Automatic washing powder putting device

A technology of automatic feeding and washing powder, which is applied to washing devices, other washing machines, textiles and papermaking, etc., and can solve the problems of washing powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

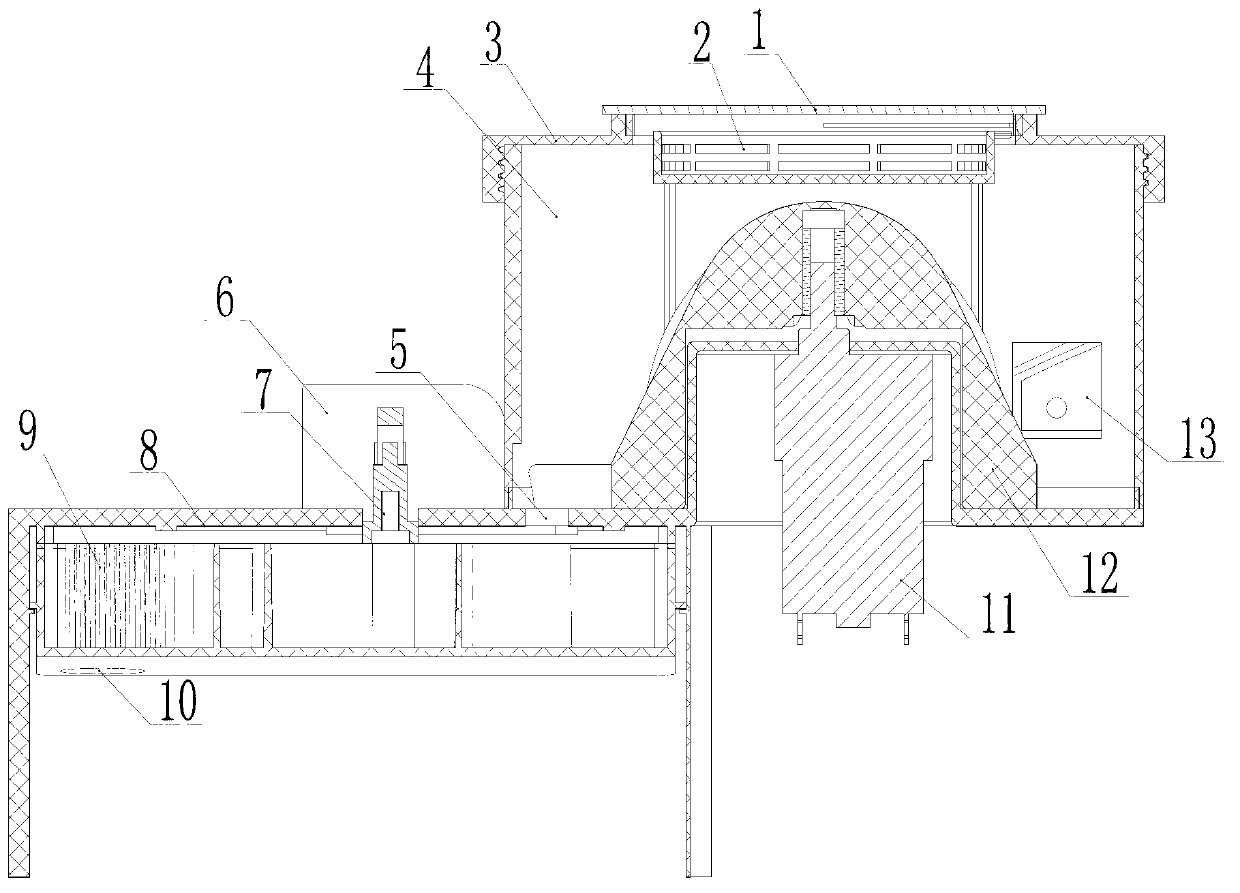

[0022] This invention is mainly driven by a motor 11, which drives the impeller 12 to rotate, and smashes and releases washing powder. The overall assembly diagram is as follows figure 1 shown.

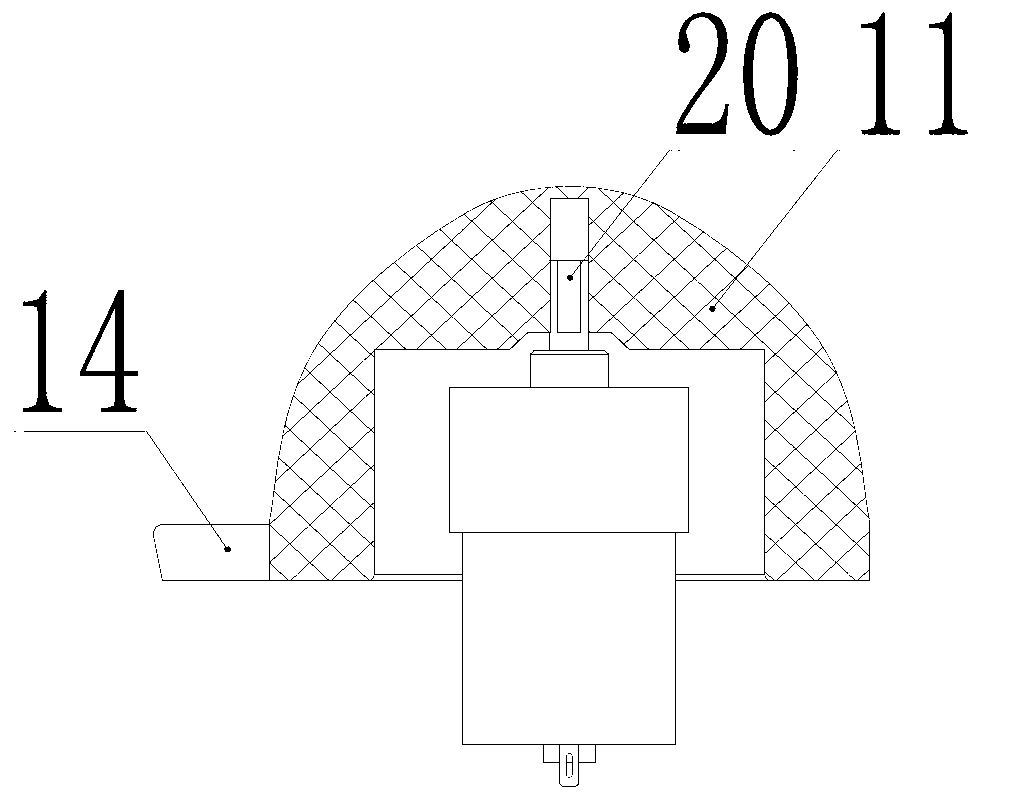

[0023] The motor 11 has a stainless steel output shaft 20, and the impeller 12 is fixed on the output shaft 20 of the motor 11 through interference fit. The fixed state is as follows: image 3 as shown,

[0024] The rotating speed of motor 11 is 70 revolutions per minute, can control the throwing amount of this invention per minute by adjusting the rotating speed of motor, to meet the demands of different manufacturers' washing machine specifications.

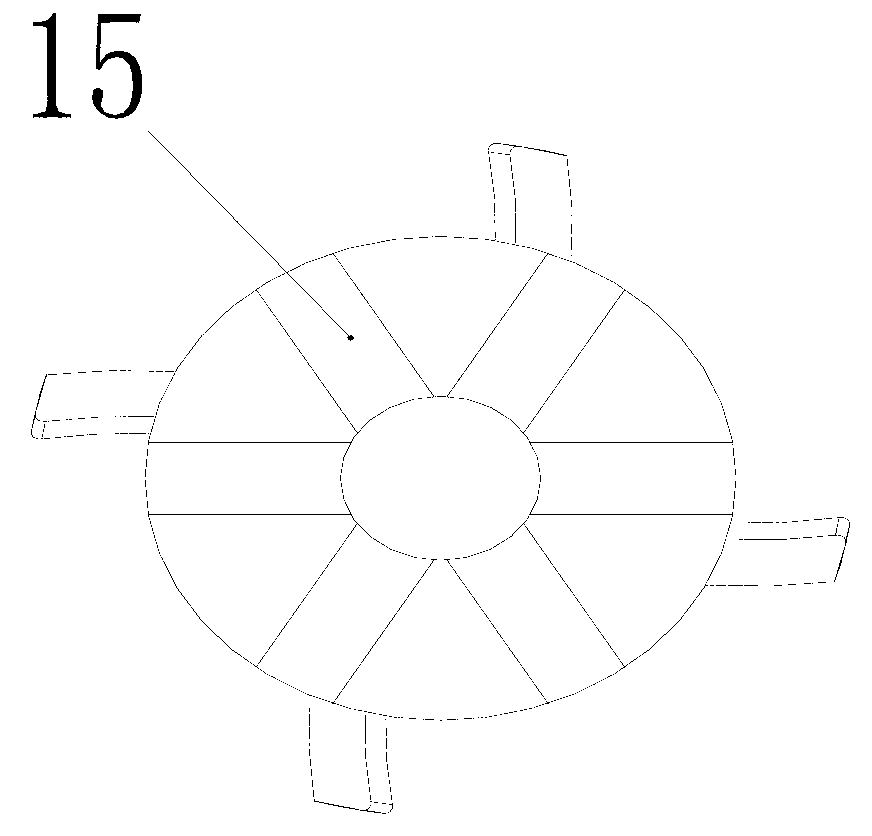

[0025] Blade 14 and impeller rib 15 are arranged on impeller 12, as figure 2 as shown,

[0026] The blade 14 has two functions. The first one is to drive the blade 14 to rotate at a constant speed through the uniform rotation of the motor. The blade 14 drives the washing powder to be accurately dispensed through the powder leakage ...

Embodiment 2

[0042]In addition to the dissolving method of the dissolving box mentioned in the above example 1, it can also be made into stirring and dissolving, such as Figure 7 .

[0043] The stirring and dissolving structure includes: 24 is the upper cover of the stirring and dissolving box, 25 is the washing powder inlet, 26 is the stirring and dissolving box, 27 is the stirring impeller, 28 is the stirring motor, 29 is the leakage hole after dissolution, and 30 is the water inlet of the stirring device (1 referred to as stirring water inlet).

[0044] The stirring motor 28 and the stirring impeller 27 are connected by interference fit, the stirring motor 28 is connected and fixed with the chassis 8 by screws, the washing powder is put into the washing powder feeding port 25 through the powder leakage hole 5, and then the water enters the washing powder feeding port 25 through the stirring water inlet 30. Stir to dissolve the box.

[0045] The stirring and dissolving box upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com