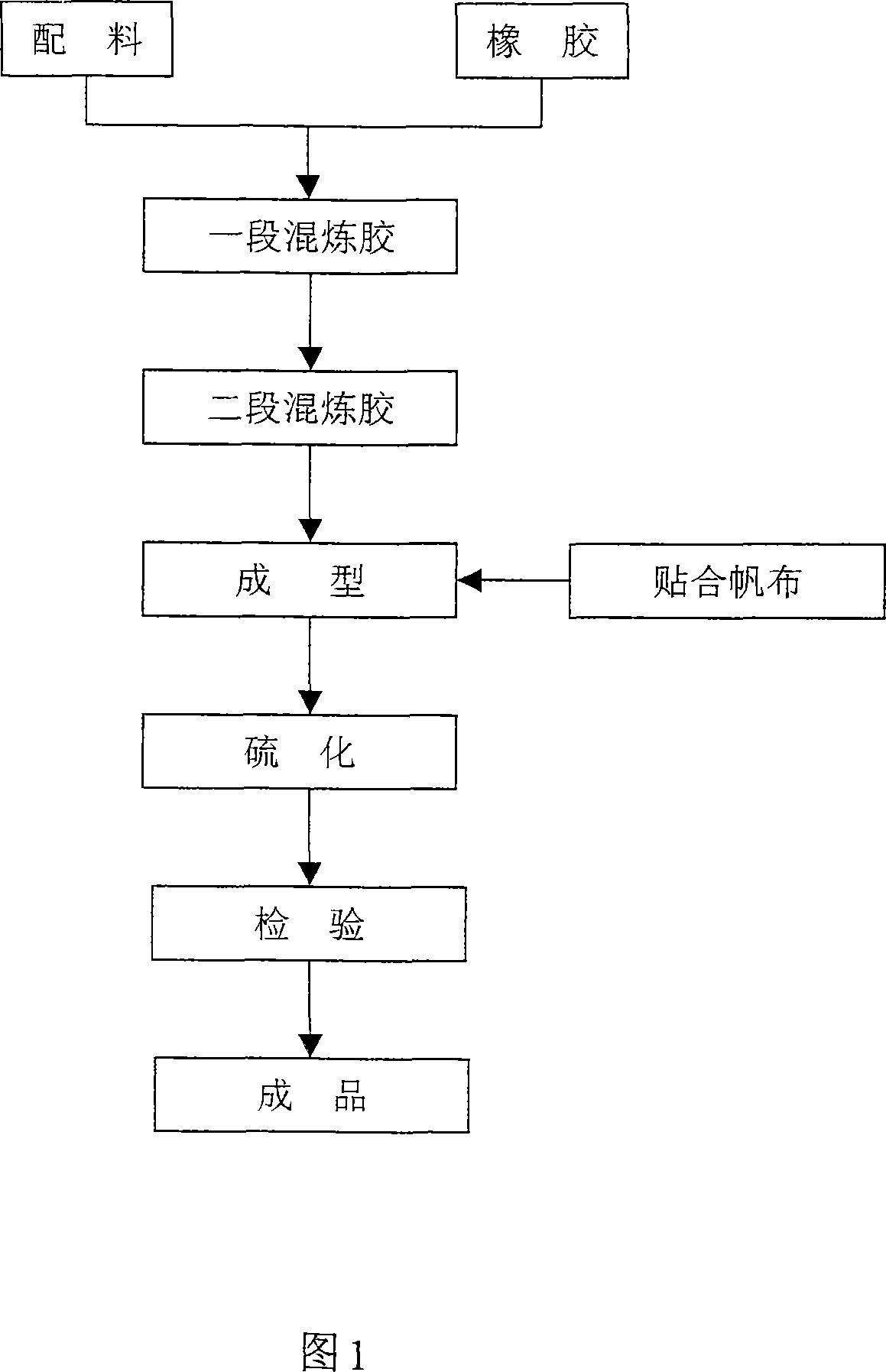

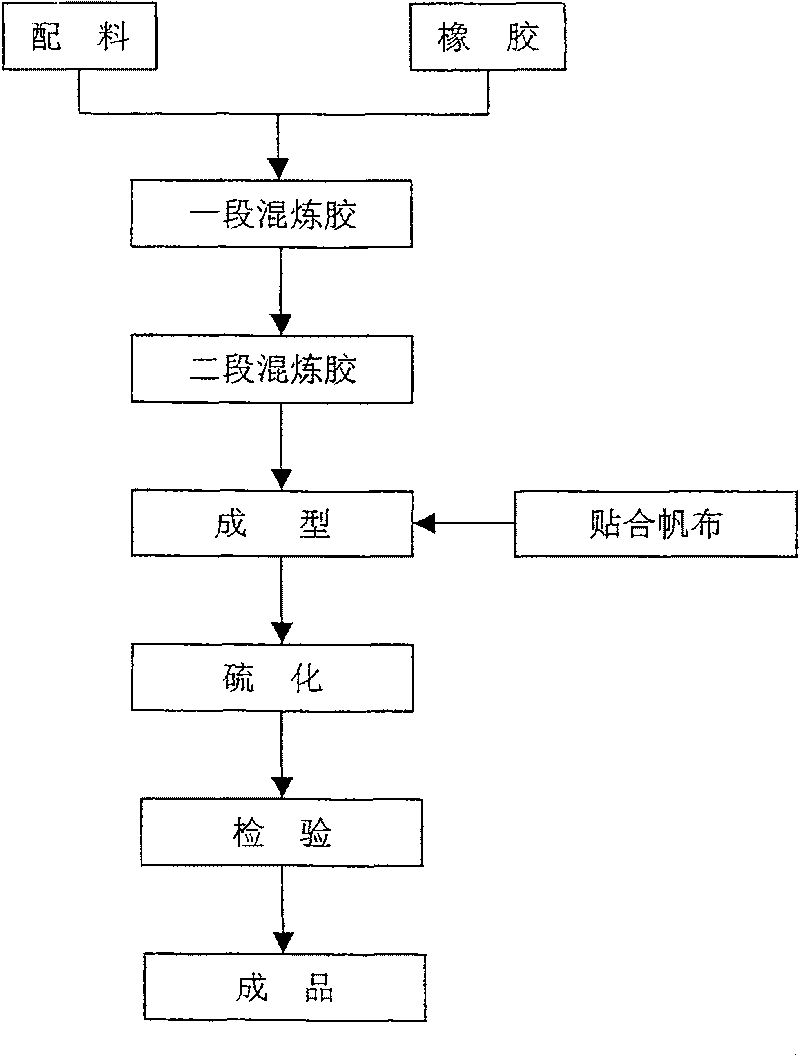

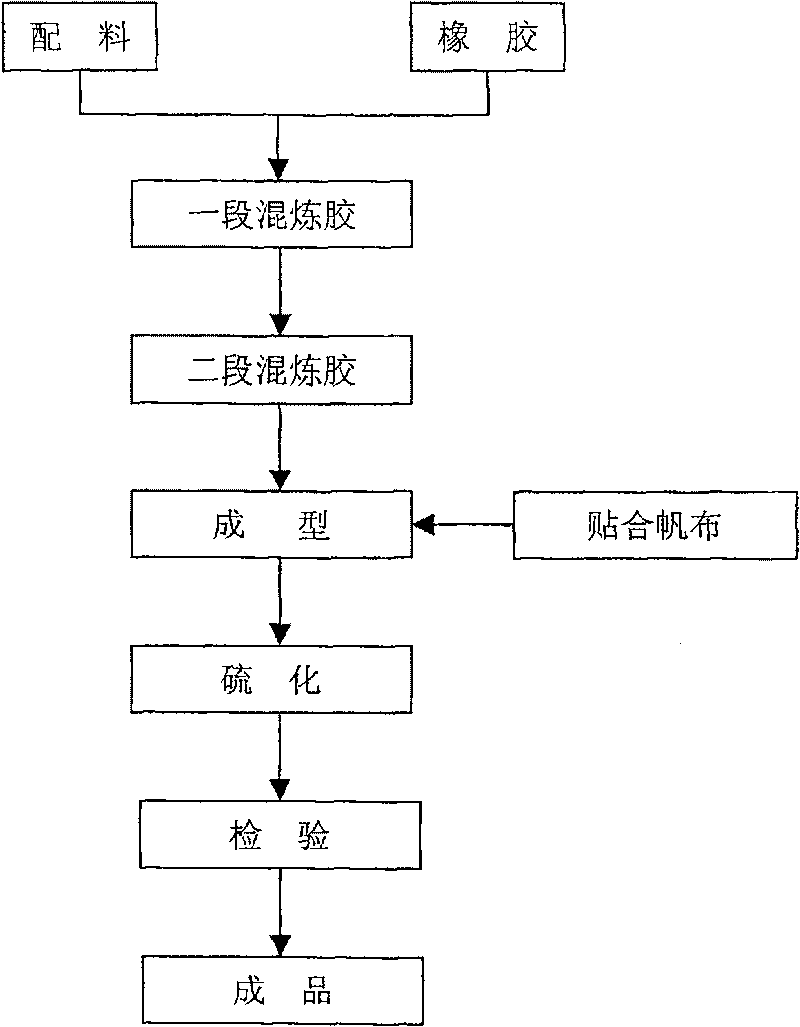

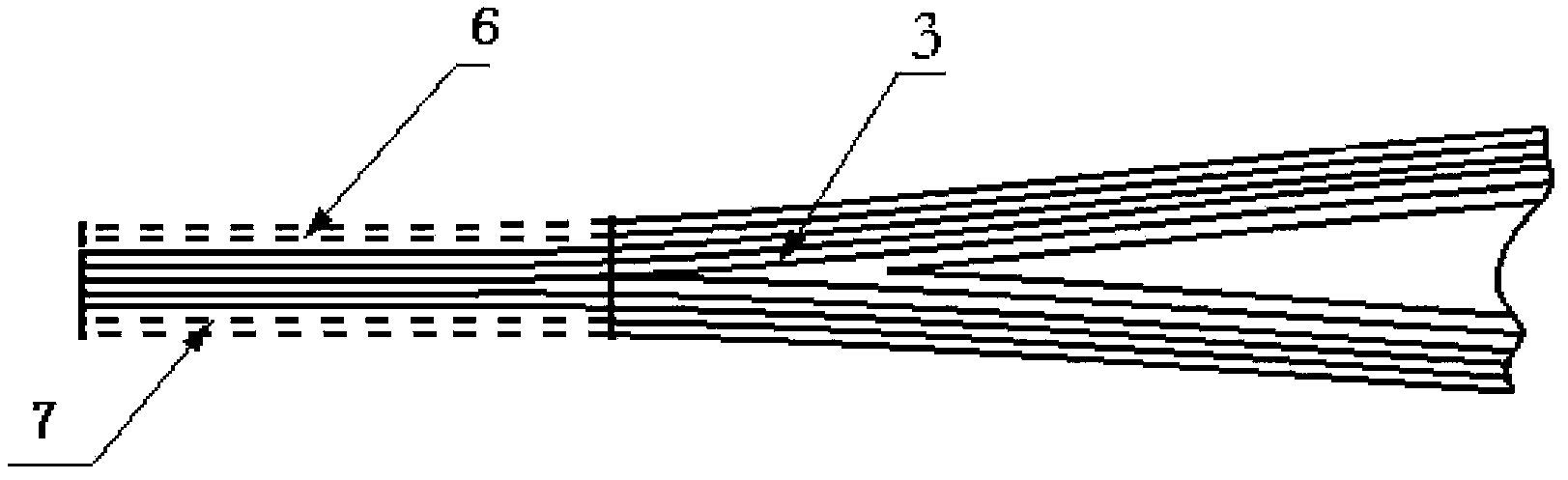

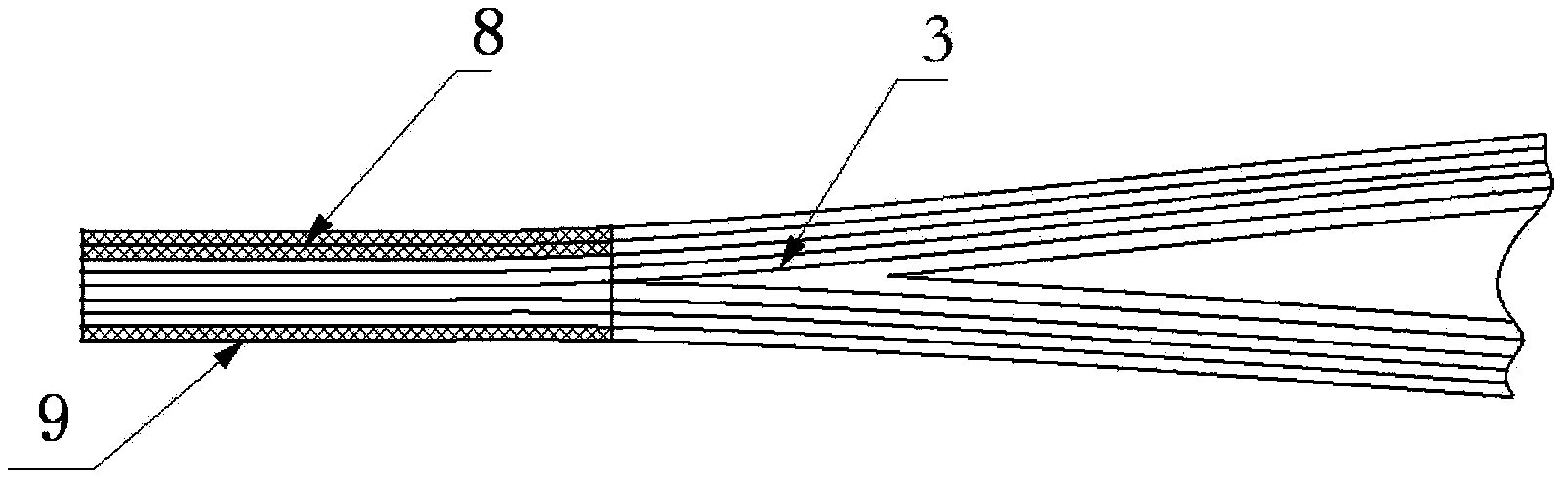

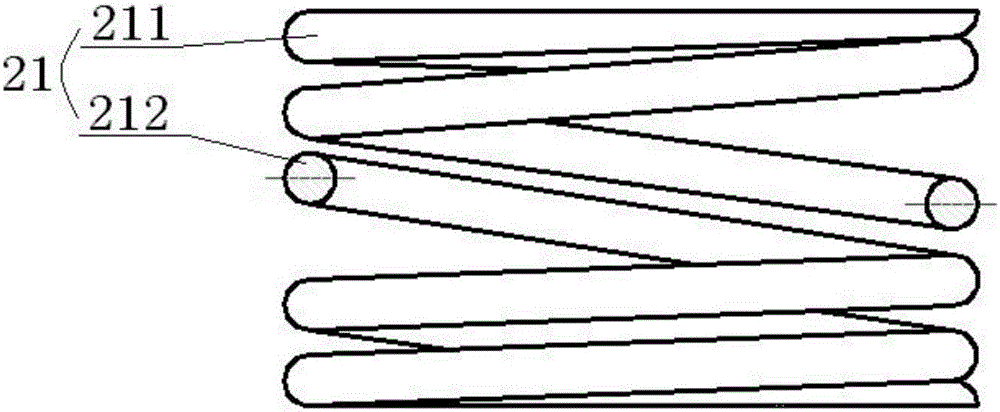

High-temperature-resisting conveyer belt

ActiveCN101028888AImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

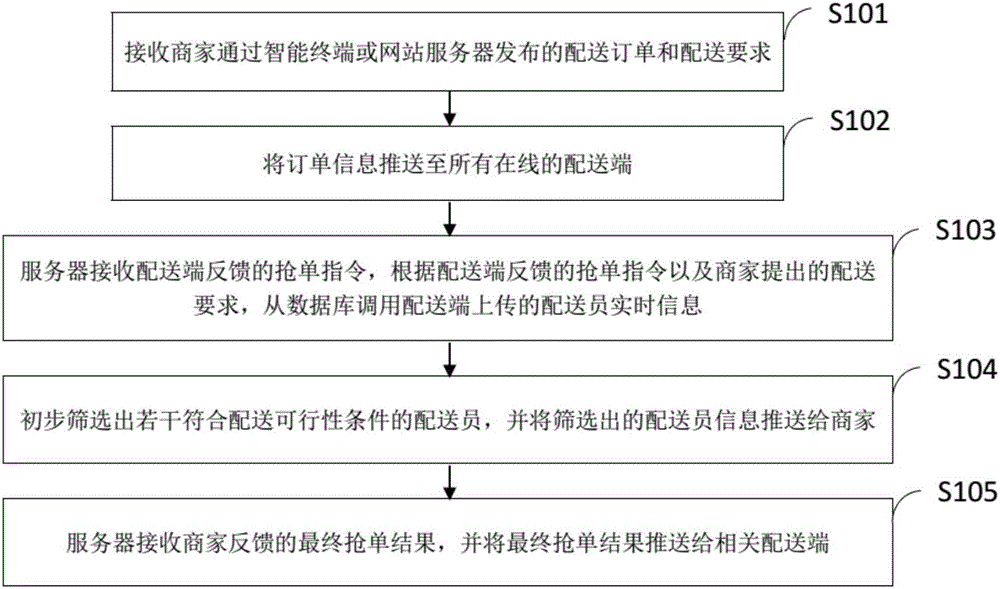

Method and system for merchant to participate in delivery staff order competition

InactiveCN106296086AReduce riskIncrease motivationBuying/selling/leasing transactionsLogisticsLogistics managementOrder form

The invention discloses a method and system for merchants to participate in delivery staff order competition and is applicable to the technical field of order allocation of an internet O2O industry and a city wide logistics industry. The method comprises the steps that a server receives delivery orders and delivery demands issued by the merchants through smart terminals and pushes order information to all online delivery ends; the server receives order competition instructions fed back by the delivery ends, preliminarily screening a plurality of delivery staff according to the order competition instructions of the delivery ends and the delivery demands proposed by the merchants and pushes the information to the merchants; and the merchants carries out secondary selection on the preliminarily screened delivery staff, and the server pushes final order competition results to related delivery ends. According to the method and the system, through adoption of a mode for the merchants to participate in the delivery staff order competition, the enthusiasm of the delivery staff is fully aroused, moreover, the previous working quality of the delivery staff is taken into full consideration, the participation degree and supervision degree of the merchants for delivery links are enhanced, and the integrated quality of the order delivery service is effectively improved.

Owner:温泉

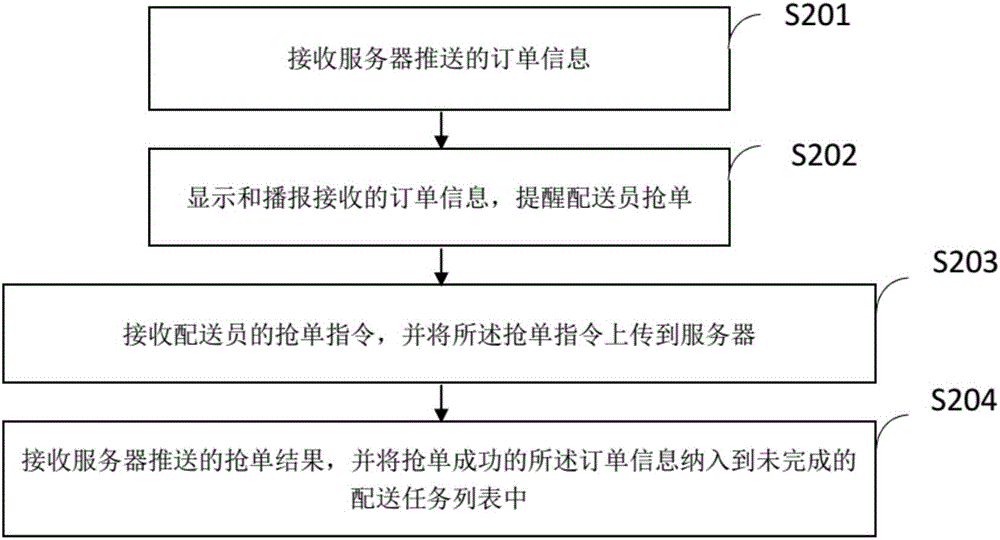

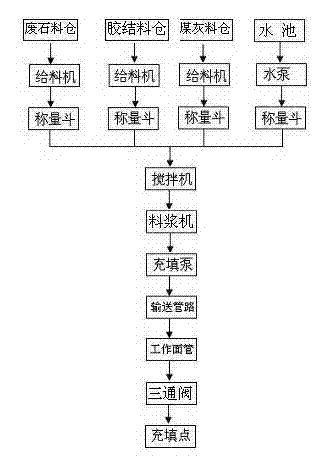

Filling method and system of coal mine goaf

ActiveCN102865101AImprove protectionAvoid missingMaterial fill-upMining engineeringPulverized fuel ash

The invention relates to a filling method and system of coal mine goaf. The filling system comprises a filling bin, a feeder, a weighing hopper, a stirrer, a slurry machine, a filling pump, a delivering pipeline, a working face pipe and a tee pipe, wherein the filling bin is respectively connected with the inlet of the stirrer through the feeder and the weighing hopper; and the outlet of the stirrer is connected to a filling point through the slurry machine, the filling pump, the delivering pipeline and a tee valve. The filling method comprises the steps that barren rocks with granularity of less than 25mm, a cementing agent, pulverized fuel ash and water are delivered to the weighing hopper through the feeder for weighing; the barren rocks, the cementing agent and the pulverized fuel ash are mixed in a mass ratio of 1:(0.22-0.80):(0.35-0.57), and are added with water to produce slurry in a mass concentration of between 70 and 83 percent through the stirrer; and the slurry is delivered to the filling point for filling through the slurry machine, the filling pump, the delivering pipeline, the working face pipe and the tee valve. According to the filling method and system, the sources of filling materials can be enlarged, the filling substance strength and durability can be increased, the filling material can be delivered to the filling point and uniformly filled by delivering and filling in a slurry state, and the filling effect can be improved.

Owner:河北充填采矿技术有限公司

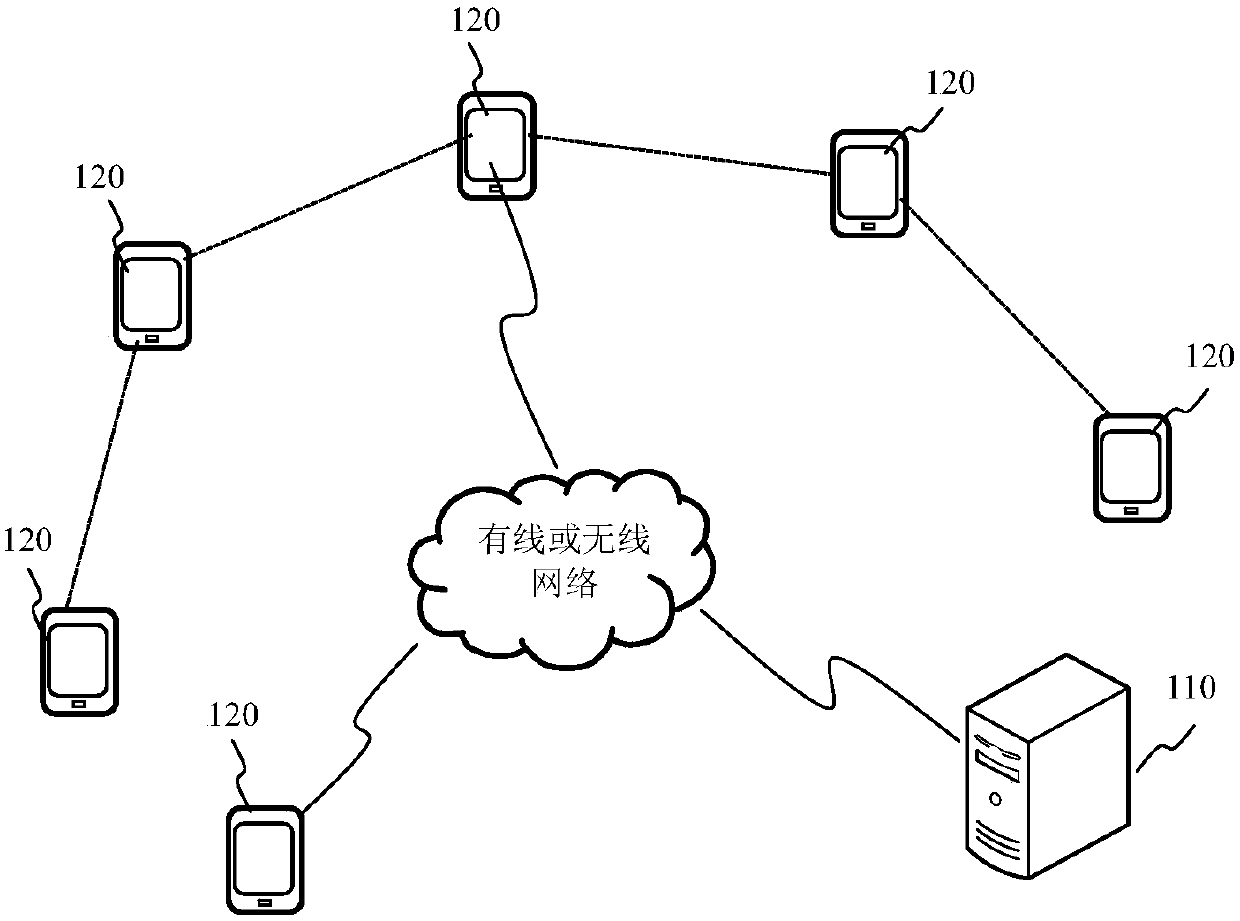

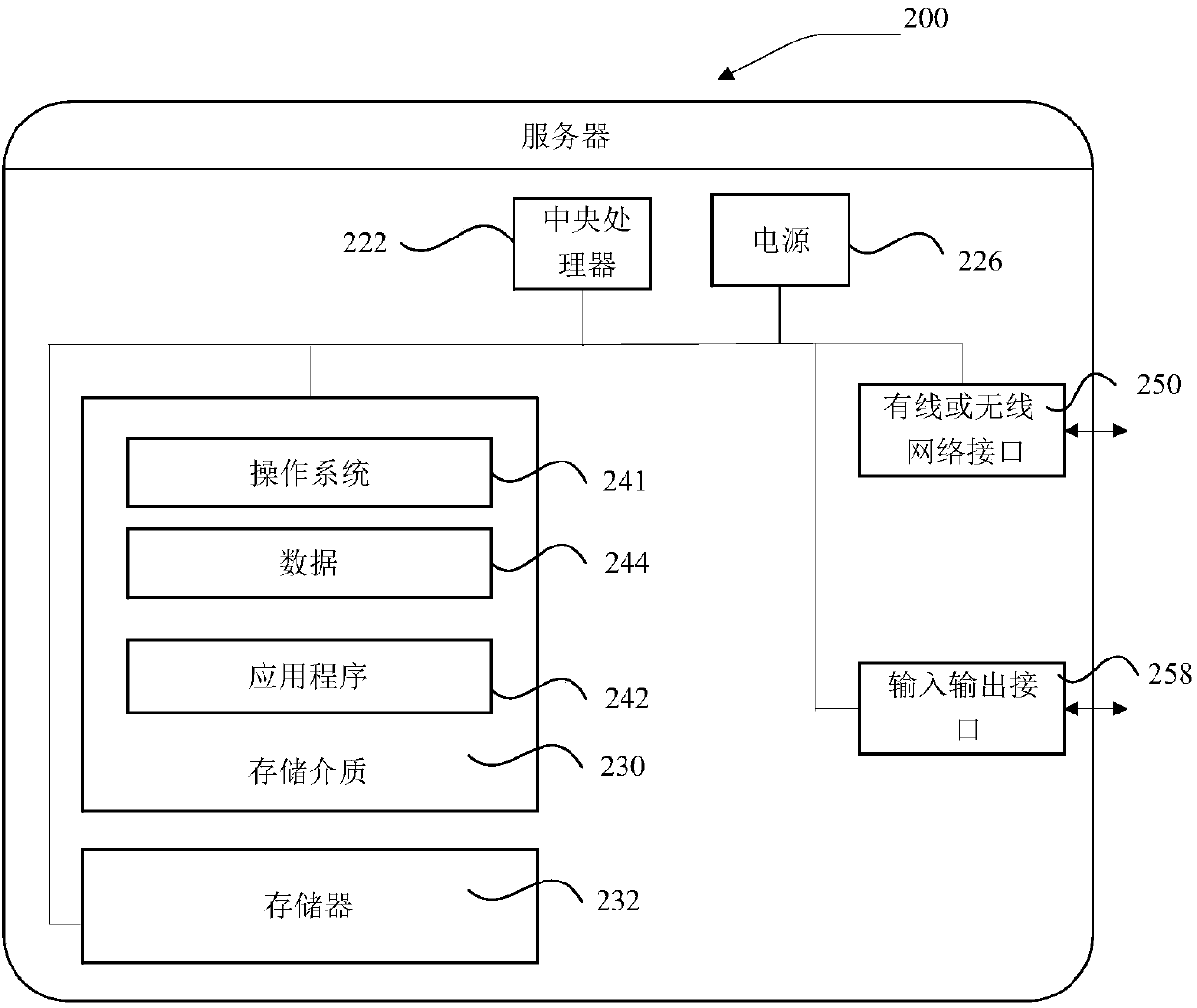

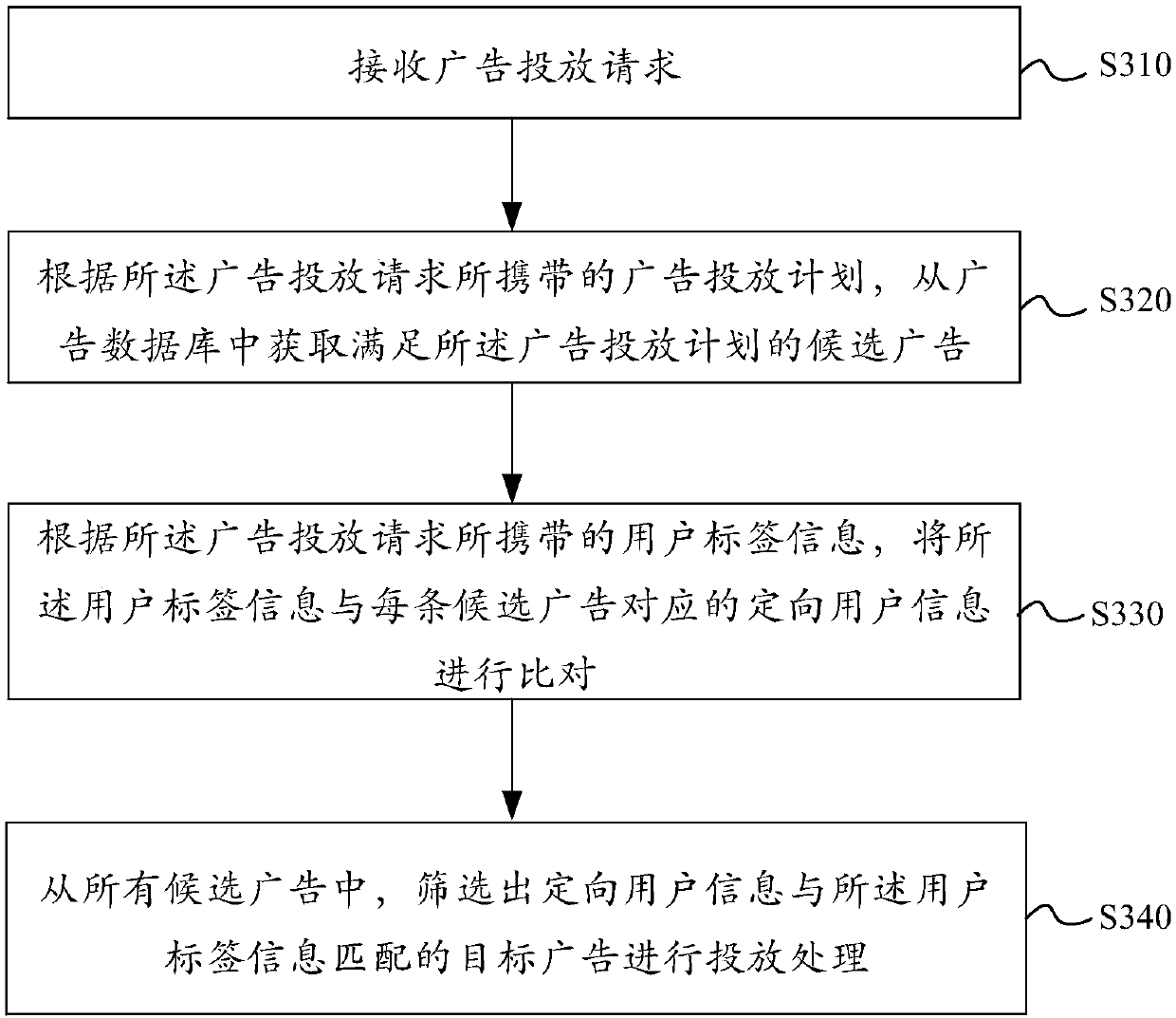

Advertisement putting processing method and device based on advertisement matching

InactiveCN107657488AMeet delivery requirementsGuaranteed delivery effectMarketingUser informationAd serving

The invention discloses an advertisement putting processing method and device based on advertisement matching. The method comprises: receiving an advertisement putting request; according to an advertisement putting plan carried in the advertisement putting request, obtaining, from an advertisement database, candidate advertisements satisfying the advertisement putting plan; according to user labelinformation carried in the advertisement putting request, comparing the user label information with the target user information corresponding to each candidate advertisement; and screening out, fromall the candidate advertisements, the target advertisements with the target user information matched with the user label information and carrying out putting processing. According to the technical scheme provided by the invention, by matching the user label information and the advertisement target user information, the advertisements are delivered to users meeting the advertisement putting requirements, so that the advertisements delivered can better satisfy the requirements of the users, the problem that advertisement resources are wasted due to the fact that advertisements are delivered in anon-targeted manner is avoided, and the advertisement putting effect is guaranteed.

Owner:XIAMEN MEET YOU INFORMATION TECH

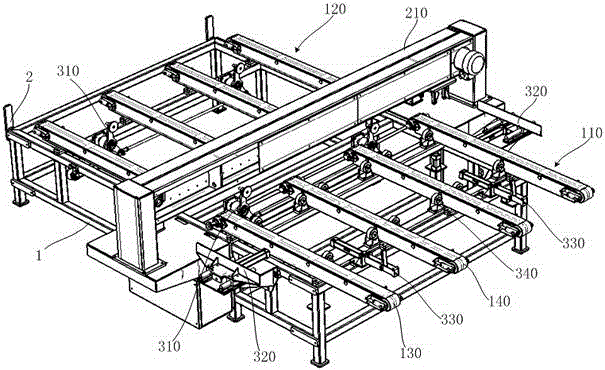

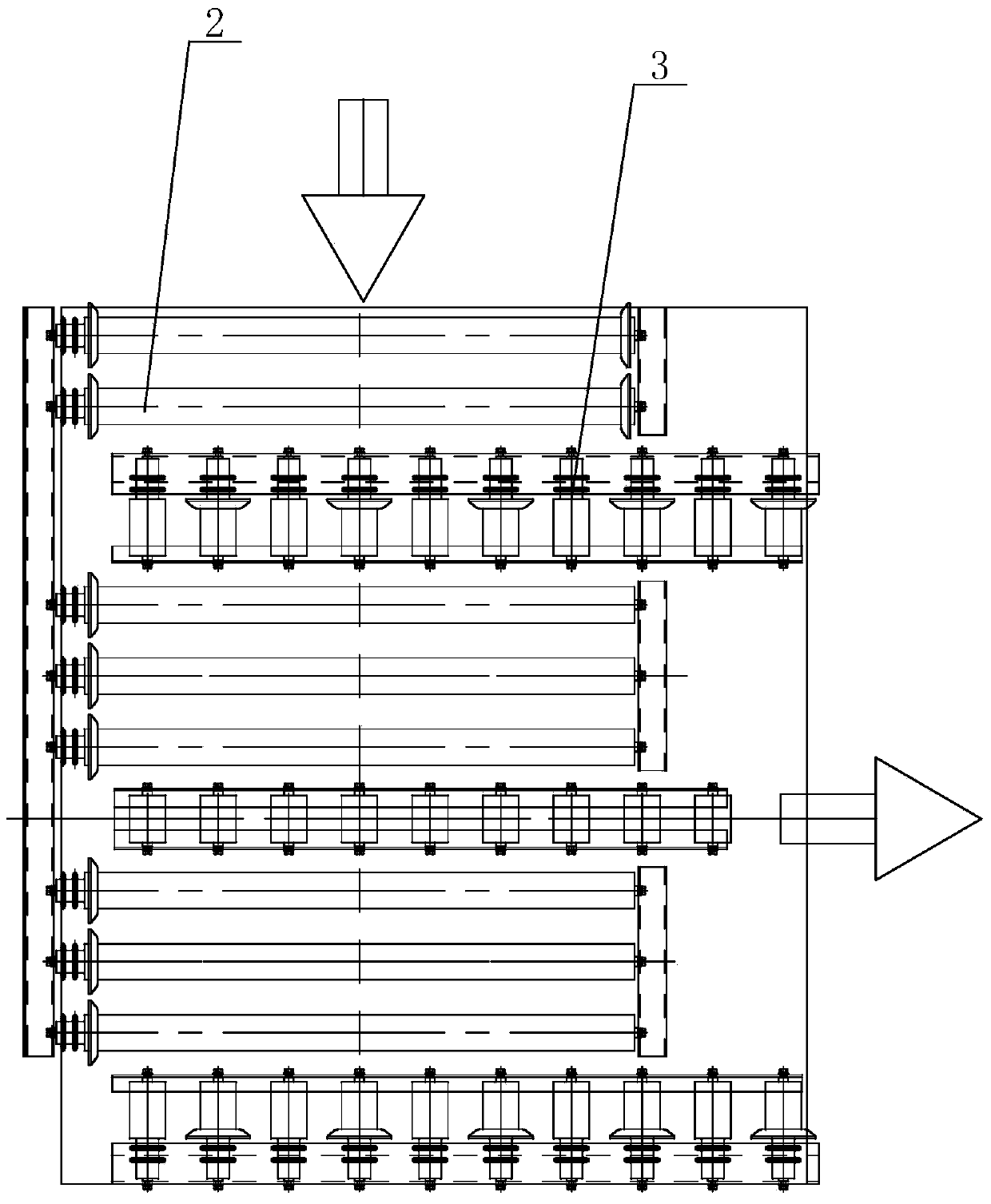

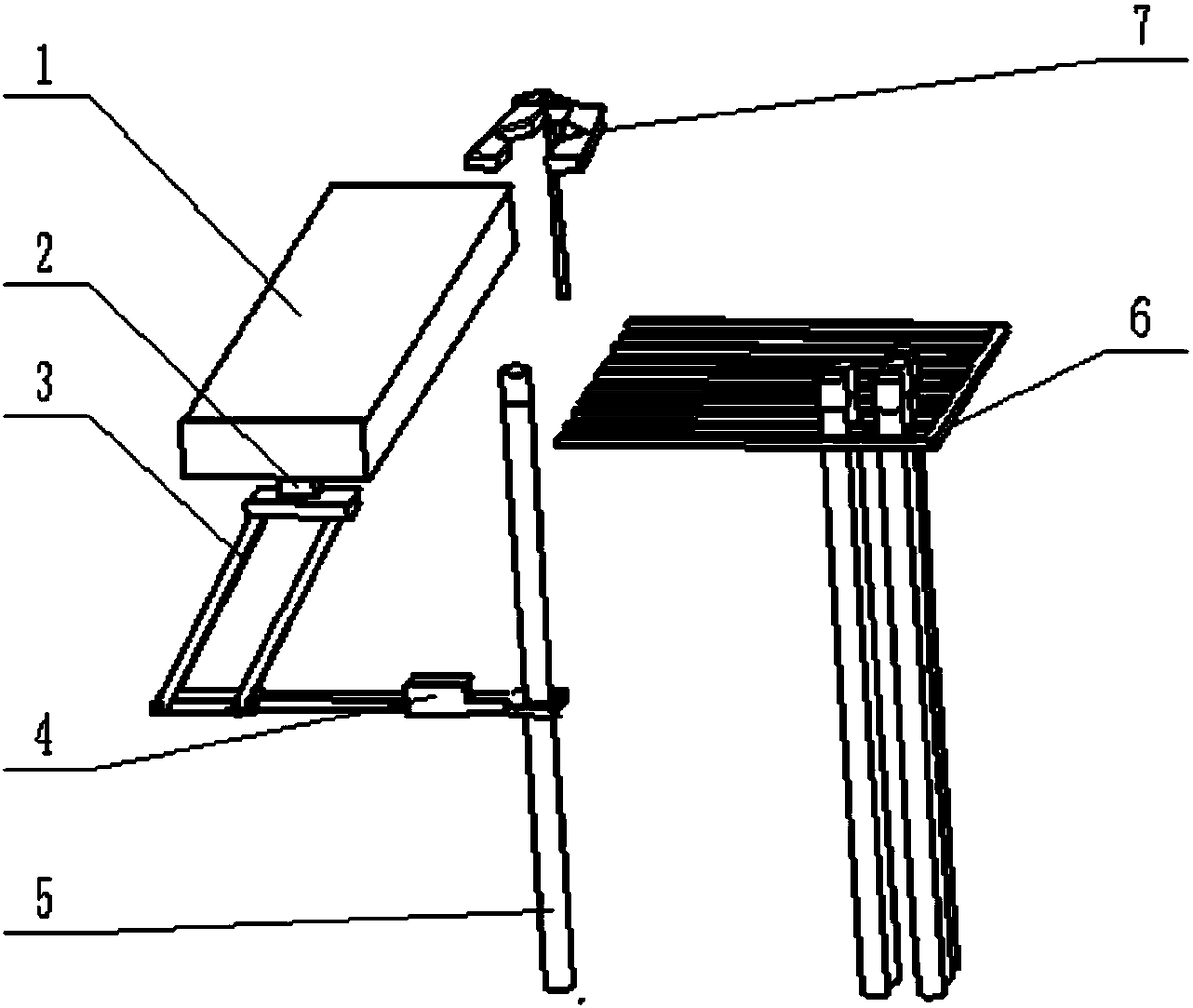

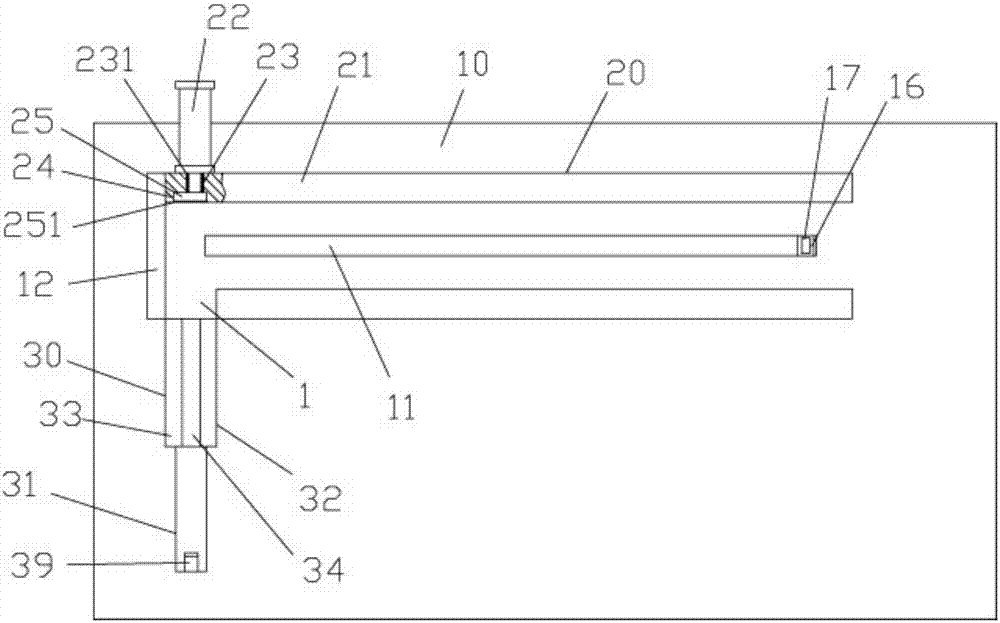

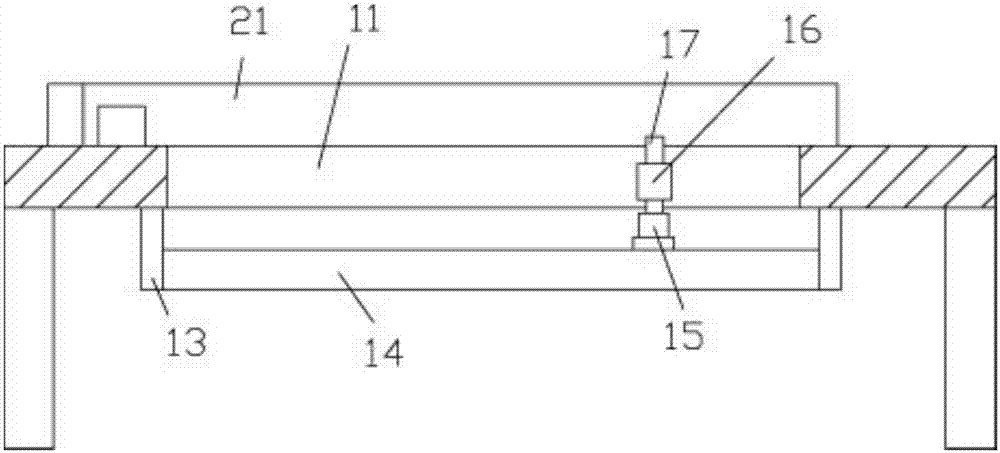

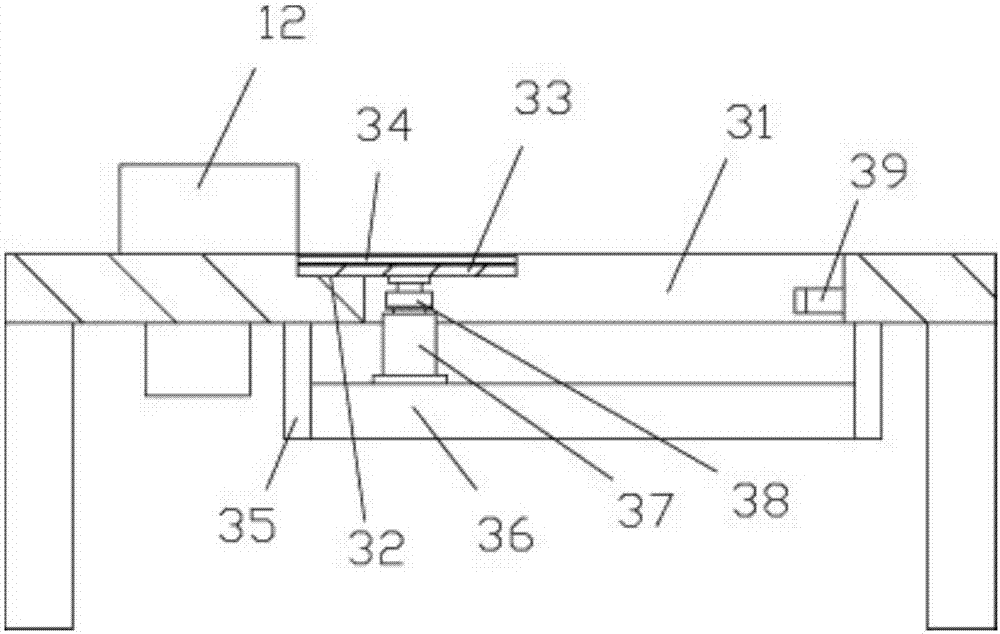

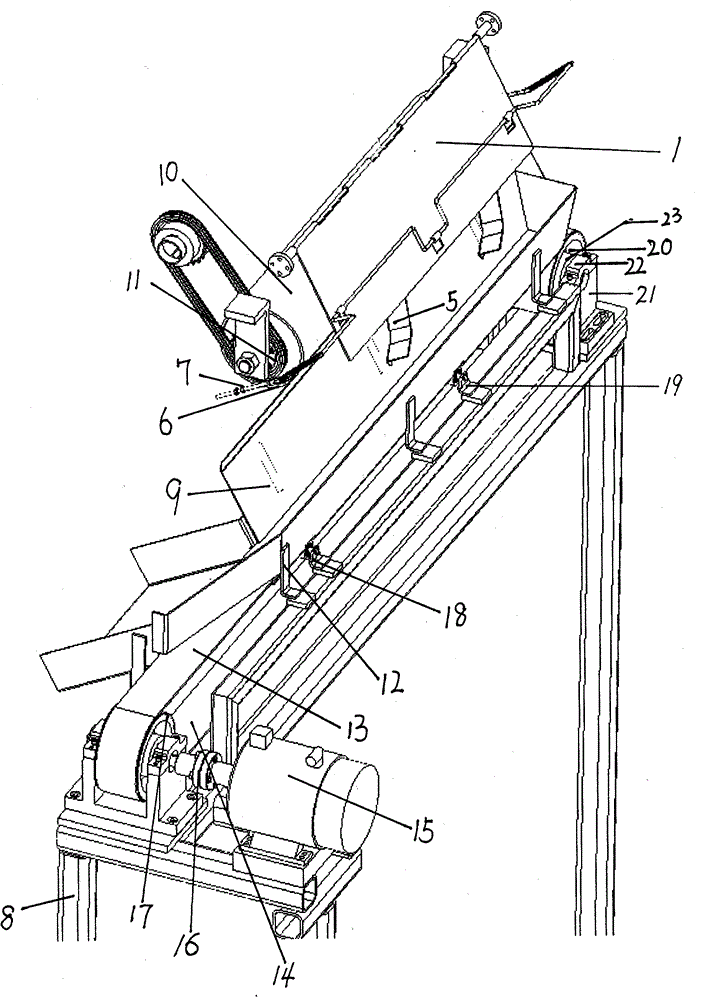

Conveying and trimming assembly used for melamine board, trimming and board discharging assembly and achieving method of conveying and trimming assembly and trimming and board discharging assembly

InactiveCN104444480AReduce labor intensityHigh precisionOther plywood/veneer working apparatusRegistering devicesHeat pressEngineering

The invention discloses a conveying and trimming assembly for a melamine board. The conveying and trimming assembly comprises a bottom frame arranged outside a discharging port of a hot press, a two-section type conveying mechanism arranged on the bottom frame in the discharging direction, a positioning and position adjusting mechanism installed on the bottom frame and used for adjusting the position of a board on the two-section type conveying mechanism to as to conveniently conduct trimming, a trimming mechanism arranged at the sectioned position of the two-section type conveying mechanism in a crossing mode, and a tail-end baffle located at the tail end of the two-section type conveying mechanism. The invention further discloses a trimming and board discharging assembly which comprises the conveying and trimming assembly and a board discharging and carrying mechanism connected with the conveying and trimming assembly. Under the cooperation action of the conveying mechanism and the positioning and position adjusting mechanism, the board obtained after hot pressing is conveyed to a designated position, trimming is conducted on the board through the trimming mechanism, the board is well placed through the board discharging and carrying mechanism, an automatic mechanical device can fully replaced labor force, the labor intensity of workers is greatly lowered, the labor cost is reduced, and the production efficiency is effectively improved.

Owner:李茂华

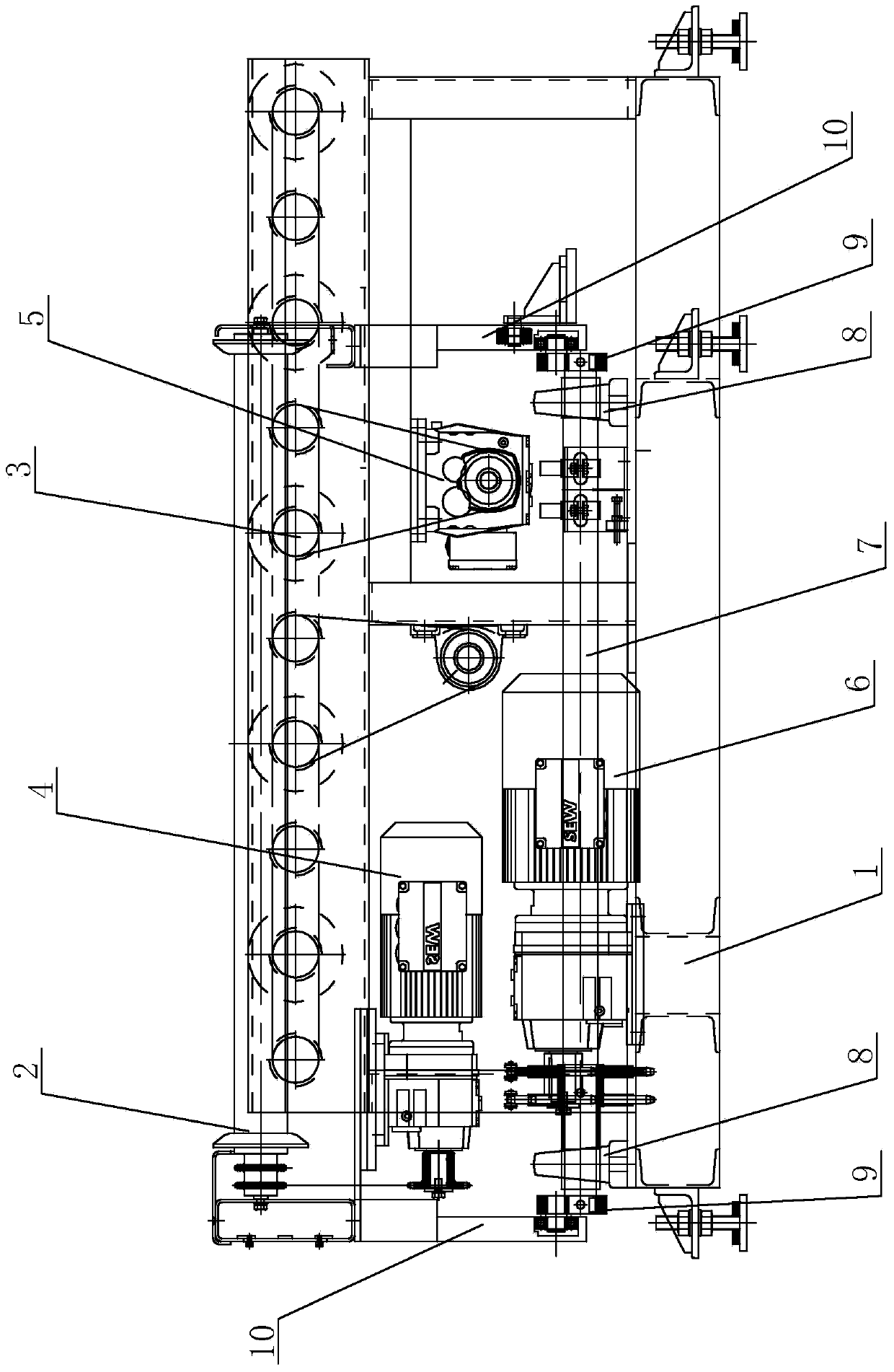

Intersected transversely-moving type roller conveyer

The invention discloses an intersected transversely-moving type roller conveyer which is used for achieving the aim of conveying nonmetal trays in the vertical direction to meet special requirements. The intersected transversely-moving type roller conveyer comprises a machine frame. First roller conveyer lines and second roller conveyer lines are arranged on the machine frame in an intersected mode and connected with corresponding driving motors through transmission assemblies, the bottoms of the first roller conveyer lines are connected with jacking driving motors through jacking assemblies, and the first roller conveyer lines are driven by the jacking driving motors to vertically move. According to the intersected transversely-moving type roller conveyer, the partitioned roller conveyer lines are used for intersected layouts, the roller conveyer lines in one partition have the jacking function, so that once trays enter a working area, the motors drive the conveyer lines with the jacking function to carry out conveying in the vertical direction, the conveyer lines are matched with the roller conveyer lines in the other partition to achieve the purpose of conveying the trays in the 90-degree-included-angle conveying direction, and the conveying requirements are met.

Owner:WUXI ZHONGDING INTEGRATION TECH CO LTD

Terpolymer oil soluble viscosity reducer for thick oil exploration and transportation and preparation method thereof

InactiveCN101824314AGood viscosity reduction effectImprove universalityDrilling compositionMethacrylateSolvent

The invention relates to a terpolymer oil soluble viscosity reducer for thick oil exploration and transportation and a preparation method thereof. The terpolymer oil soluble viscosity reducer for thick oil exploration and transportation is characterized in that the viscosity reducer is prepared from methacrylate ester, N, N'- 2 (methacryloyloxyethyl) diamine, styrene, azobisisbutyronitrile and toluene, and the molar ratio of all the raw materials is as follows: methacrylate ester: N, N'- 2 (methacryloyloxyethyl) diamine: styrene is (4 to 5): (2 to 3): (2 to 4), the added amount of the azobisisbutyronitrile is 0.5 to 2 percent of the total mass of the methacrylate ester, the N, N'- 2 (methacryloyloxyethyl) diamine and the styrene, and toluene serves as the solvent; the methacrylate ester is prepared from acrylic acid, C16 to C22 higher alcohols, sulfoacid catalyst and phenolic inhibitor; and the N, N'- 2 (methacryloyloxyethyl) diamine is prepared from methyl acrylate and diamine. The oil soluble viscosity reducer has the advantages of good effect, strong universality, no pollution and relaxed use conditions, and can simultaneously meet the needs of thick oil exploration and transportation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

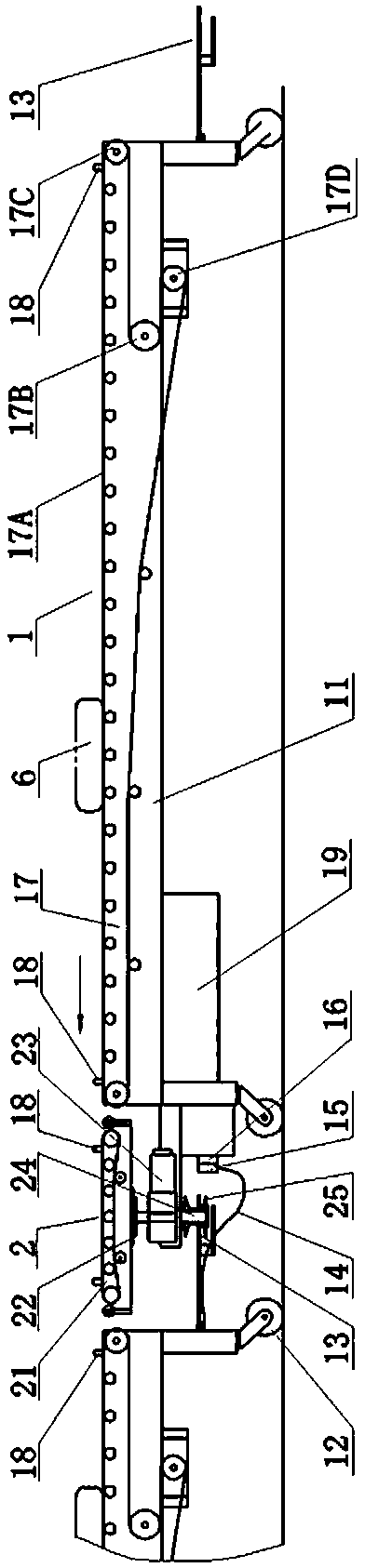

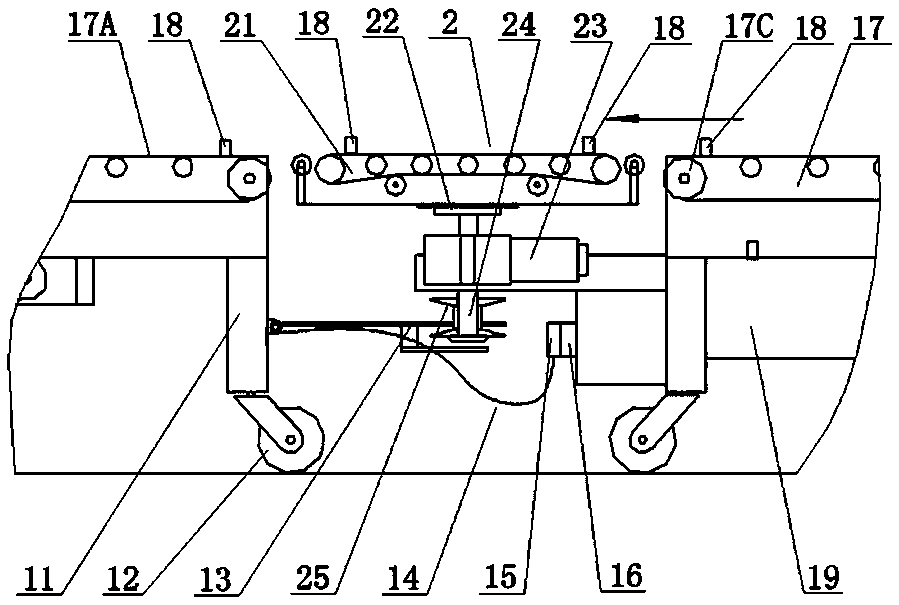

Flexible combined belt conveyor

PendingCN108394675ARealize free angle changeIncrease or decrease quantityConveyorsControl devices for conveyorsEngineeringFuselage

The invention discloses a flexible combined belt conveyor. The flexible combined belt conveyor is formed by at least two movable conveying units which are each composed of a movable belt conveyor anda transferring platform and are connected end to end. Each movable belt conveyor comprises a conveyor body, universal wheels arranged at the bottom of the conveyor body, a belt conveying device on theupper portion, an electrical connecting socket fixedly arranged at one end of the conveyor body, and an electrical connecting plug connected to the other end of the conveyor body through a soft cable. Each transferring platform comprises a transferring conveying device, a rack, a rotation driving device arranged at one end of the corresponding conveyor body, and a connecting shaft, wherein the transferring conveying device is arranged on the upper portion of the rack, and the rack is arranged on an output shaft of the rotation driving device. A rapid connecting device between every two adjacent movable conveying units is hinged to the corresponding connecting shaft. The electrical connecting sockets are connected with the electrical connecting plugs. The electrical connecting sockets or plugs are electrically connected with the belt conveying devices and the rotation driving devices. The transferring conveying devices are as high as the top surfaces of conveying belts of the belt conveying devices. The flexible combined belt conveyor has the characteristics of being simple in structure, capable of being freely moved and deformation, and variable in length.

Owner:周兆平

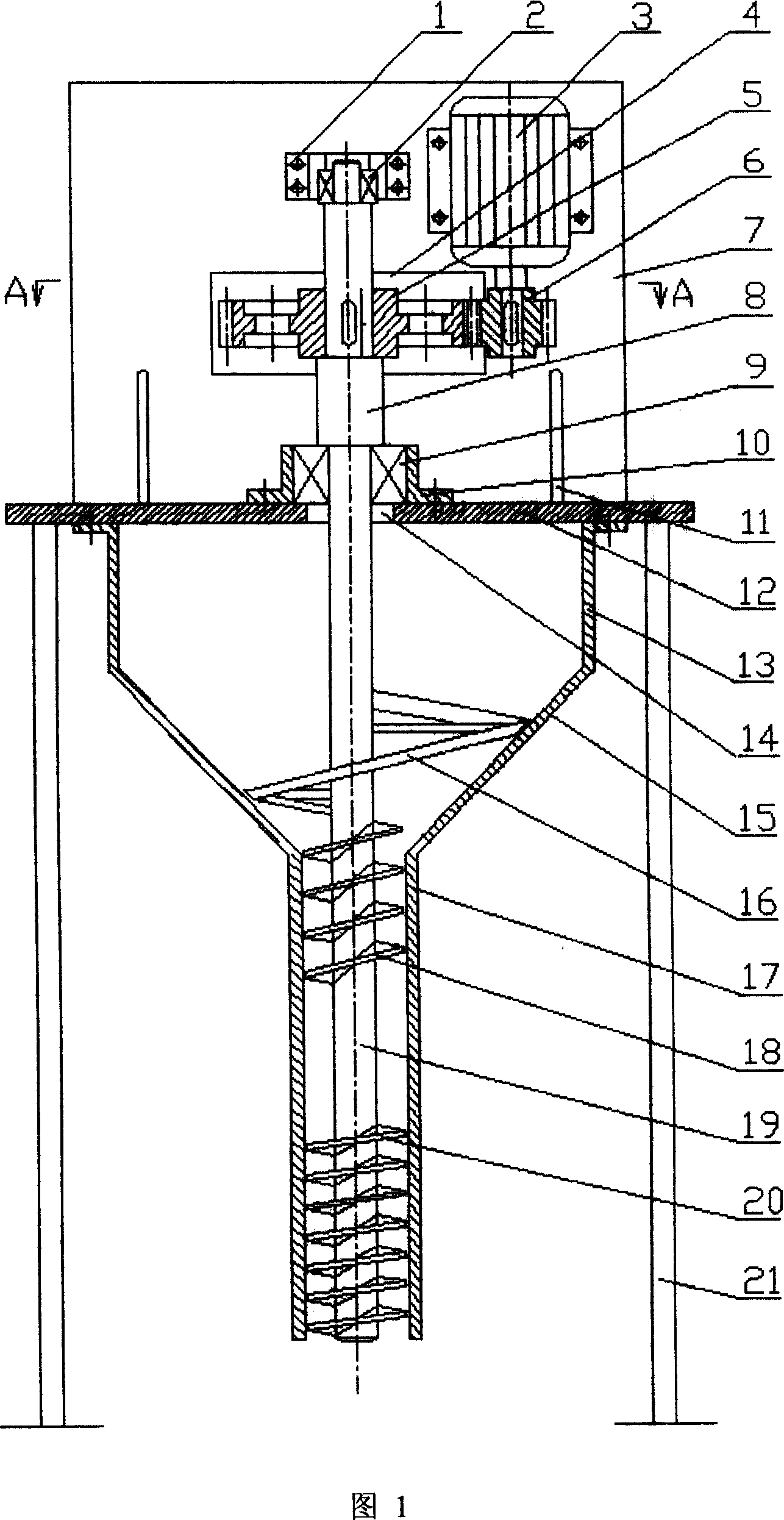

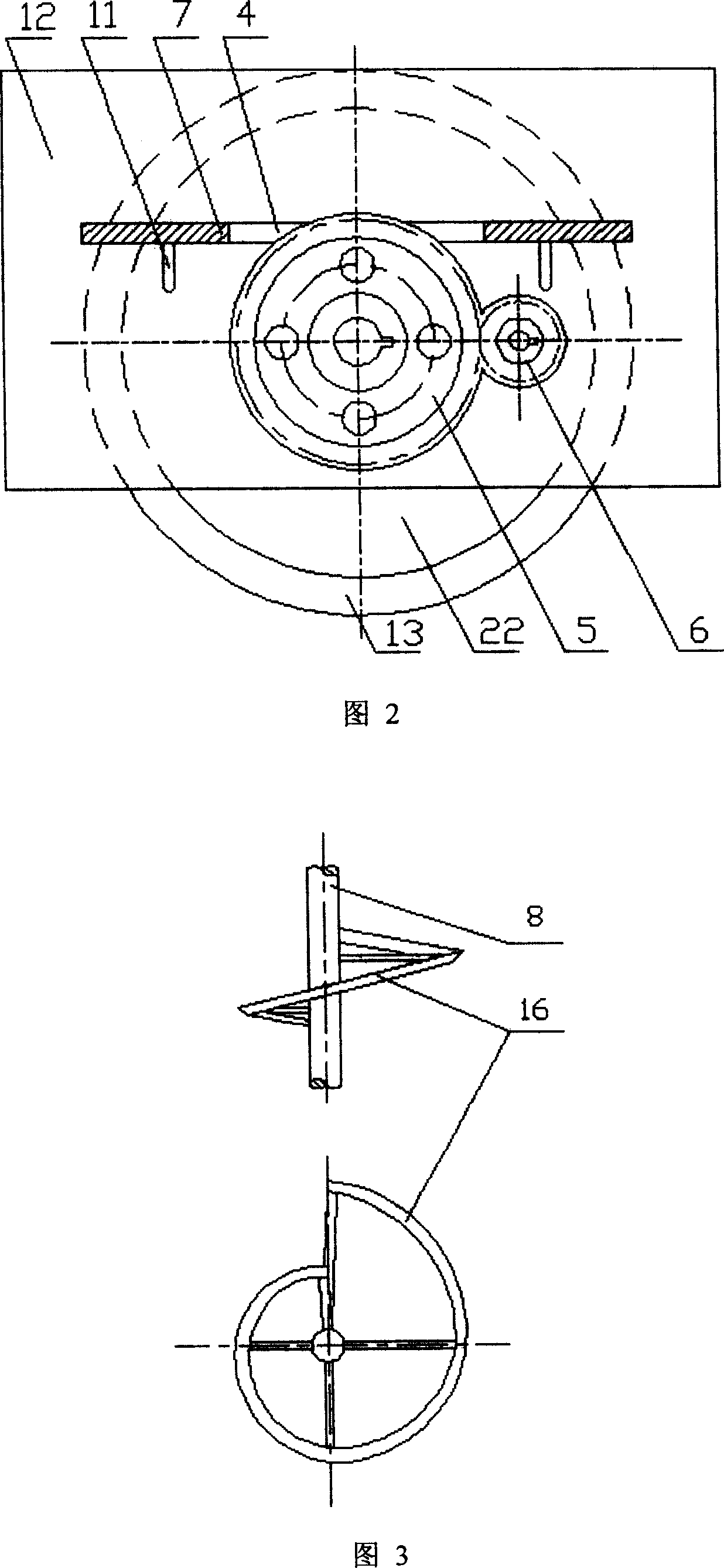

Pressurization trace quantity helix powder feeding equipment

InactiveCN101012031AGuaranteed normal rotationTo achieve the purpose of sealed deliveryToothed gearingsPackagingColloidEngineering

The pressurized micro spiral powder feeder drives the screw shaft through drive mechanism by generators, hopper and material outlet pipe integrated under the lower surface of the support platform, featuring in its being load bore by support platform and positioned by the middle up shaft bearing, vertically going through the insert hopper of the round hole, the lower end sticking to the material output pipe in arm shape, blender at the screw shaft of the corresponding position of the conical sectional hopper, intermittently fixing two sections spiral vanes with different pitches, lower spiral vane pitch smaller than the pitch of the upper spiral vane, leaving a section of emptiness between the spiral shaft of the spiral vanes. It is simple and compact in structure, adjustable in feeding quantity, even and stable in pressurized transportation.

Owner:UNIV OF SCI & TECH OF CHINA

Automatic washing powder putting device

InactiveCN102995359APrecise deliveryStable deliveryOther washing machinesTextiles and paperImpellerElectricity

The invention relates to an automatic washing powder putting device. The device comprises a solvent box, an upper cover of the solvent box, and a powder leakage hole in a bottom disc. The device is characterized in that an impeller is arranged in the solvent box; a motor supplies kinetic energy to the impeller so as to drive the impeller to rotate; and a dissolving box is arranged on the other side of the powder leakage hole and is provided with a water inlet and a liquid leakage hole. According to the invention, the dissolving box can be used for fully dissolving washing powder, thus improving the purifying capacity of the washing powder, and avoiding waste caused by the inaccuracy of the quantity of the washing power manually put by a user; and the time for dissolving the washing power in a washing machine before is shortened since the washing powder is fully dissolved, so that the washing time of the washing powder is prolonged, and within the same set time, the frequency of rinsing is reduced and water and electricity are saved to achieve the aim of energy conservation. The automatic washing powder putting device conforms to green design and is energy-saving and man-machine.

Owner:NANJING ZHONGJINGKE ELECTRONICS TECH

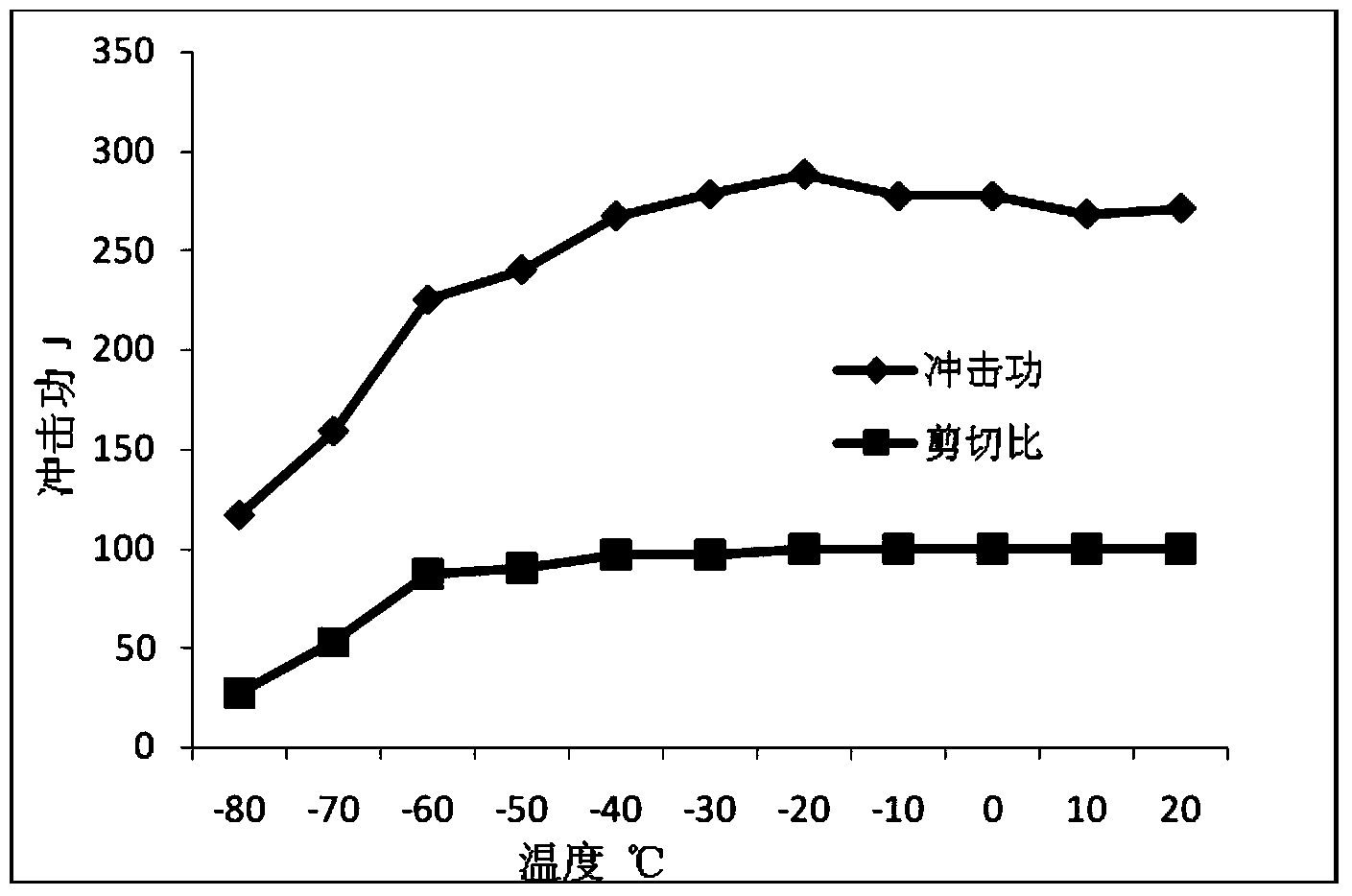

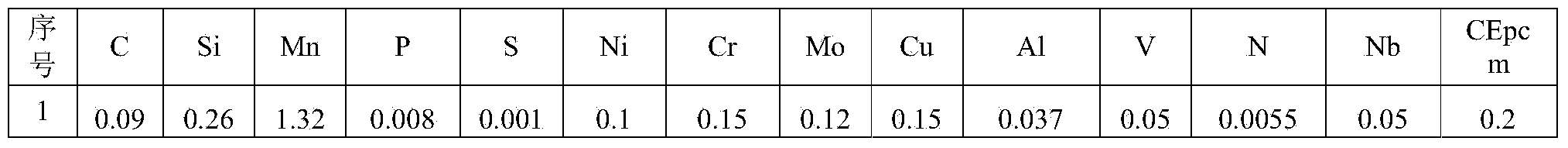

Method for manufacturing large-aperture high-strength gathering and transportation seamless steel tube for environment with high content of hydrogen sulfide

The invention provides a method for manufacturing a large-aperture high-strength gathering and transportation seamless steel tube for the environment with the high content of hydrogen sulfide. The method includes the steps of steel type reasonable matching, steel making, PQF continuous rolling, 720EM skew rolling spin expanding and thermal refining and machining. The method has the advantages that by the utilization of contributions of residual elements to the performance, element control is reasonably adjusted, the gathering and transportation tube suitable for the environment with the high content of hydrogen sulfide is obtained through the rolling technology of skew rolling spin expanding and the special heat treatment technology, the requirement for strength under high gathering and transportation operating pressure is met, and the requirement of an acid environment for the hydrogen sulfide corrosion resistant performance is met. The steel tube has the good physical and chemical performance, is high in size accuracy of a tube body, convenient to apply, beneficial to ensuring safety of a delivery pipeline, and can be widely applied to acid oil and gas fields with the high content of hydrogen sulfide.

Owner:TIANJIN PIPE (GROUP) CORP

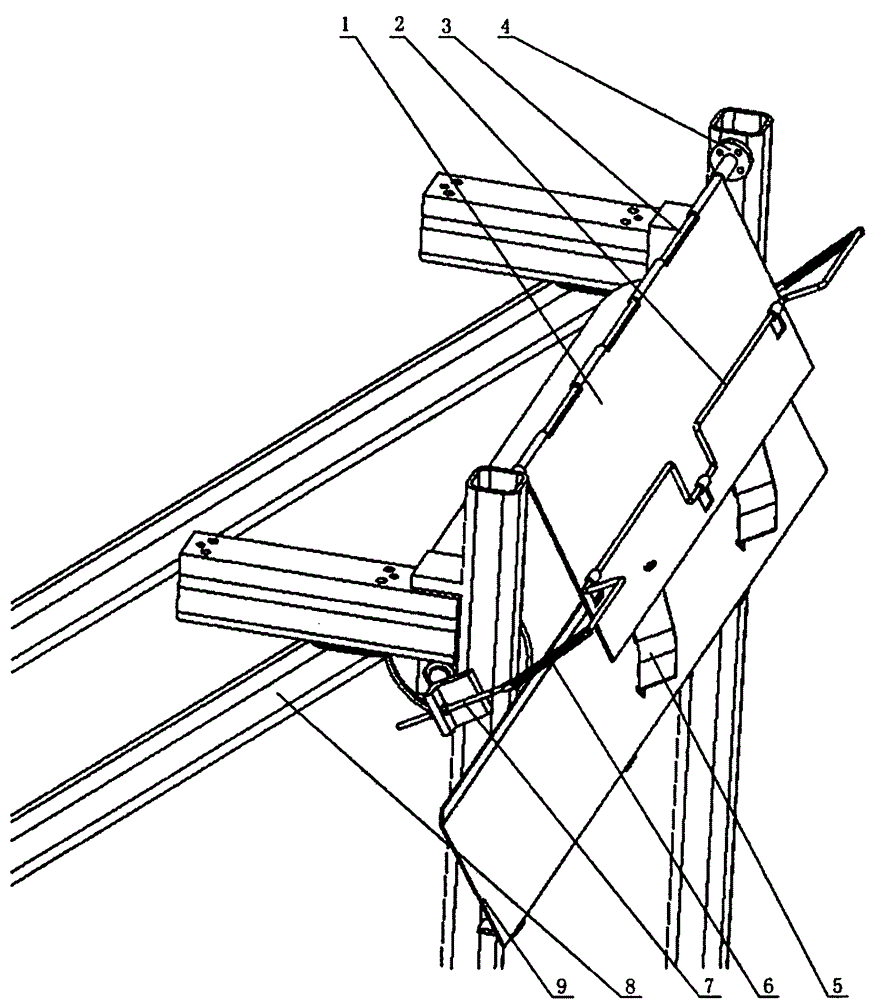

Automatic pipe arrangement system for land drill rig racking platform

PendingCN108533194AReduce labor intensityAvoid damageDrilling rodsDrilling casingsPhysical hard workEngineering

An automatic pipe arrangement system for a land drill rig racking platform comprises a racking platform manipulator mounted on the racking platform and a drill floor auxiliary manipulator mounted on adrill floor. The racking platform manipulator comprises a transverse-moving mechanism; the transverse-moving mechanism comprises a guide rail and a sliding block, and the sliding block is mounted onthe guide rail and connected with a rotating mechanism through a bolt; the rotating mechanism is connected with a parallelogram mechanism, and a clamping mechanism used for clamping drill pipes is arranged on the parallelogram mechanism and feeds the drill pipes located on a stand arrangement frame into an elevator; the transverse-moving mechanism is located on the upper portion of the rotating mechanism, and the parallelogram mechanism operates along the guide rail and transforms the angle through the rotating mechanism; and the drill floor auxiliary manipulator used for conveying the drill pipes is arranged below the elevator. The automatic pipe arrangement system has the main effects that reciprocating moving of the drill pipes from a racking platform finger board to the wellhead centeris completed, safe and efficient work can be conducted according to a preset program, thus operators are disengaged from burdensome physical labor, the operation efficiency is improved, and automation of a drill rig is achieved.

Owner:XI'AN PETROLEUM UNIVERSITY

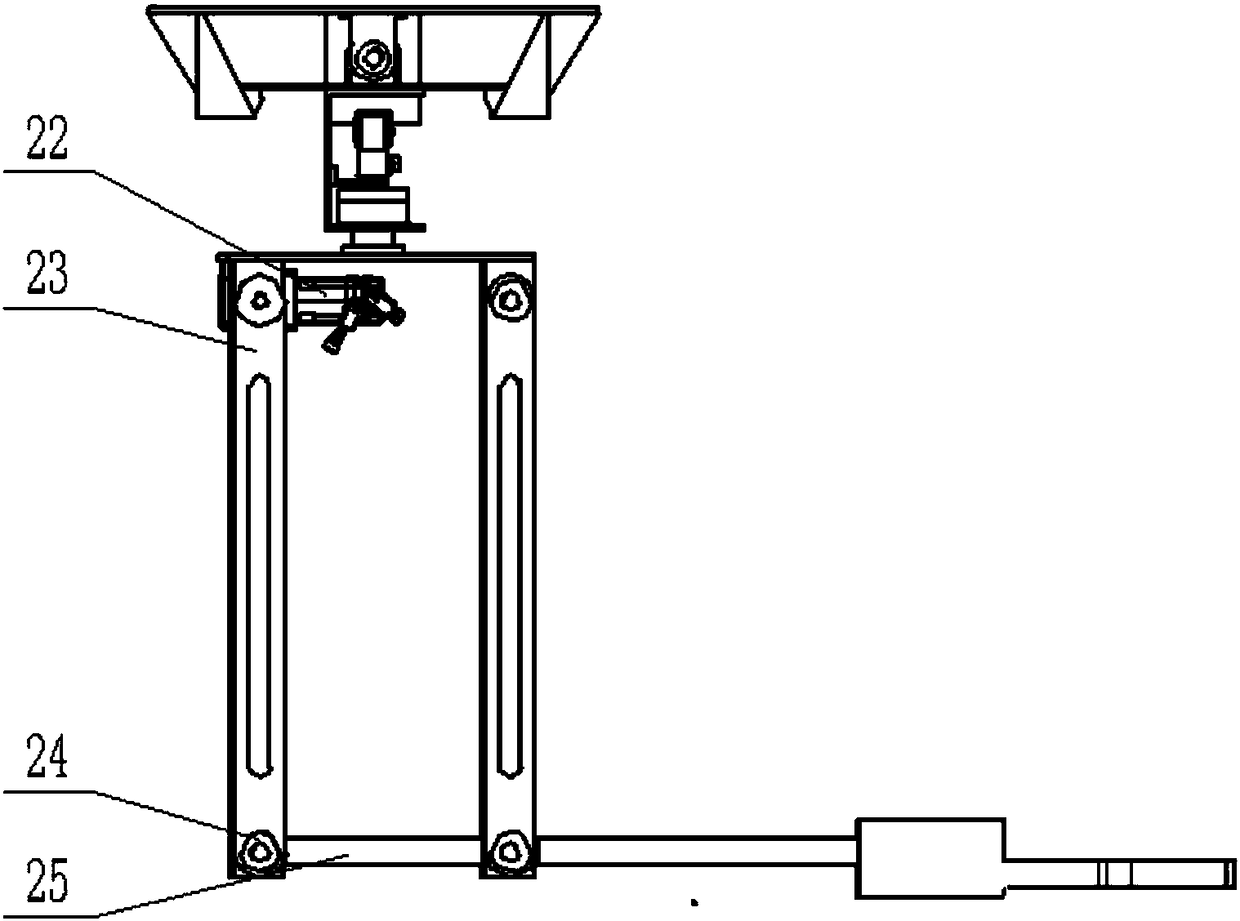

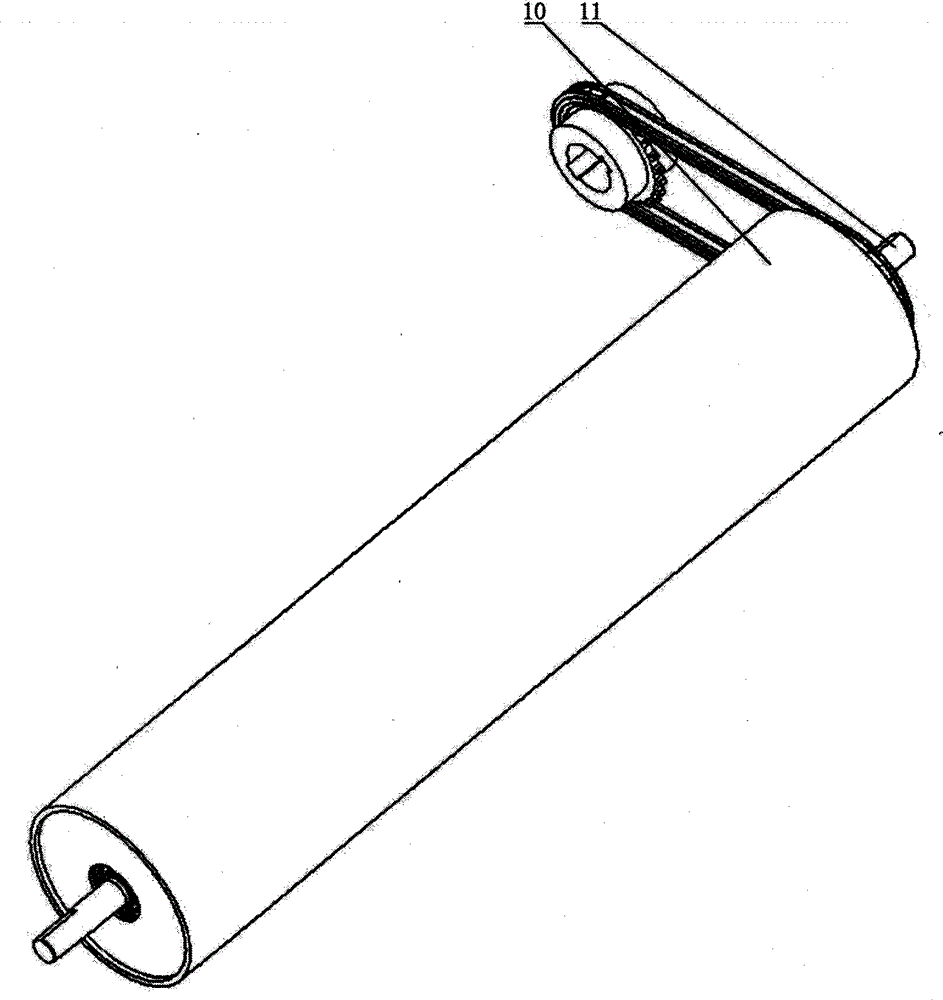

Inner frame paper fixed length conveying system and method

PendingCN109808961ARealize deliveryPrecise control of conveying speedWrapping material feeding apparatusPackaging automatic controlControl theoryDelivery system

The invention relates to the technical field of cigarette packaging, in particular to an inner frame paper fixed length conveying system. The inner frame paper fixed length conveying system is arranged on a cigarette packaging machine, and comprises a servo driving mechanism, a detector, an encoder and a controller; the servo driving mechanism is connected with a conveying roller for conveying inner frame paper and drives the conveying roller to rotate; the detector is used for detecting color codes on the inner frame paper, and the encoder is used for acquiring a main engine phase position ofthe cigarette packaging machine; and the servo driving mechanism, the detector and the encoder are all connected with the controller. The invention further relates to an inner frame paper fixed length conveying method adopting the inner frame paper fixed length conveying system. Mainly the controller determines a reference position according to an action signal of the encoder and a first color code position signal detected by the detector, and zero searching operation is completed; and the controller controls the rotating speed at which the servo driving mechanism drives the conveying rollerto rotate according to a deviation value between the color code position signal detected by the detector and a reference position, so that the conveying speed of the inner frame paper meets the fixedlength conveying requirement. High-precision fixed length conveying can be achieved.

Owner:SHANGHAI TOBACCO MACHINERY

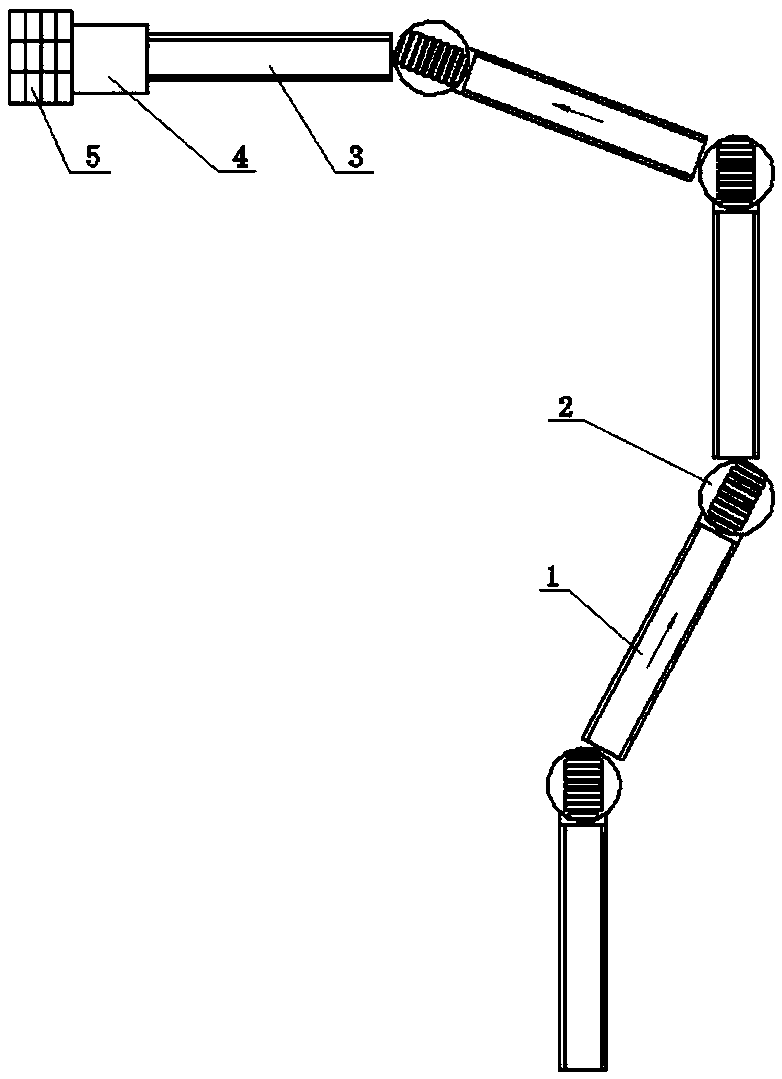

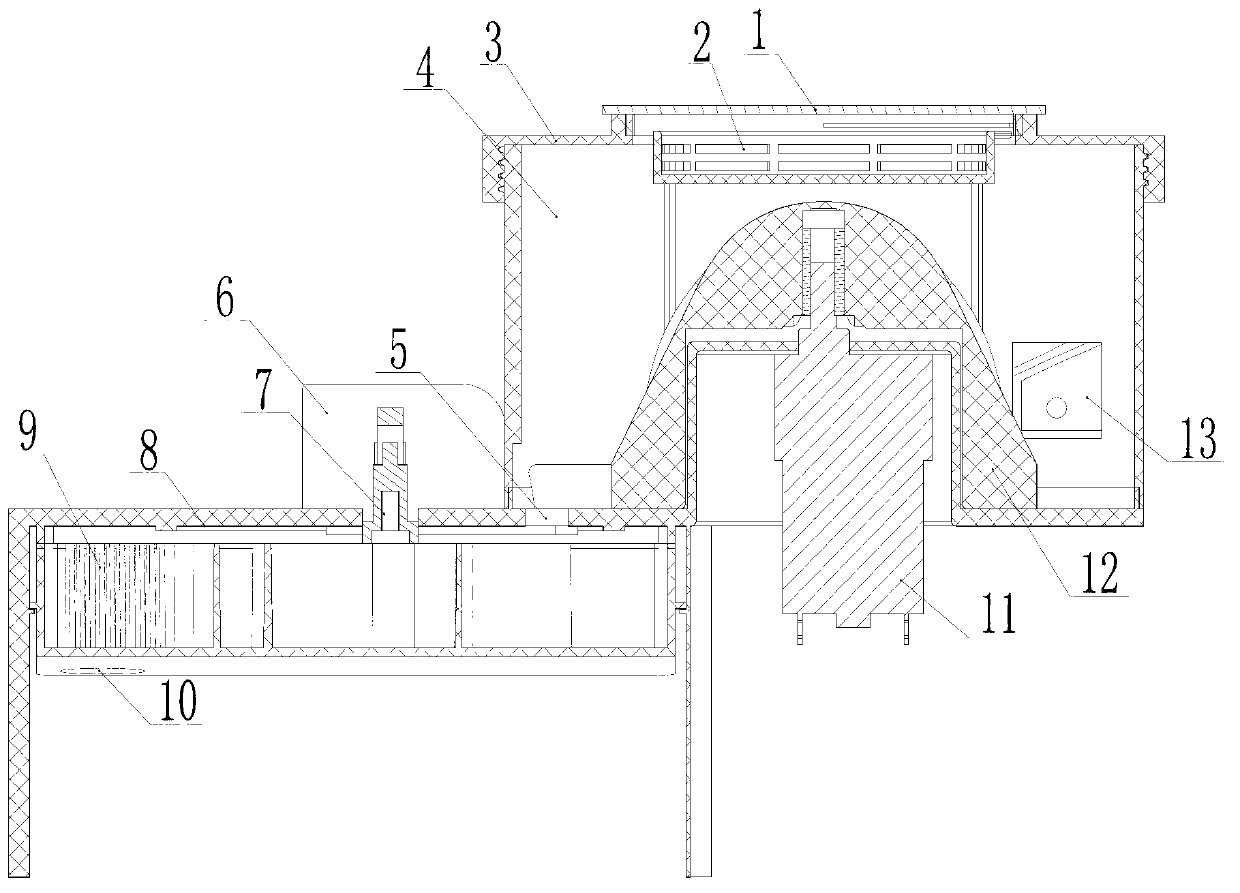

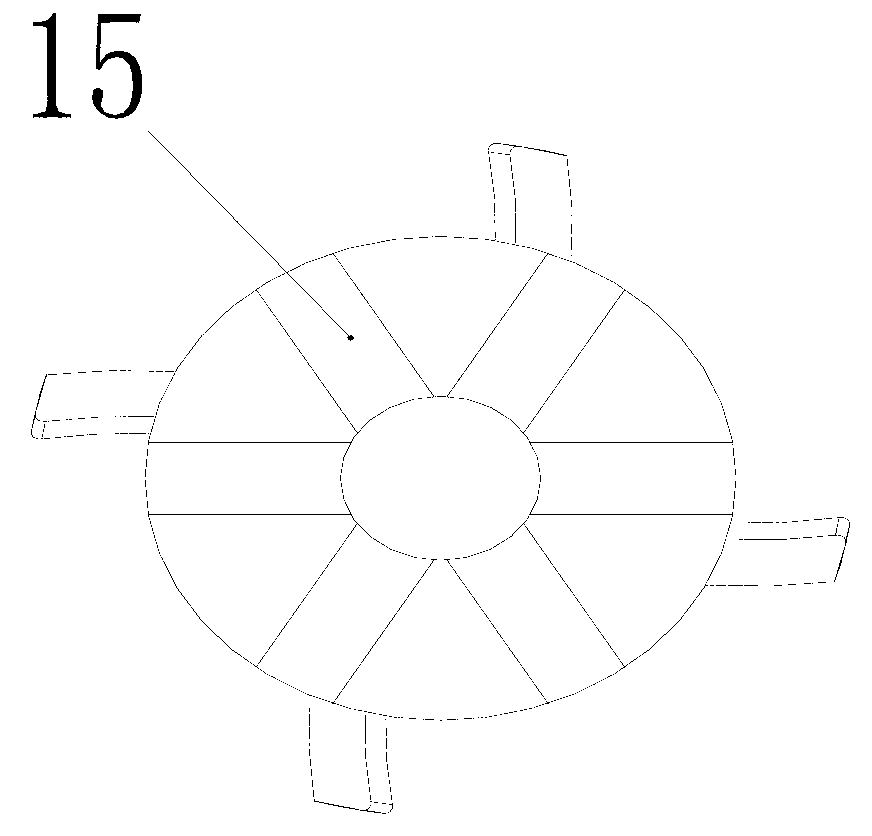

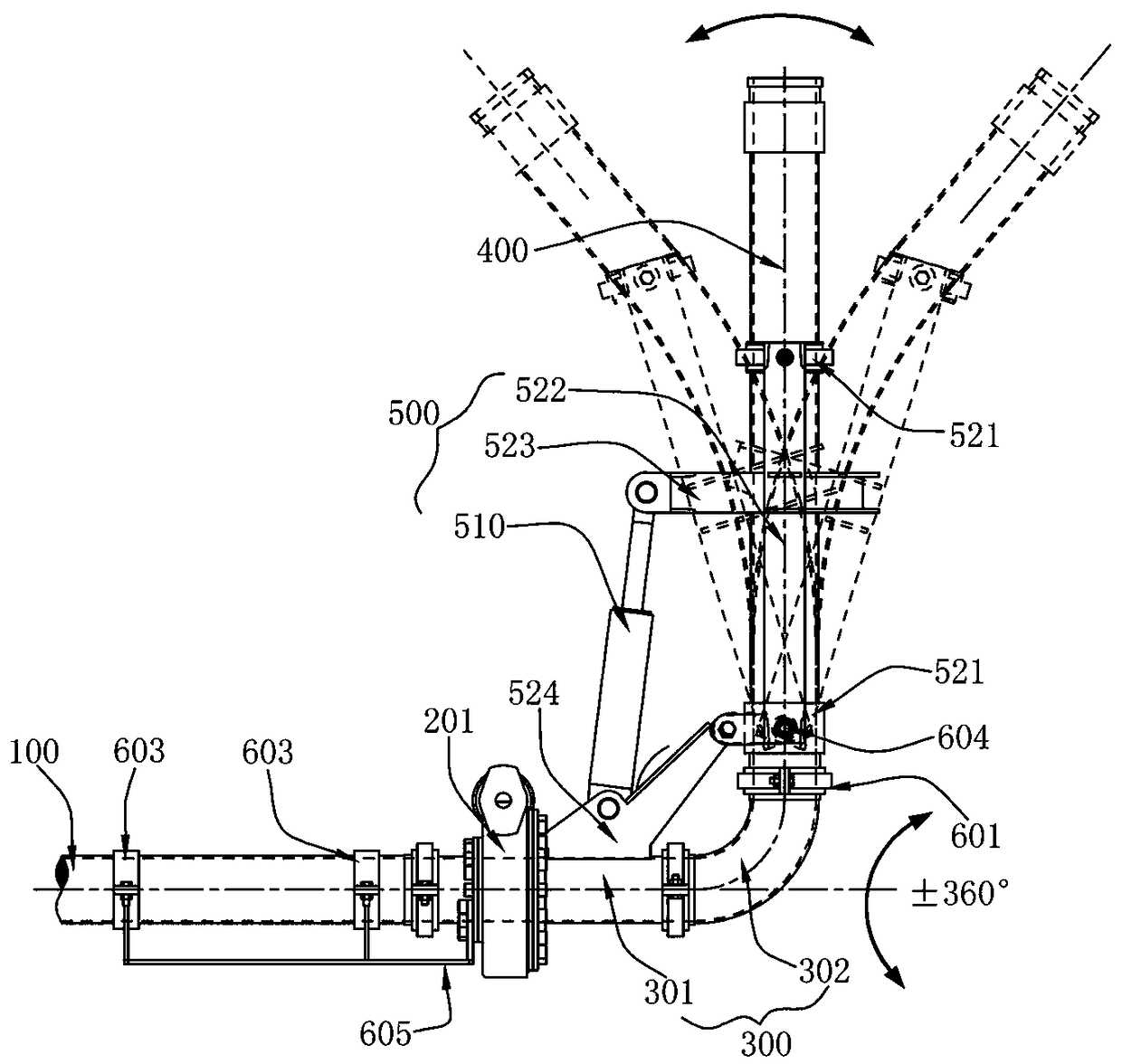

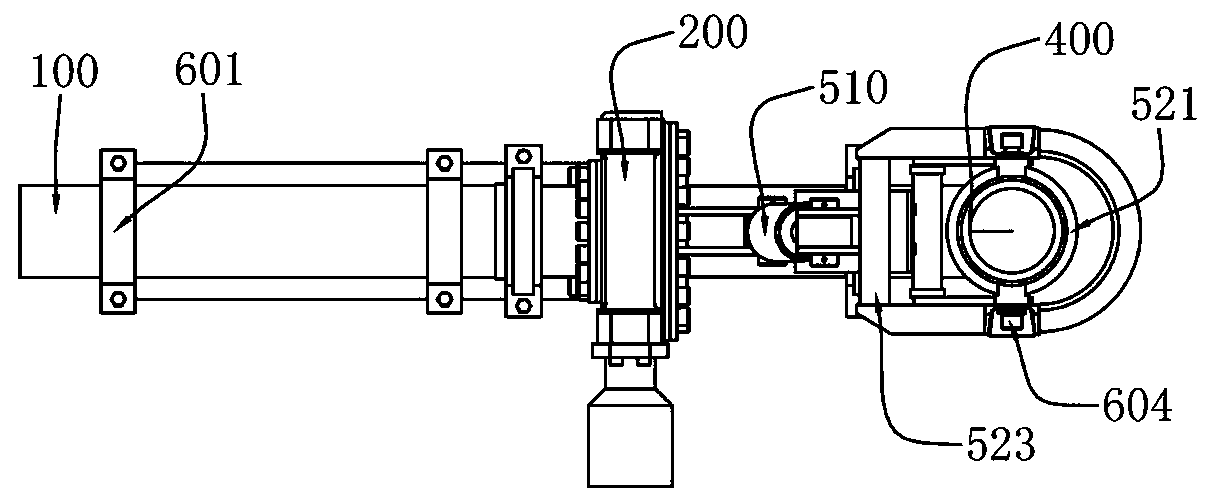

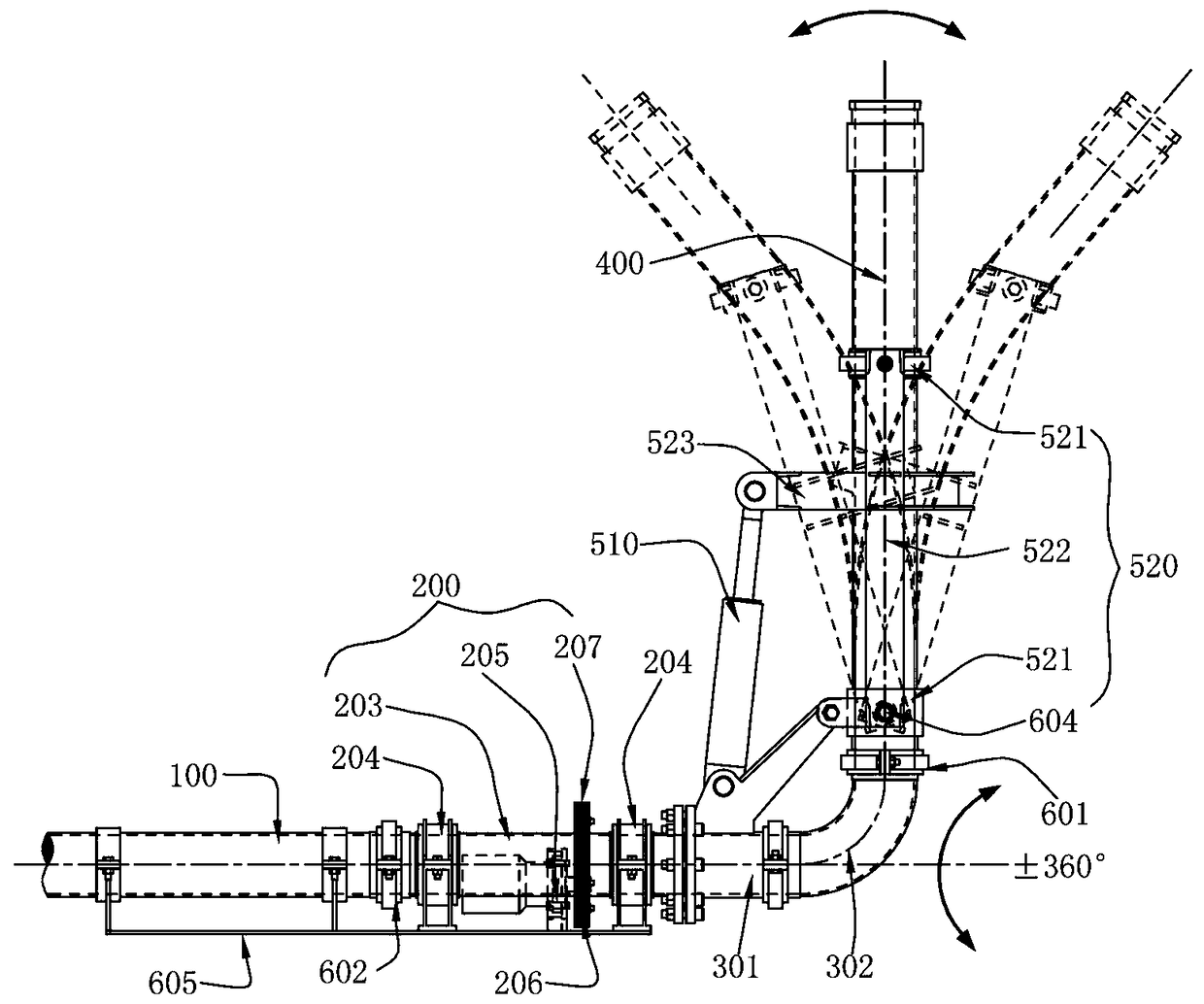

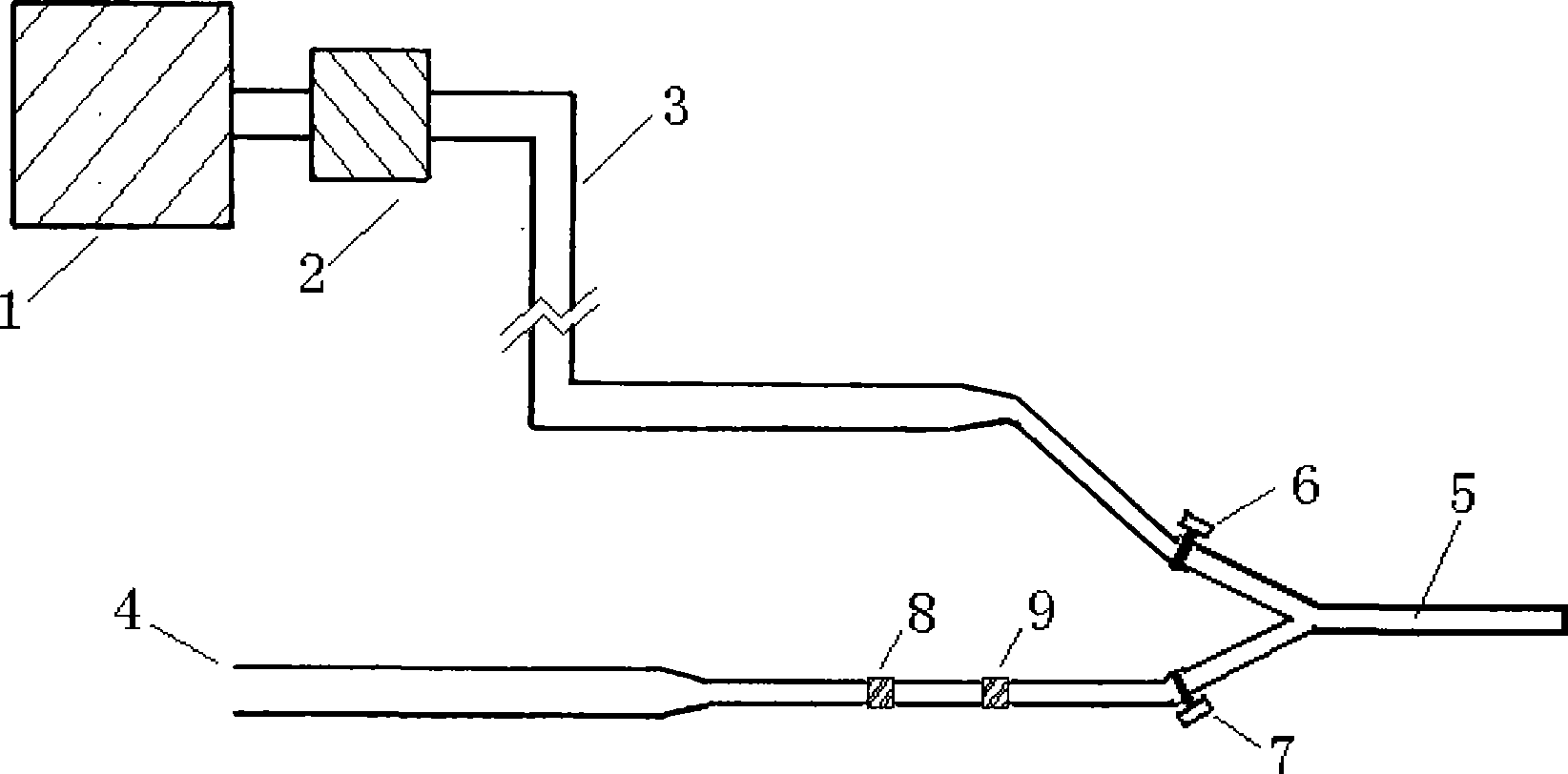

Terminal mechanism for concrete distributor and multi-degree-of-freedom concrete distribution system

PendingCN108716411ARealize multi-degree-of-freedom adjustmentMeet delivery requirementsUnderground chambersTunnel liningGyrationDistribution system

The invention belongs to the technical field of the conveying of concrete during tunnel lining and relates to a terminal mechanism for a concrete distributor and a multi-degree-of-freedom concrete distribution system. The terminal mechanism is connected to a discharging pipe of the concrete distributor and comprises a movable pipe, wherein the movable pipe is communicated with the discharging pipeand is supported at the end part of the discharging pipe through a gyration assembly; a distribution flexible pipe is communicated with the movable pipe, and a swinging assembly is arranged between the movable pipe and the distribution flexible pipe; and the gyration assembly is used for driving the movable pipe and the distribution flexible pipe to execute an gyration action, and the swinging assembly is used for driving the distribution flexible pipe to execute an floatation swinging action relative to the movable pipe. According to the terminal mechanism, the multi-degree-of-freedom adjustment of concrete can be realized on a hemisphere surface, so that the practicability of the concrete distributor is greatly improved, the terminal mechanism can meet the concrete conveying requirementduring the secondary lining of a tunnel, the movement of the whole equipment and the adjustment of the concrete conveying direction are reduced, and the working efficiency is effectively improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

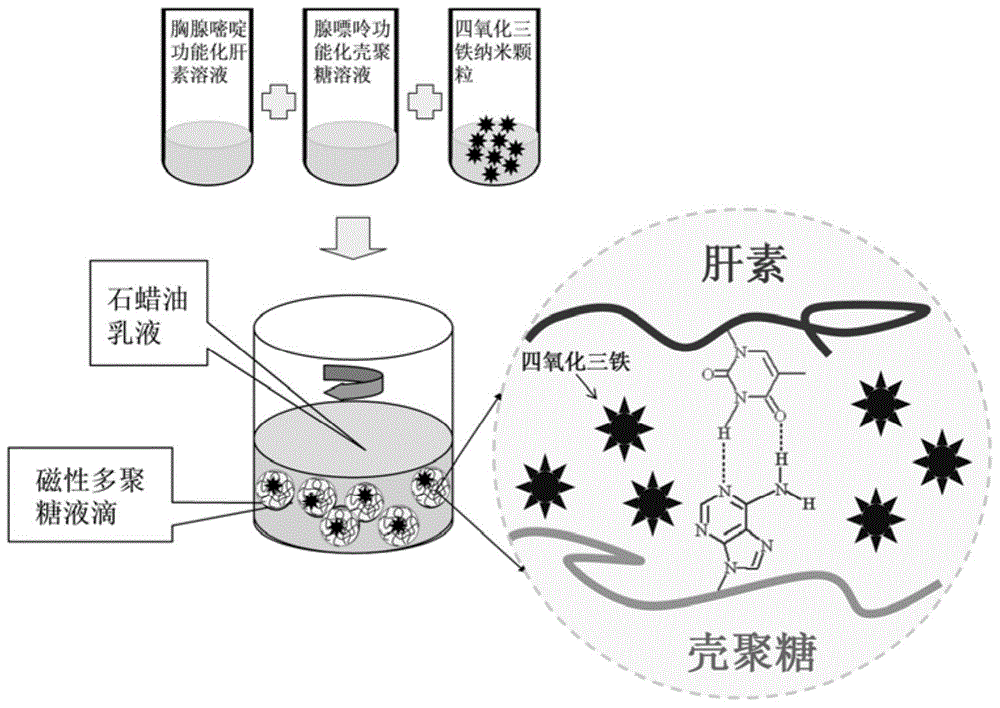

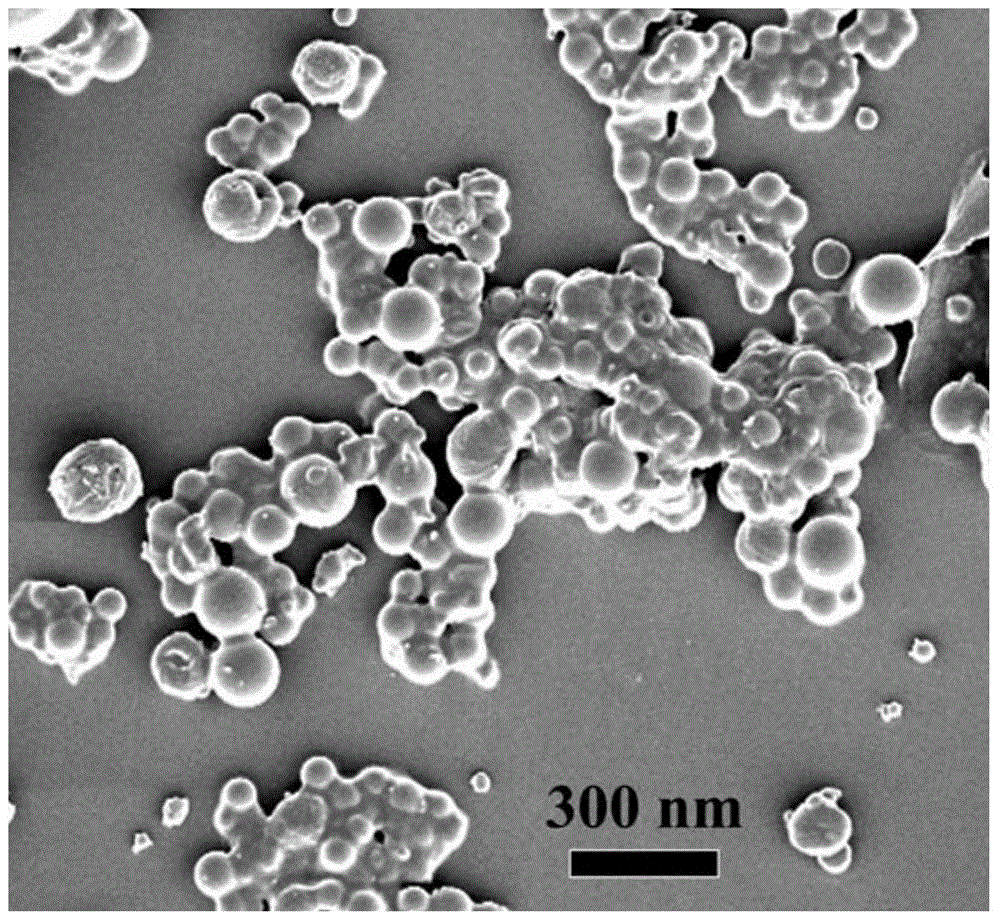

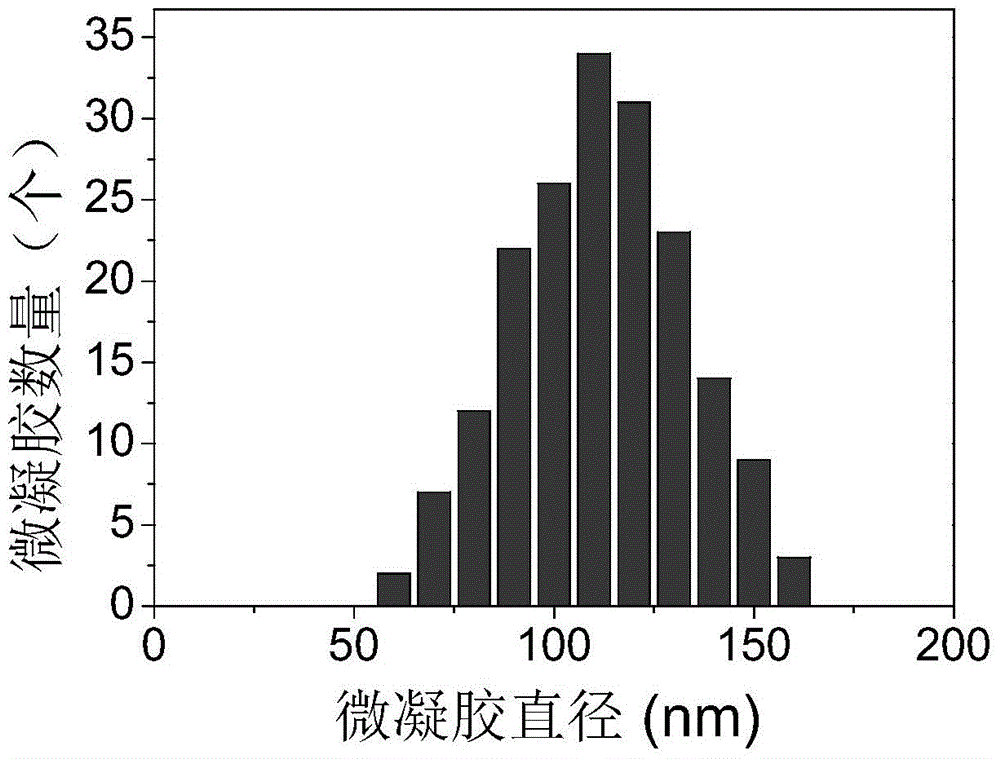

Magnetic polysaccharide nanometer gel material preparation method

InactiveCN105327356AMaintain biological activityReduce usageAerosol deliveryInorganic non-active ingredientsDrug biological activityRegenerative medicine

The invention discloses a magnetic polysaccharide nanometer gel material and a preparation method thereof, and provides a targeting controlled release means for a cell growth factor based on magnetic force effect. According to the invention, magnetic ferriferrous oxide nano particles are embedded in polysaccharide nano gel, base pairing crosslinking of the nano gel can be realized, and the magnetic polysaccharide nanometer gel material with a stable structure can be obtained. In the invention, the cell growth factor enables targeting controlled release by applying magnetic force externally, and usage of a chemical cross-linking agent can be avoided, biological activity of the embedded medicine can be guaranteed, and material usage security can be obviously improved. The preparation method has the advantages of simple process, easy operation, low temperature, fast solidification speed and short processing period, and has the application value on medicine controlled release, tissue engineering and regenerative medicine.

Owner:NANJING UNIV OF SCI & TECH

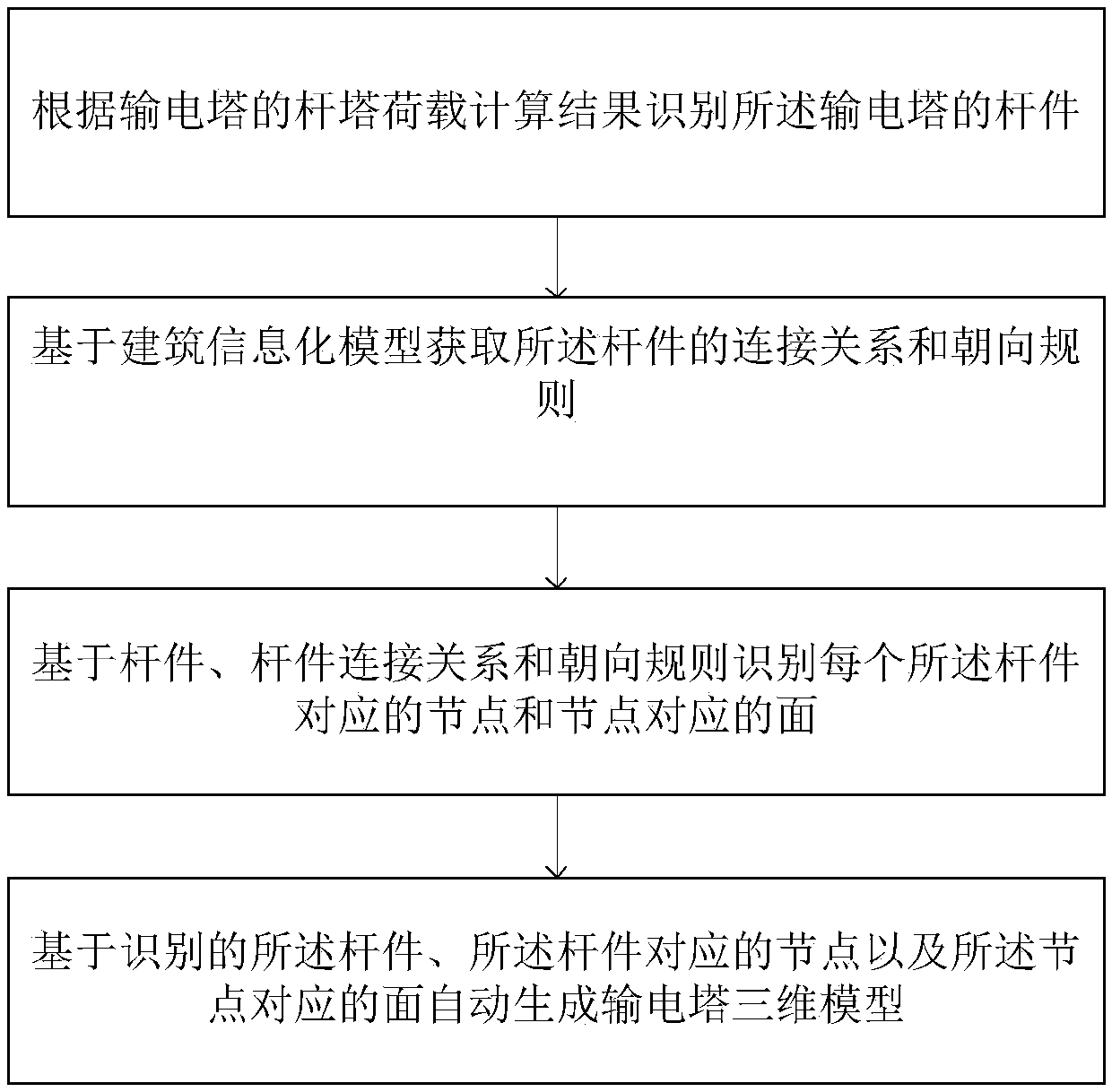

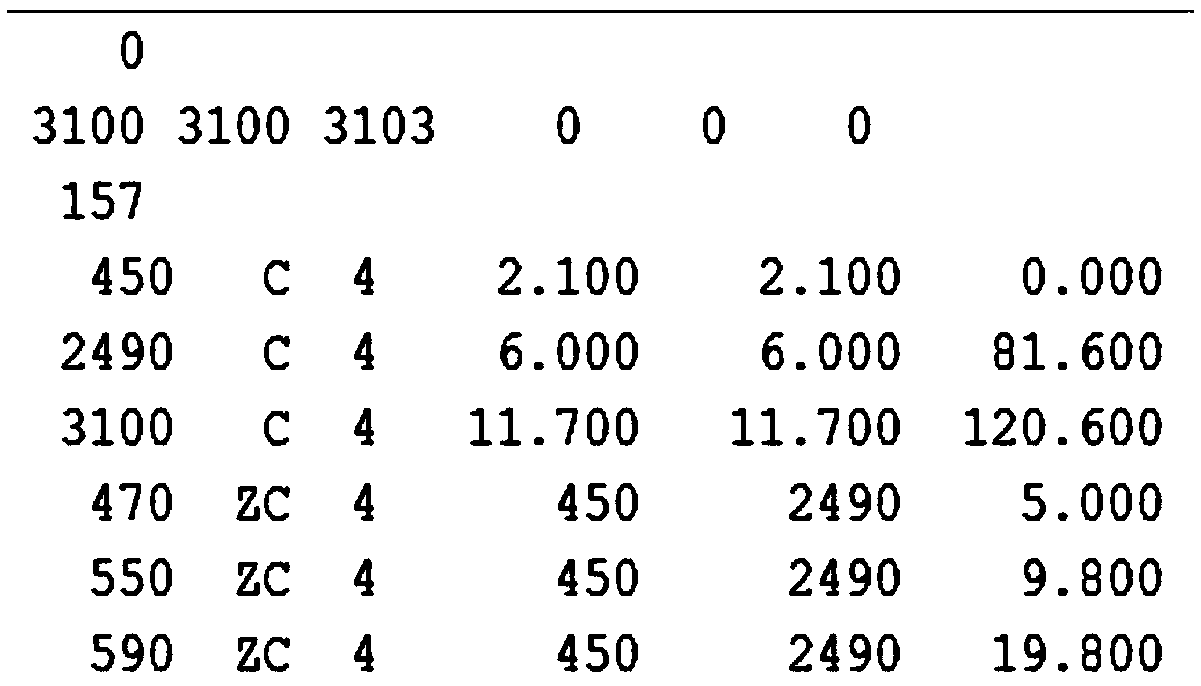

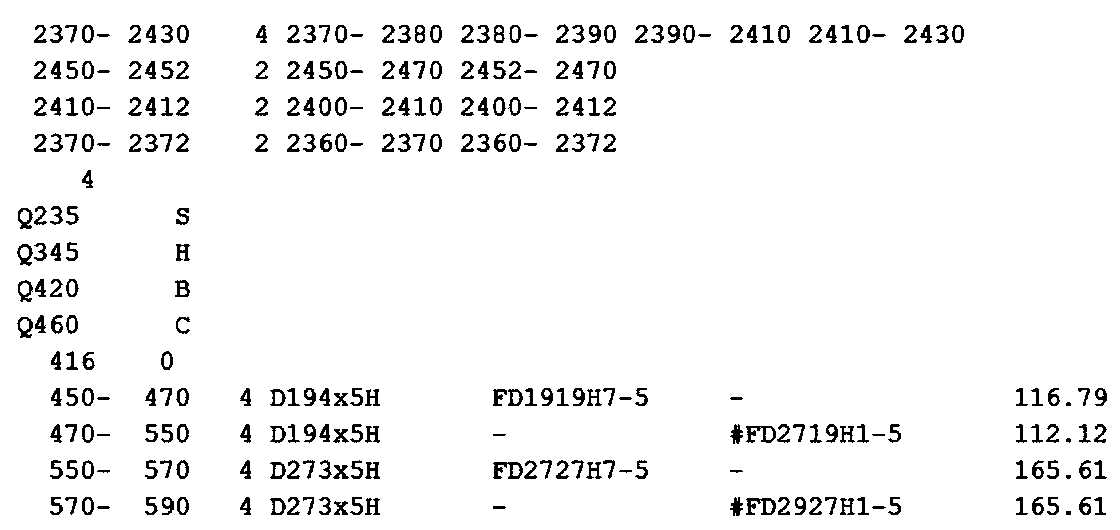

Power transmission tower automatic modeling method and system based on building information model

PendingCN110727972AImprove performanceMeet delivery requirementsGeometric CADTowersSocial benefitsTransmission tower

The invention discloses a power transmission tower automatic modeling method and system based on a building information model. The power transmission tower automatic modeling method comprises the steps: recognizing rod pieces of a power transmission tower according to a tower load calculation result of the power transmission tower; acquiring a connection relationship and an orientation rule of therod pieces based on the building information model; identifying a node corresponding to each rod piece and a surface corresponding to the node based on the rod piece, the rod piece connection relationship and the orientation rule; and automatically generating a power transmission tower three-dimensional model based on the identified rod pieces, the nodes corresponding to the rod pieces and the surfaces corresponding to the nodes. According to the technical scheme, the performance is stable, and the function meets the delivery requirement; and compared with traditional three-dimensional lofting, the workload can be effectively reduced, and very remarkable economic benefits and social benefits are achieved.

Owner:CHINA ELECTRIC POWER RES INST +2

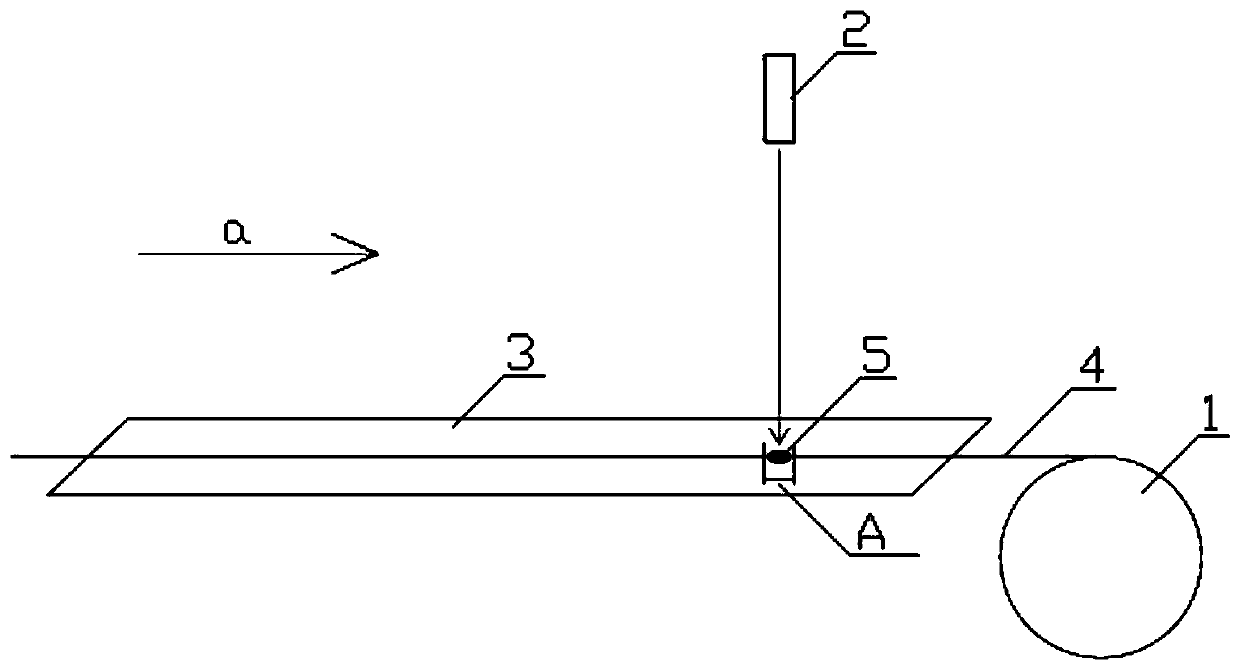

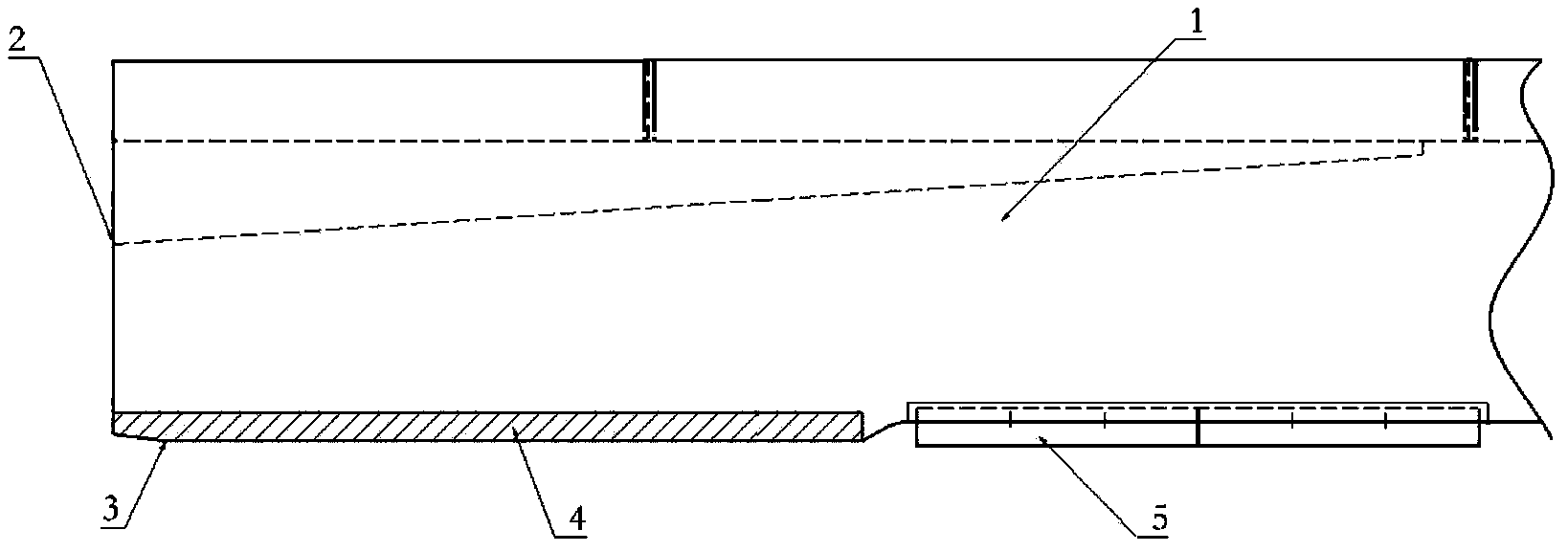

Stainless steel pipe conveying and rotating mechanism

InactiveCN106865170AChange delivery statusMeet delivery requirementsConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a stainless steel pipe conveying rotary mechanism, which comprises a frame, a transverse conveying mechanism is fixed on the rear of the top surface of the top plate of the frame, and a longitudinal conveying rotating mechanism is fixed on the left side of the top surface of the frame. Mechanism; the horizontal conveying mechanism includes two horizontal baffles parallel to each other fixed on the top rear of the top plate of the frame, between the two horizontal baffles is a conveying trough, and the frame between the two horizontal baffles The top plate of the frame is formed with a transverse moving channel, the side baffle is fixed on the top surface of the top plate of the rack, the right rear part of the side baffle is fixed on the rear horizontal baffle, the front horizontal line baffle and the side baffle There is a discharge port formed between the plates; it can automatically rotate while the stainless steel pipe is being conveyed, thereby changing the conveying state of the stainless steel pipe to meet the conveying requirements.

Owner:SUZHOU LIAORUO ELECTROMECHANICAL TECH CO LTD

High-temperature-resisting conveyer belt

ActiveCN101028888BImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

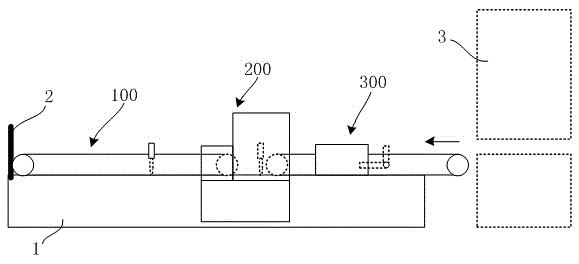

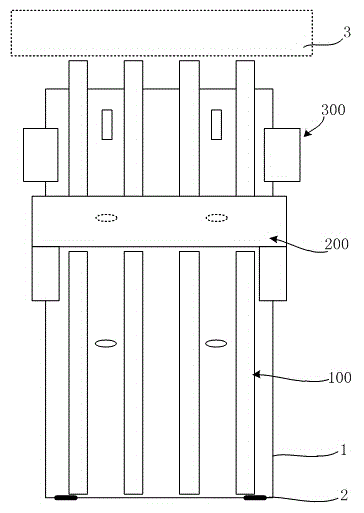

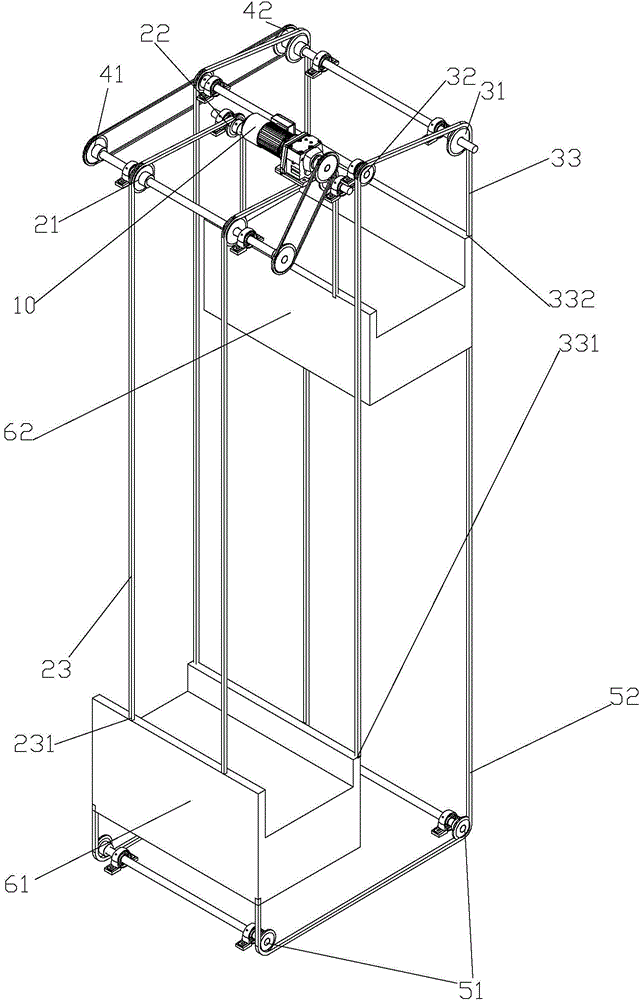

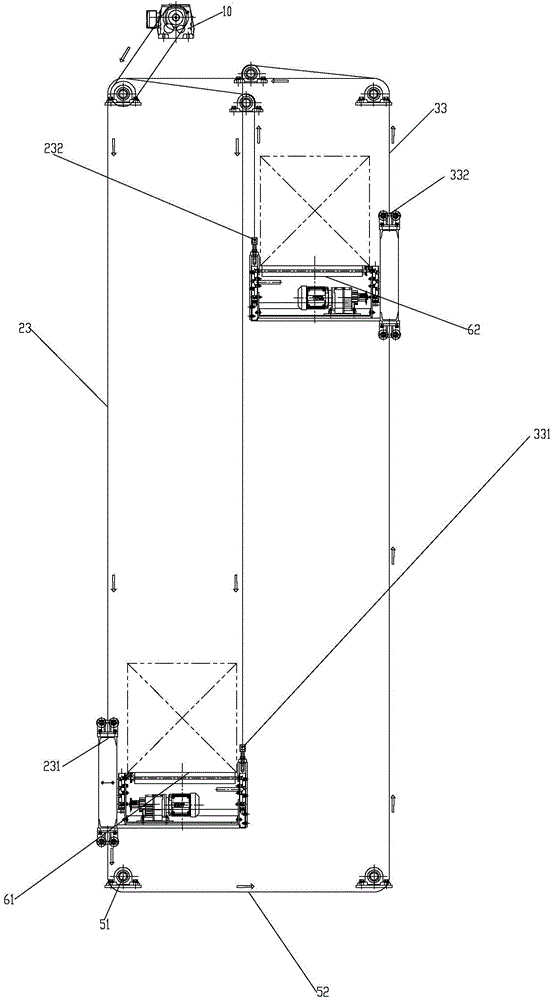

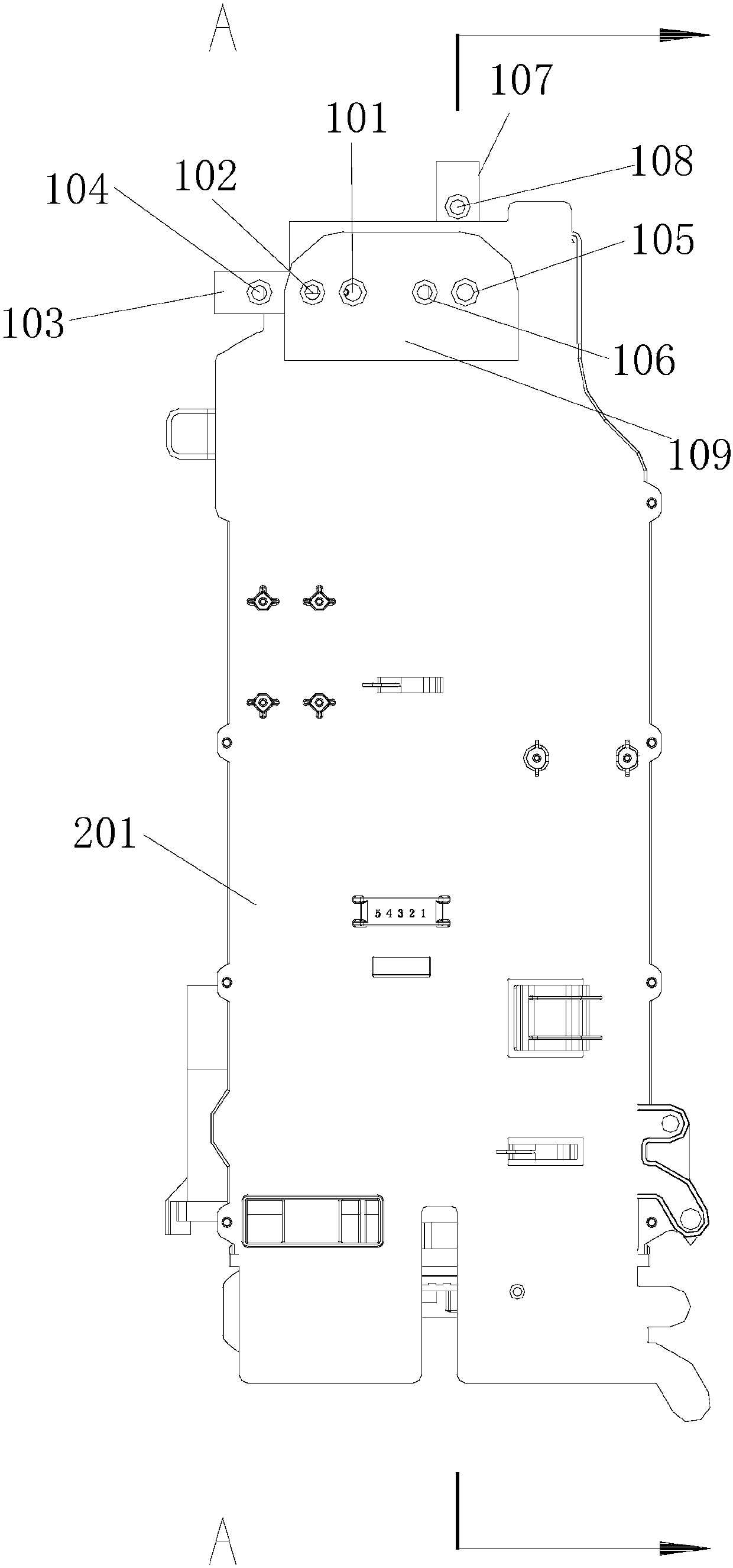

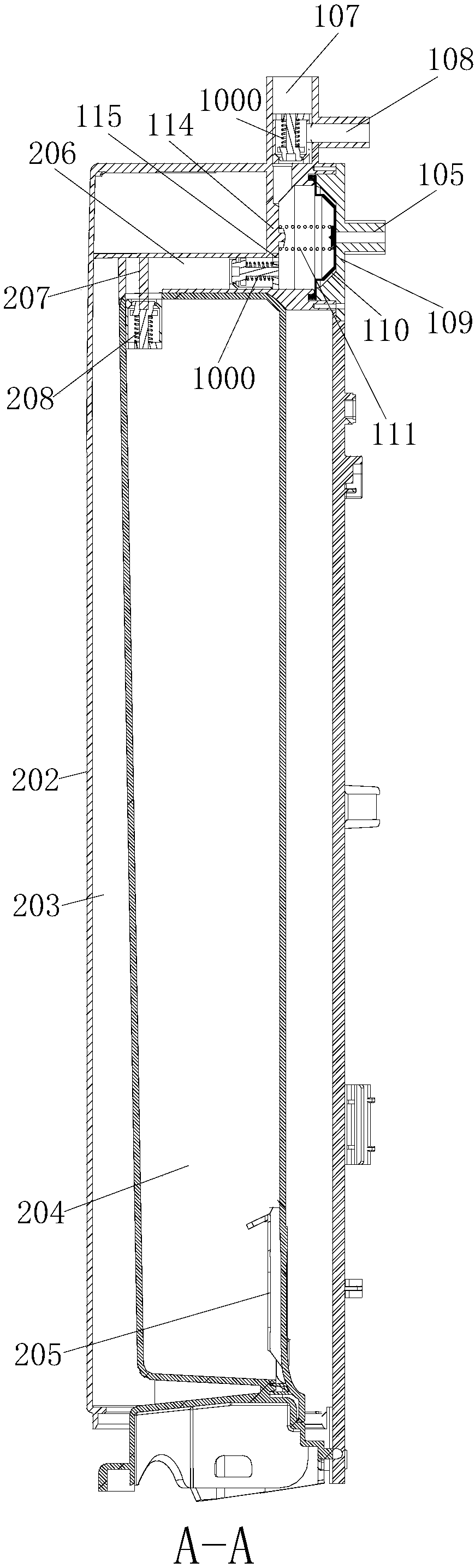

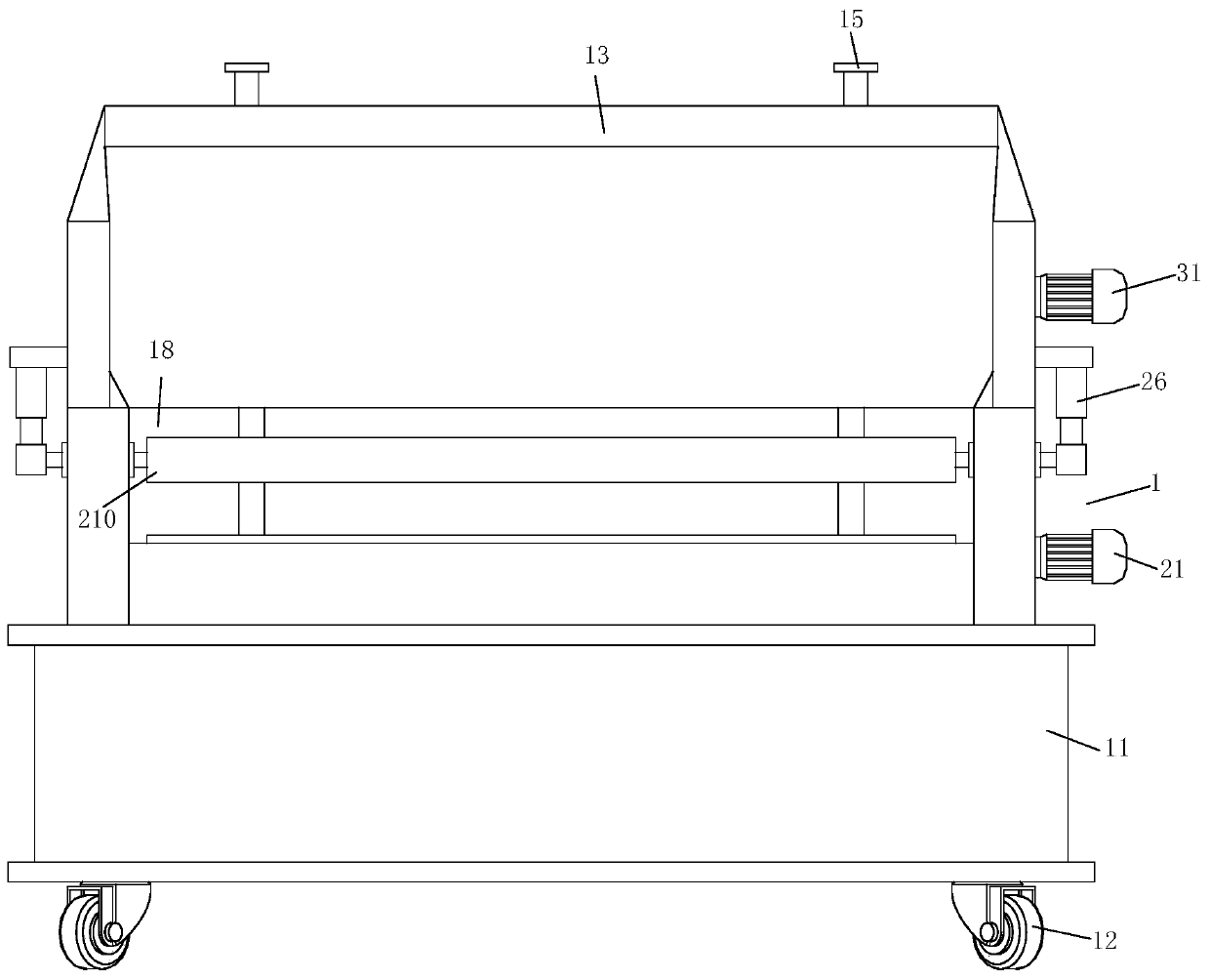

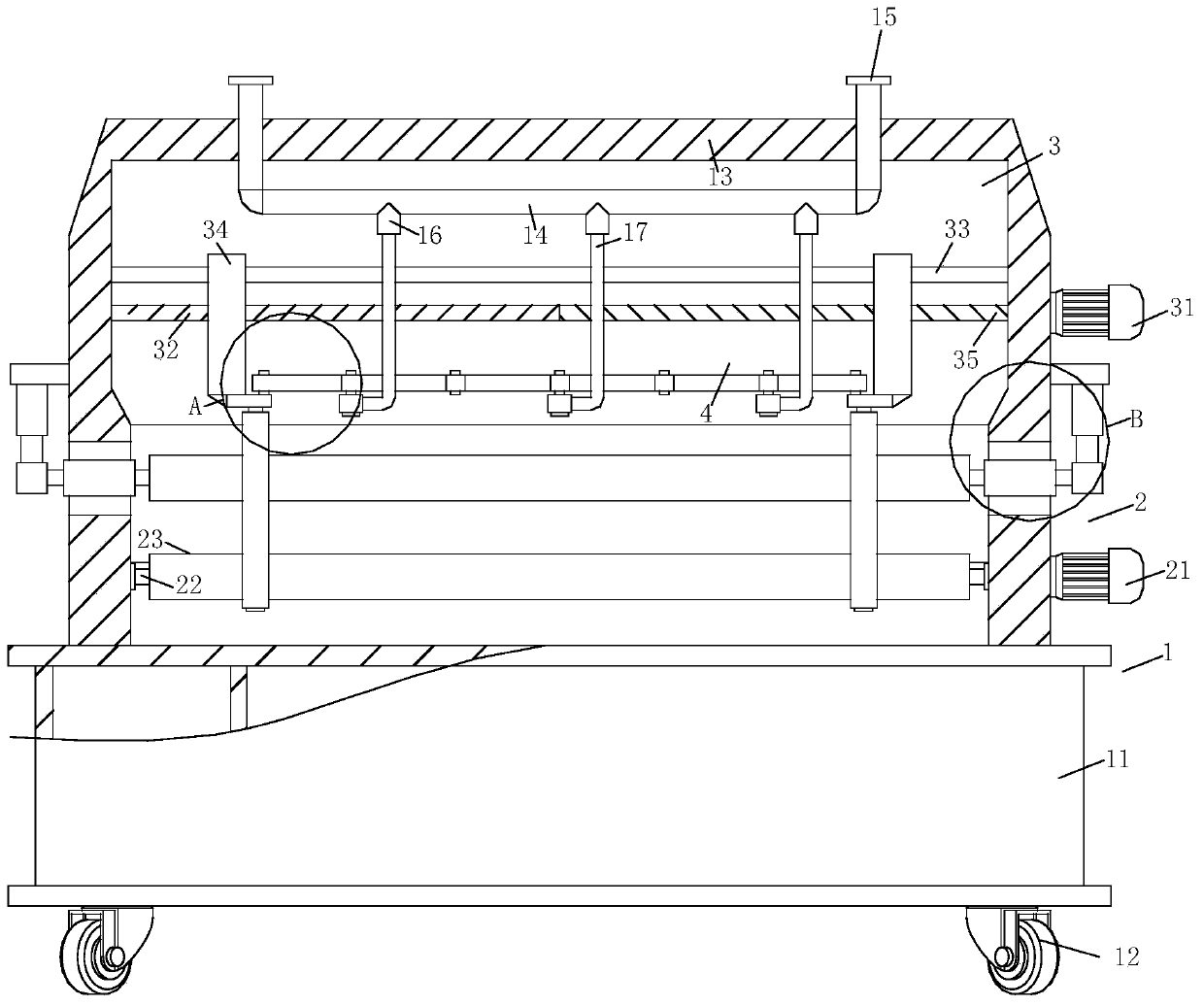

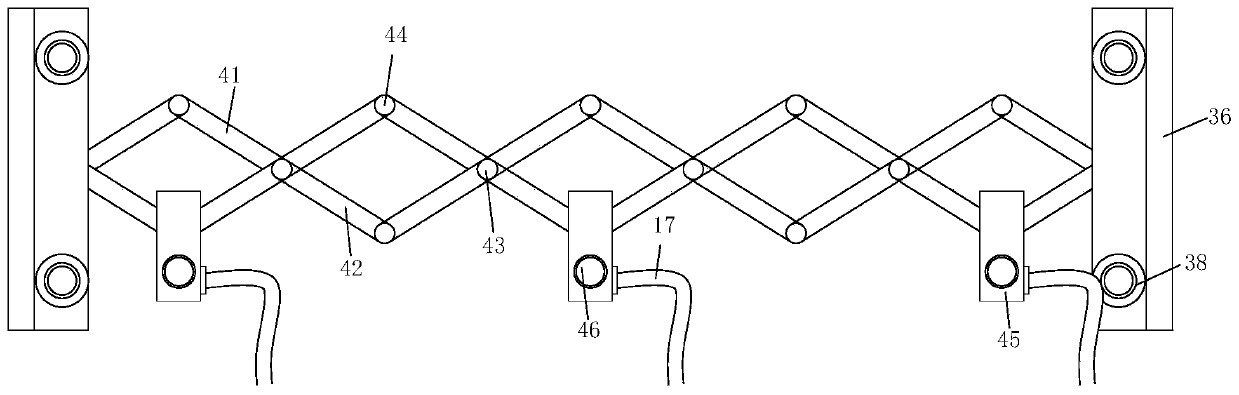

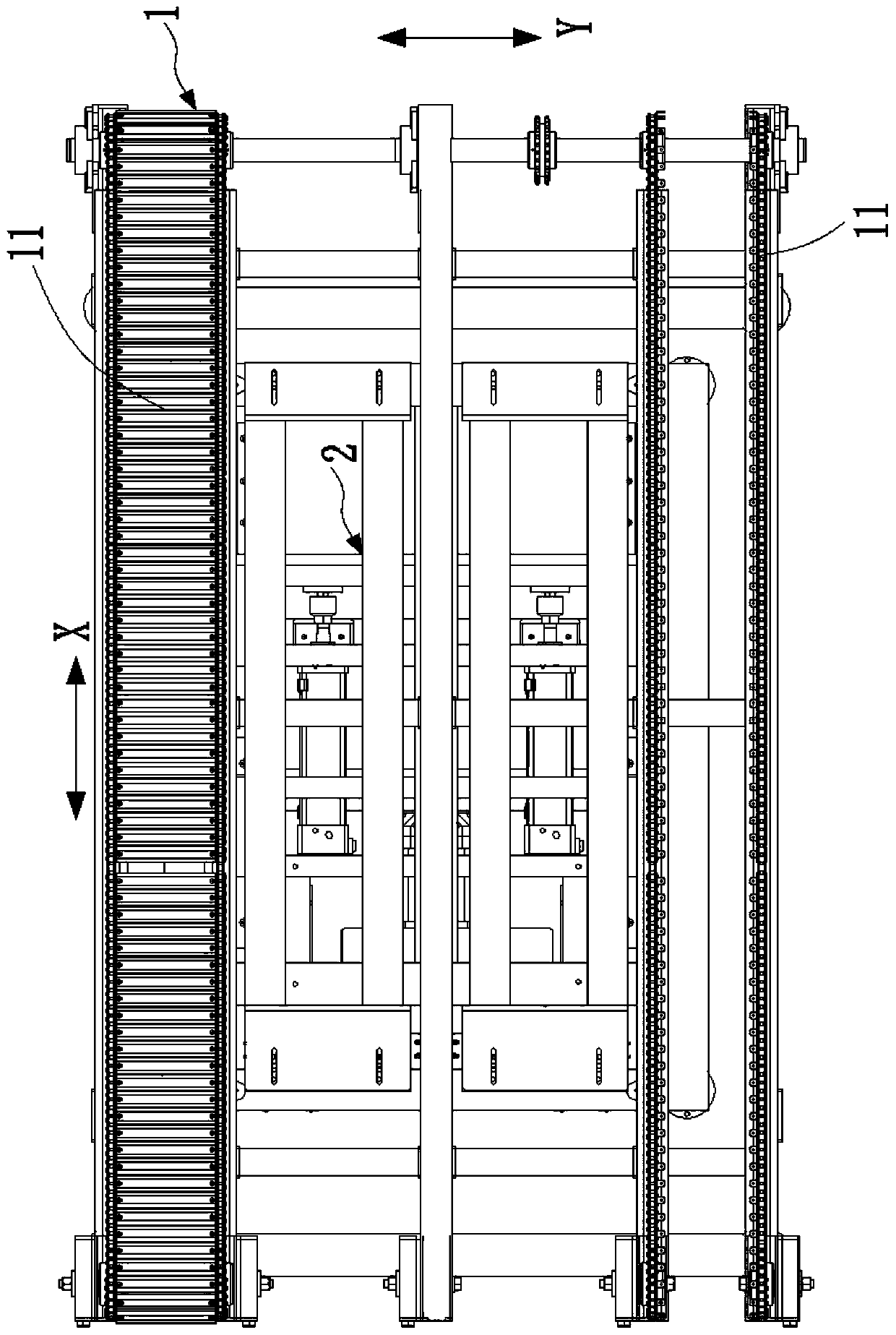

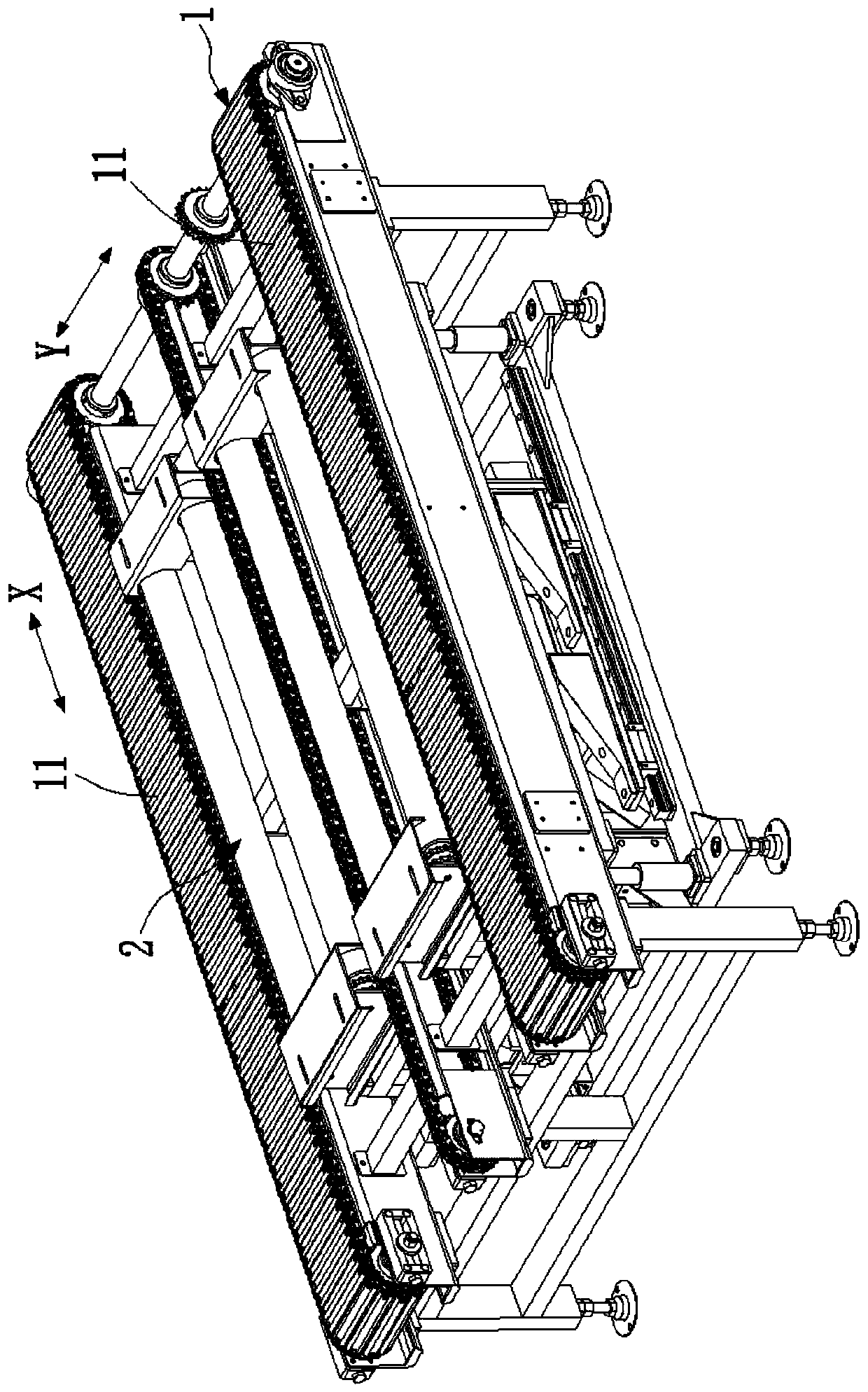

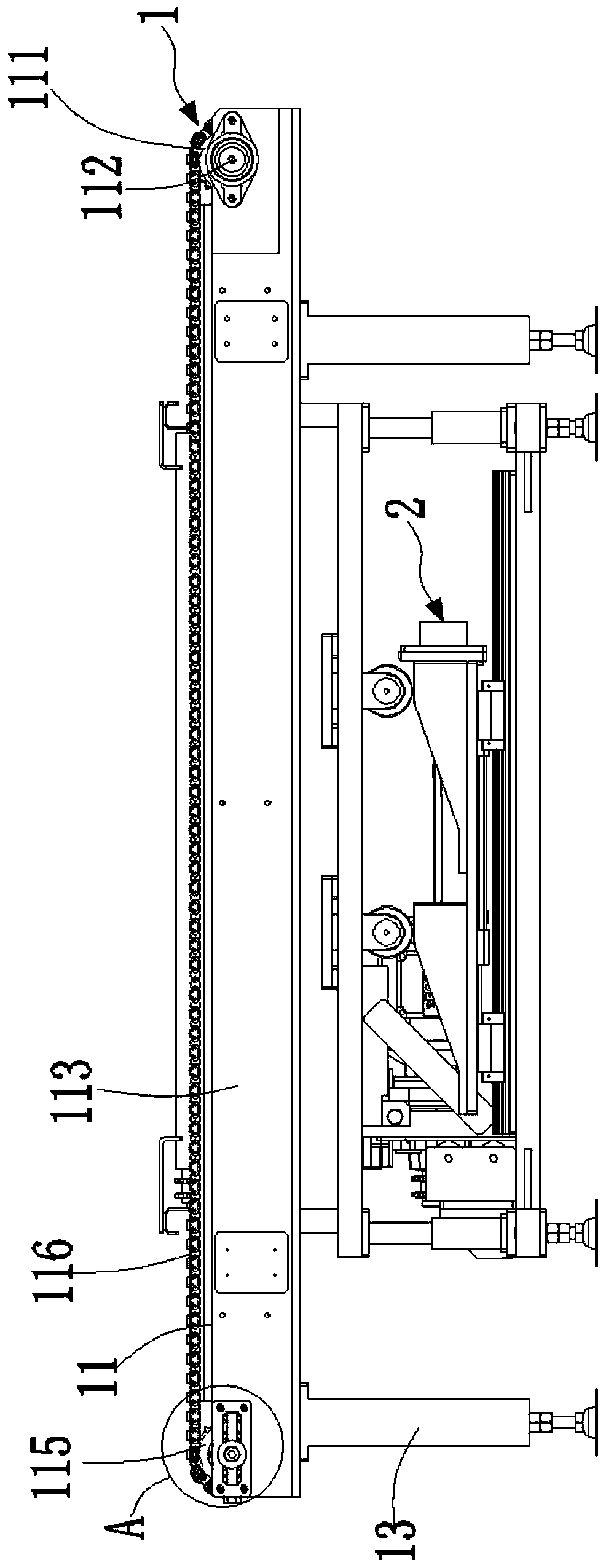

Conveying device

ActiveCN104627616AMeet delivery requirementsImprove delivery efficiencyConveyorsEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

Arrangement mechanism for corn husker

InactiveCN105875072AImplement sortingAchieve left and right swingThreshersRollersMotor driveCoupling

An arrangement mechanism for a corn husker belongs to the field of corn processing devices. The arrangement mechanism includes a metal plate curled edge large baffle plate, a spring shaft, a baffle plate shaft, a rotary sleeve, guide plates, an extension spring, a bolt hook, a rack, a baffle plate, a boosting cylinder, a boosting cylinder shaft, arrangement supports, an arrangement plate, a delivering belt, a motor, a flange coupling, a driving pulley, a driven pulley, a pulley seat, a pulley seat cover, a carrier roller, a carrier roller support and a snap spring. Corns fall into a tray from a hopper, the motor drives an eccentric shaft to allow a sieve plate to swing horizontally, and then the large ends of the corns face the same direction, automatic arrangement can be achieved, and earlier stage preparation of fresh corn husking is finished; automation is achieved in the whole process, and the efficiency is high; the feeding requirement of the corn husker can be met; and the corncob cutting delivering mechanism is efficient, practical, simple in structure, and easy to maintain.

Owner:JILIN NORMAL UNIV

Spray coating material for preventing air leakage in roadway, use method thereof and special spray gun

The invention discloses a coating material used for preventing the air leakage of a laneway, an application method and a special spray gun thereof. The components of the coating material are clay, cement, sodium silicate, glass fiber and water which are mixed, stirred and made into clay cement slurry according to certain proportion and processes. The clay cement slurry is transported to an underground spraying area by a slurry pump through a grouting pipe, and sprayed to a coal roadway wall by the special spray gun to prevent the air leakage of the laneway. The clay cement slurry has strong suspension property, short initial concreting time, certain strength after solidification, rinse-resistance, not easy craze, excellent air partition performance, strong flame-retardant property, ideal effect of preventing the air leakage of the laneway, quick shotcreting process operations, safety and simplicity, is applicable to the spraying to the coal roadway walls of mines with serious hazards, and prevents the air leakage of the laneway so as to reduce the possibility of the occurrence of spontaneous combustion.

Owner:冀中能源股份有限公司葛泉矿

Repair method of composite main paddle with hinge moment variance

ActiveCN104340378AMeet delivery requirementsThe repair method is feasibleAircraft maintainanceManufacturing technologyDynamic balance

The invention relates to the technical field of helicopter paddle manufacture, in particular to a repair method of a composite main paddle with hinge moment variance. A method for repairing the rear edge of the paddle to compensate the pneumatic force of the paddle is proposed through data analysis and analogy tests according to the characteristics of the structure and pneumatic force of the main paddle by analyzing the pneumatic principle and structure of the main paddle. By changing the laying mode of carbon cloth and glass cloth on the rear edge of the main paddle to influence the upward or downward moment of the paddle, the moment value of the main paddle is changed and meets the requirement; after the main paddle with the hinge moment variance is repaired by the method, through verification, the repair method is feasible, effective and strong in operability, and various performance indexes all meet the paddle delivery requirements; the basis is provided for repairing the main paddle with unqualified dynamic balance.

Owner:HARBIN

Releasing device for clothing treating agent, washing machine and control method of releasing device

ActiveCN109750456ARealize automatic deliveryRealization of the principle of automatic deliveryOther washing machinesControl devices for washing apparatusLaundry washing machineNursing care

The invention provides a releasing device for a clothing treating agent, a washing machine and a control method of the releasing device. The releasing device for the clothing treating agent includes ashell, the shell is internally provided with two or more hollow cavities, and a flexible separation body is installed in each hollow cavity in a sealed mode to separate each hollow cavity into a water inlet cavity and a liquid storage cavity; a water inlet end communicating with the water inlet cavity and a pressure relief end are arranged on the positions, corresponding to each hollow cavity, ofthe shell correspondingly, and each water inlet end communicates with a water inlet pipe of the washing machine; liquid discharging ends communicating with the liquid storage cavities are arranged onthe positions, corresponding to the hollow cavities, of the shell correspondingly, and the liquid storage cavities are filled with the clothing treating agent; and incoming water of the washing machine enters the water inlet cavities from the water inlet ends, squeezes the flexible separation bodies to deform to the liquid storage cavities, and discharge the clothing treating agent holding in theliquid storage cavities from the liquid discharge ends. According to the releasing device for the clothing treating agent, it can be ensured that residue is avoided in the adding processes of variousdetergents and nursing agents, the problem that the different detergents and nursing agents contaminate each other can be solved, and the washing effect of clothes is effectively improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

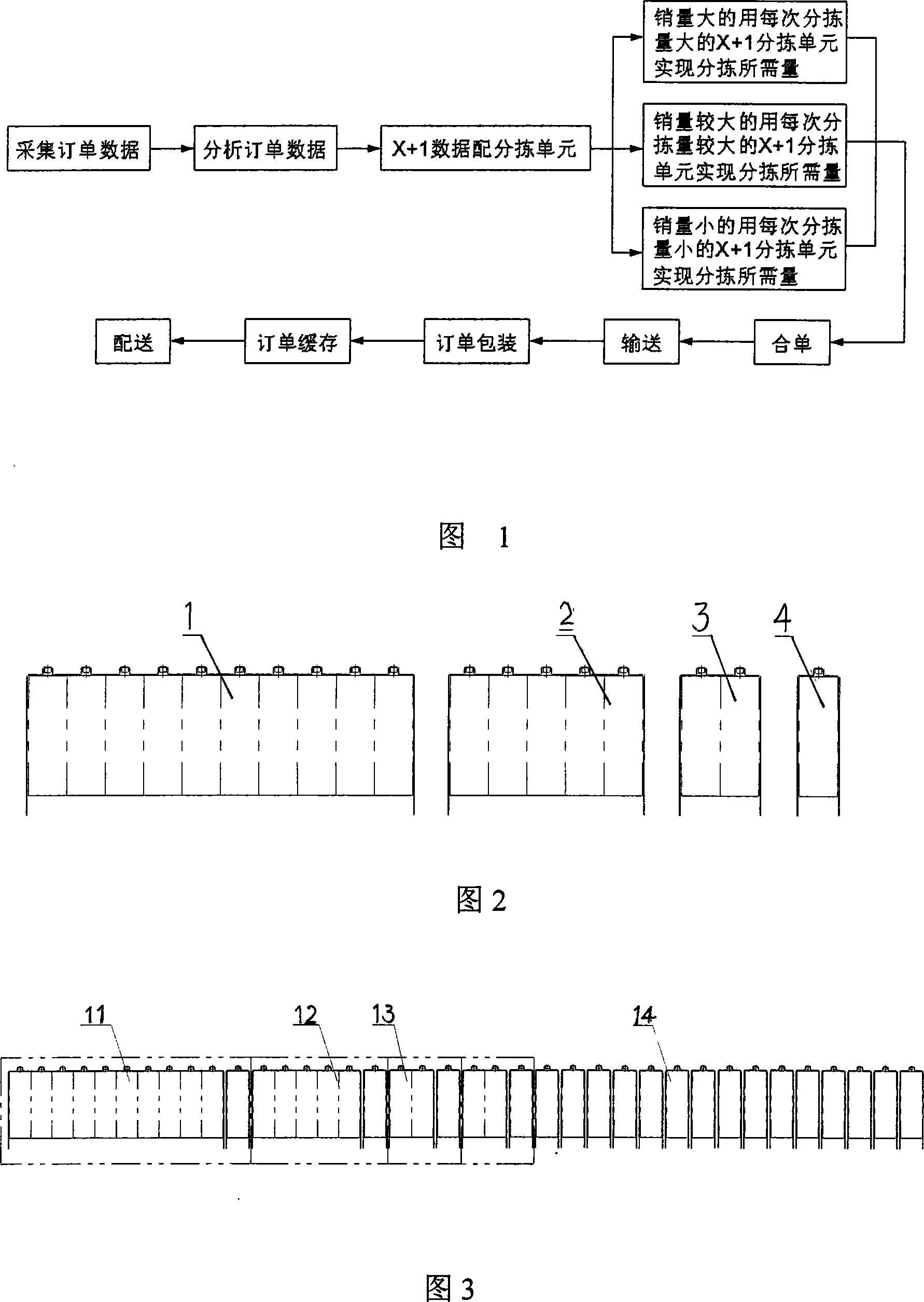

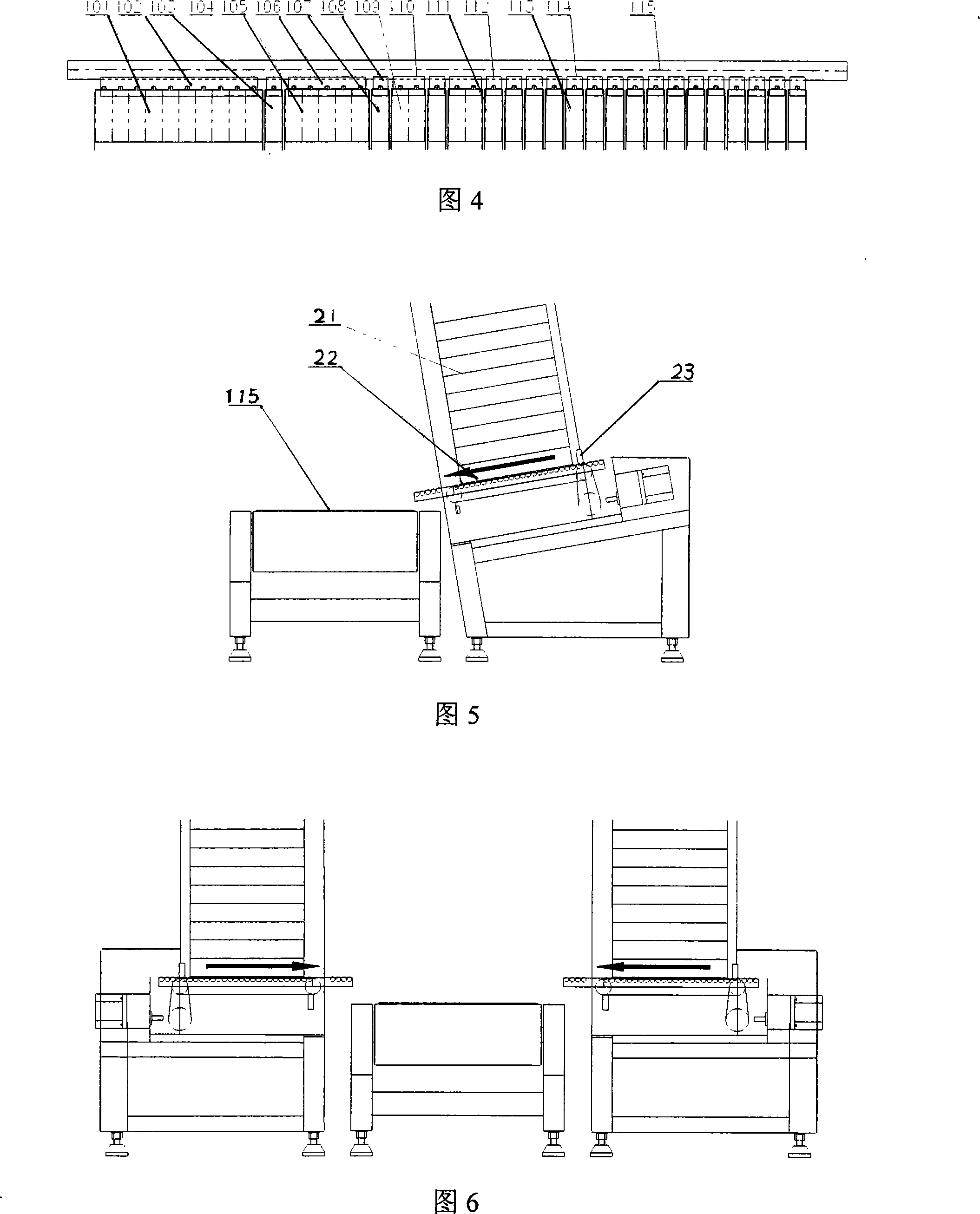

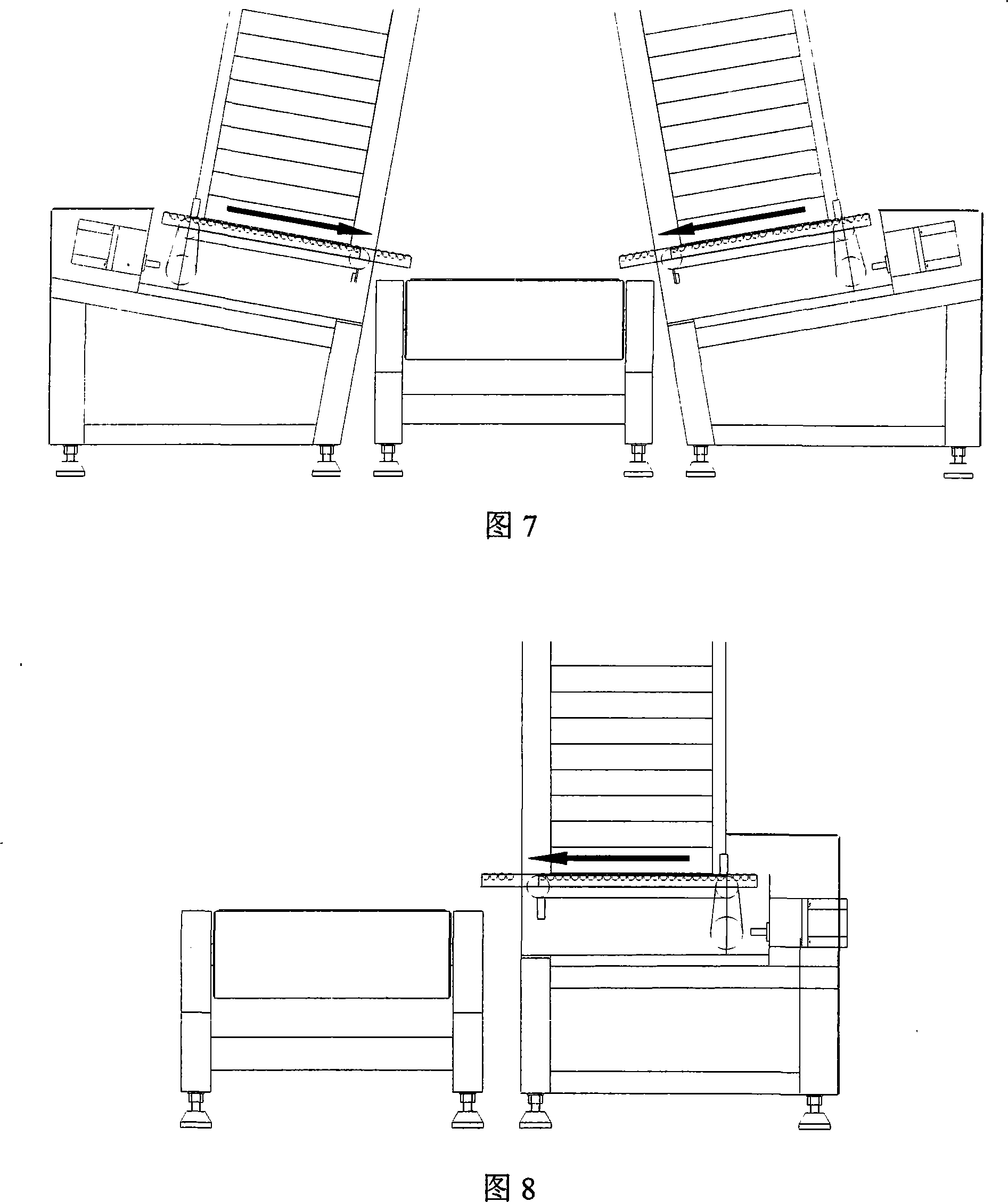

Dispensing order automated sorting, grouping and goods-distribution process

InactiveCN101236628AMeet delivery requirementsImprove work efficiencyLogisticsCommerceProduction lineAutomatic control

The present invention discloses an automatic separation order-organizing freight-distribution production process for distribution orders, in particular to separation freight-organizing production process method in cigarette sale distribution. The production process comprises: A. according to order product amount ni, using the separation characteristic number X of unit separation conveyer equipment which is greater than 1 step by step from greater to smaller, to be divided by ni to obtain the unit separation conveyer equipment integral times larger than 1 as an optional separation conveyer equipment; B. if having no remainder, setting a combined order conveyer equipment to spatially configure with the optional unit separation conveyer equipment; C. if having remainder, arranging a unit separation conveyer equipment with a characteristic number which is 1 to spatially configure with the combined order conveyer equipment and the optional unit separation conveyer equipment; D. setting the combined order conveyer equipment and a set of unit separation conveyer equipment with different separation characteristic numbers to combined into a quick automatic separation production line. After unitization of the separation conveyer equipment of each separation amounts Xj, the production process can be flexibly combined into various automatic separation lines, and a plurality of automatic separation lines can be combined into a separation system of a logistic distribution center to realize high efficiency of automatic separation distribution. The entire separation process adopts a central control system to automatically control, and the separation process meets the production requirements of product distribution and separation work with informationization, digitization, large scale and low running cost.

Owner:冉文学

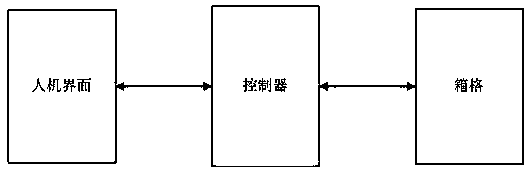

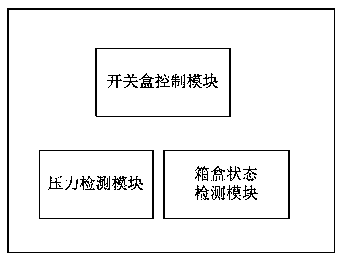

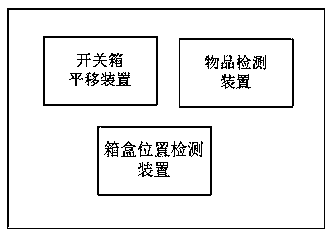

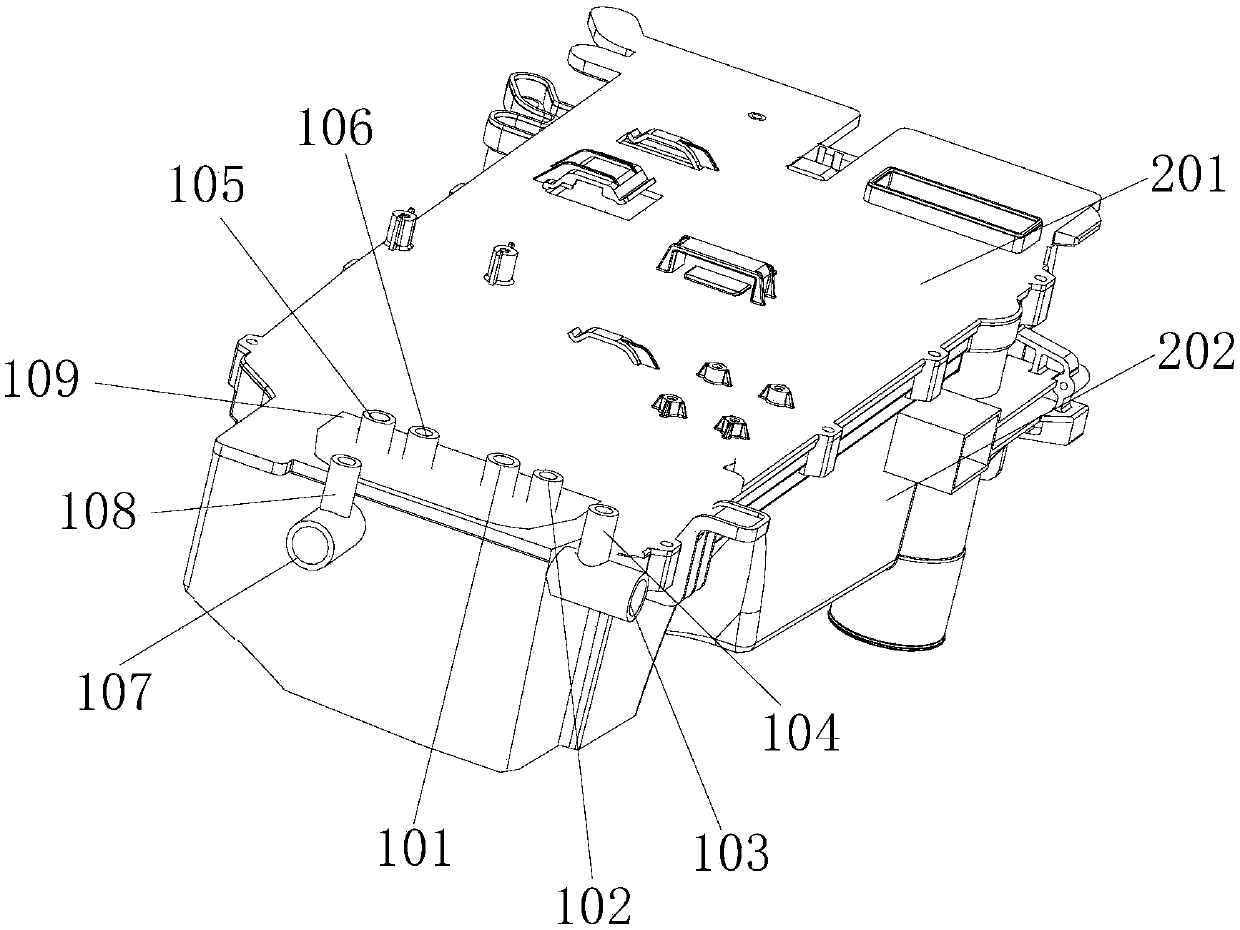

Drawer type double-surface locker control system and control method thereof

ActiveCN105366153APrivacy protectionEasy to installCabinetsDischarging meansPush outHuman–machine interface

The invention discloses a drawer type double-surface locker control system and a control method thereof. The drawer type double-surface locker control system comprises a man-machine interface, a controller, a box body and a plurality of cases, wherein the cases are installed on the box body in a sliding mode; the man-machine interface is used for obtaining information input by a user and sending the information to the controller; the controller controls the corresponding case to be pushed out or drawn back from a case outlet in the front surface of the box body or from a case outlet in the reverse surface of the box body after judgment according to the received information. The drawer type double-surface locker control system and the control method thereof can realize two-surface use of a locker, mail inputting and taking motions can be carried out on two surfaces of the locker, and requirements in some special occasions and work environments can be totally met.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

Storage and feeding device for garment treatment agent and washing machine

ActiveCN109868619AConnectivity simplificationSimple structureOther washing machinesTextiles and paperEngineeringLiquid storage

The invention provides a storage and feeding device for a garment treatment agent and a washing machine. The storage and feeding device for the garment treatment agent comprises a storage device and afeeding device which are integrally arranged; the storage device comprises a storage box for storing the garment treatment agent; the feeding device is provided with a hollow cavity, and a flexible partition body is hermetically installed in the hollow cavity so as to divide the hollow cavity into a water inlet cavity and a liquid storage cavity; the liquid storage cavity is provided with a liquid inlet end and a liquid outlet end, and the liquid inlet end is communicated with the storage box; water entering the washing machine flows in / out of the water inlet cavity for extruding the flexiblepartition body to deform towards the liquid storage cavity, and the garment treatment agent placed in the liquid storage cavity is discharged from the liquid discharging end. According to the storageand feeding device for the garment treatment agent, the garment treatment agent is stored through the storage device, the garment treatment agent in the storage device is automatically fed through the feeding device, the storage device and the feeding device are integrally arranged, and the device is simple in structure and convenient to assemble.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

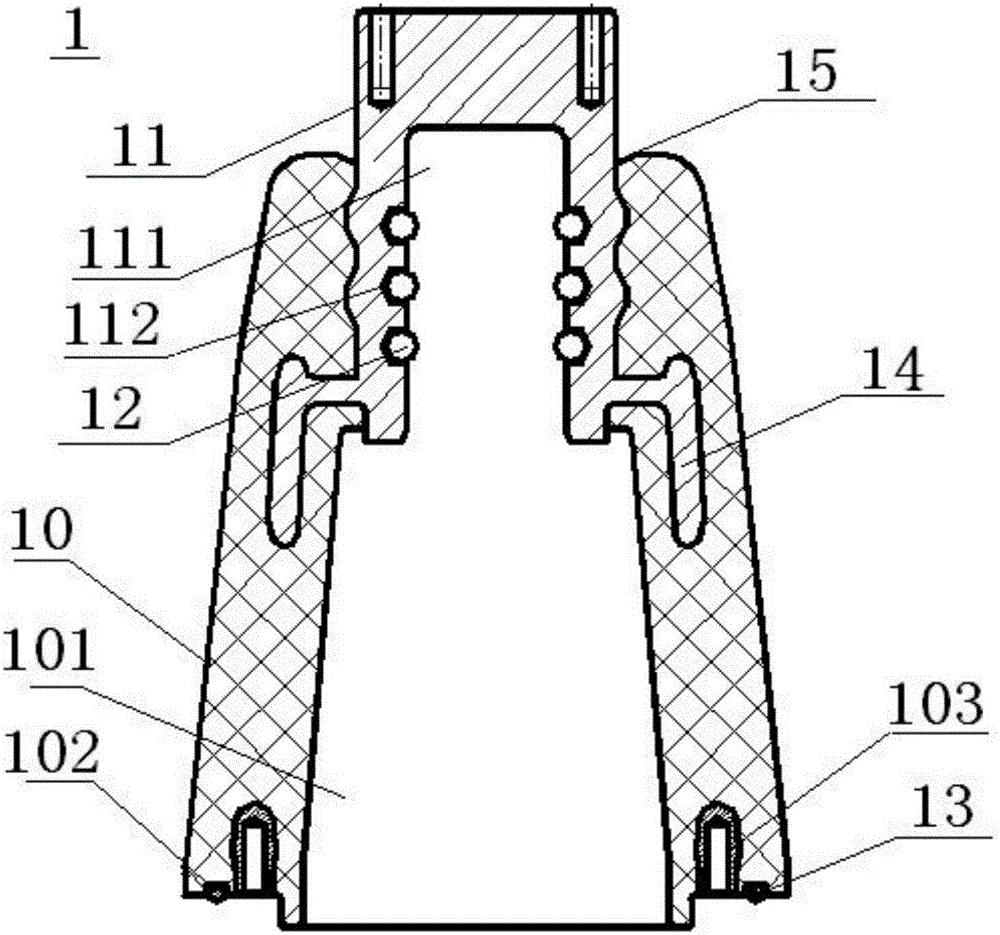

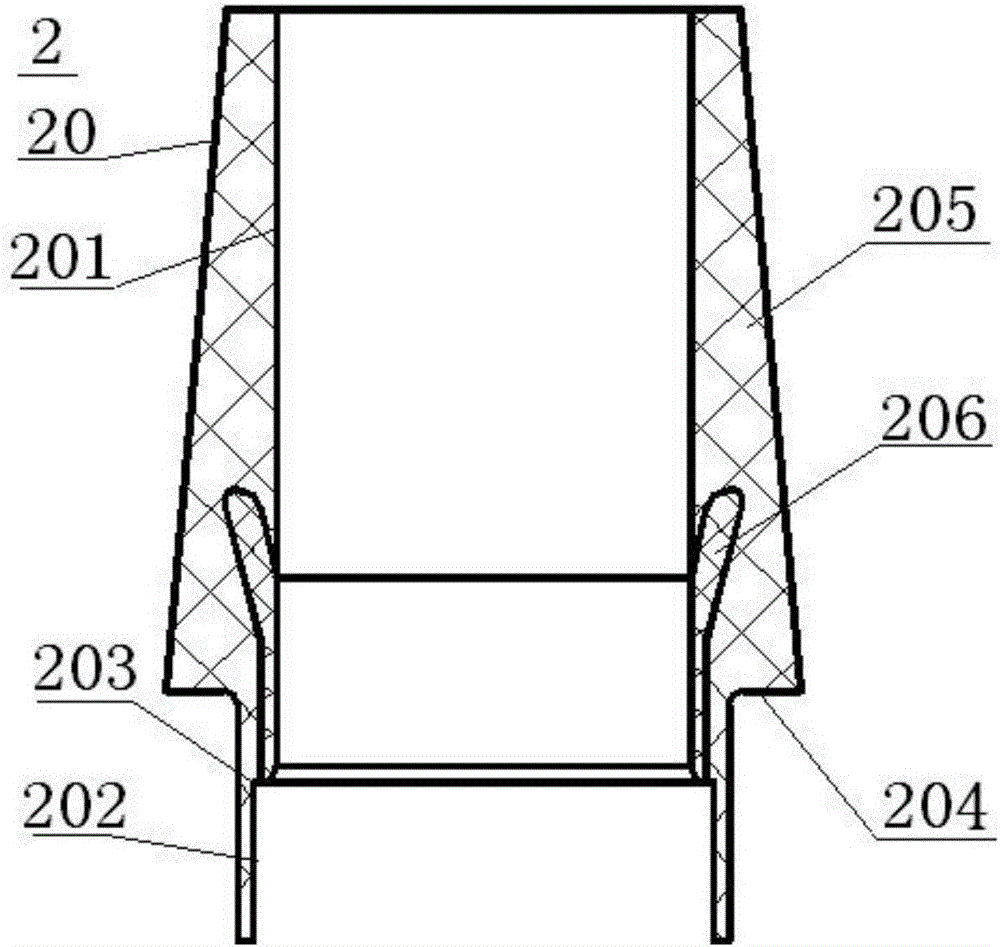

Tubular bus connecting terminal and mounting method thereof

PendingCN106711629AMeet delivery requirementsInsulationTotally enclosed bus-bar installationsCable terminationsElectric power transmissionElectrical conductor

The invention discloses a tubular bus connecting terminal and a mounting method thereof. The tubular bus connecting terminal comprises a socket and a plug, wherein the socket is mounted in electric equipment, and the plug is mounted on a tubular bus. The mounting method of the tubular bus connecting terminal comprises the following steps: mounting a contact finger into a socket conductor fixed in a socket body, and mounting the socket into the electric equipment; peeling a conductor, an insulating layer, an insulating shielding layer and a metal shielding layer from the end part of the tubular bus according to a preset peeling size, sequentially sleeving the tubular bus with a support shell, a spring set and a rubber component of the plug, integrally inserting the plug connected with the tubular bus into the socket to enable the conductor of the tubular bus to be in direct contact with the contact finger of the socket conductor, and finally fixedly connecting the plug with the socket by virtue of a first fastening component. The tubular bus connecting terminal meets the electric power transmission requirements and plays the roles of insulation and seal of equipment and has very wide application prospects, and the connection between the tubular bus and electric equipment is realized.

Owner:成都盛帮双核科技有限公司

Automatic sprayer

ActiveCN111250300APrevent left and right shiftSmooth transmissionSpraying apparatusVehicle frameSprayer

The invention relates to the technical field of sprayers, in particular to an automatic sprayer. The automatic sprayer comprises an equipment frame, a transmission mechanism, a guide mechanism and a spraying mechanism, wherein the transmission mechanism, the guide mechanism and the spraying mechanism are mounted on the equipment frame; the transmission mechanism and the guide mechanism are arranged in a staggered mode; the spraying mechanism is mounted on the guide mechanism; the equipment frame comprises a frame, foot wheels, a machine enclosure, a material tube, a flange, branch tubes, a rubber hose and a charge hole, wherein the four corners of the lower side of the frame are equipped with the foot wheels; and the upper side of the frame is fixedly connected to the machine enclosure. The automatic sprayer disclosed by the invention is convenient for spraying operation of the spraying mechanism, and can guarantee stable board transmission; and spacing between clamping rollers and spacing between barrel sleeves can be effectively regulated, so that conveying requirements of different boards can be met.

Owner:广德金恒金属处理有限公司

Multi-direction heavy-load conveyor and conveying method thereof

PendingCN110228696AReduced risk of deformationKeep the position fixedConveyorsConveyor partsHeight differenceEngineering

The invention discloses a multi-direction heavy-load conveyor and a conveying method thereof. The multi-direction heavy-load conveyor comprises a first conveying line and a second conveying line, wherein the first conveying line carries out conveying in a first direction, and the second conveying line carries out conveying in a second direction perpendicular to the first direction, the first conveying line comprises two chain plate conveying belts, wherein the two conveying surfaces of the two chain plate conveying belts are equal in height and are arranged at an interval, the width of the chain plate conveying belts is smaller than 1 / 4 width of the conveying surface of the first conveying line, the second conveying line is located between the two chain plate conveying belts, and the conveying surface of the second conveying line and the conveying surface of the first conveying line have a height difference. According to the scheme, the second conveying line capable of ascending and descending is additionally arranged between the two chain plate conveying belts, and the width of the chain plate conveying belts is controlled, so that the bearing capacity of the first conveying lineis effectively guaranteed, the conveying requirement of large-weight articles is met, and the deformation risk of chain plates can be reduced, and meanwhile, the two conveying lines are different in conveying direction and have two position states, so that bidirectional transfer between the two conveying lines can be effectively realized.

Owner:SUZHOU HONBEST CLEAN TECH CO LTD

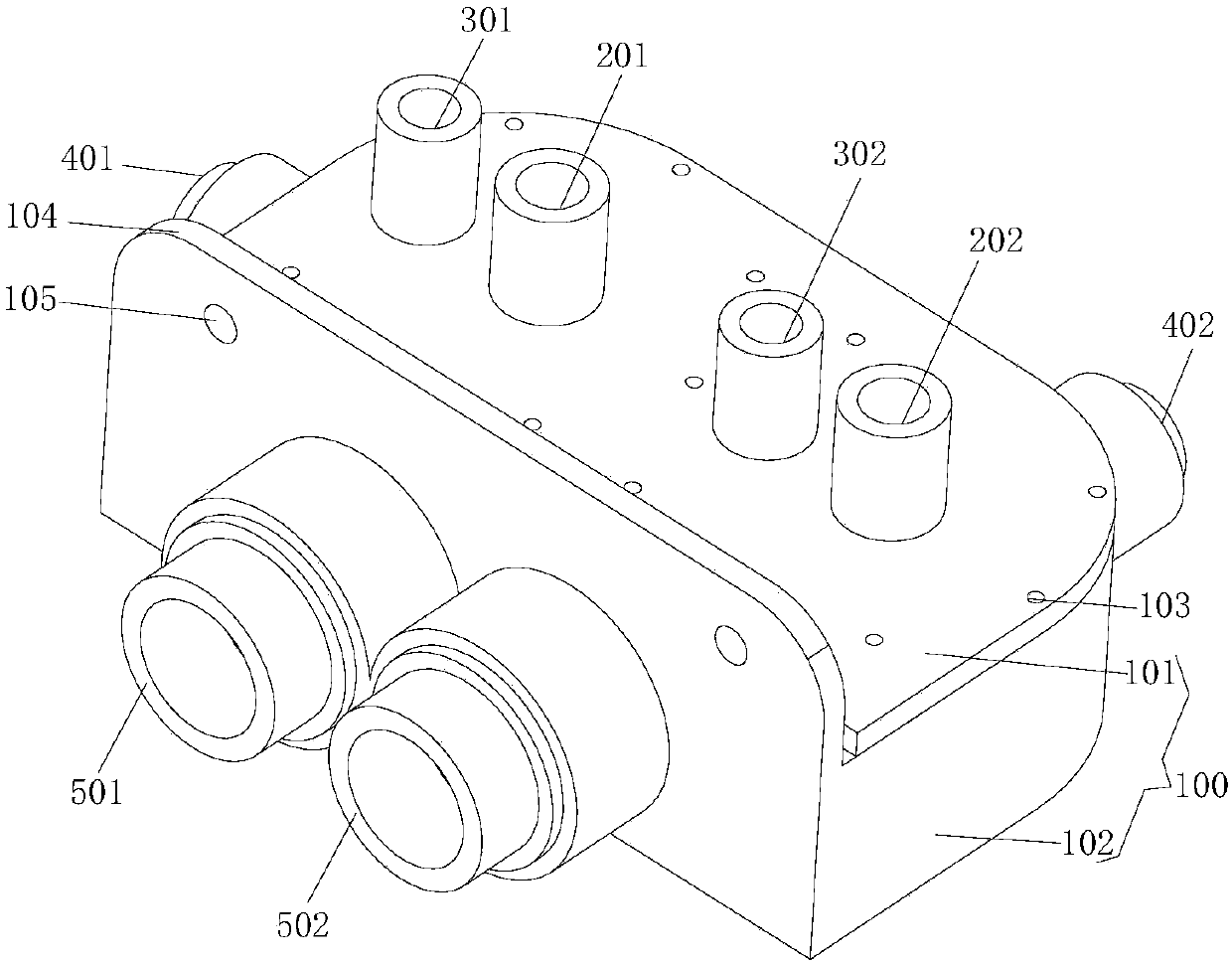

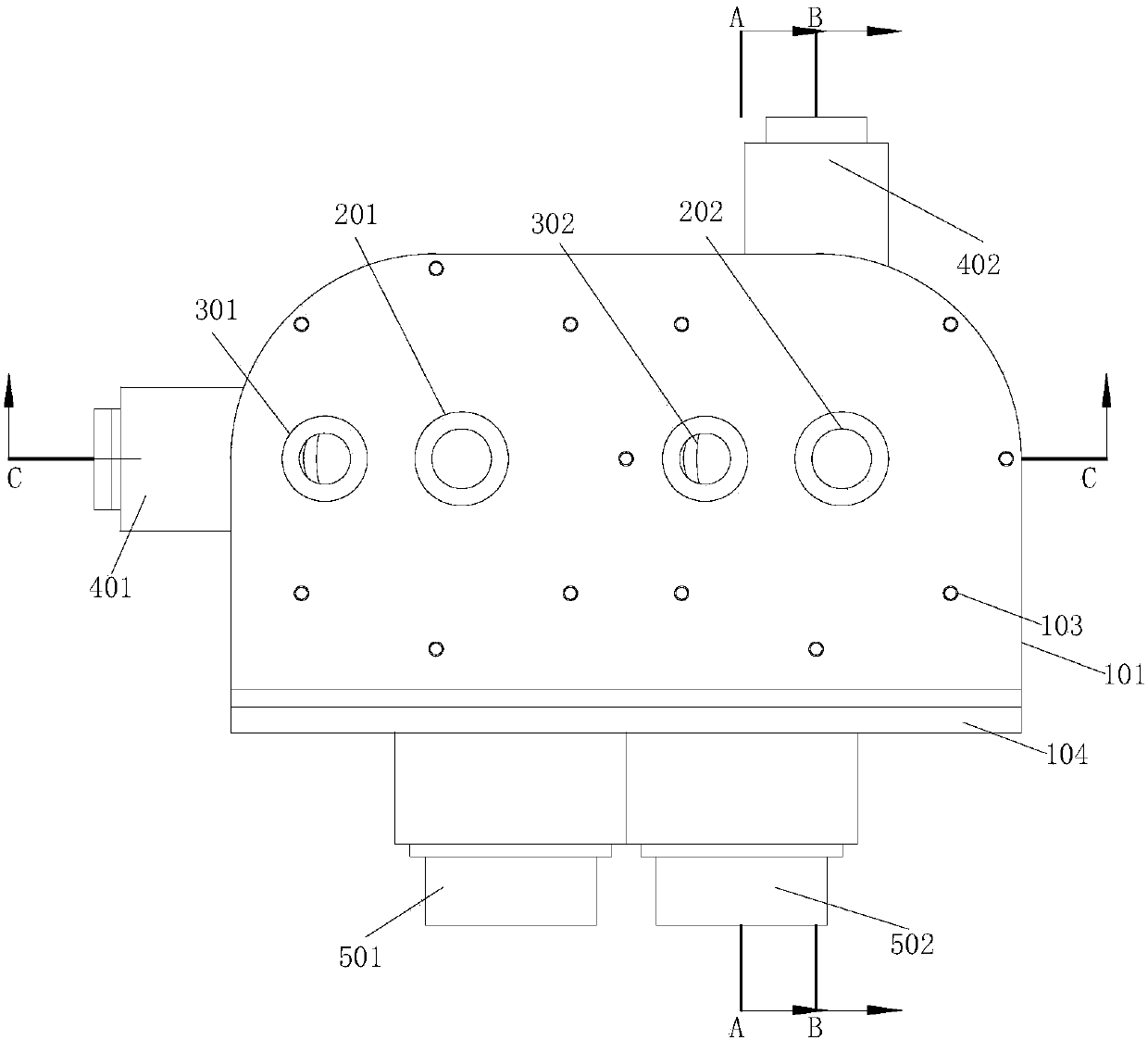

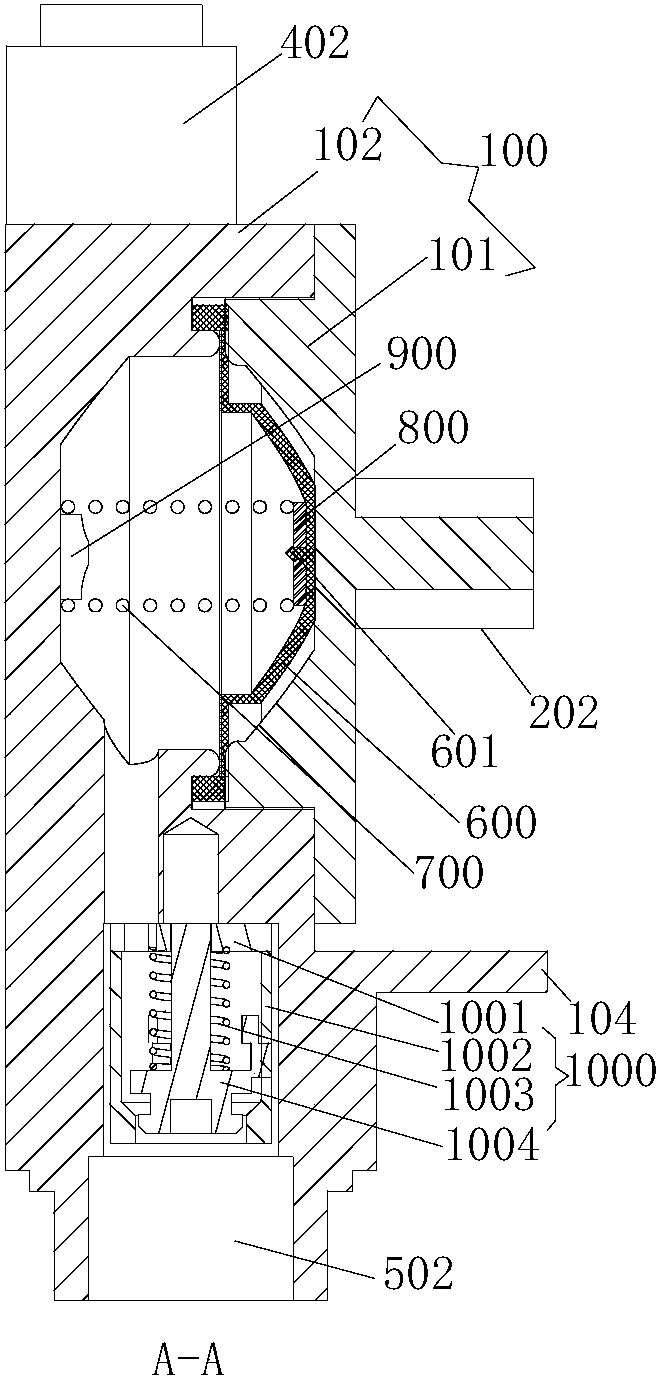

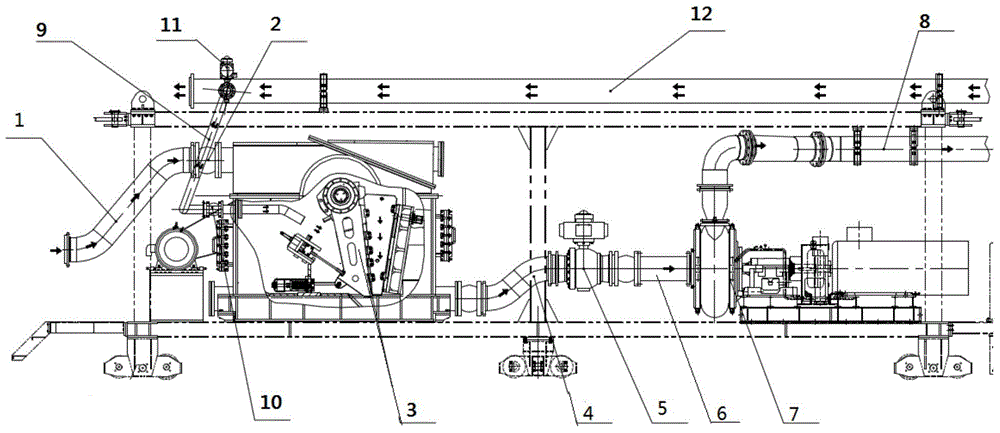

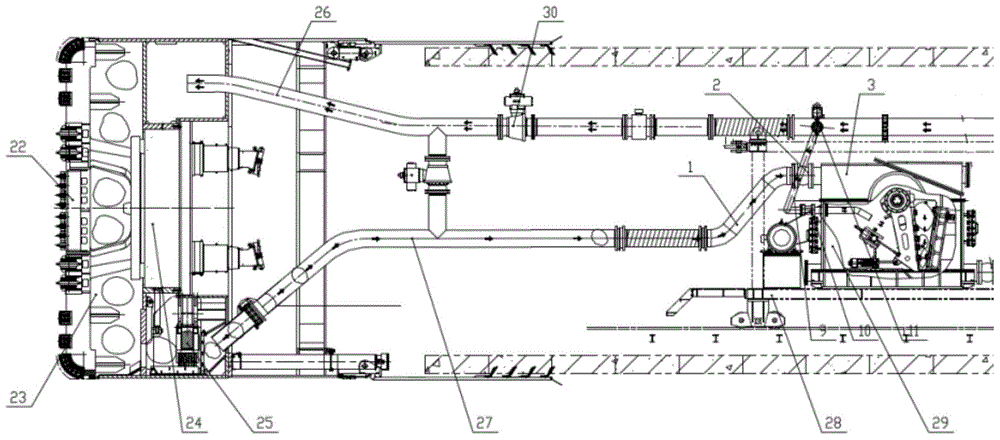

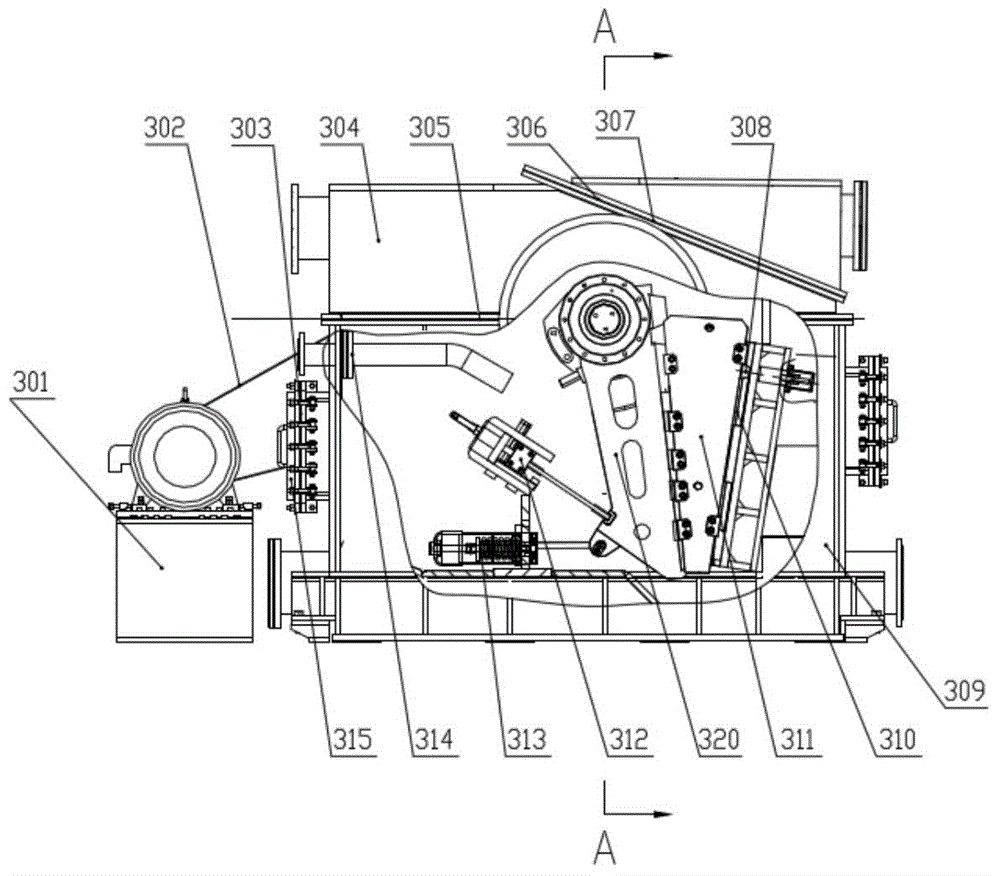

Slurry pipeline crusher used in shield machine

The invention provides a slurry pipeline crusher used in a shield machine. The slurry pipeline crusher is a closed slurry fluid jaw crusher with the inside having a sealed pressure reaching above 0.5MPa, and the slurry pipeline crusher comprises a frame, a movable jaw assembly, sealing gaskets, a fixed jaw plate positioned in the frame, and a motor driving assembly and a belt positioned outside the frame, wherein the frame, the movable jaw assembly and the sealing gaskets form an internal sealing space; the motor driving assembly and the belt are used for driving the movable jaw assembly to carry out compound pendulum extruding motion relative to the fixed jaw plate in order to extrude and crush bones between the movable jaw assembly and the fixed jaw plate; and the movable jaw assembly comprises an eccentric shaft arranged on the frame and a movable jaw plate positioned in the frame, and a rotation seal is formed between the movable jaw assembly and the frame. The slurry pipeline crusher has strong crushing ability and good maintainability, and can provide high-pressure crushing sealing environment.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com