Patents

Literature

81results about How to "Guarantee delivery quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

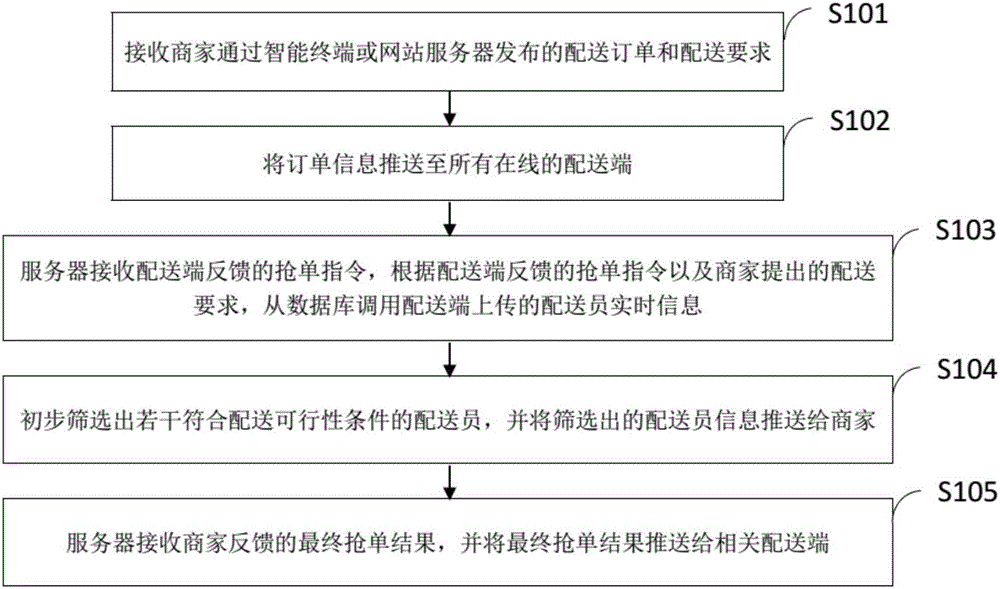

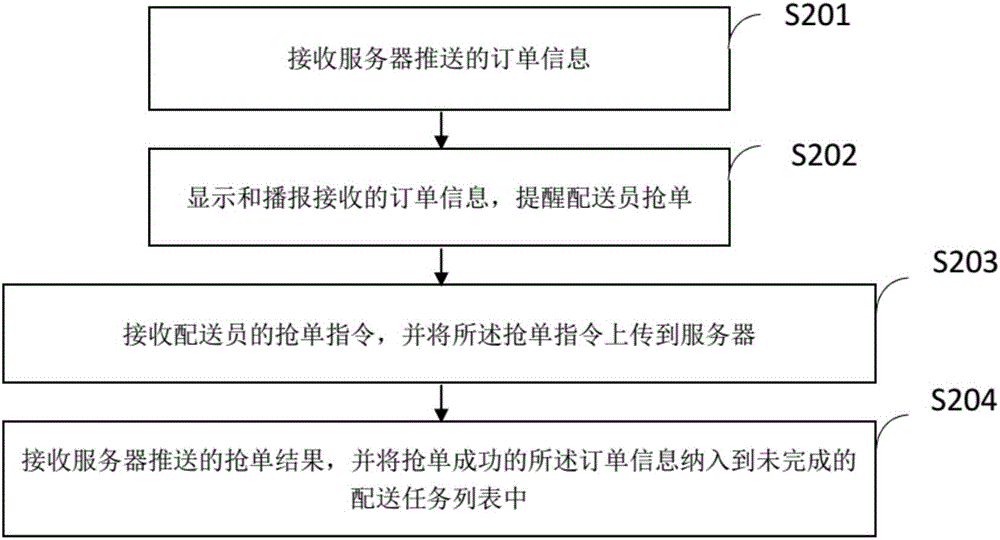

Method and system for merchant to participate in delivery staff order competition

InactiveCN106296086AReduce riskIncrease motivationBuying/selling/leasing transactionsLogisticsLogistics managementOrder form

The invention discloses a method and system for merchants to participate in delivery staff order competition and is applicable to the technical field of order allocation of an internet O2O industry and a city wide logistics industry. The method comprises the steps that a server receives delivery orders and delivery demands issued by the merchants through smart terminals and pushes order information to all online delivery ends; the server receives order competition instructions fed back by the delivery ends, preliminarily screening a plurality of delivery staff according to the order competition instructions of the delivery ends and the delivery demands proposed by the merchants and pushes the information to the merchants; and the merchants carries out secondary selection on the preliminarily screened delivery staff, and the server pushes final order competition results to related delivery ends. According to the method and the system, through adoption of a mode for the merchants to participate in the delivery staff order competition, the enthusiasm of the delivery staff is fully aroused, moreover, the previous working quality of the delivery staff is taken into full consideration, the participation degree and supervision degree of the merchants for delivery links are enhanced, and the integrated quality of the order delivery service is effectively improved.

Owner:温泉

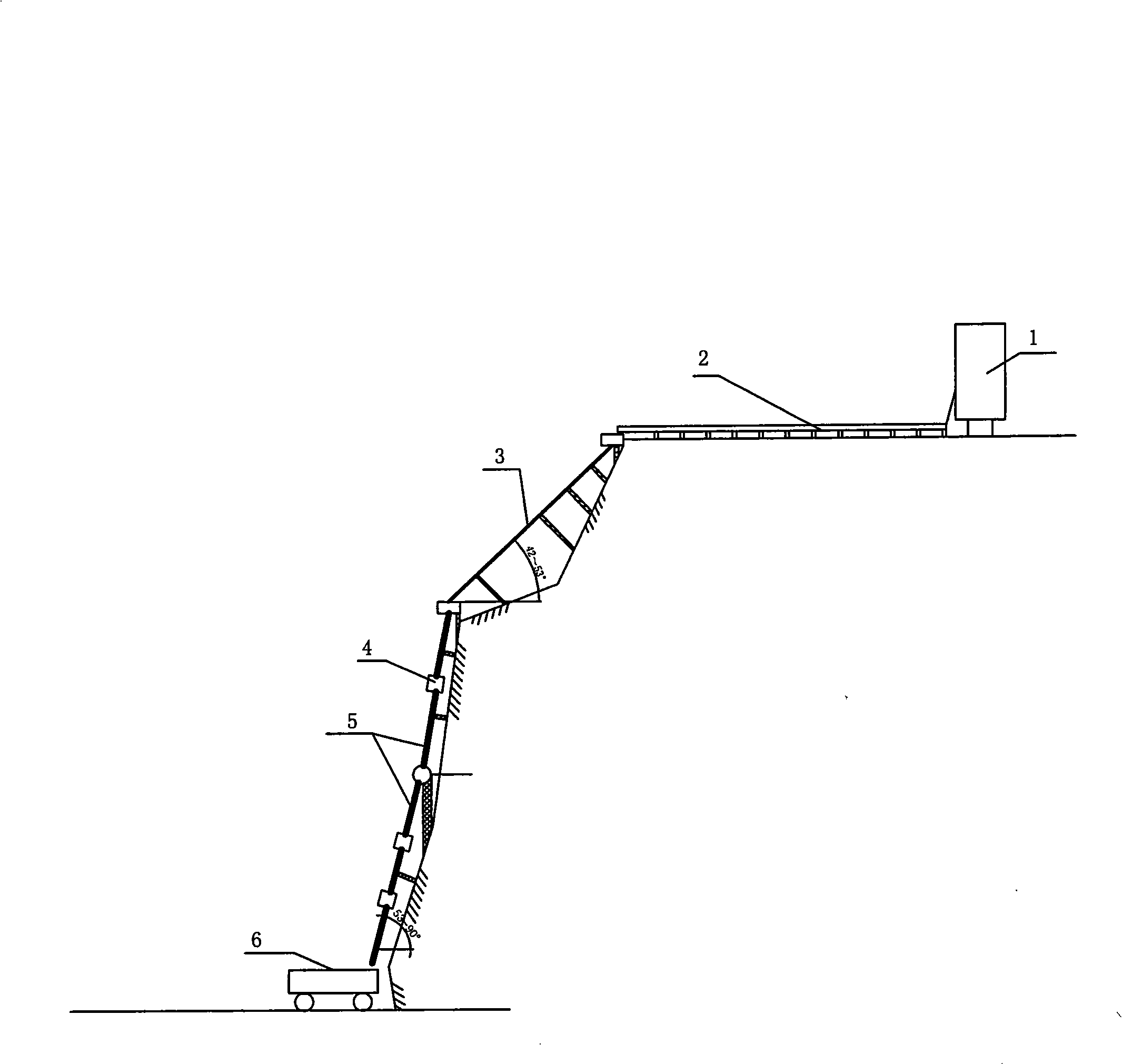

Concrete conveying process for high steep and big drop height landform

The invention relates to a concrete delivering method in the high-slope and big-drop terrain. The method comprises the following steps: the parameters of the length, the elevation, the slope angle and the scar property of the horizontal section of a concrete placement area are comprehensively mastered through field terrain investigation; concrete is horizontally delivered through a conveyer belt; when the slope angle is larger than 40 degrees and smaller than 53 degrees, the delivering is realized through a negative pressure sliding chute; when the slope angle is larger than 53 degrees and smaller than 90 degrees, the delivering is realized through the combination of a sliding cylinder and a slowly decreasing and mixing machine. The method effectively combines the economic and practical delivering means according to local conditions, and the concrete delivering purpose is achieved, thereby, under the precondition of ensuring the concrete delivering quality, the cost is reduced further. The method is particularly applicable to the high-slope and big-drop concrete delivering in valley and mountain under the limited field and road conditions.

Owner:中国葛洲坝集团建设工程有限公司

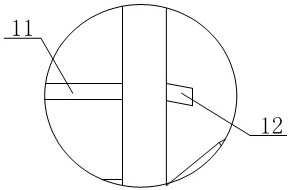

Plate material conveying mechanism for plate material environment-friendly dust collection equipment

InactiveCN106429423AWill not be damagedWon't inhaleConveyorsCleaning using gasesAgricultural engineering

Owner:盐城捷尔达环保设备有限公司

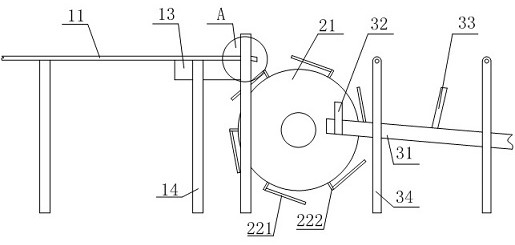

Door plate processing mechanism

InactiveCN104960070AGreat suctionAvoid Paste EffectsDomestic articlesBark-zones/chip/dust/waste removalEngineeringMechanical engineering

The invention belongs to the field of door processing technology, and relates to a door plate processing mechanism. The door plate processing mechanism comprises a door plate conveying platform, a trimming device used for trimming a door plate, a strip binding device used for binding edge sealing strips on the trimmed door plate, and a feed device used for feeding edge sealing strips to the strip binding device. The trimming device comprises a support disposed under the conveying platform, a trimming chamber mounted on the support, and trimming disc disposed on a sidewall of the trimming chamber and driven by a motor. The conveying platform penetrates the trimming chamber, and the trimming chamber is provided with a wood chip suction structure. By adopting the door plate processing mechanism, wood chips generated when doorframes are trimmed can be sucked up, so the wood chips can be prevented from influencing on adhering connection between the edge sealing strips and the doorframes, the adhering quality of the edge sealing strips can be raised, a trimming point can be aligned, so the wood chips can be effectively sucked up. The edge sealing strips can be quickly and stably conveyed, and a plurality of conveying positions of the edge sealing strips are finely adjusted, the conveying quality can be ensured, so the edge sealing strips can be adhered in high quality in the later process.

Owner:浙江采丰木业有限公司

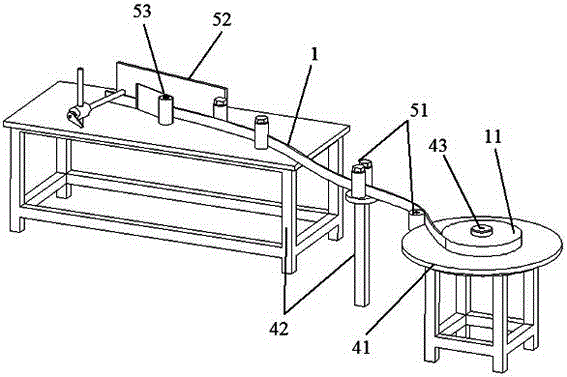

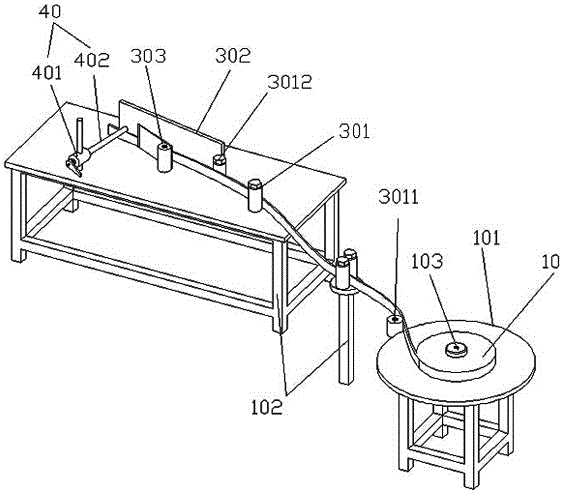

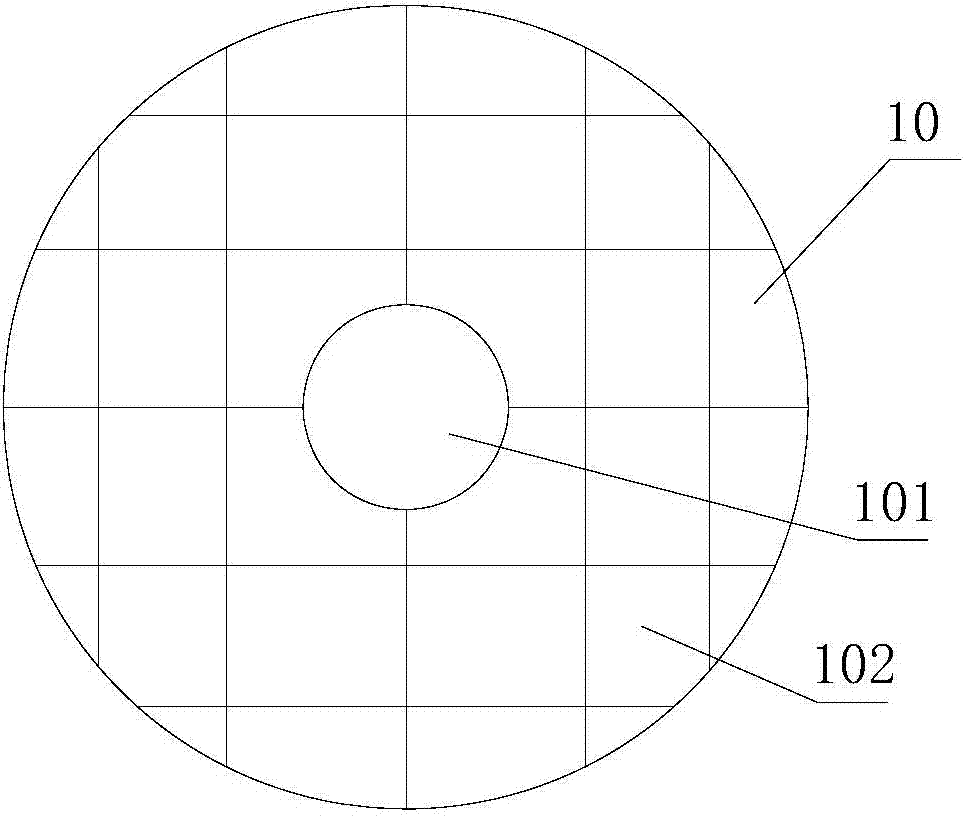

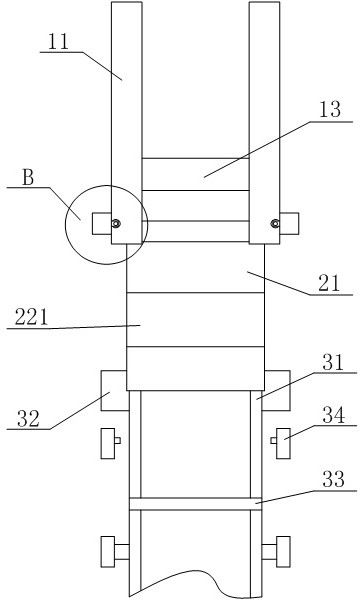

Edge banding conveying device for door sheet edge banding procedure

The invention belongs to the field of door machining and relates to an edge banding conveying device for a door sheet edge banding procedure. The edge banding conveying device comprises a conveying disc and a conveying rack which is arranged between the conveying disc and an edge banding device. A rotary shaft driving the conveying disc to rotate is arranged at the center of the conveying disc. An edge banding disc is fixed to the rotary shaft. A guiding component is arranged on the conveying rack. The edge banding conveying device is used for conveying edge bandings rapidly and stably; the conveyance of the edge bandings is adjusted slightly at multiple positions so that the conveying quality is guaranteed; and the later high-quality sticking of the edge bandings is better guaranteed.

Owner:浙江采丰木业有限公司

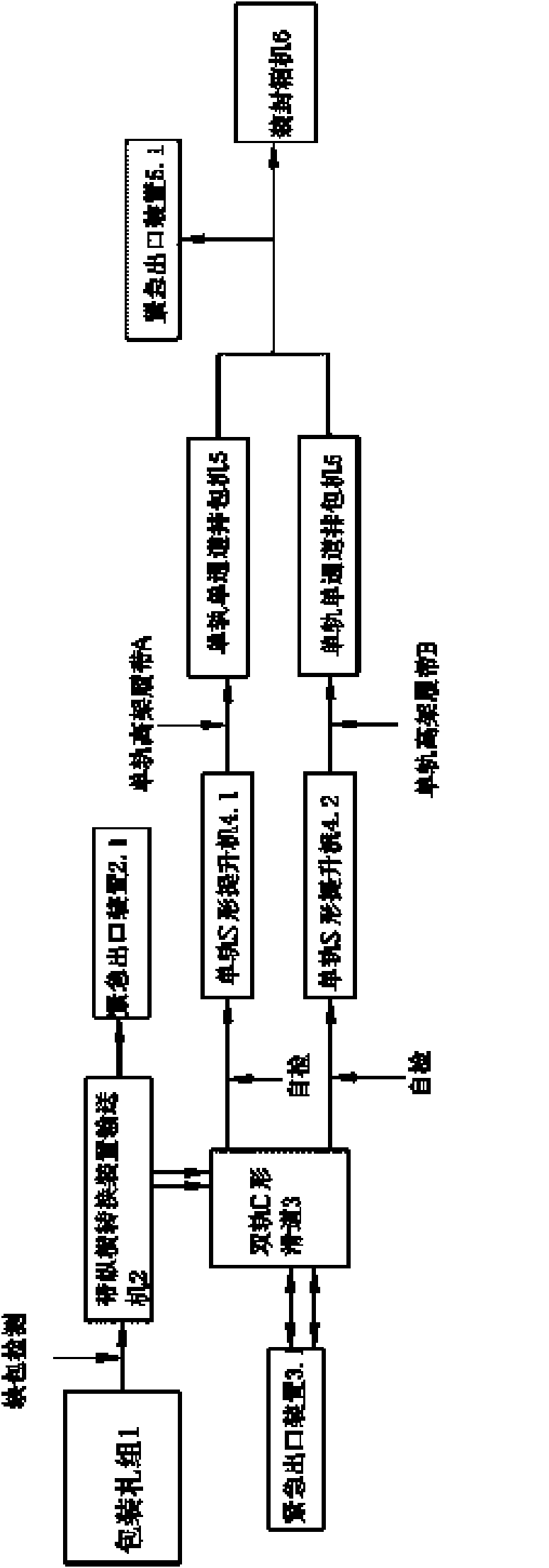

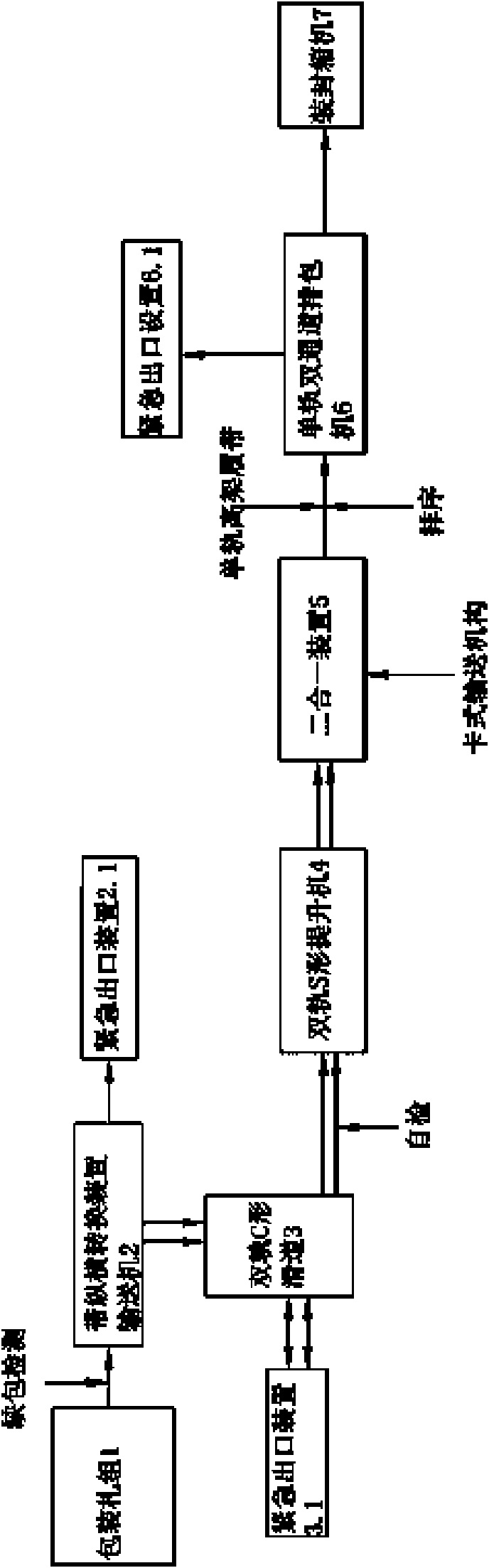

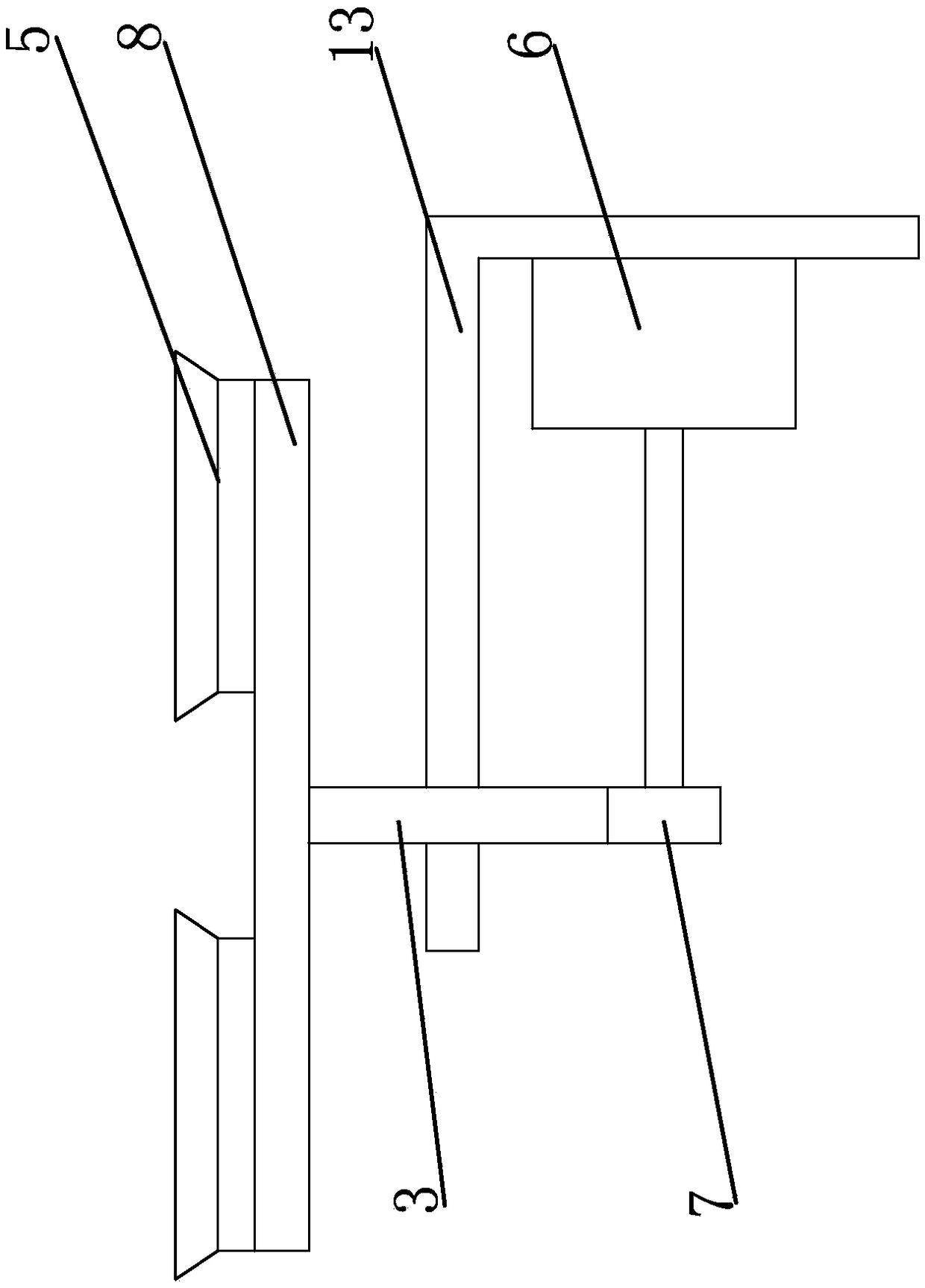

Conveying system of carton cigarette and method

ActiveCN101665158AGuarantee delivery qualityLayout duty cycle is smallPackaging automatic controlIndividual articlesComing outCarton

The invention discloses a conveying system of carton cigarette and a method. The method comprises the following steps: step 1, the carton cigarette comes out of a packaging machine set (1) and is sentto a conveyor (2) with a longitudinal and lateral conversion device after pack missing detection; step 2, the conveyor (2) with the longitudinal and lateral conversion device arranges every two cartons of disordered cigarettes continuously conveyed by an outlet of the packaging machine set (1) as a group so as to carry out lateral conversion and longitudinal output; step 3, a double-track C-shaped slide rail (3) leads a group of carton cigarettes to be lowered from a high position to a low position for self-checking; step 4, a double-track S-shaped lifter lifts respective carton cigarettes toa two-in-one device (5); step 5, the two-in-one device (5) carries out dislocation asynchronous conveying of two synchronous carton cigarettes, and then converges the two synchronous carton cigarettes to one overhead aluminum alloy conveyor line; step 6, carton cigarettes penetrate through a plurality of automatic vertical package arranging machines (6) with single track and two channels; and step 7, the carton cigarette enters a case filling and sealing machine (7) fixedly from a certain package arranging machine through a bypass mode preset by electrons so as to carry out case filling and sealing.

Owner:LONGYAN CIGARETTE FACTORY

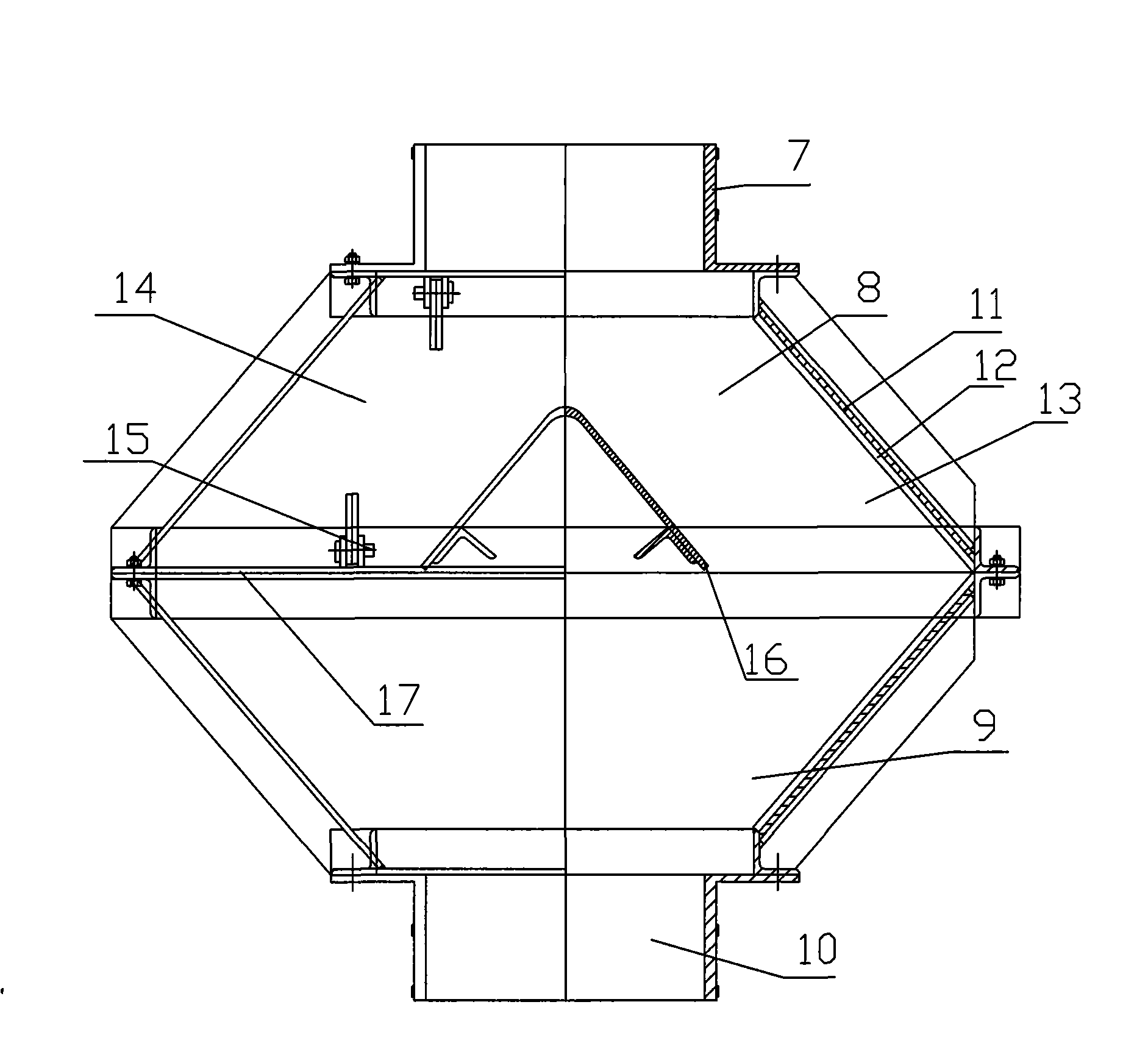

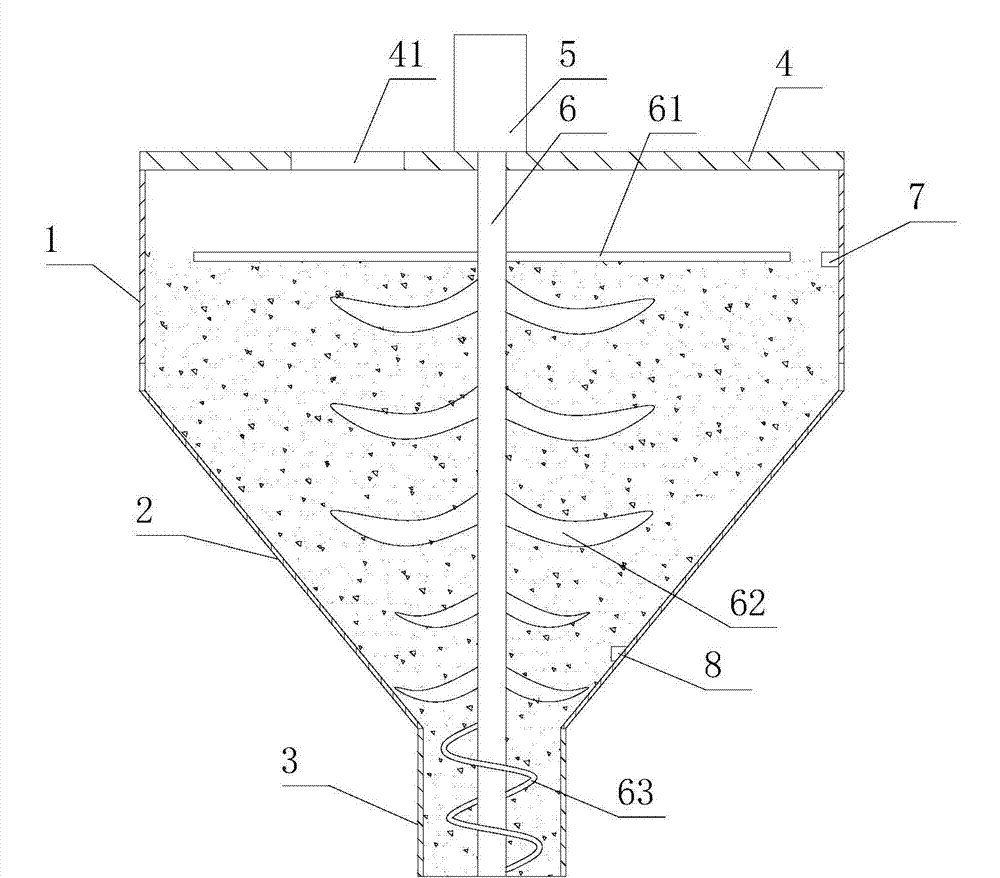

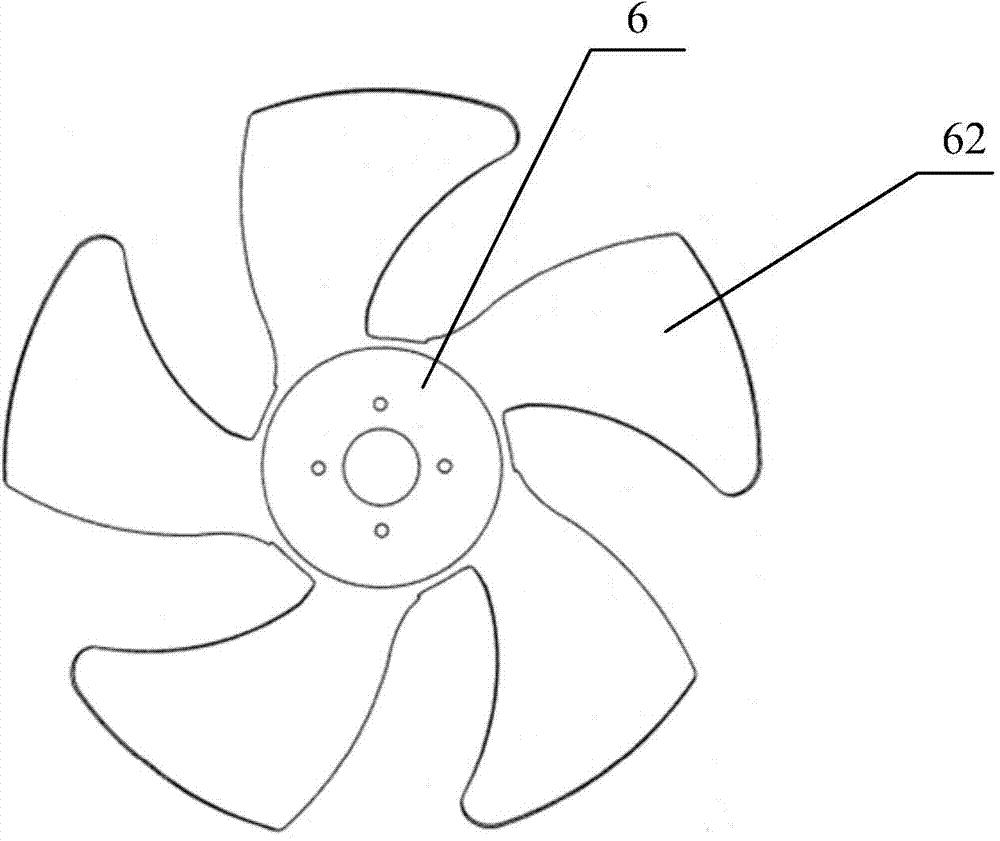

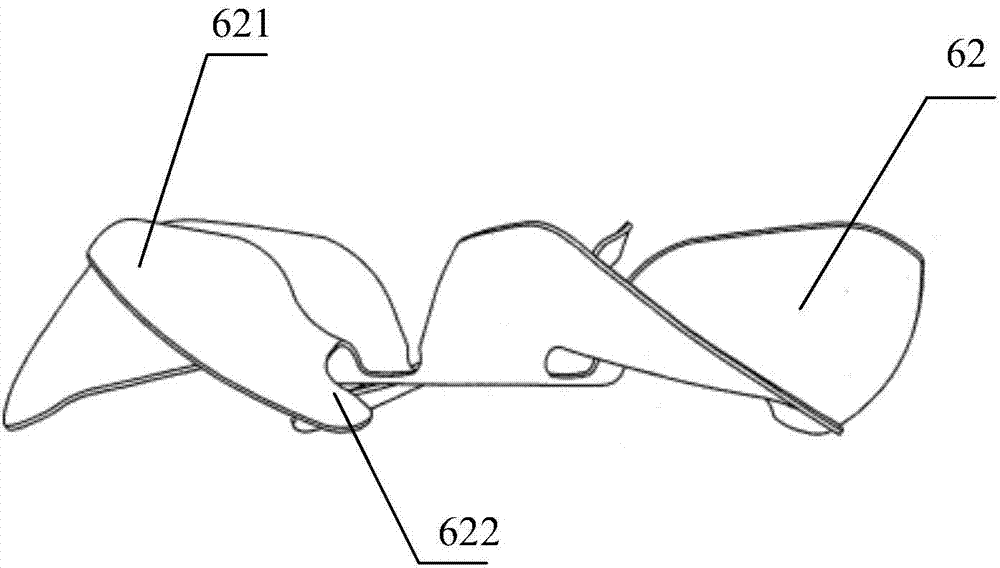

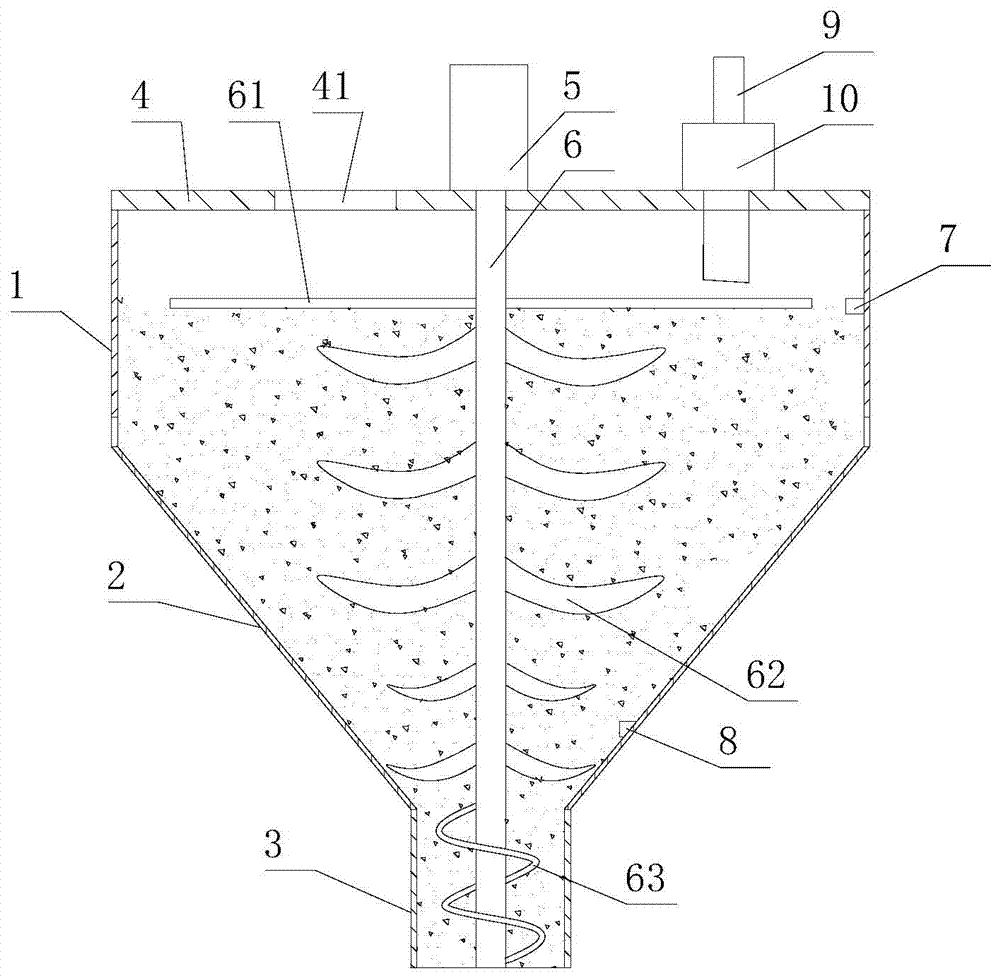

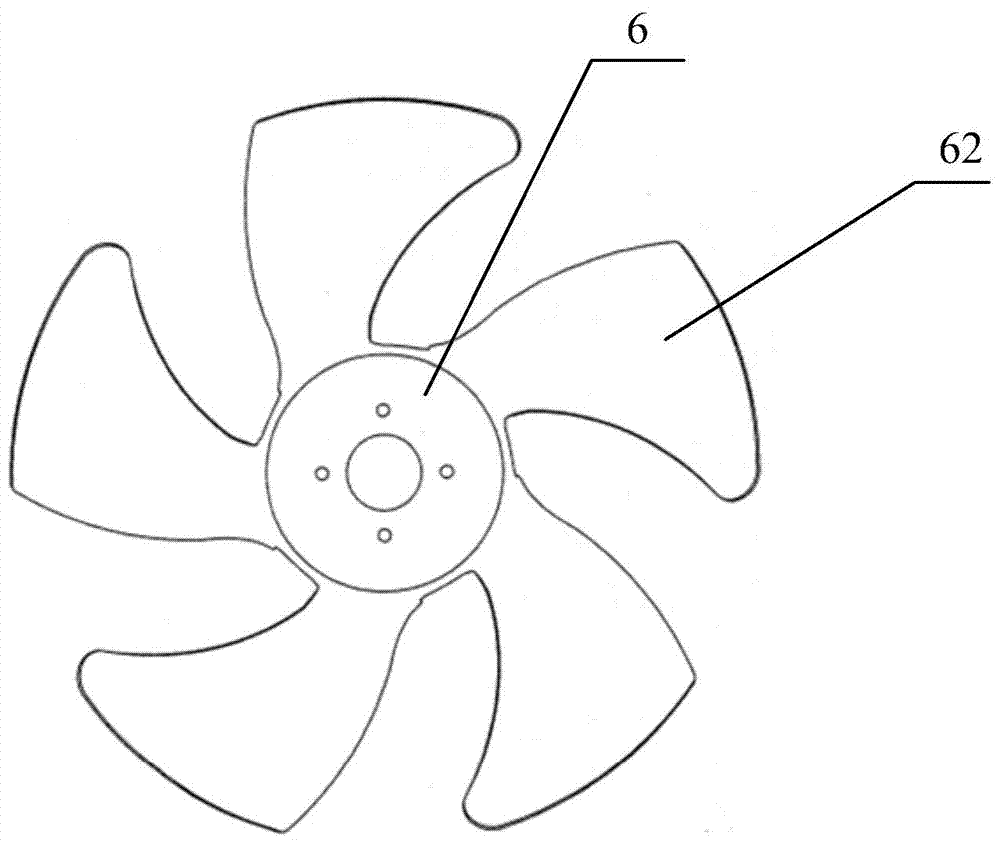

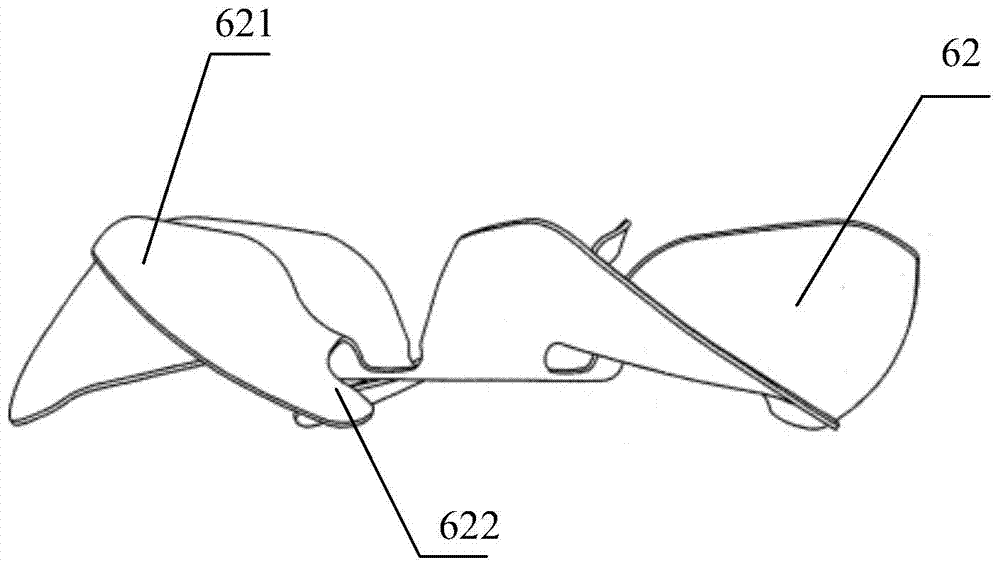

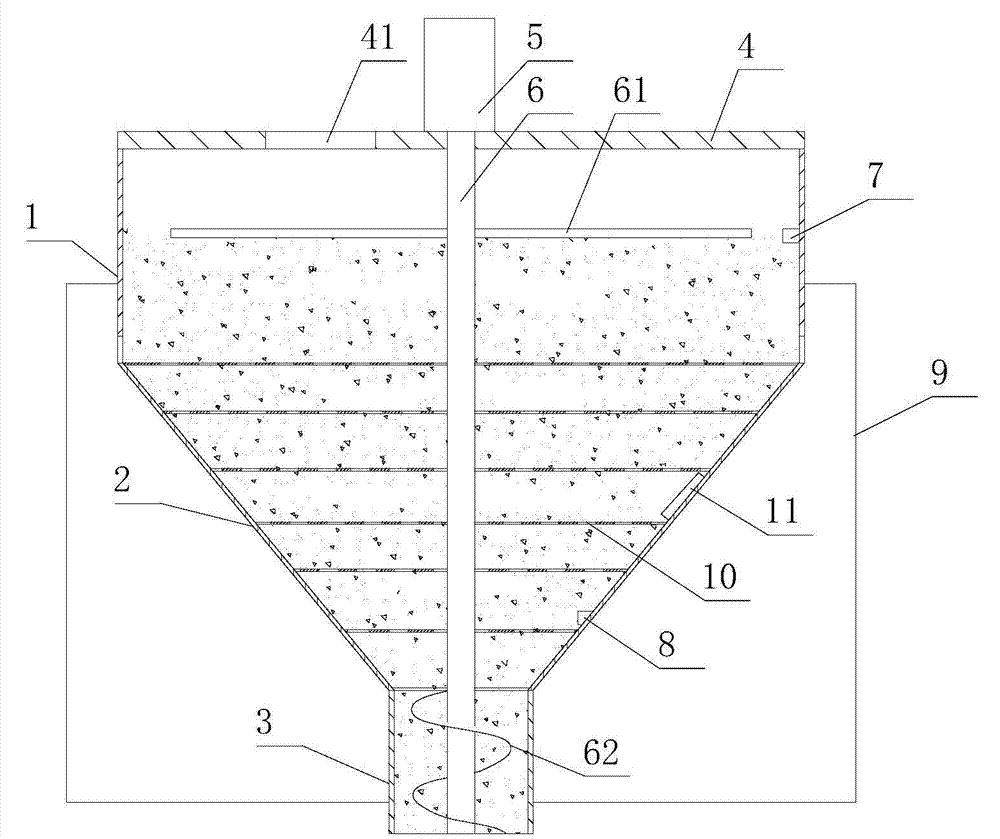

Feeding hopper of extruding machine

The invention discloses a feeding hopper of an extruding machine. The feeding hopper comprises a hopper body, wherein the hopper body comprises an inverted-cone-shaped storing section and an annular discharging section; the storing section and the discharging section are coaxially arranged; the top of the storing section is provided with a cover plate, the cover plate is provided with a feed port, and the top of the cover plate is provided with a driving motor; the driving motor is connected with a main shaft which is arranged in a manner of stretching into the hopper body, the main shaft is provided with multiple groups of loose blade structures at intervals, the loose blade structures are positioned in the storing section, and each loose blade structure comprises at least four loose blades which are uniformly distributed in an annular manner, and each loose blade is arranged in an inclined manner; the blade surface of each loose blade is arranged in a manner of facing the rotating direction of the main shaft, the tail end of the main shaft is provided with a helical blade, and the helical blade is positioned in the discharging section. The feeding hopper of the extruding machine, provided by the invention, has the advantages that the feed is easy, and the power consumption is low.

Owner:昆山市华浦塑业有限公司

Feeding device with drying function

The invention discloses a feeding device with a drying function. The feeding device comprises a feeding hopper, wherein the feeding hopper comprises an inverted-cone-shaped storing section and a ring-shaped discharging section; the storing section and the discharging section are coaxially arranged, the top of the storing section is provided with a cover plate, the cover plate is provided with a feed port, the top of the cover plate is provided with a driving motor, and the driving motor is connected with a main shaft which stretches into the feeding hopper; the main shaft is provided with multiple groups of loose blade structures at intervals, the loose blade structures are positioned in the storing section, each blade structure comprises at least four loose blades which are uniformly distributed in an annular manner, and each loose blade is arranged in an inclined manner; the blade surface of each loose blade is arranged in a manner of facing the rotating direction of the main shaft, the tail end of the main shaft is provided with a helical blade, and the helical blade is arranged in the discharging section; the top of the cover plate is also provided with a material drying device, and the material drying device is communicated with the interior of the feeding hopper. The feeding device with the drying function, provided by the invention, has the advantages that the dryness of a material is kept, and the feed is easy.

Owner:昆山市华浦塑业有限公司

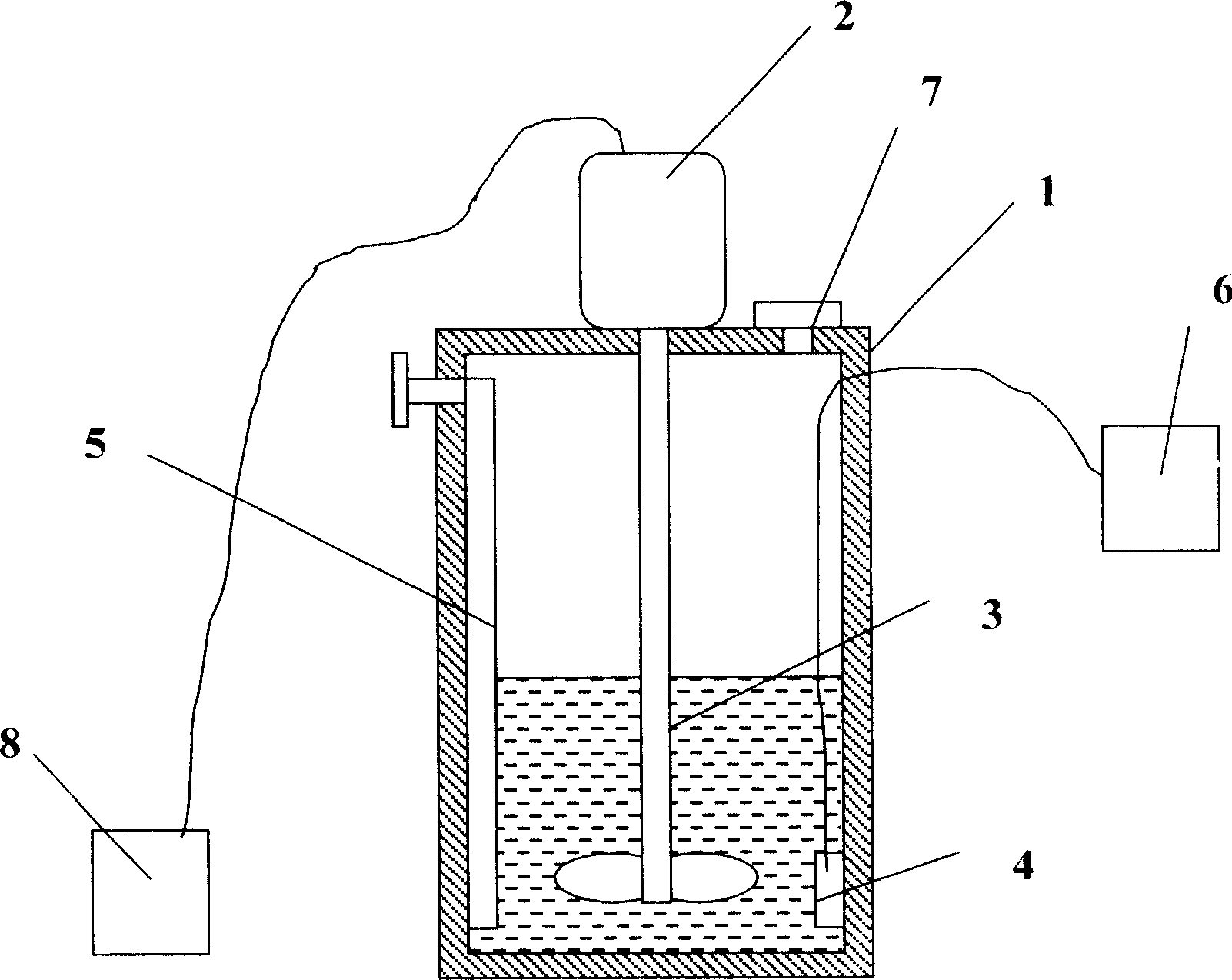

Water-treating soup supplier against deposition

A water-treating chemical feed supplier for preventing deposition consists of a container with a level valve on external wall and a discharging tube. A dog house and an electric motor are arranged on top of the container. The output shaft is connected with a reducer mechanism which connects with an extended axle set on axis position in container. The bottom of extended axle is arranged with a stirring impeller, the surfaces of extended axle and stirring impeller are covered with ceramic material, container is made form polyethylene material, electric motor is connected with controller from electric cable, the controller has a timer, and level valve is connected with sound alarming circuit from wire. It can generate alarming signal.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Feeding device capable of vibrating

The invention discloses a feeding device capable of vibrating. The feeding device comprises a bucket body, wherein the bucket body comprises a circular-ring shaped charging section, an inverted cone-shaped material storage section and a circular-ring shaped discharging section which are coaxially arranged; the top end of the material storage section is flexibly connected with the charging section; the bottom end of the material storage section is flexibly connected with the discharging section; a rack is arranged outside the charging section; the rack is connected with the outer side of the charging section; a vibrator is arranged on the side wall of the material storage section; the material storage section is provided with a plurality of screen meshes which are arranged at intervals from top to bottom and are in detachable connection; sieve pores of adjacent two screen meshes are arranged in a staggered manner; shaft through holes are formed at centers of the screen meshes; a cover plate is arranged on the top of the charging section; the cover plate is provided with a charging hole; a drive motor is arranged on the top of the cover plate; the drive motor is connected with a main shaft; the main shaft extends into the bucket body and passes through the shaft through holes to reach the discharging section; a spiral blade is arranged at the tail end of the main shaft; and the spiral blade is arranged in the discharging section. The feeding device capable of vibrating can be used for avoiding material accumulation and is easy for feeding.

Owner:昆山市华浦塑业有限公司

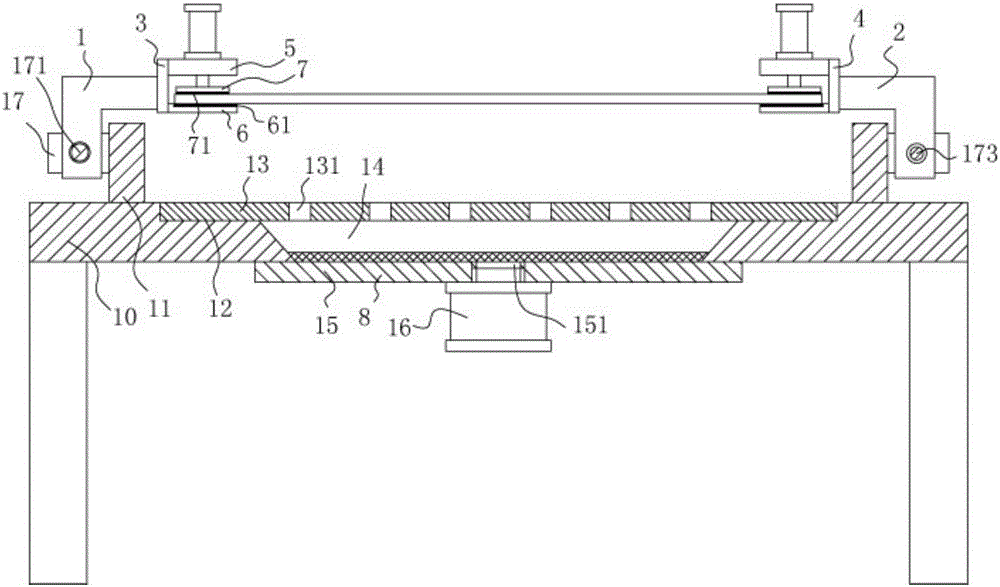

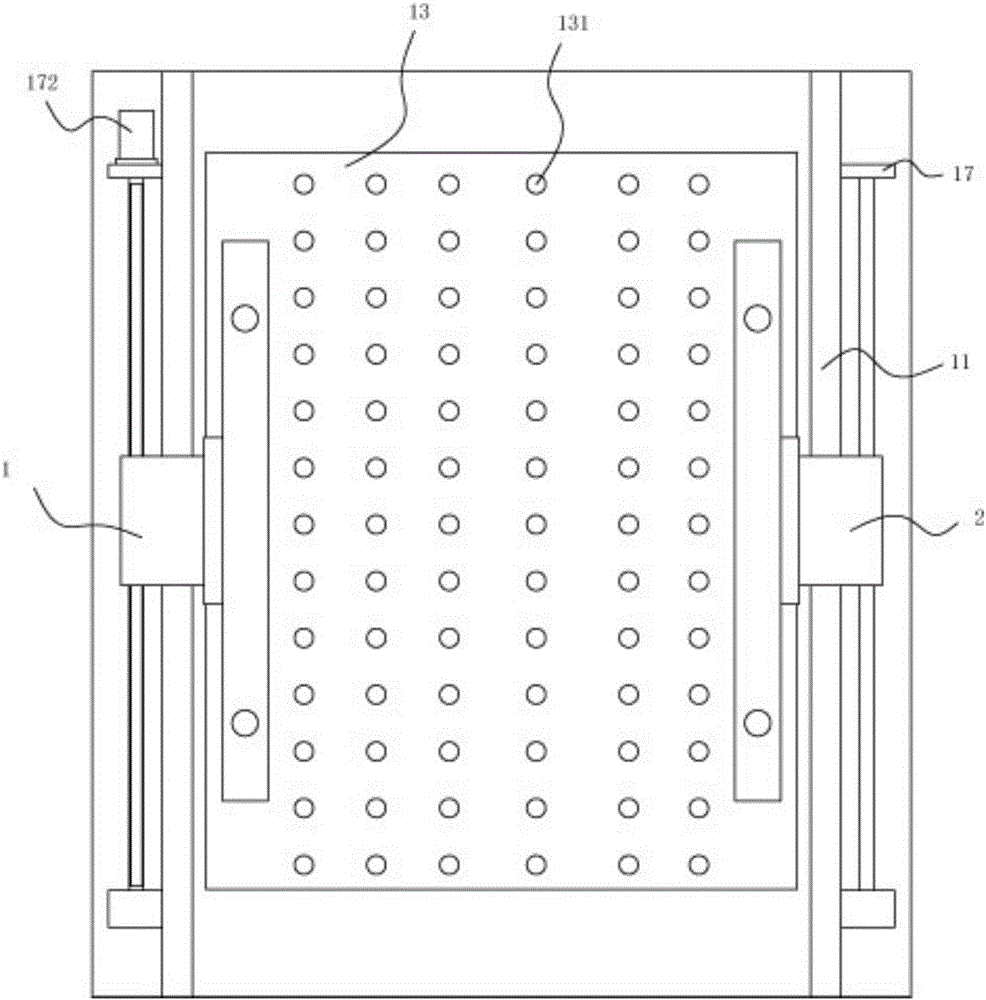

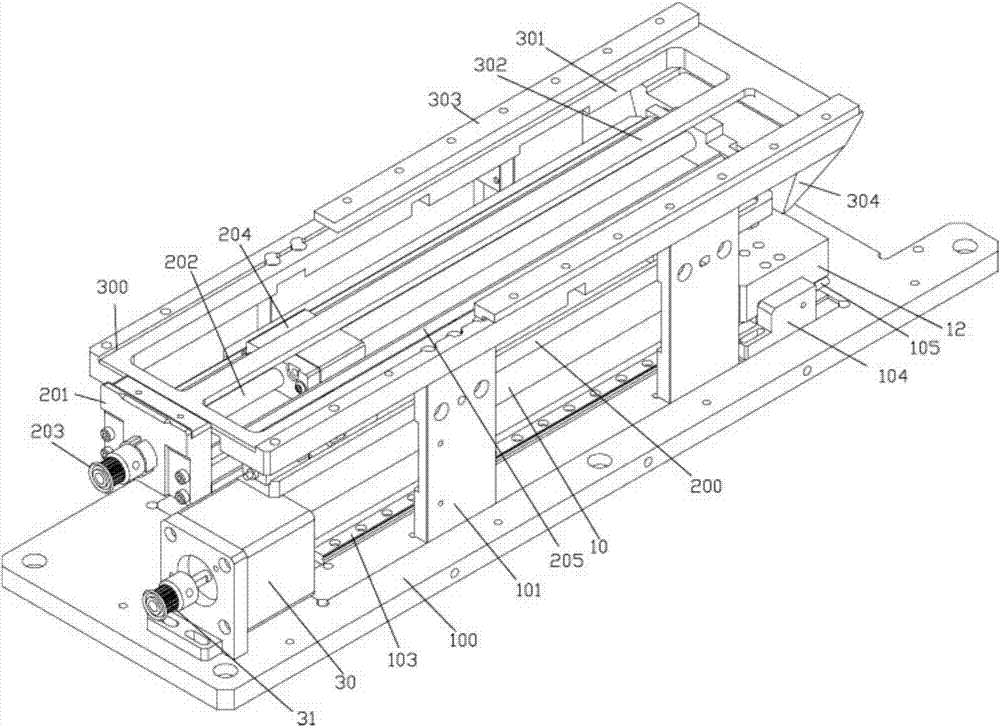

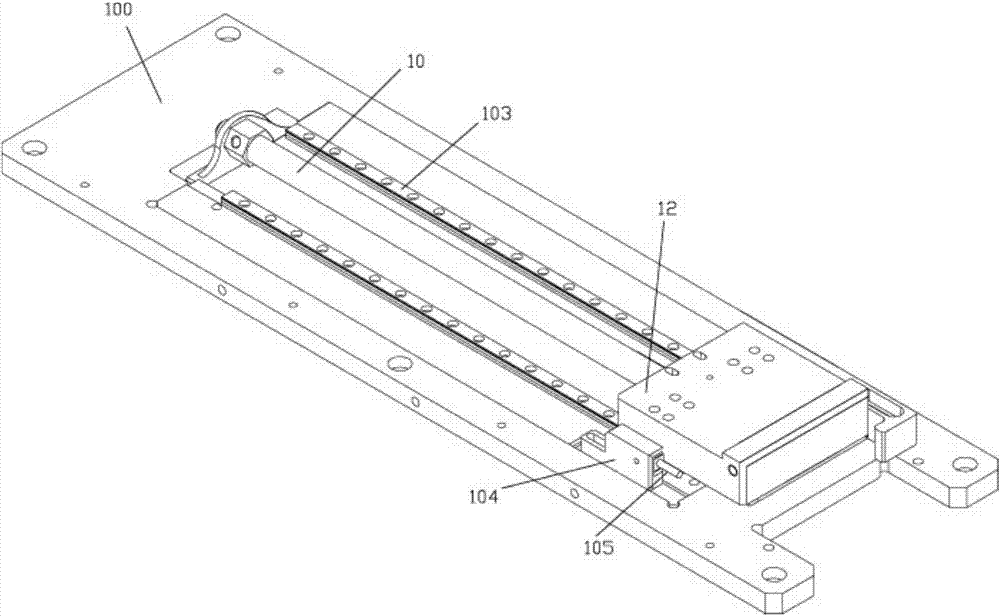

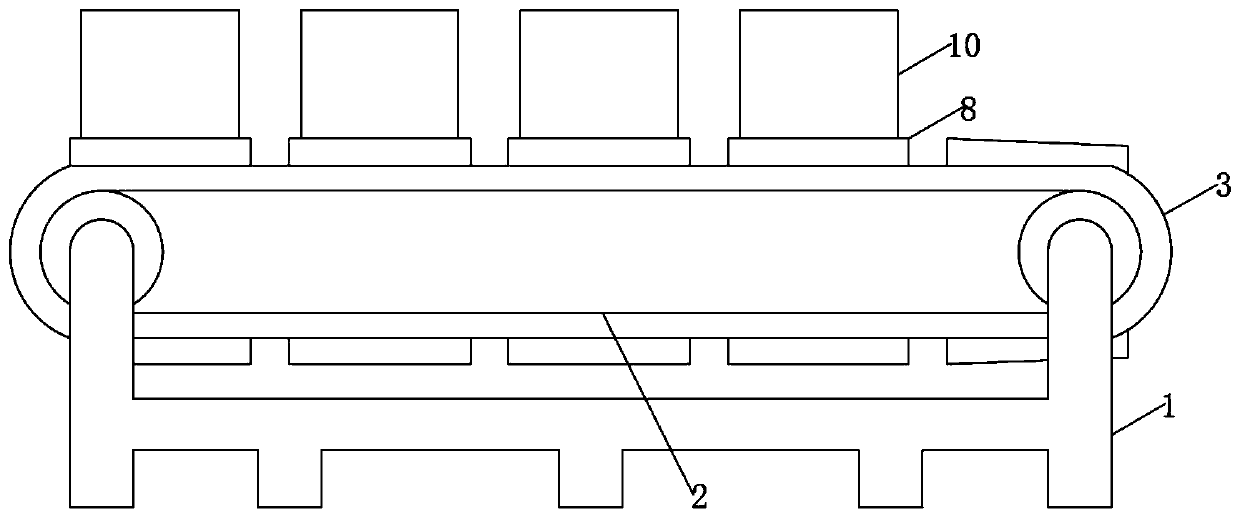

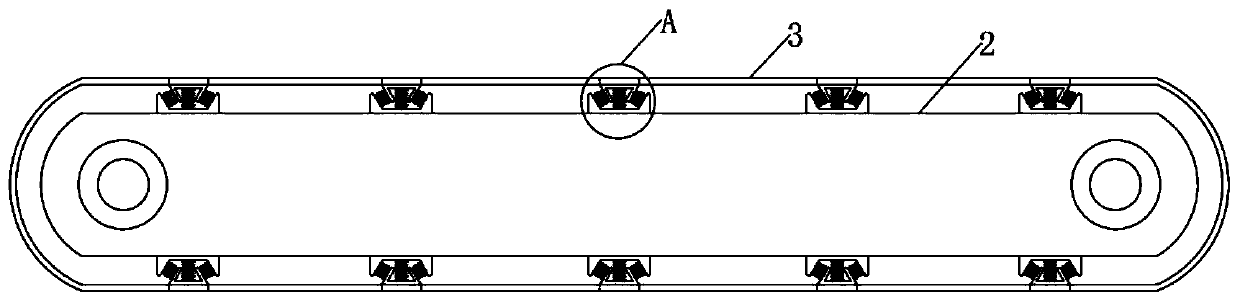

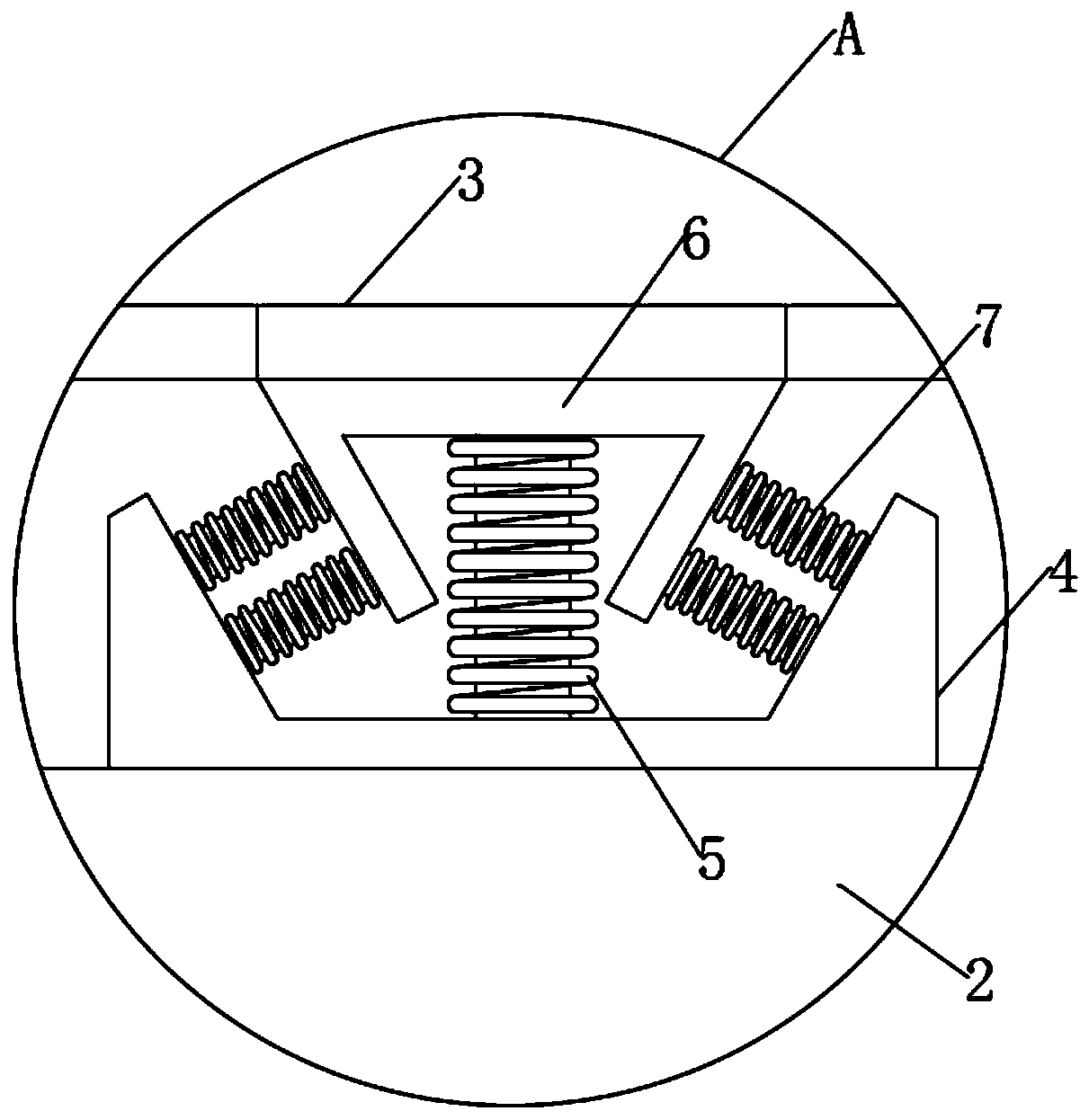

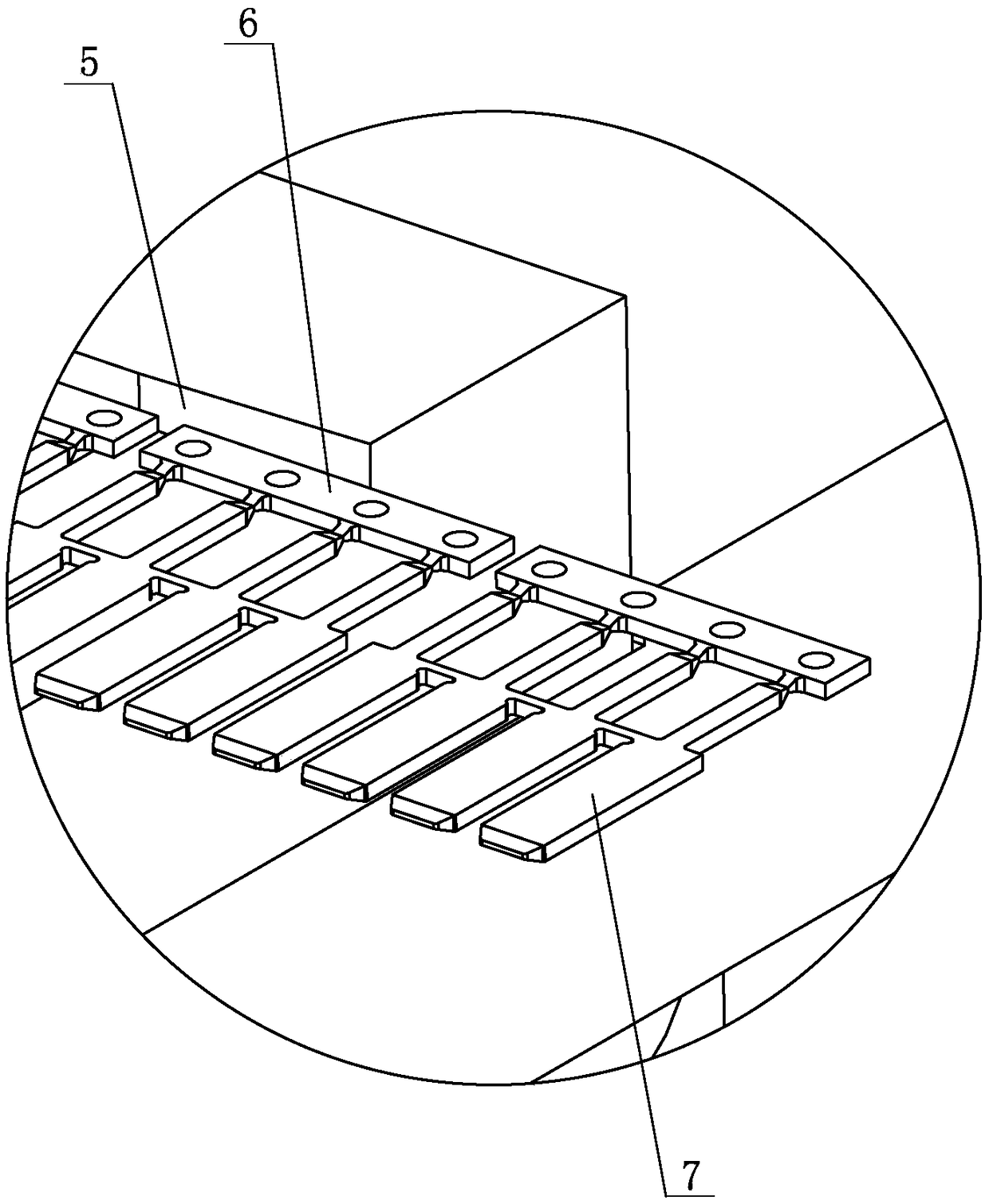

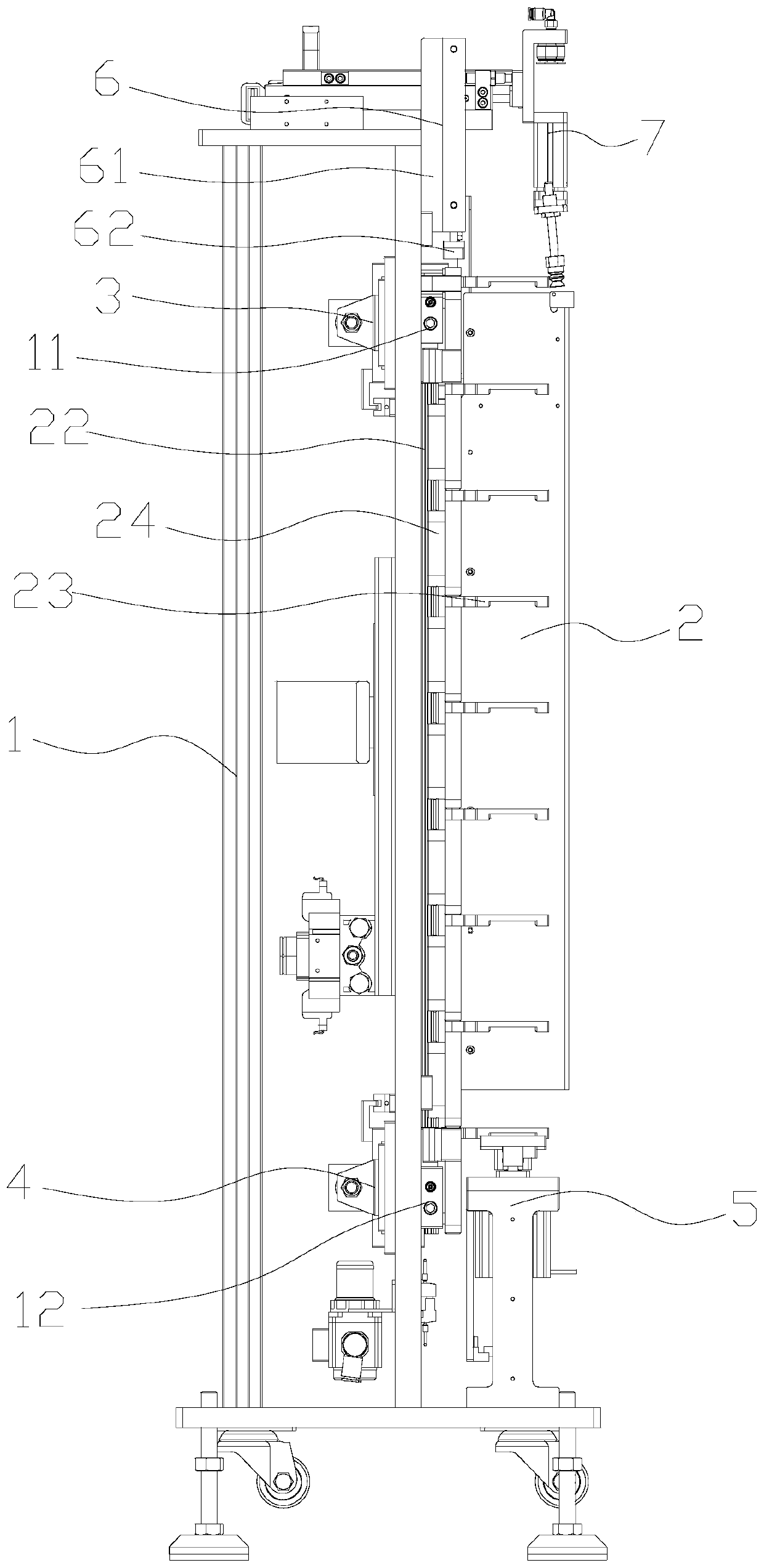

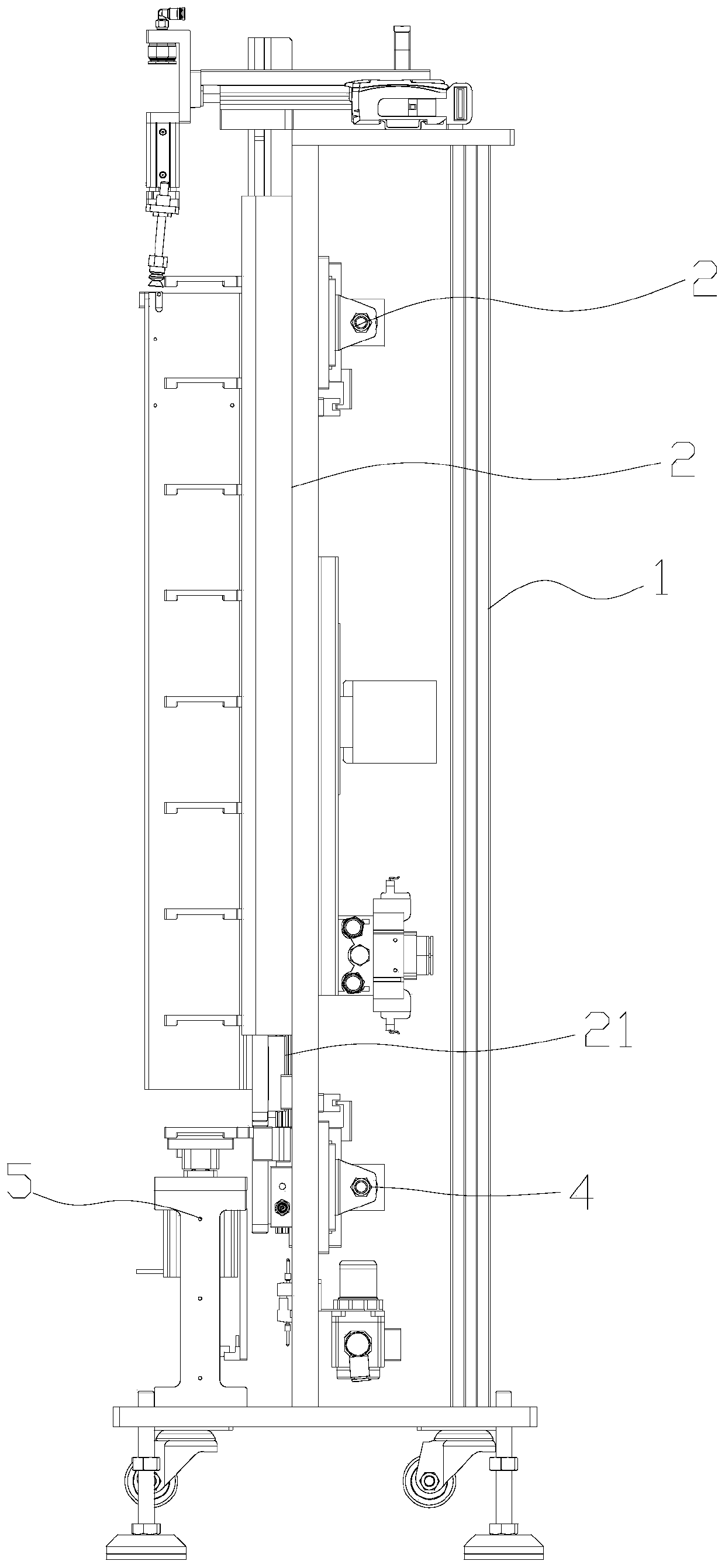

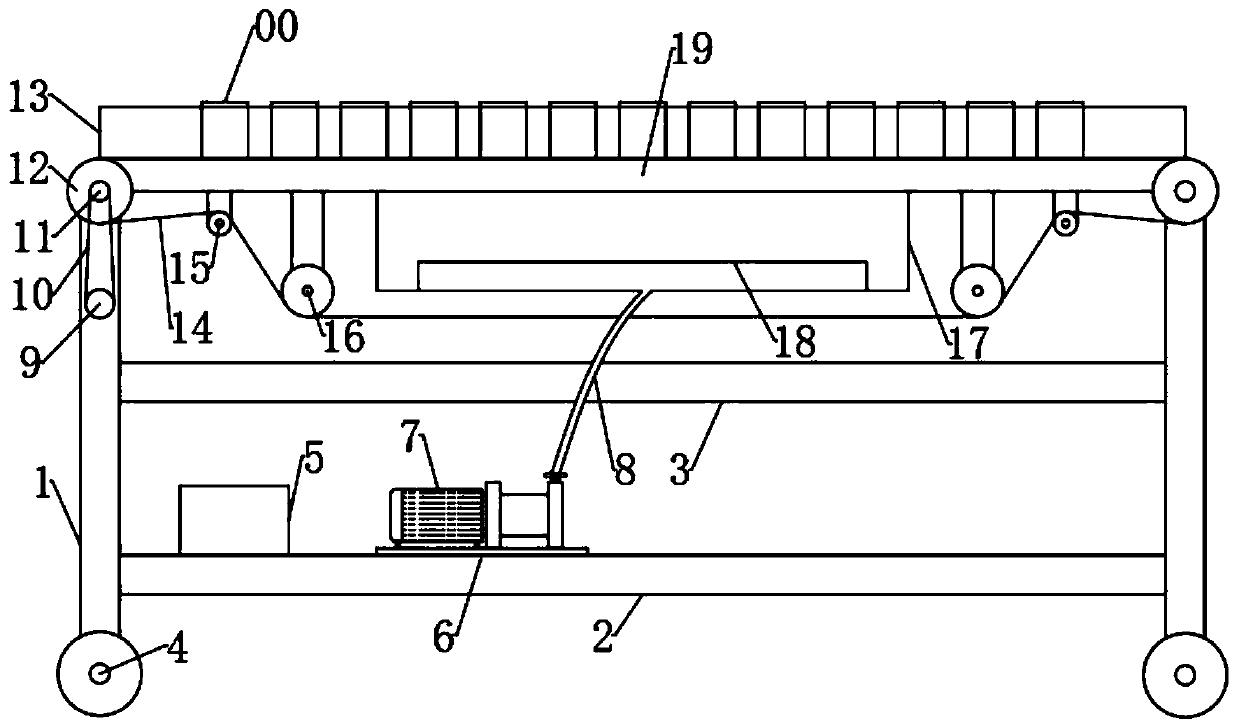

Transmission device of a sheet material automatic feeding mechanism

ActiveCN104986548BGuarantee delivery qualityCharge manipulationConveyor partsDrive wheelAutomatic transmission

The invention discloses a transmission device of a sheet material automatic feeding mechanism, comprising a fixed plate, a plurality of support plates are fixed on the front and rear sides of the fixed plate, an upper moving frame is fixed on the upper part of the support plate, and a material placing frame is fixed on the support plate On the top surface of the upper mobile frame, a rodless cylinder is fixed on the fixed plate below the upper mobile frame, a stepping motor is fixed on the left end of the fixed plate, a driving wheel is fixed on the output shaft of the stepping motor, and the left and right ends of the upper mobile frame Both ends of the moving screw are fixed with connecting plates, and the two ends of the moving screw are respectively hinged on the corresponding connecting plates. The left end of the moving screw protrudes from the connecting plate and is fixed with a driven wheel. Screwed into the moving screw. It fixes the clamps on the rear sliding block and the slider of the rodless cylinder respectively, clamps the two ends of the sheet material on the two clamps, and realizes the conveying of the sheet material through the synchronous operation of the rodless cylinder and the stepping motor. Ensure that the sheet material is always in a taut state.

Owner:BOZHON PRECISION IND TECH CO LTD

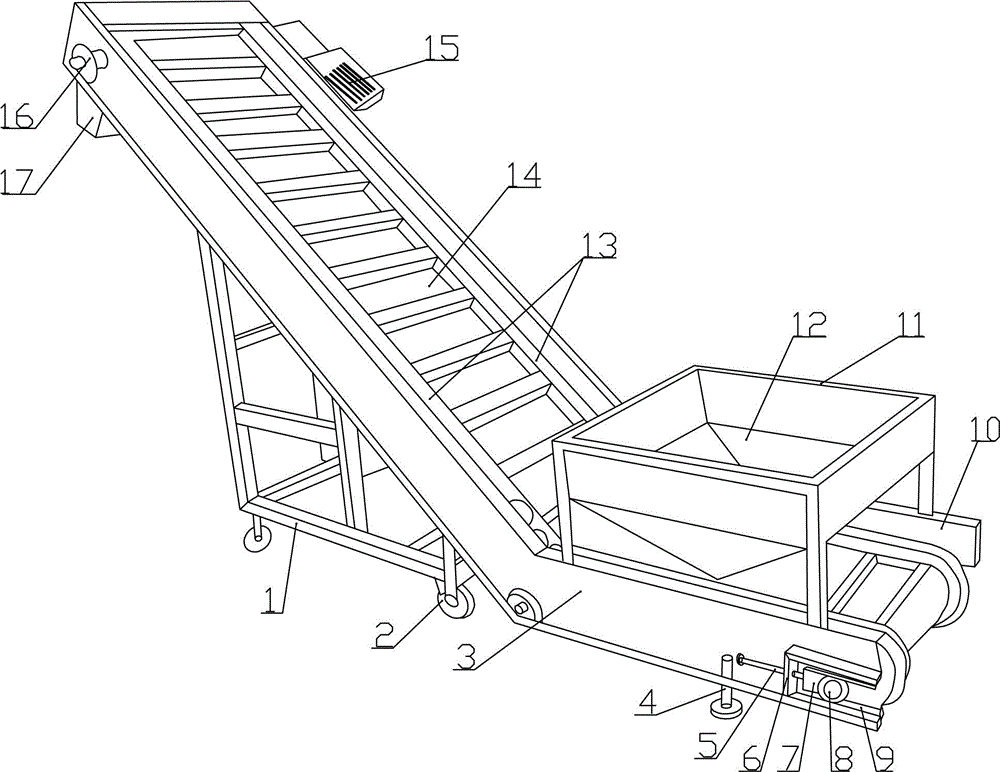

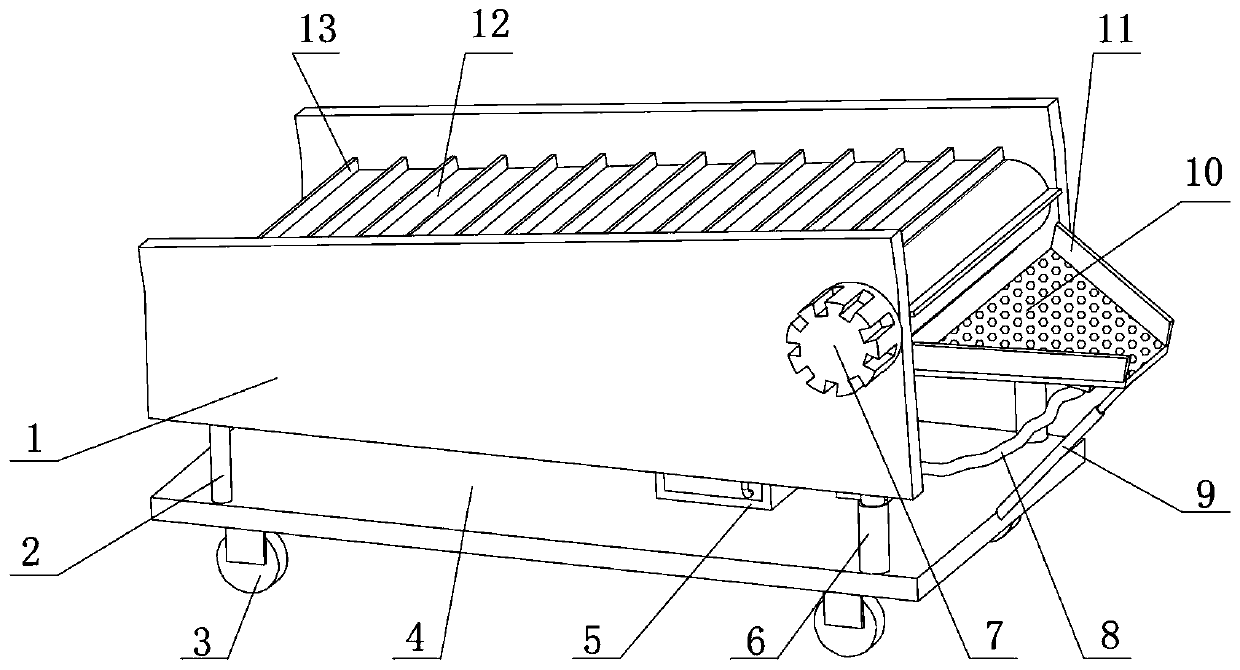

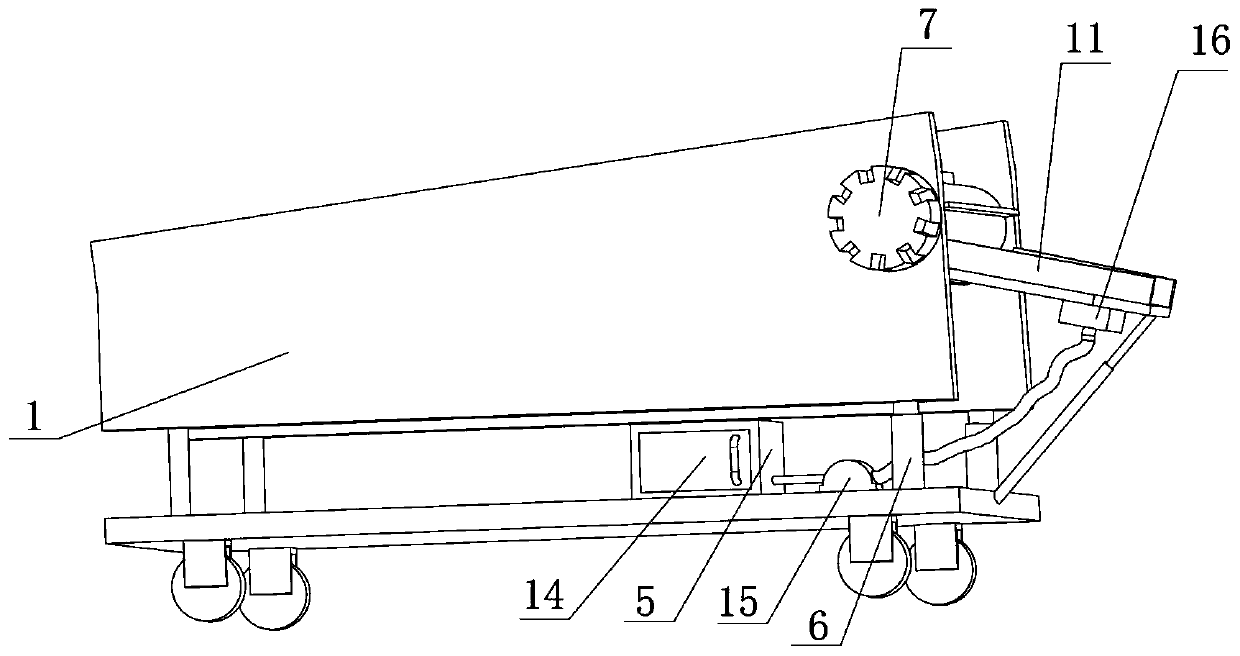

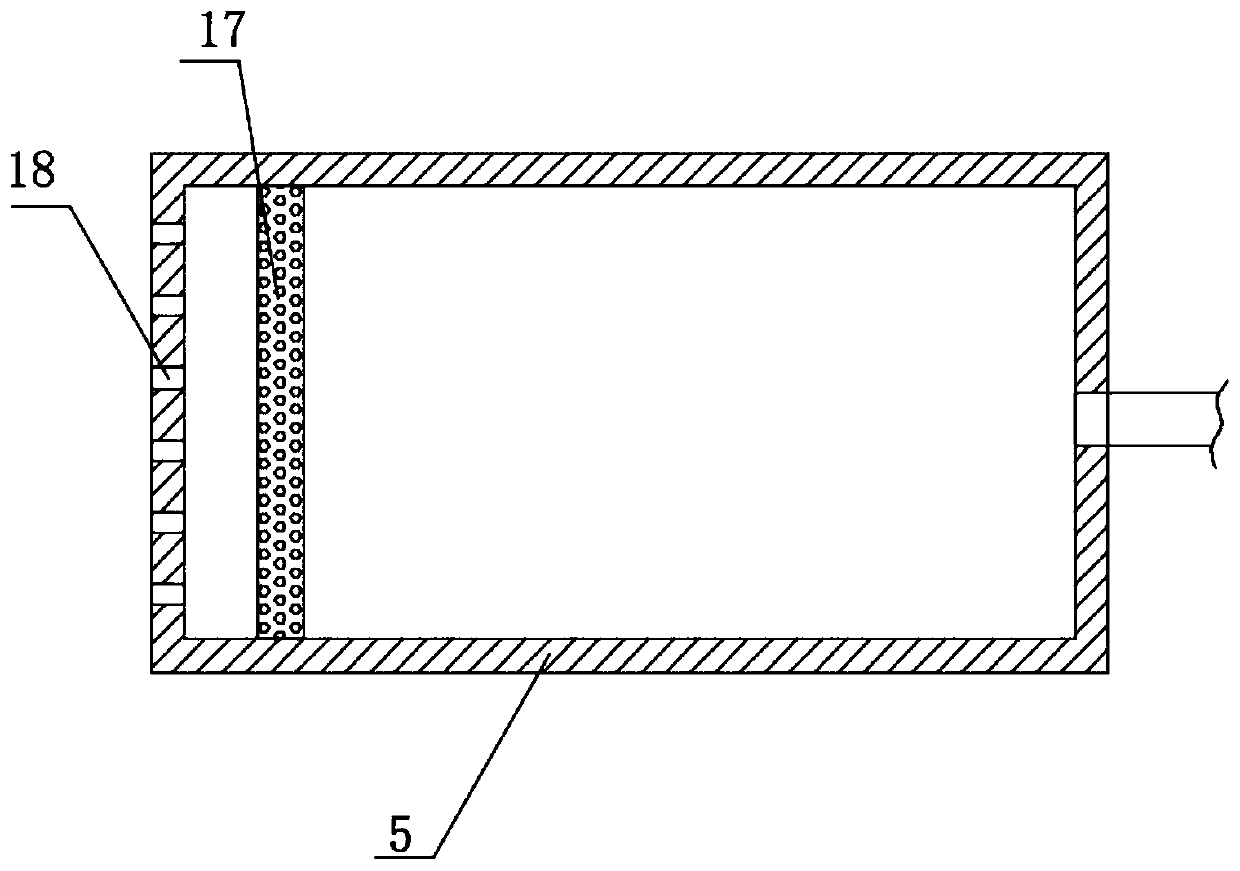

Traditional Chinese medicine material hoister with transportation quantity convenient to control

InactiveCN106516582ANo changeTo achieve the purpose of quantitative deliveryConveyorsLoading/unloadingDrive shaftEngineering

The invention relates to a traditional Chinese medicine material hoister with the transportation quantity convenient to control. Sliding wheels are mounted at the bottom end of a rack. A left protection plate and a right protection plate are obliquely mounted on the rack. The horizontal section of the left protection plate and the horizontal section of the right protection plate are mounted on threaded adjustable supporting legs. A discharging support is mounted on the top face of the horizontal section of the left protection plate and the top face of the horizontal section of the right protection plate and provided with a discharging funnel. A hopper is mounted under the discharging funnel and arranged between two conveying belts. The conveying belts are connected with a driving shaft and a driven shaft at the same time. The driving shaft is connected with a motor, and the motor is fixedly mounted on the side face of the right protection plate. According to the hoister, automatic feeding can be achieved, traditional Chinese medicine materials are conveyed to a higher position from a lower position, and therefore manual operation is saved; and when granular traditional Chinese medicines are transported, the transportation quantity of every time can be controlled, and it is guaranteed that the transportation quantities of all times are approximately identical.

Owner:HUBEI KUNYAN PHARMA

OLED electronic display screen production conveying device

The invention relates to the technical field of display screen production equipment, in particular to an OLED electronic display screen production conveying device comprising a mounting rack. A fixingbelt is welded on the surface of the mounting rack, and the surface of a mounting disk is in bolt connection with outer fixing sleeves; clamping plates are welded on the surfaces of inner telescopicrods, and the surfaces of the clamping plates are in bolt connection with inner pneumatic push plates; and regulating grooves are welded on the surfaces of fixing frames, and regulating blocks are slidably connected with the interiors of the regulating grooves. The conveying device has the beneficial effects that a speed reduction motor is started when an OLED display screen is conveyed to a second conveyor belt, so that the clamping plates are rotated to the upper end of the OLED display screen; the inner telescopic rods are regulated towards the lower end, so that the regulating blocks enterthe regulating grooves; outer pneumatic push plates are regulated outwards the outer end, so that the two groups of the fixing frames are separated; at the moment, the two groups of the inner pneumatic push plates are regulated inwards for enabling the OLED display screen to be clamped and fixed; the speed reduction motor is regulated continuously, and then the OLED display screen can be transferred; the operation is automatic, and the conveying efficiency is high; and the conveying device is suitable for promotion.

Owner:WEIFANG UNIVERSITY

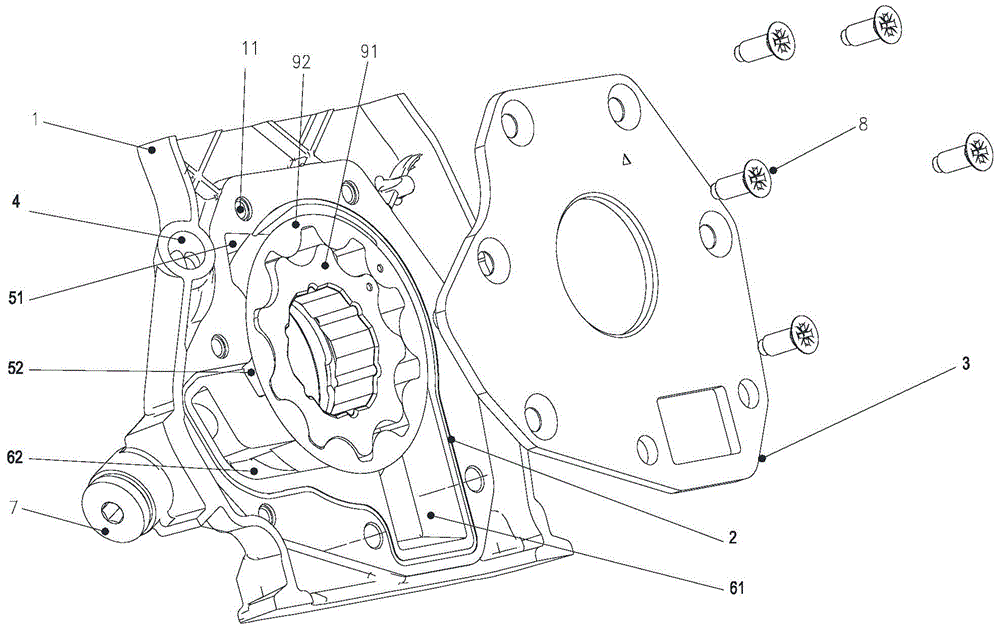

Engine oil pump of internal combustion engine

ActiveCN104482385AAvoid foamingImprove machine performanceLubricating pumpsPressure lubrication with lubrication pumpExternal combustion engineInternal combustion engine

The invention discloses an engine oil pump of an internal combustion engine. The engine oil pump comprises a pump shell provided with an oil inlet cavity, wherein a sealing groove for sealing the oil inlet cavity is also formed in the pump shell; an oil outlet and an oil outlet cavity I communicated with the oil outlet are formed in the pump shell; the sealing groove is an oil groove which is communicated with the oil outlet cavity I and is filled with high-pressure engine oil to realize oil sealing. According to the engine oil pump of the internal combustion engine, the sealing groove special for sealing the oil inlet cavity is formed in the pump shell, so that air can be effectively prevented from being sucked into the oil inlet cavity in an oil sealing way through the sealing groove, the situations of insufficient engine oil pressure and foaming of engine oil are avoided, and successful conveying of engine oil and the lubricating quality are ensured. Therefore, the overall performance of the engine is enhanced, the service life of the engine is prolonged, and the energy-saving effect is enhanced.

Owner:重庆渝安淮海动力有限公司

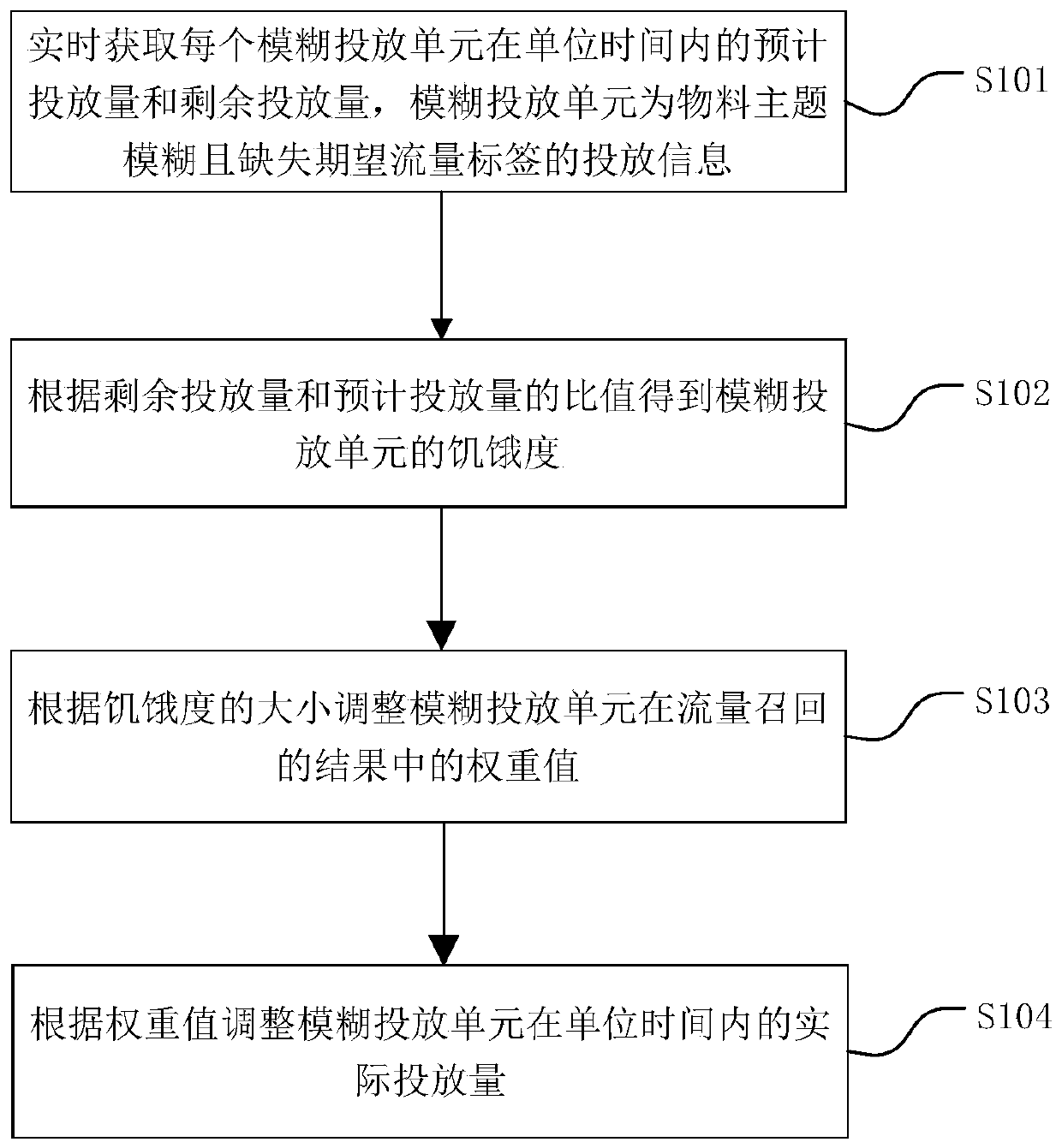

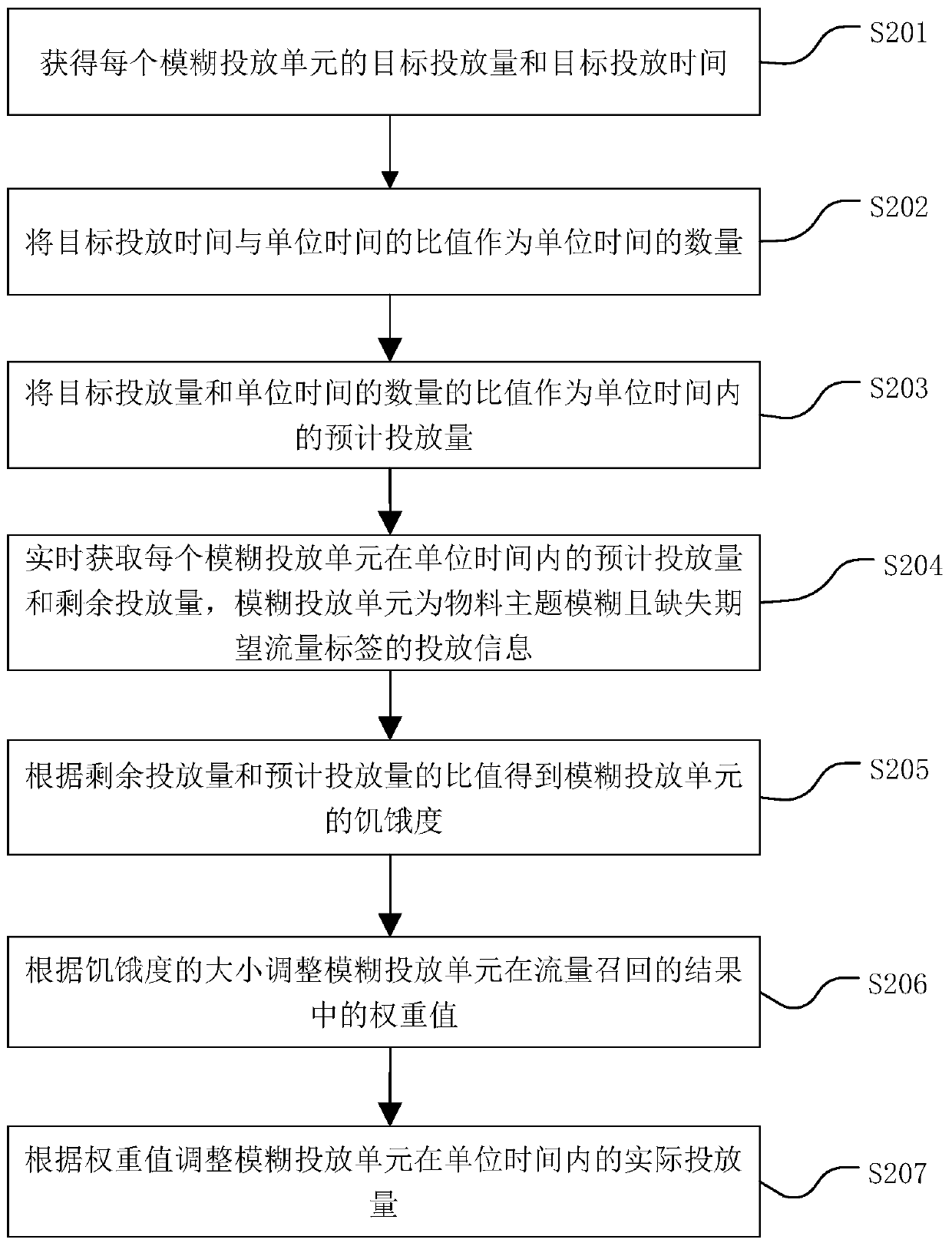

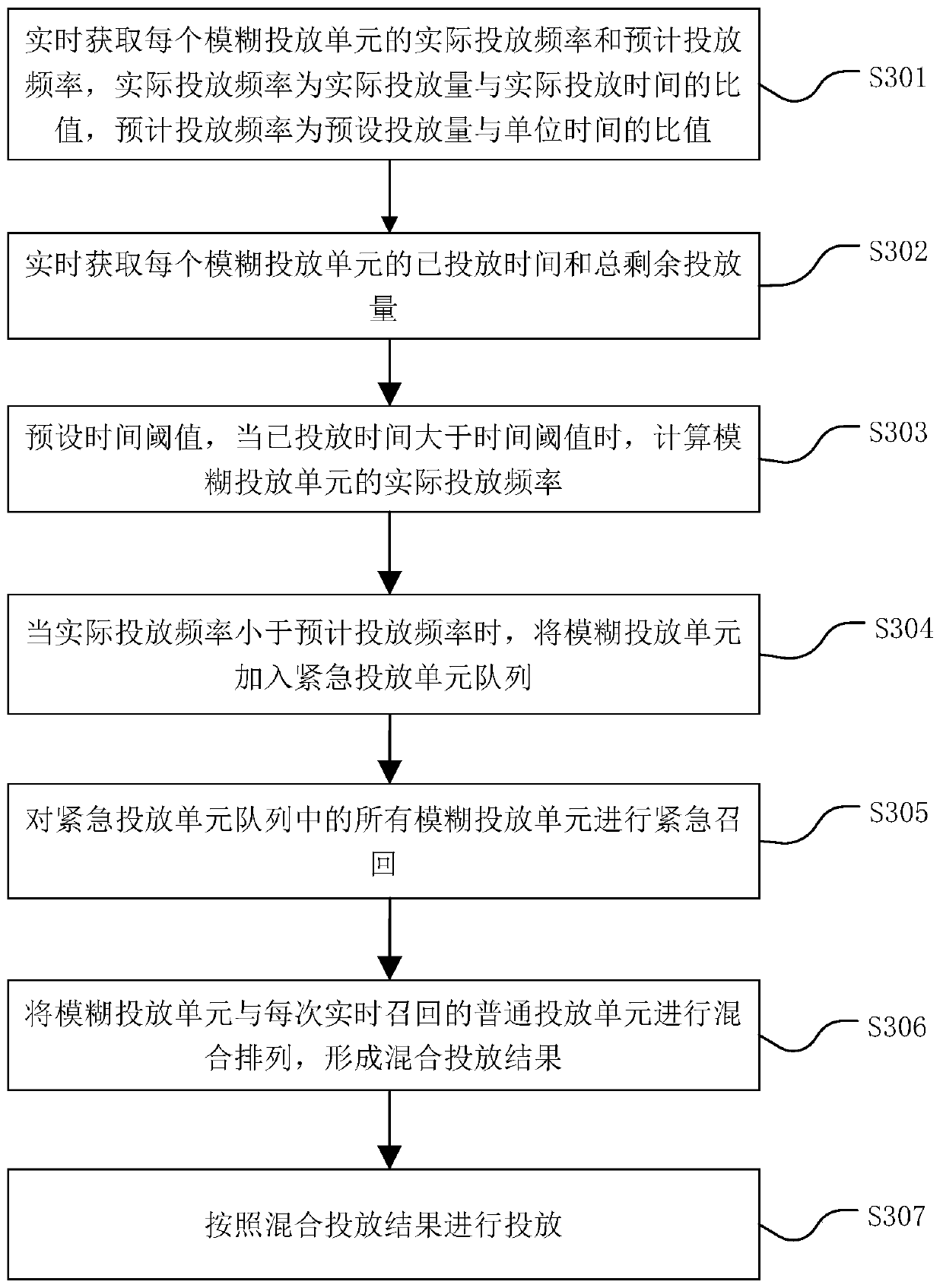

Information delivery method, information delivery device and computer readable storage medium

PendingCN111598598AReal-time monitoring of delivery volumeReal-time monitoring of delivery timeAdvertisementsReliability engineeringReal-time computing

The invention relates to an information delivery method, an information delivery device and a computer readable storage medium. The information delivery method comprises the steps that the predicted delivery amount and the remaining delivery amount of each fuzzy delivery unit in unit time are obtained in real time, and the fuzzy delivery units are delivery information with fuzzy material themes and missing expected flow labels; the starvation degree of the fuzzy putting unit is obtained according to the ratio of the remaining putting amount to the estimated putting amount; a weight value of the fuzzy putting unit in a flow recall result is adjusted according to the starvation degree; and the actual putting amount of the fuzzy putting unit in unit time is adjusted according to the weight value. According to the information delivery method, the weight value of each fuzzy delivery unit in the recall result is adjusted by calculating the hunger degree of each fuzzy delivery unit in unit time, so that the delivery effect can be optimized, the delivery quality can be pursued and the user experience can be improved on the premise of ensuring the quantity.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Novel solar thermal insulation snack cabinet

InactiveCN105996793ARealize the insulation effectImprove delivery efficiencyWarming devicesThermal insulationEngineering

The invention discloses a novel solar heat preservation fast food cabinet, which comprises a body, a heat collecting tube, a block, a placement plate, an inner body, a heat preservation cavity, an outer body and a buffer base, the body is composed of an outer body and an inner body, the outer body and A thermal insulation cavity is provided between the inner bodies, several heat collecting tubes are provided on the upper end of the outer body, transparent baffles are provided on the upper ends of the heat collecting tubes, blocks are arranged at equal intervals on the left and right inner walls of the inner body, and the inner body is provided with There are several placement plates, and the bottom of the main body is provided with a buffer base. The present invention has a simple and reasonable structure, good heat preservation effect, maximizes the utilization rate of the inner space of the dining cabinet, and improves the delivery efficiency of the staff.

Owner:成都锦汇绿源环保技术有限公司

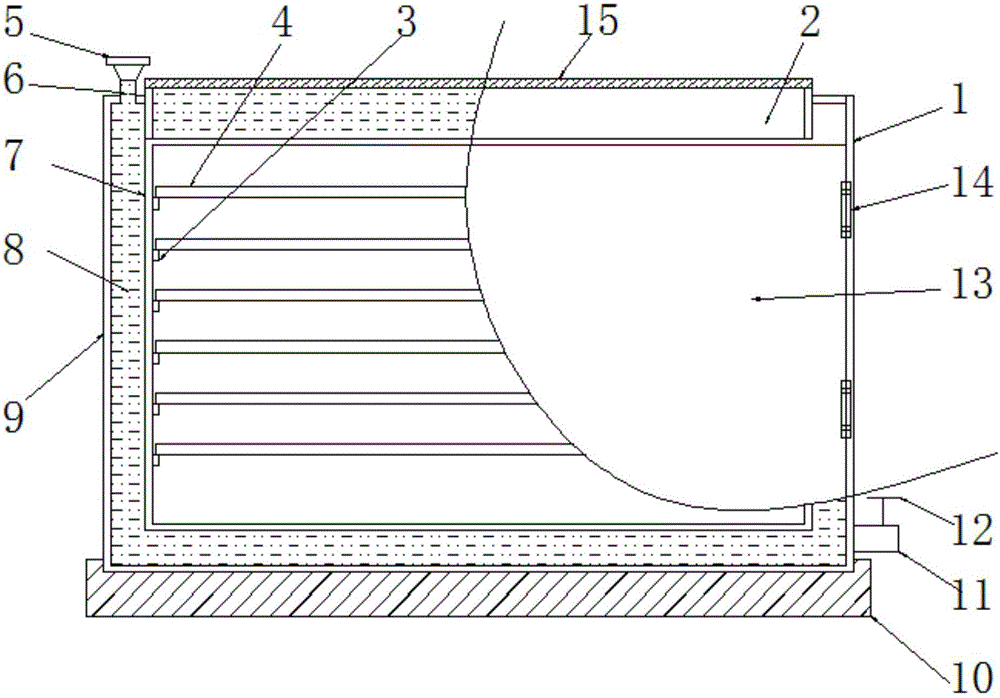

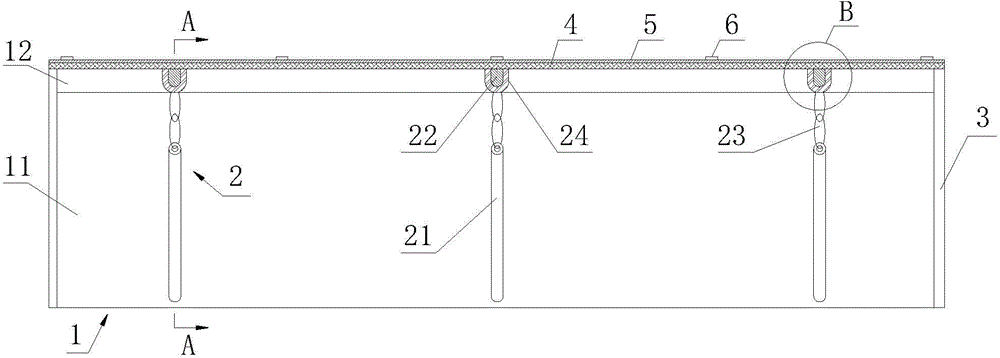

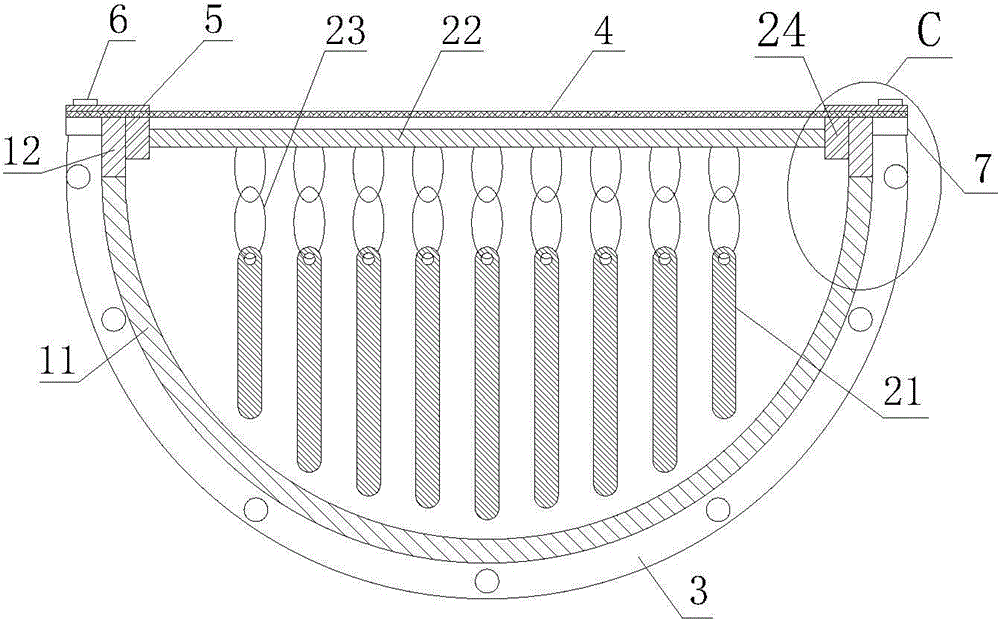

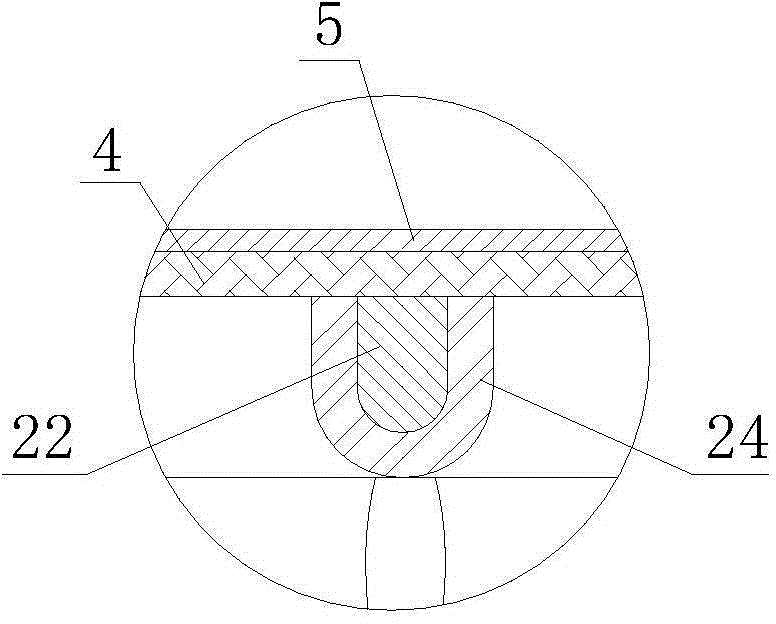

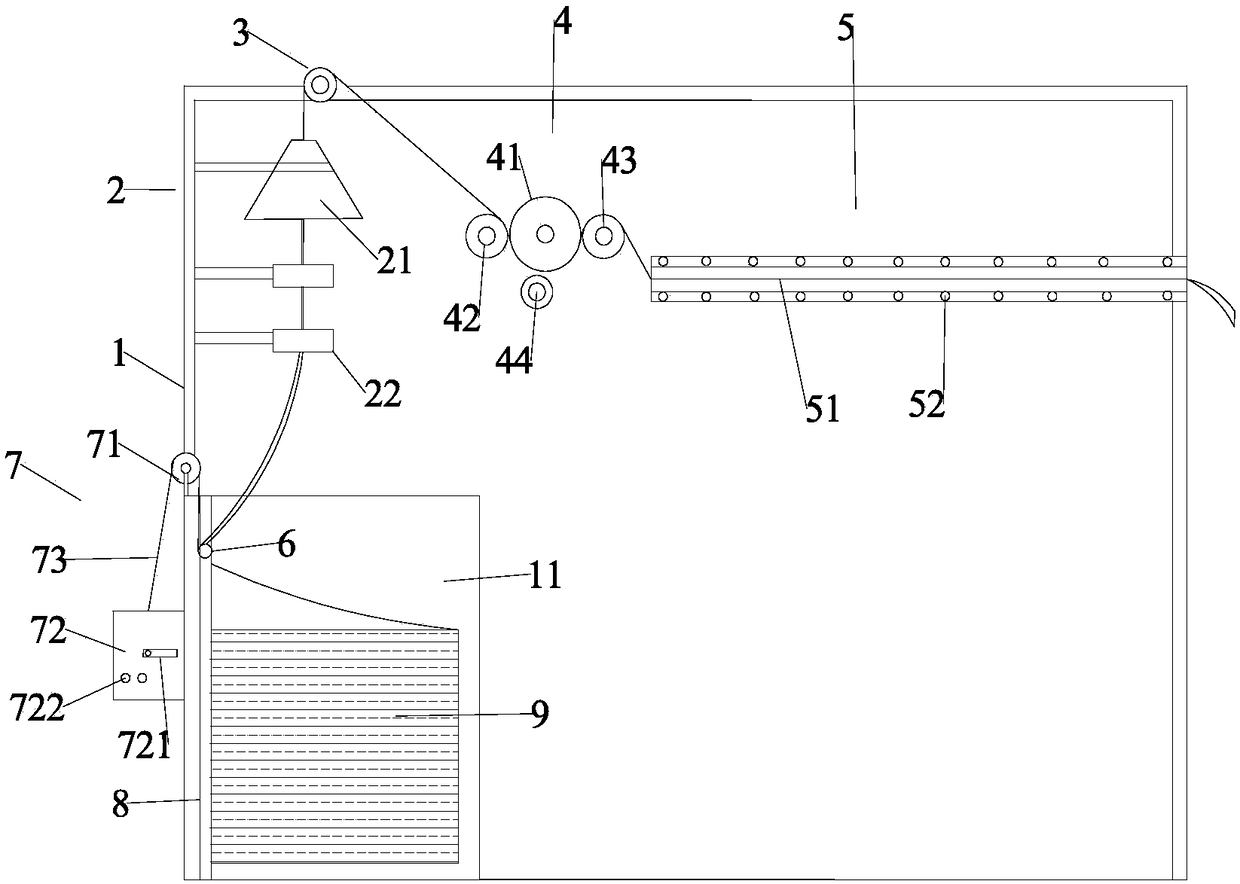

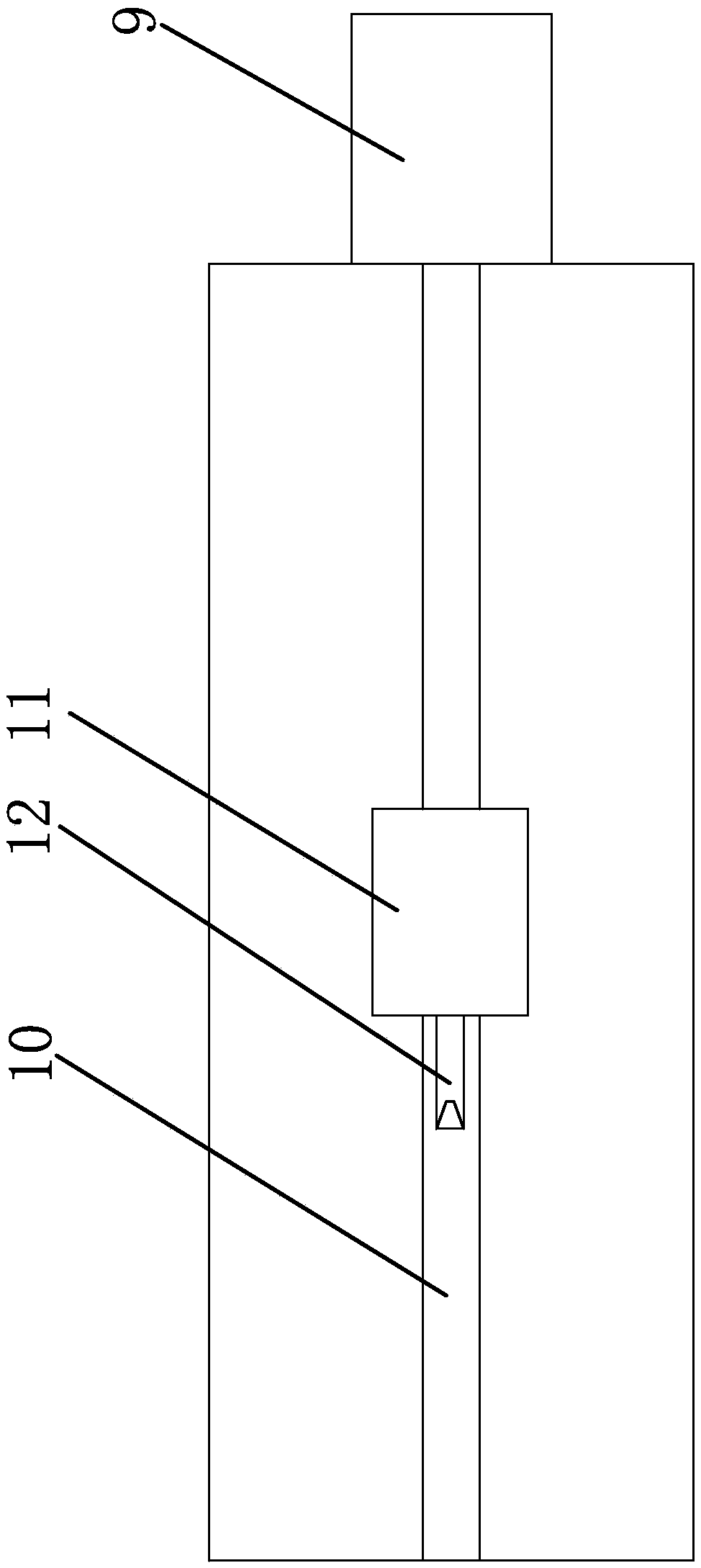

Heavy hammer type slow descent chute for conveying concrete

ActiveCN104790403AOptimize layoutImprove delivery capacityFoundation engineeringStructural engineeringUltimate tensile strength

The invention discloses a heavy hammer type slow descent chute for conveying concrete. The heavy hammer type slow descent chute for conveying the concrete comprises a chute body which is composed of a semicircular steel tube and a perpendicular section which is arranged on an opening of the semicircular steel tube, and the chute body is further internally provided with multiple damping devices, wherein each damping device comprises heavy hammers, a cross bar and connection parts, U-shaped necks are formed in the inner wall of the perpendicular section, the two ends of cross bars are installed in the U-shaped necks respectively, the heavy hammers are evenly arranged on the corresponding cross bars through the connection parts, the top end of the chute body is covered with a rubber cover plate, the two sides of the rubber cover plate are fixed on the opening of the chute body through rubber cover depression bars, and chute lugs are arranged on the outer side of the perpendicular section of the chute body and used for fixing and connecting the rubber cover plate at the top end. According to the heavy hammer type slow descent chute for conveying the concrete, the conveying quality of the concrete is guaranteed in the concrete conveying process, the phenomena of aggregate separation, aggregate secondary crushing, chute blocking and the like are avoided, and meanwhile the conveying intensity of the concrete can be guaranteed.

Owner:SINOHYDRO BUREAU 9

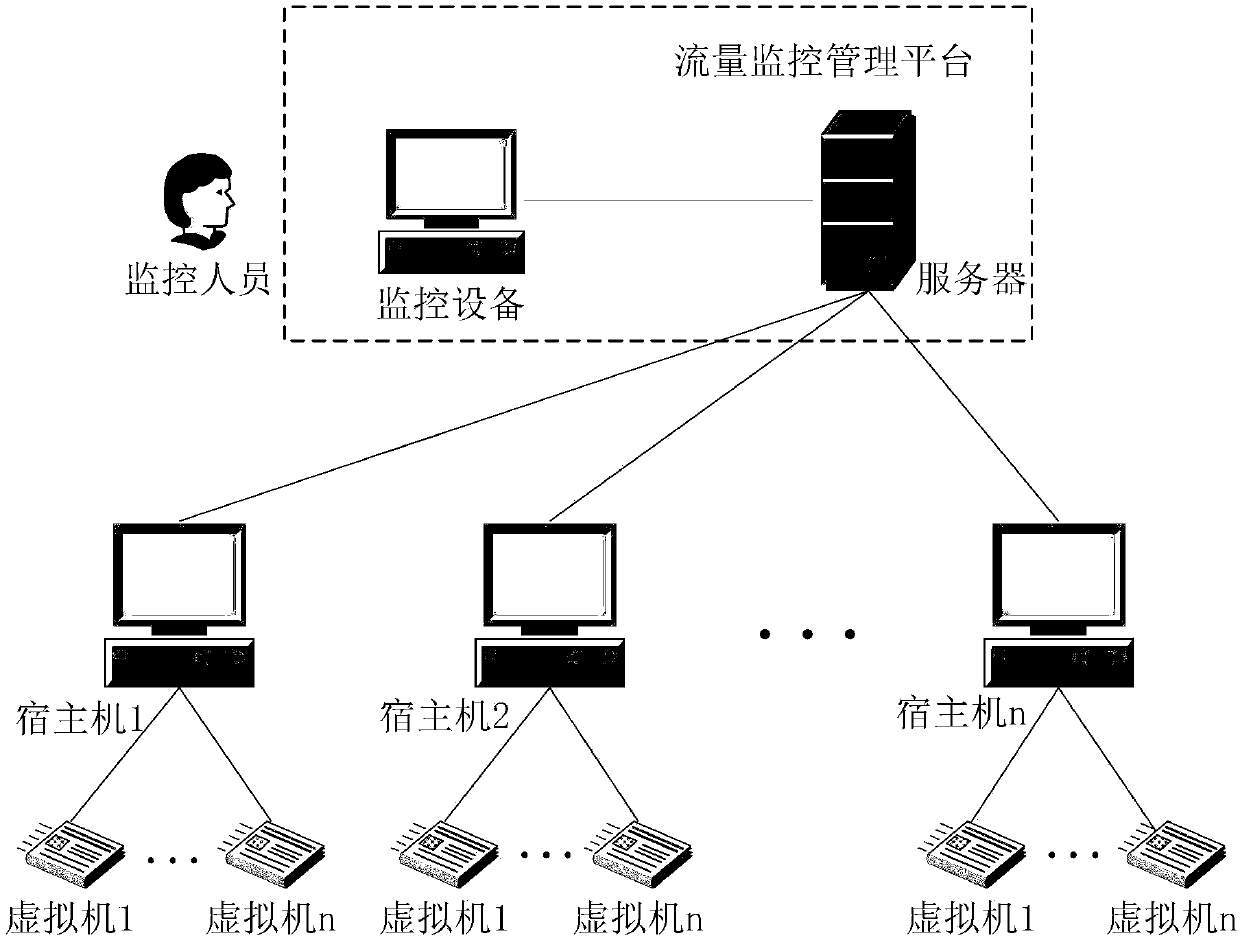

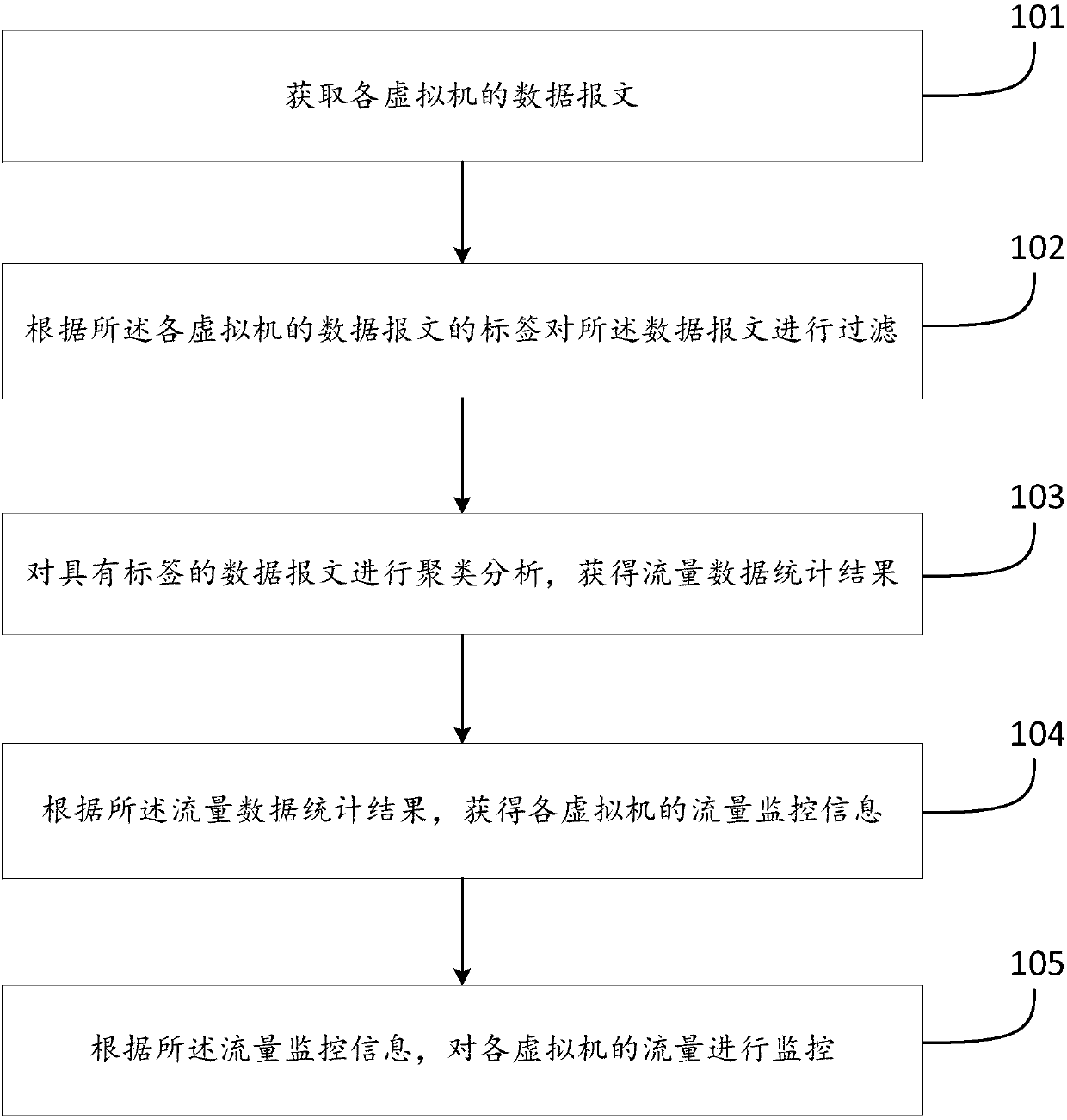

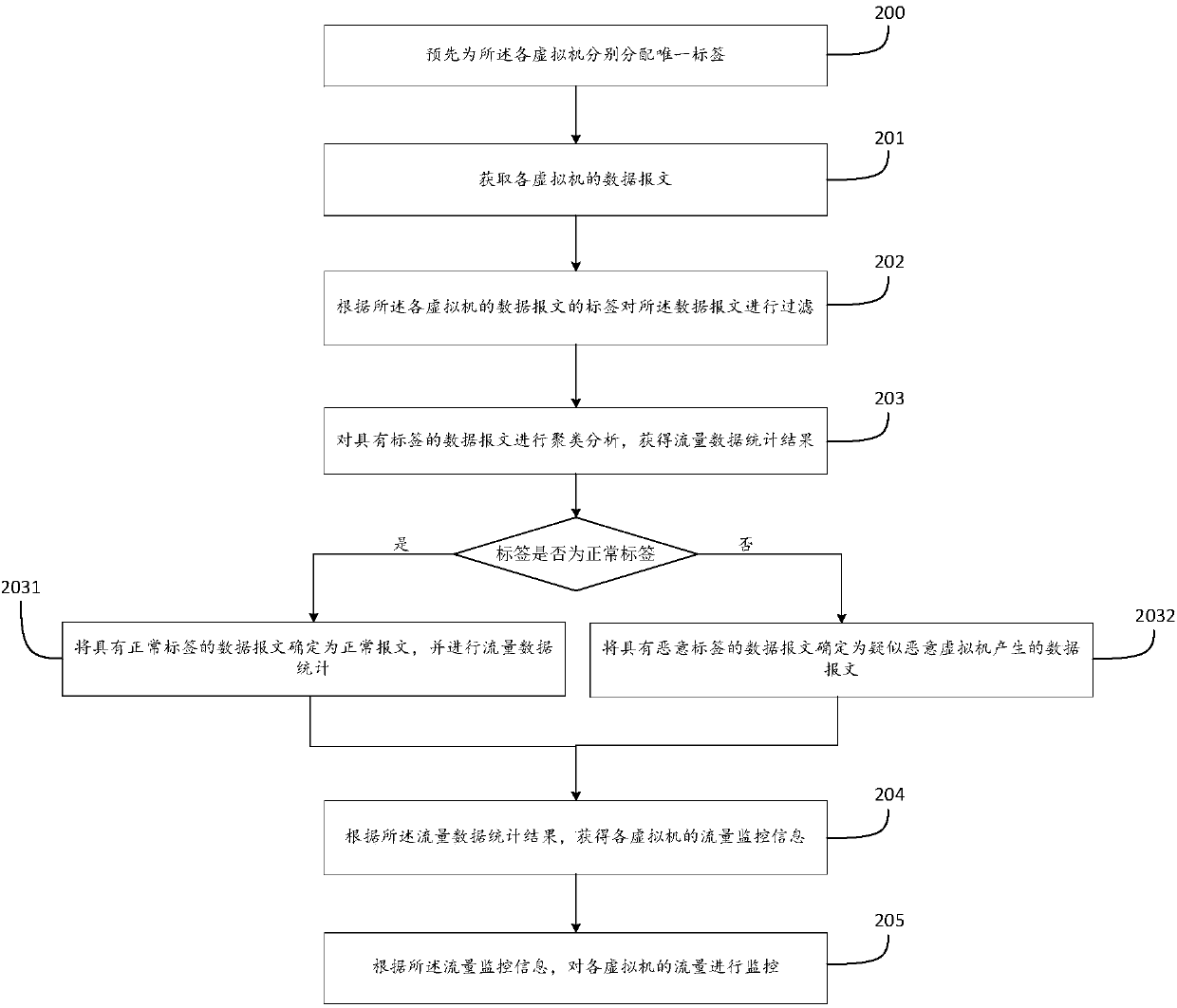

Flow monitoring method and system

ActiveCN110198246AImprove securityReduced risk of tamperingData switching networksSoftware simulation/interpretation/emulationTraffic capacityData mining

The invention relates to a flow monitoring method and system. The method comprises the following steps: binding a flow label to a container / virtual machine in advance; classifying and filtering according to the labels of the data messages of the container / virtual machine; carrying out clustering analysis on the data messages with the same labels to obtain a flow data statistical result; further, obtaining the flow monitoring information of each container / virtual machine; and finally, according to the flow monitoring information, monitoring the flow of each container / virtual machine. The problem that flow monitoring of a container / virtual machine without an independent network card is difficult is solved, and meanwhile the technical effects of being high in monitoring accuracy, zero in system overhead, capable of meeting the important flow monitoring requirement of online services, guaranteeing the delivery quality of online services and facilitating rapid discovery and positioning of the problems are achieved.

Owner:TENCENT TECH (BEIJING) CO LTD

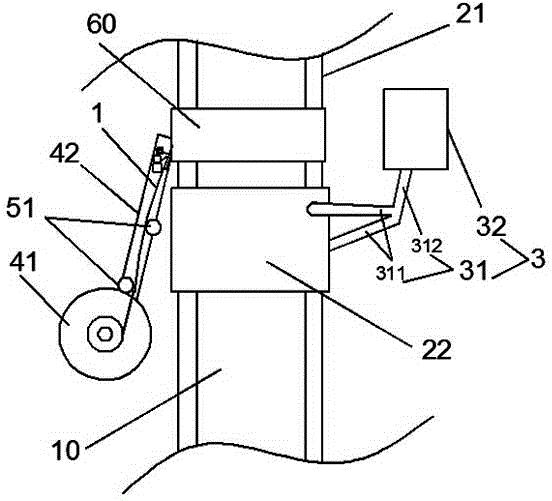

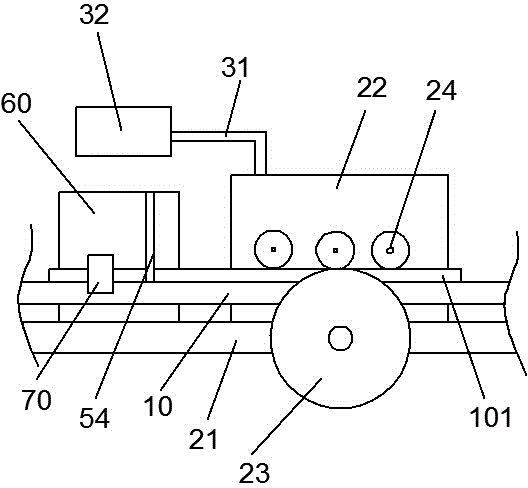

Turning conveying device for lamp circuit board machining

ActiveCN112591420AIncrease the tilt angleStable center of gravityConveyorsCharge manipulationRotational axisEngineering

The invention is applicable to the technical field of material conveying, and provides a turning conveying device for lamp circuit board machining. The turning conveying device comprises a feeding device, a turning device and a collecting device, wherein the feeding device comprises a first conveying belt, an inclined block and a jacking device, the jacking device comprises a fixing shell, a rotating shaft and a jacking block, the jacking block comprises fixing rings and bulges, the turning device comprises a rotating wheel and a limiting piece, the collecting device comprises a material guiding plate, a telescopic piece and a limiting plate, a supporting plate is installed on the side face of the material guiding plate, a limiting block is installed at the upper end of the inner side of the supporting plate, the bottom of the limiting block is arc, a limiting column is arranged on one side of the extending section, a torsion spring is installed between the limiting block and the supporting plate, one side of the material guiding plate is provided with a moving space for containing the limiting plate, and elastic pieces are installed between the two sides of the end of the limitingplate and the moving space. According to the turning conveying device, the direction-changing conveying of materials can be effectively realized, and the working efficiency and the direction-changingconveying stability are improved.

Owner:山东三晶照明科技有限公司

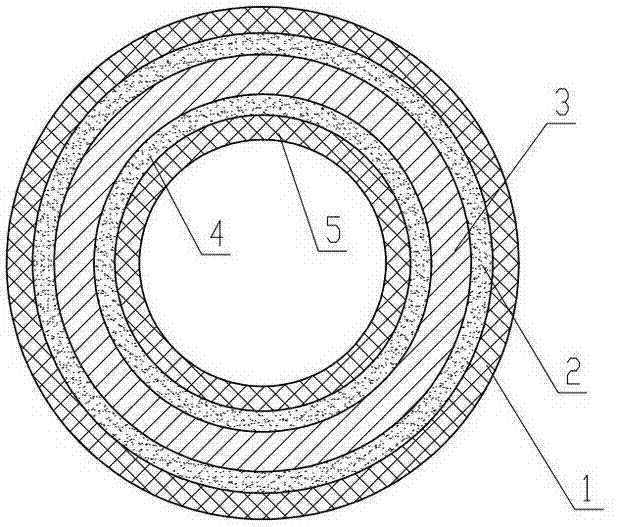

Composite steel-plastic pressure pipe for conveying hot water

InactiveCN103195986APrevent oxidation and rustExtended service lifeRigid pipesElectrogalvanizationAdhesive

The invention discloses a composite steel-plastic pressure pipe for conveying hot water. The composite steel-plastic pressure pipe for conveying hot water comprises an outer polyethylene layer, a stainless steel pipe layer and an inner polyethylene layer sequentially from outside to inside, the outer polyethylene layer and the stainless steel pipe layer are adhered through an outer adhesive layer, and the stainless steel pipe layer and the inner polyethylene layer are adhered through an inner adhesive layer. The composite steel-plastic pressure pipe has the advantages that stainless steel pipes substitute for traditional electro-galvanized steel tapes or electrolytic tinning steel tapes to serve as the middle layer of the composite steel-plastic pressure pipe, and stainless steel pipes are resistant to oxidation, so that oxidation and corrosion of the middle steel tape layer caused by oxygen permeation of the inner polyethylene layer can be prevented, and the service life of the composite steel-plastic pressure pipe can be prolonged; and the composite steel-plastic pressure pipe can be used for conveying hot water at the temperature higher than 70 DEG C and is applicable to the technical field of concentrated heating of buildings or chemical conveying of hot water.

Owner:XINXING DUCTILE IRON PIPES CO LTD

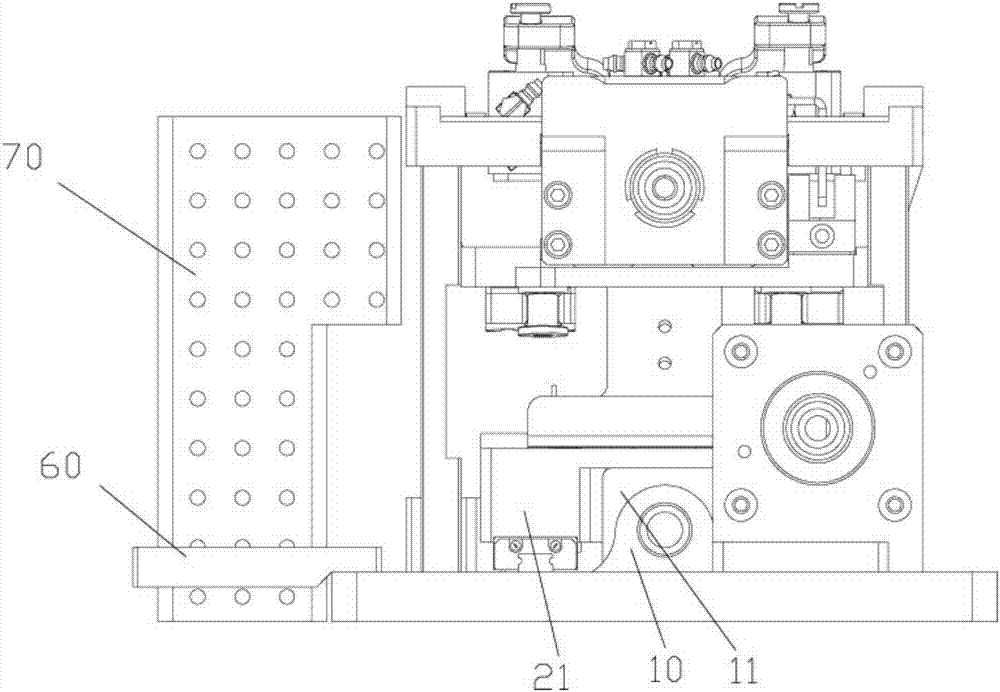

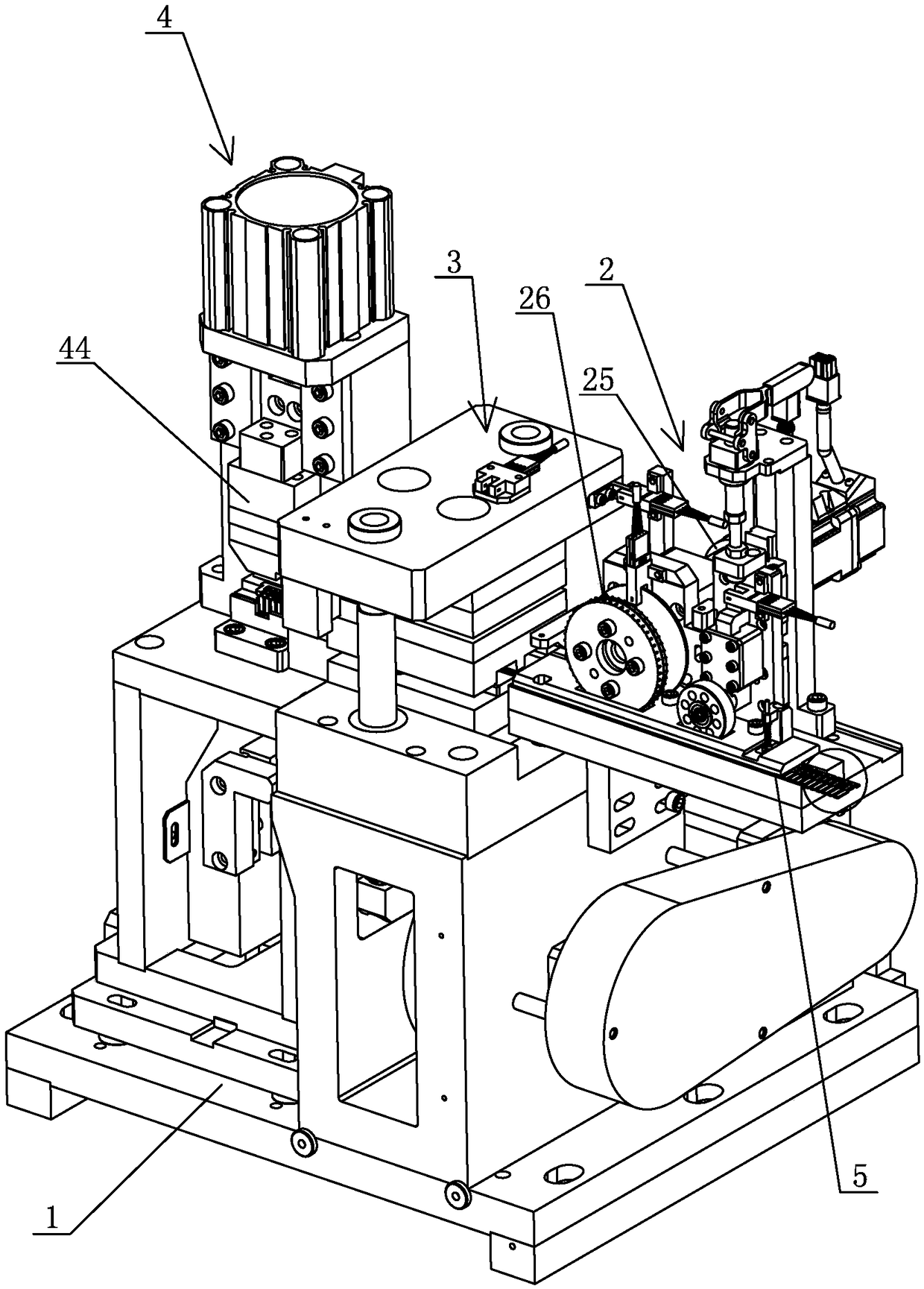

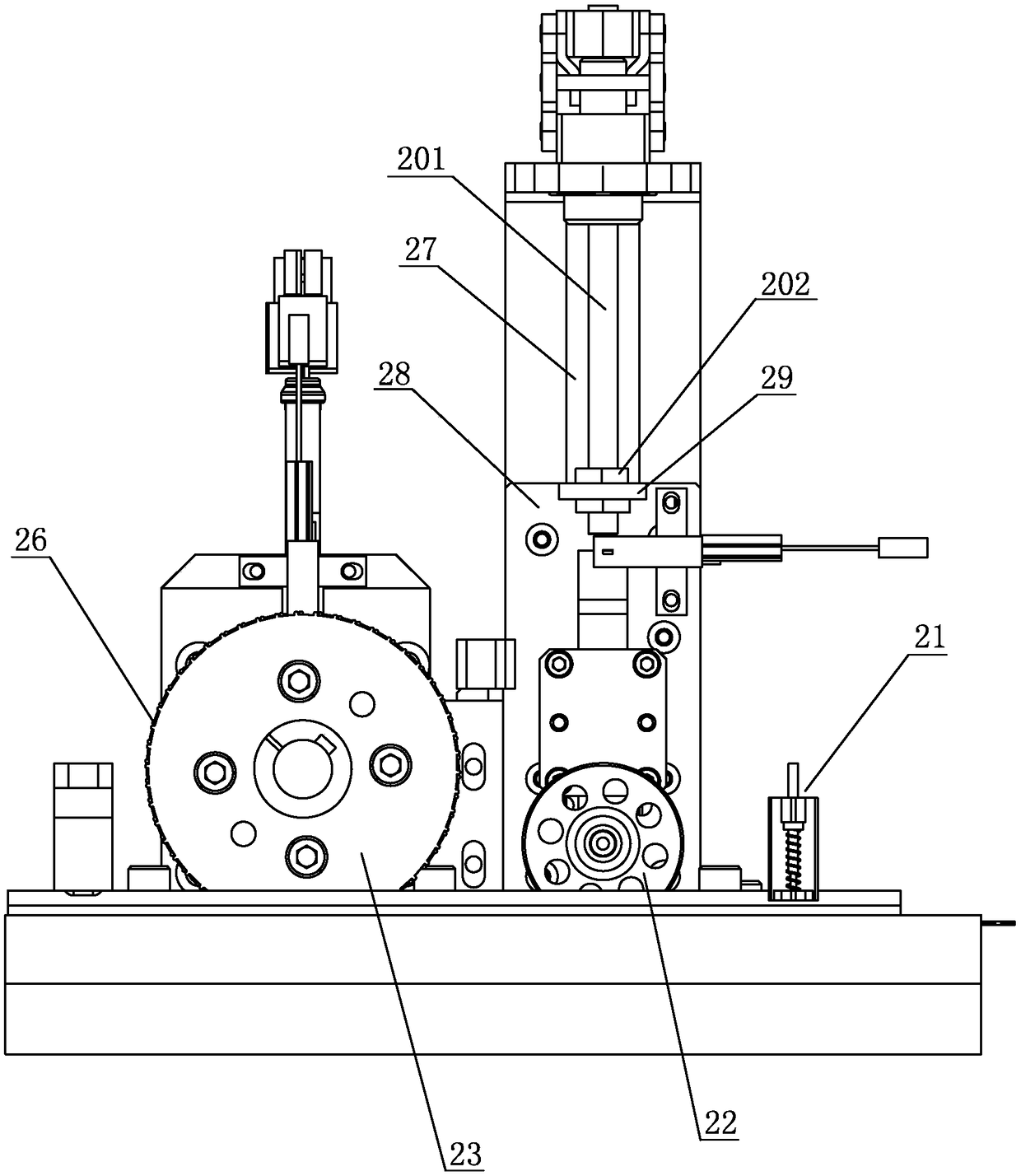

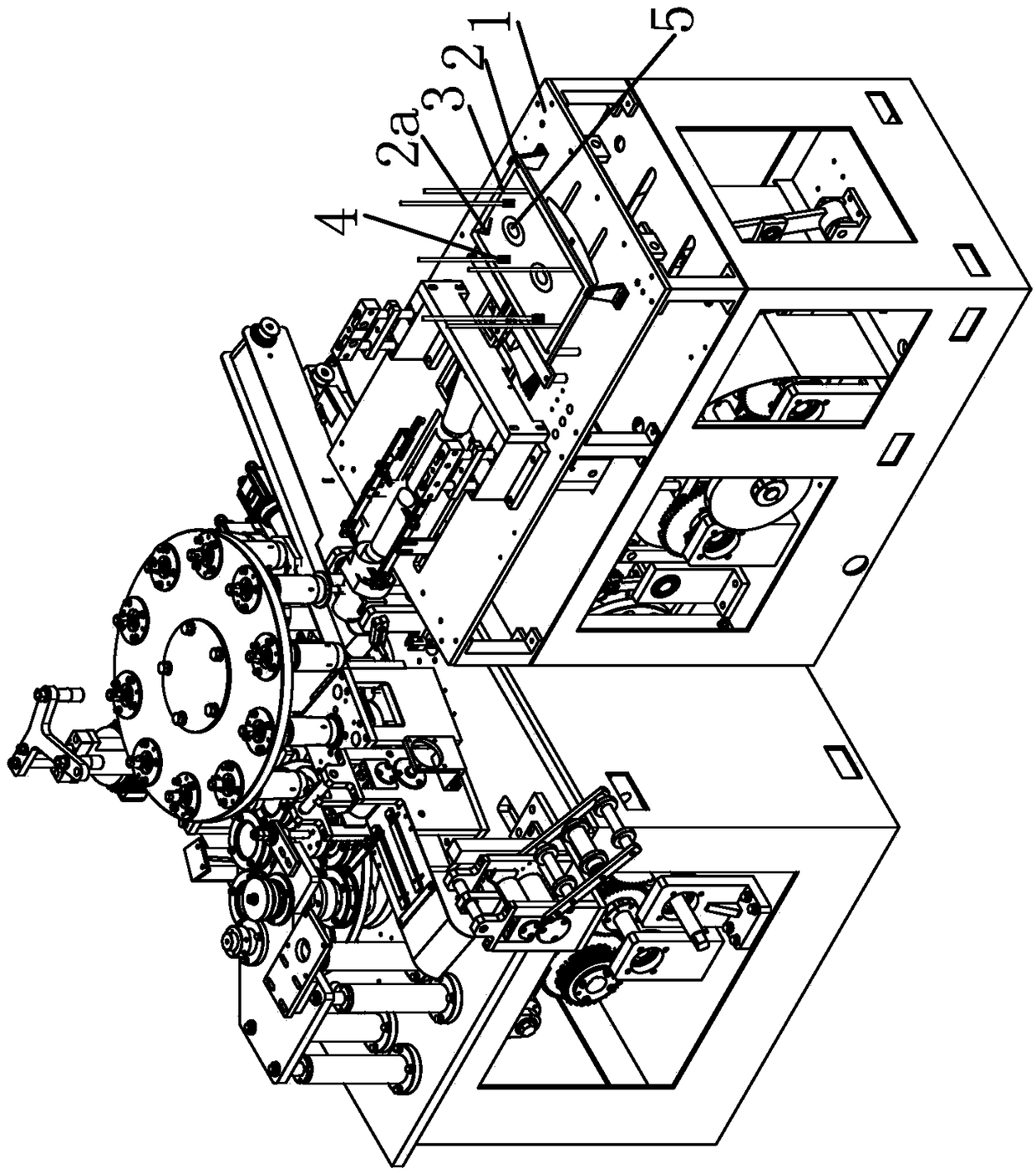

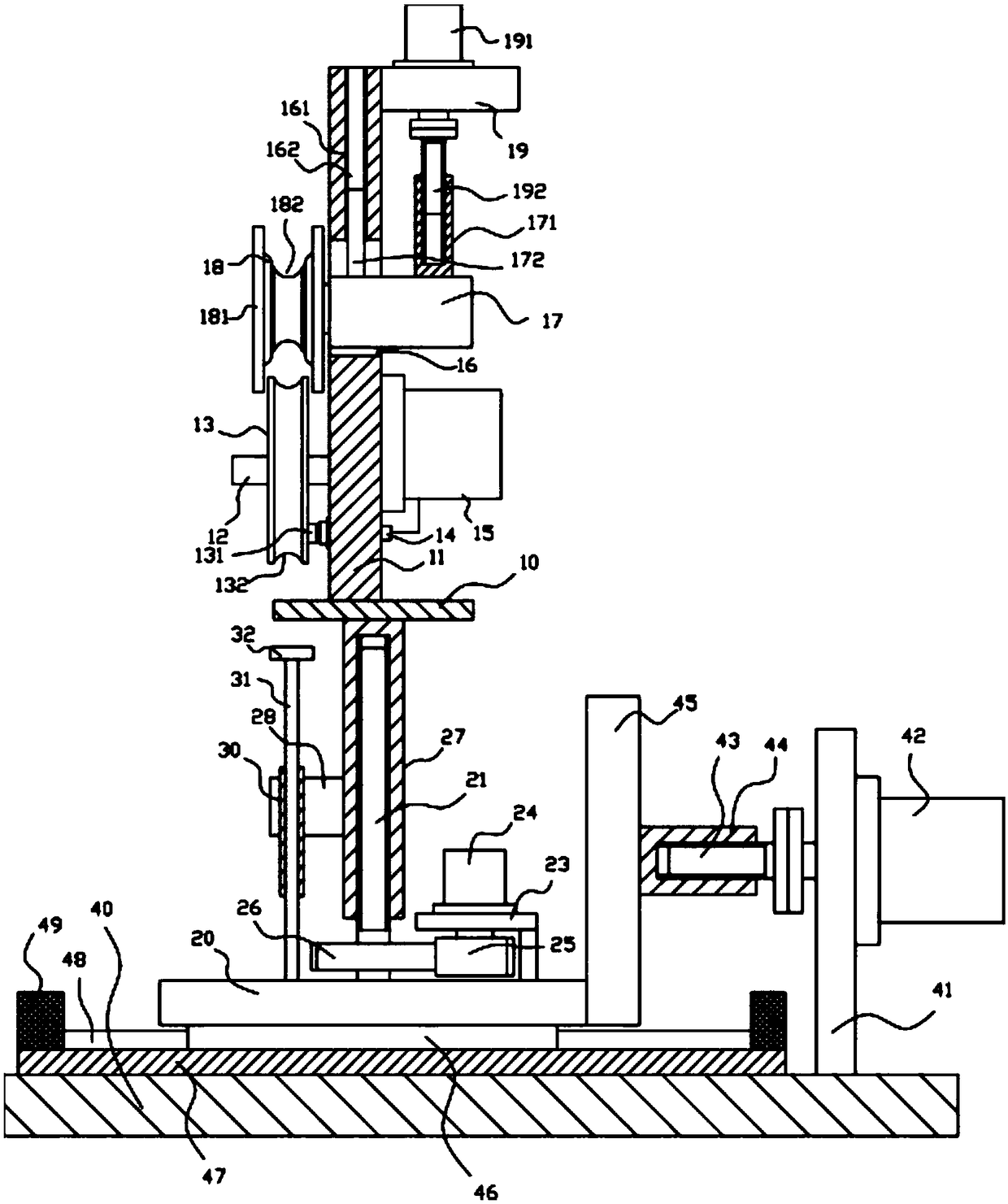

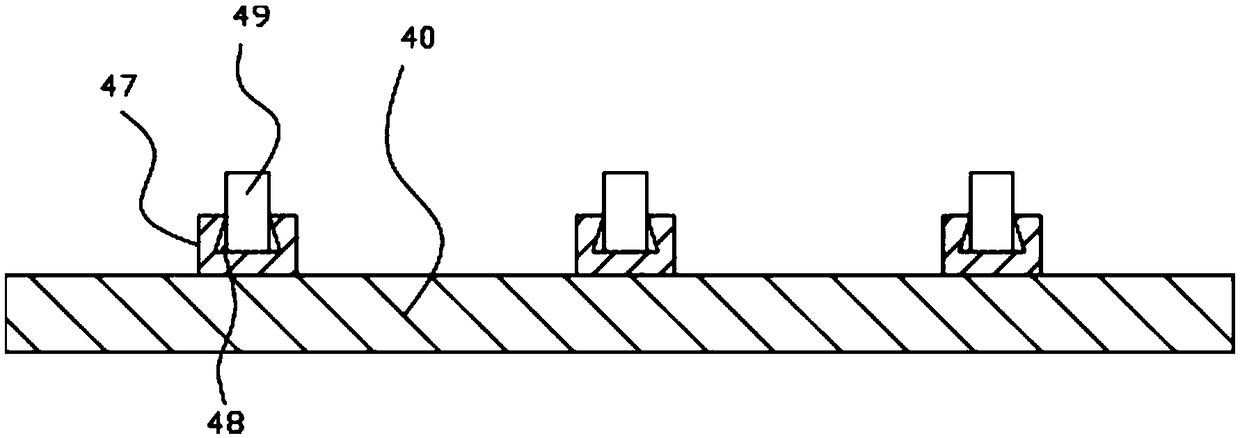

Connector contact pin bending trimming device

PendingCN109473848AReduce labor intensityImprove securityContact member manufacturingEdge surfaceEngineering

The invention discloses a connector contact pin bending trimming device. The connector contact pin bending trimming device is characterized by comprising a rack, a feeding mechanism arranged on the rack, a bending mechanism and a trimming mechanism, wherein the bending mechanism is arranged between the feeding mechanism and the trimming mechanism; a feeding sliding chute is formed in the rack, andthe feeding sliding chute is arranged among the feeding mechanism, the bending mechanism and the trimming mechanism in a penetrated manner; the feeding mechanism comprises a product positioning mechanism, a pinch roller and a conveying roller arranged above the feeding sliding chute, the pinch roller is arranged between the conveying roller and the product positioning mechanism, the rear end of the conveying roller is connected with a conveying motor, a plurality of longitudinal clamping bars are uniformly distributed on the outer edge surface of the conveying roller, the longitudinal clamping bars are arranged parallel to the axis of the conveying roller, and the conveying roller is arranged close to the bending mechanism. According to the connector contact pin bending trimming device, the product processing efficiency and quality are improved.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

Composite core horizontal conveying device

Owner:HANGZHOU HAOYUE INDAL

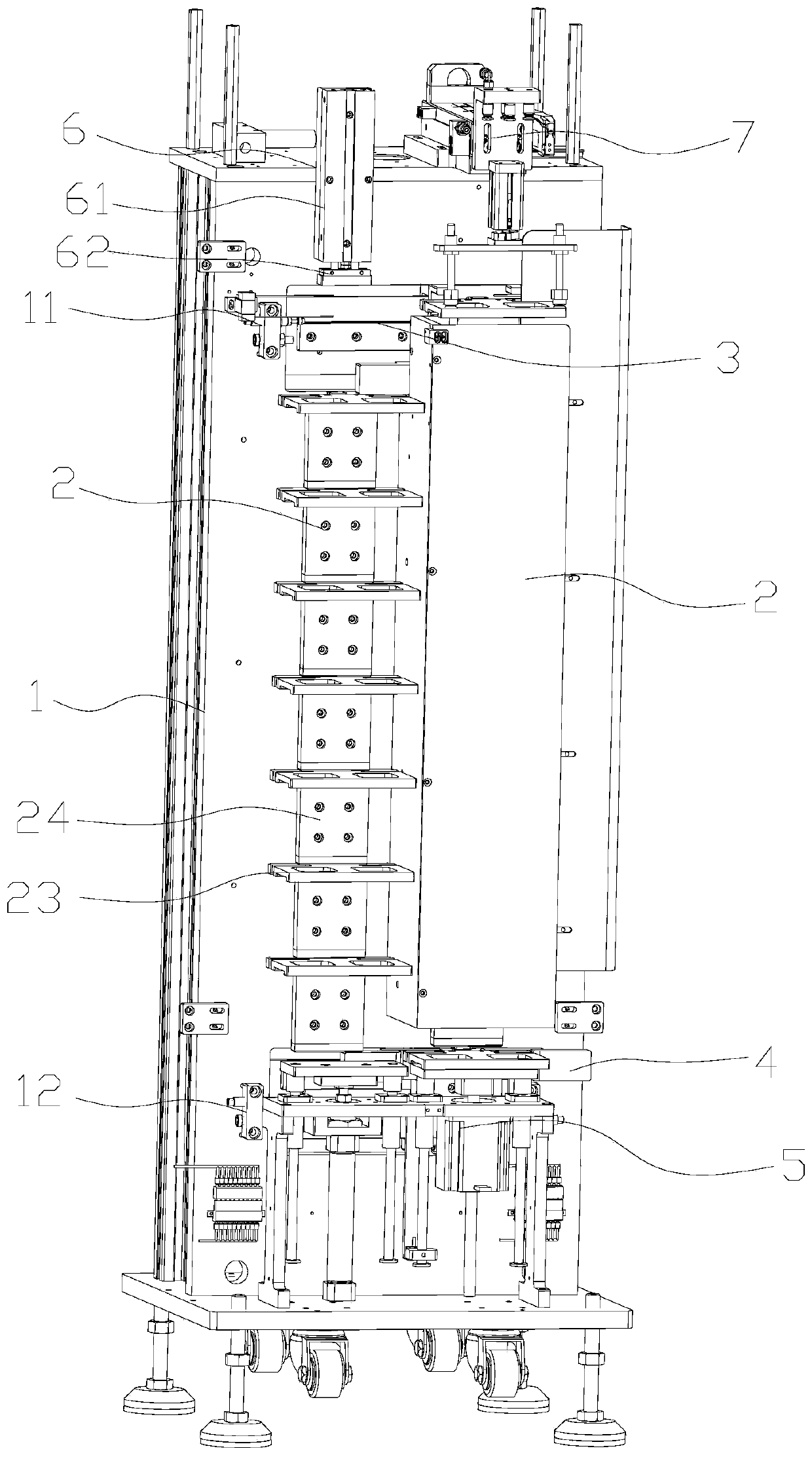

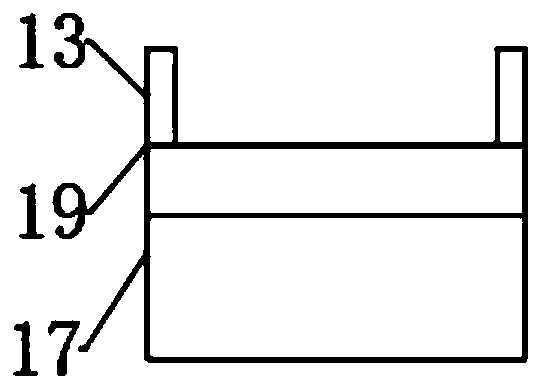

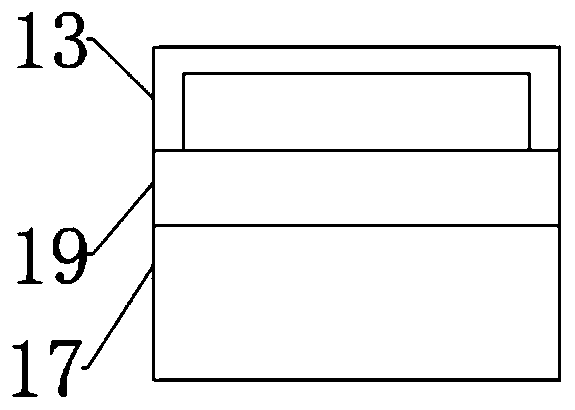

Layered conveying mechanism

PendingCN110759066AFully automatedAvoid damageConveyor partsStructural engineeringMechanical engineering

The invention discloses a layered conveying mechanism. The layered conveying mechanism comprises a rack, a circulating assembly, an upper translation assembly, a lower translation assembly, a jackingassembly and a downward pressing assembly, wherein the circulating assembly, the upper translation assembly, the lower translation assembly, the jacking assembly and the downward pressing assembly arearranged on the rack. The circulating assembly comprises two circulating guide rails and a plurality of circulating conveying plates arranged on the circulating guide rails and used for circulating and conveying workpieces. The upper translation assembly is used for conveying the circulating conveying plates on the top of the first circulating guide rails to the top of a second circulating guiderail. The lower translation assembly is used for conveying the circulating conveying plates at the bottom of the second circulating guide rail to the bottom of the first circulating guide rail. The jacking assembly is used for jacking the circulating conveying plates on the first circulating guide rail. The downward pressing assembly is used for pressing the circulating conveying plates on the second circulating guide rail downwards. Compared with the prior art, the layered conveying mechanism has the advantages that the structure is simple, the performance is stable and reliable, the implementation cost is low, the automation degree is high, the labor cost is saved, the production efficiency is improved, and the like.

Owner:SHENZHEN ZOWEE SMART MFG CO LTD

Improved paper feeding mechanism for straight barrel machine

InactiveCN108749139AAvoid Paper JamsImprove delivery efficiencyPaper/cardboard wound articlesBox making operationsPulp and paper industryTechnology/technique

The invention provides an improved paper feeding mechanism for a straight barrel machine and belongs to the technical field of straight barrel machine manufacturing. The problem that in the prior art,paper feeding efficiency is low is solved. According to the improved paper feeding mechanism for the straight barrel machine, the straight barrel machine comprises a rack and a workbench fixed to therack. The paper feeding mechanism comprises a seat board, the seat board is fixed to the workbench through a plurality of supporting feet, the seat board is provided with rectangular holes, hole walls of the rectangular holes are vertically and fixedly provided with a plurality of vertical rods, the lower ends of the vertical rods penetrate through the rectangular holes and are provided with threaded sleeves in a sleeved manner, the upper ends of the vertical rods penetrate through the rectangular holes, and a paper taking structure capable of sucking sheets of paper is arranged below the rectangular holes. The improved paper feeding mechanism for the straight barrel machine has the advantage of being high in paper feeding efficiency.

Owner:海宁诚达机械有限公司

Object conveying device for cold chain logistics

InactiveCN110759001AGuaranteed storage qualityAffect work efficiencyConveyorsCompression machines with non-reversible cycleCold chainLogistics management

The invention discloses an object conveying device for cold chain logistics. The device comprises a mounting base; vertical side plates are connected to the two sides of the mounting base; worktablesare placed on the side plates; conveying belts are distributed at the outer peripheries of the worktables; goods are placed on the conveying belts; refrigerating mechanisms are arranged at the lower parts of the worktables; and the refrigerating mechanisms cool the worktables, so that the goods are always maintained in a low-temperature state when conveyed on the conveying belts, and the storage quality of the goods is guaranteed; and tensioning mechanisms are arranged on the conveying belts for preventing influence on the goods conveying efficiency due to deformation of the conveying belts caused by higher weight in cold chain logistics. In addition, protecting plates are distributed on the side edges of the worktables in order to prevent damage of the goods due to falling from the conveying belts in the placing or conveying process, and the goods conveying quality is guaranteed.

Owner:ANHUI AGRICULTURAL UNIVERSITY

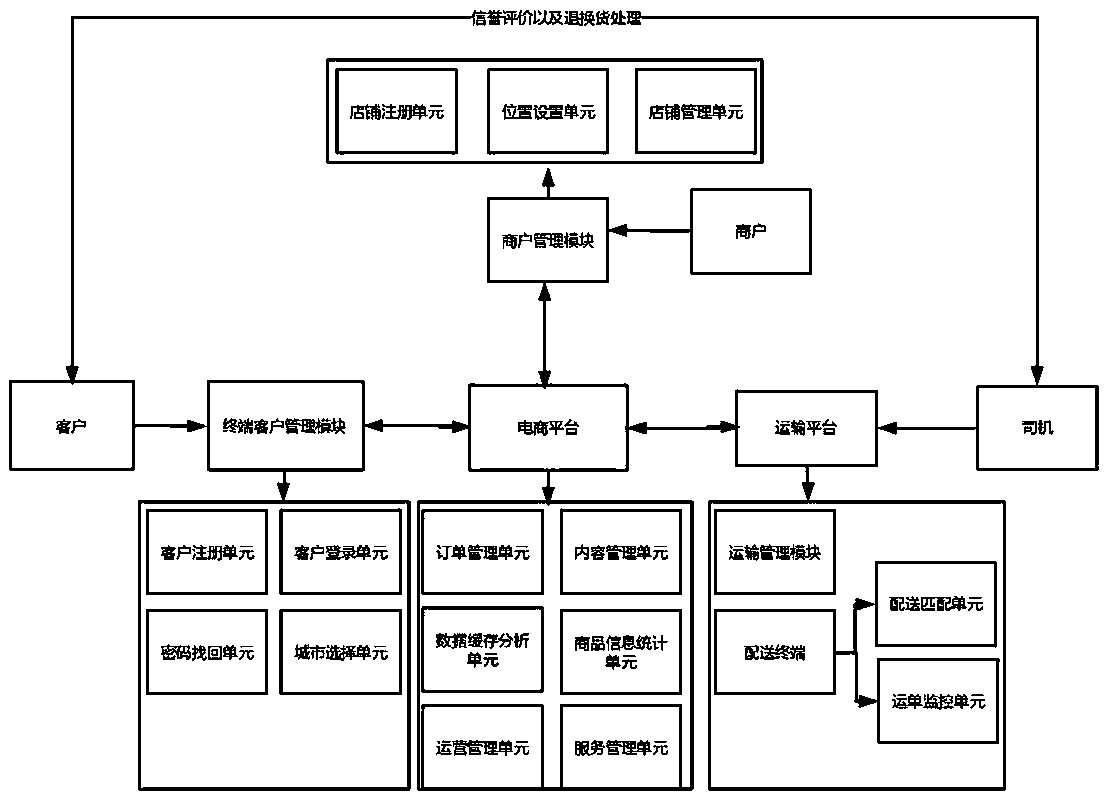

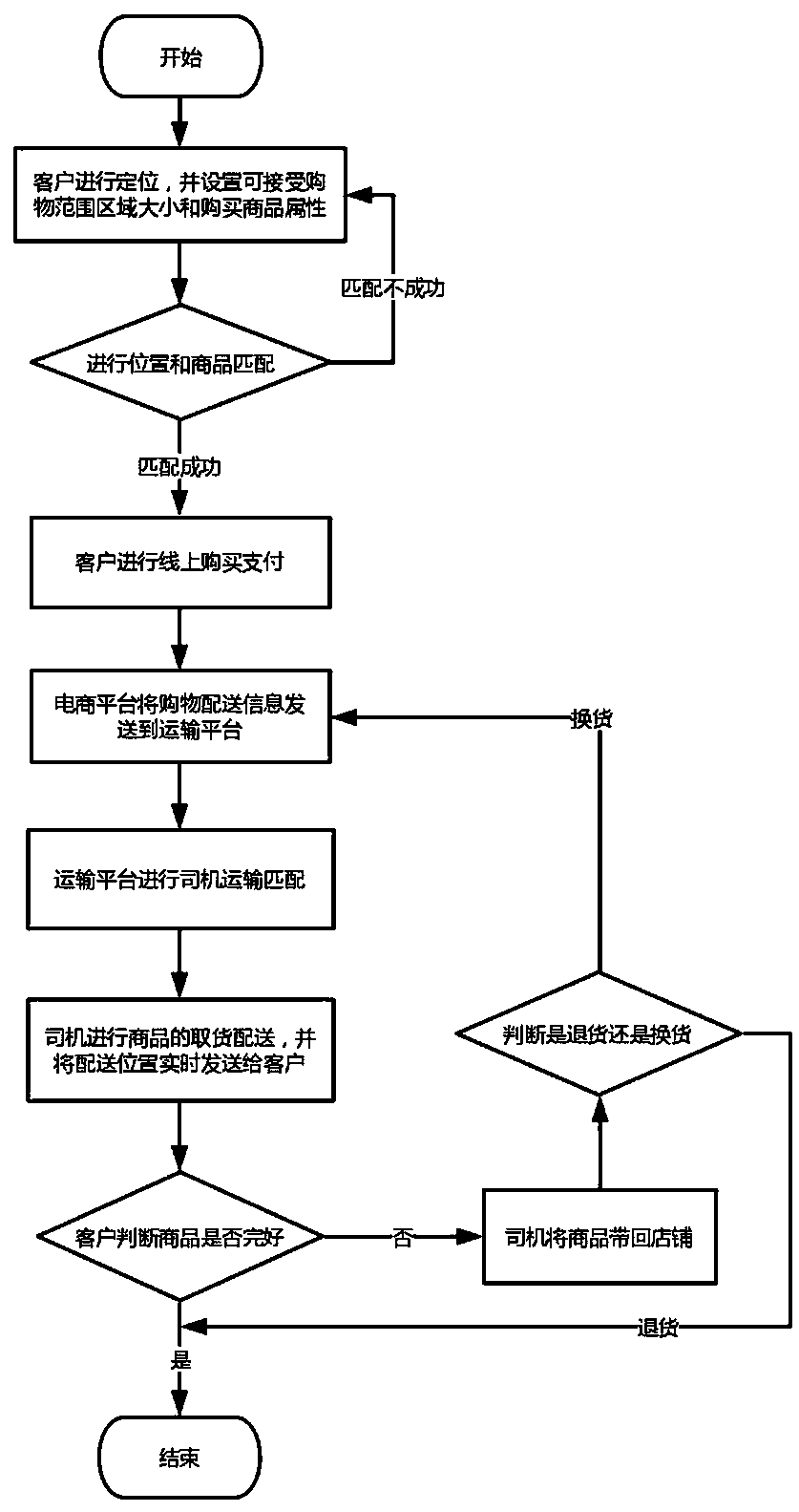

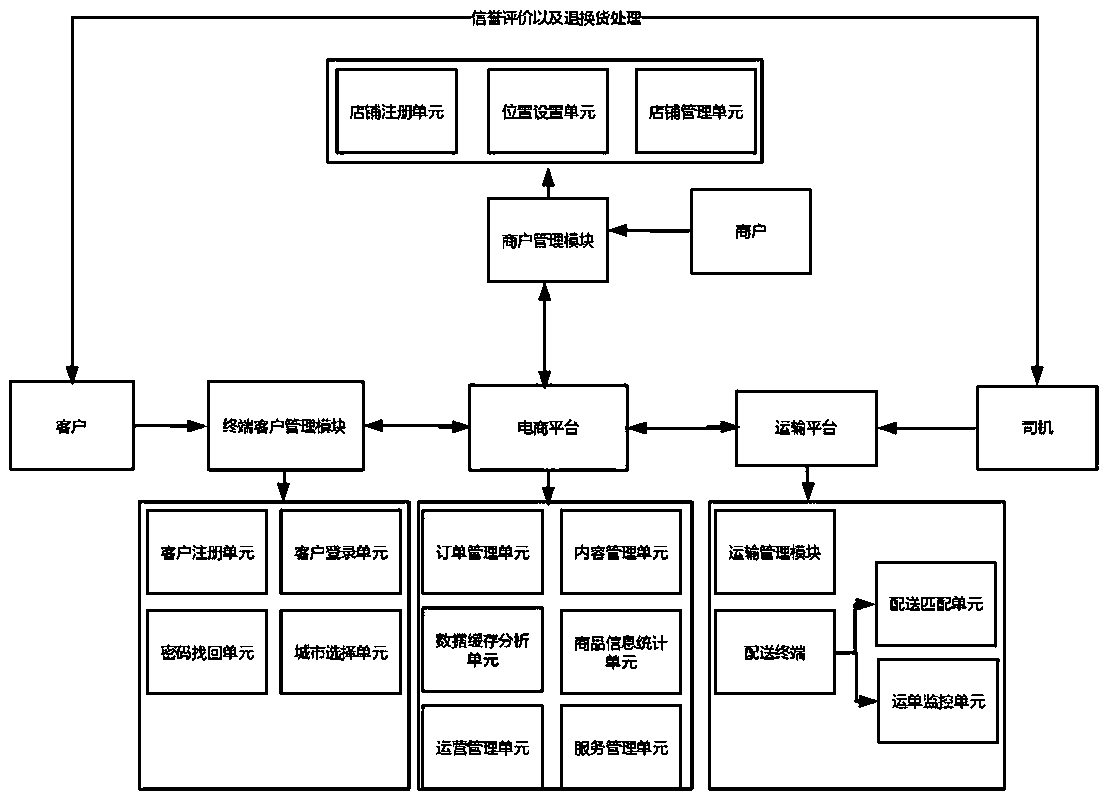

City-wide instant transaction e-commerce platform system

InactiveCN111178997AImprove matchGuarantee delivery qualityBuying/selling/leasing transactionsLogisticsFinancial transactionCustomer information

The invention provides a city-wide instant transaction e-commerce platform system, and relates to the field of e-commerce operation management. The system comprises a terminal customer management module for customer information management, a merchant management module for providing city-wide commodity transaction support, an e-commerce platform which is connected with the merchant management module and the terminal customer management module to facilitate online city-wide transaction of merchants and customers, and a transportation platform which communicates with the e-commerce platform to achieve city-wide instant distribution. The problems that in the prior art, commodity transportation and commodity quality monitoring of the same-city instant e-commerce platform are difficult, and thecommodity returning and changing process is complex are solved.

Owner:成都红苹果旅智科技有限公司

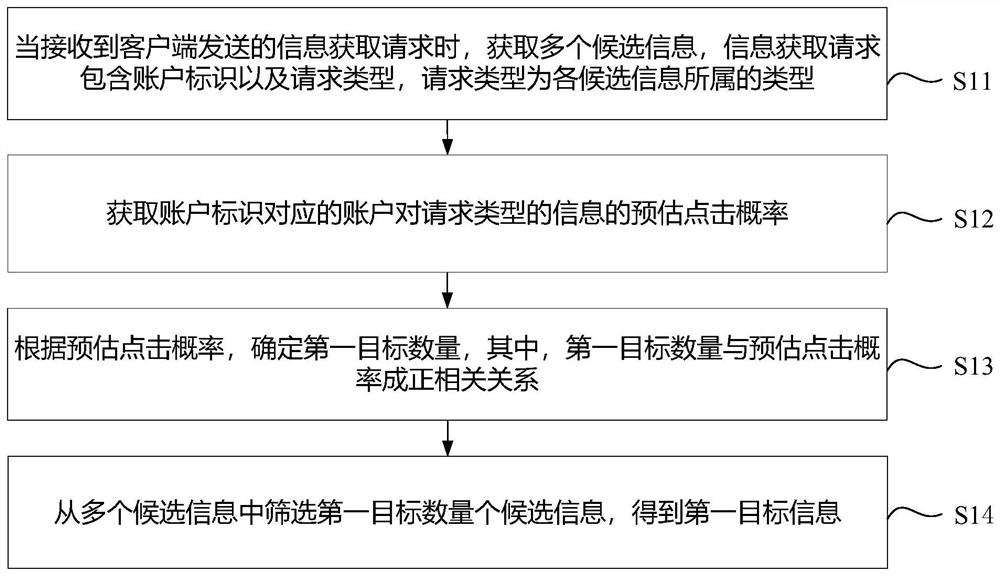

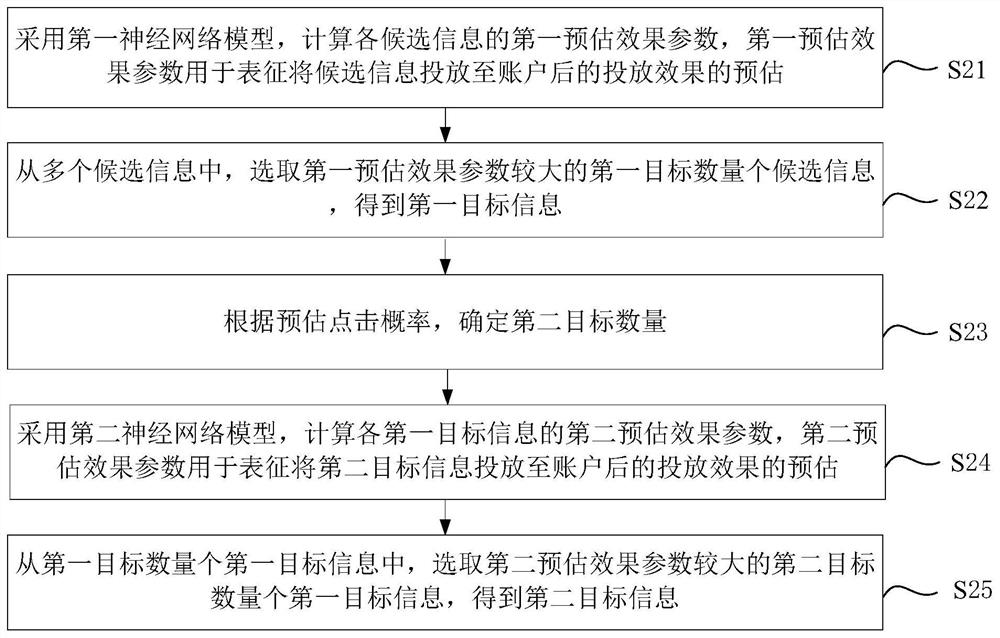

Information processing method and device, electronic equipment and storage medium

PendingCN112767053AGuarantee delivery qualitySave computing resourcesAdvertisementsEngineeringData mining

The invention discloses an information processing method and device, electronic equipment and a storage medium, and the method comprises the steps of when an information acquisition request sent by a client is received, acquiring multiple pieces of candidate information, and the information acquisition request comprises an account identifier and a request type; obtaining an estimated click probability of the account on the information of the request type; according to the estimated click probability, determining a first target number, and the first target number and the estimated click probability are in positive correlation; and screening a first target number of pieces of candidate information from the plurality of pieces of candidate information to obtain first target information. The first target number is determined by the estimated click probability, and the first target number and the estimated click probability are in positive correlation, so that a large number of candidate information can be screened out for accounts with high estimated click probability, and the probability of finally screening out high-quality candidate information is improved; for an account with a low estimated click probability, a small amount of candidate information can be screened out, so that computing resources required to be occupied by post-stage screening are saved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Cable length counter capable of being regulated between left and right

InactiveCN109186519AGuarantee delivery qualityMeasurement devicesArchitectural engineeringFine-tuning

The invention discloses a cable length counter capable of being regulated between left and right. The cable length counter comprises a fixing plate, an installation bottom plate and a lower installation movement plate, wherein the top surface of the right side of the lower installation movement plate is provided with a main vertical plate; the right side wall of the main vertical plate is fixedlyprovided with a fine tuning movement main motor; the output shaft of the fine tuning movement main motor penetrates through the main vertical plate and is connected with a lateral movement screw through a coupler; a lateral movement sleeve is screwed to the lateral movement screw; the left end of the lateral movement sleeve is fixedly provided with the fine tuning vertical plate; the left side wall of the lower end of the fine tuning vertical plate is fixedly provided with the installation bottom plate; a plurality of swallow tail shaped sliding blocks are fixed on the bottom surface of the installation bottom plate; the top surface of the lower installation movement plate is fixedly provided with a plurality of sliding rail bars, the top surface of each sliding rail bar is provided with aswallow tail shaped chute; and each swallow tail shaped sliding block is inserted in the corresponding swallow tail shaped chute. By use of the cable length counter, the fixing plate can be automatically subjected to vertical position regulation and horizontal position fine turning so as to meet the conveying length counting requirements of different positions, and the normal conveying and the conveying quality of a conveyed cable are guaranteed.

Owner:叶佑君

Belt conveyor for rice processing

InactiveCN110844465AChange the feeding directionEasy to collectConveyorsConveyor partsAgricultural engineeringStructural engineering

The invention discloses a belt conveyor for rice processing, and relates to the technical field of rice processing. The belt conveyor for rice processing aims to solve the problem that dust and impurities in rice cannot be removed, so that the impurities are still mixed in the rice. The belt conveyor for rice processing specifically comprises two mounting plates, wherein rotating shafts are rotatably connected to the two sides of the outer walls of the opposite ends of the two mounting plates, and the circumferential outer walls of the two rotating shafts are sleeved with the same conveying belt; stop blocks distributed at equal intervals are mounted on the circumferential outer wall of the conveying belt; the same discharging net plate is rotatably connected to one sides of the outer walls of the opposite ends of the two mounting plates; and partition plates are mounted at the two ends of the outer wall of the top of the discharging net plate. According to the belt conveyor for rice processing, an air pump, an air inlet hopper, an air inlet pipe, a storage housing, a filter screen plate and air outlet holes are arranged, so that dust on the surface of the rice passing through thedischarging net plate can be adsorbed and stored in the storage housing, workers can conveniently obtain purer rice, and the rice processing quality is guaranteed.

Owner:HUNAN LVHAI RICE & OIL LIMITED

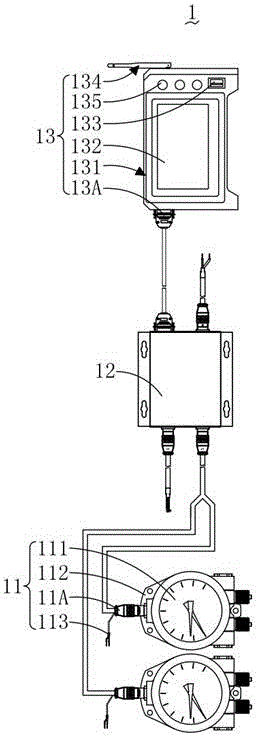

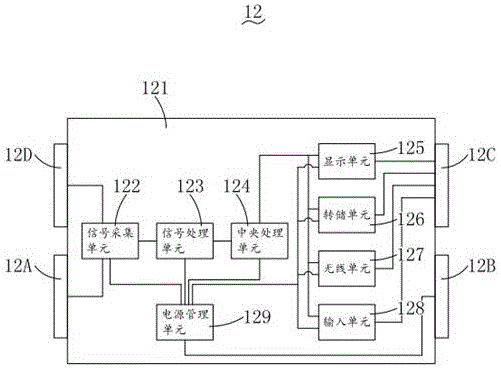

Brake test intelligent management system and diagnosis method thereof

InactiveCN106441957ARealize on-board online diagnosisEasy to diagnoseRailway vehicle testingDiagnosis methodsInteraction device

The invention provides a brake test intelligent management system and a diagnosis method thereof. The brake test intelligent management system comprises a plurality of pressure gages, a host and an interaction device. The host comprises a host body, a signal acquisition unit, a central processing unit, a display unit, a dump unit, a wireless unit, an input unit and the like. The diagnosis method comprises the steps of scheme selection, acquisition and conversion, signal processing, cyclic diagnosis and data uploading. The brake test intelligent management system and the diagnosis method thereof solve the technical problems that in locomotive brake inspection in the prior art, large personal errors are caused, and the accuracy and authenticity of diagnosis results are low.

Owner:湖南广思科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com