Door plate processing mechanism

A technology for processing mechanisms and door panels, applied in wood processing utensils, manufacturing tools, bark area/debris/dust/waste removal, etc. It is very large, which is not conducive to the production of high-quality fire doors, etc., to achieve the effect of improving the quality of paste, good suction effect and smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

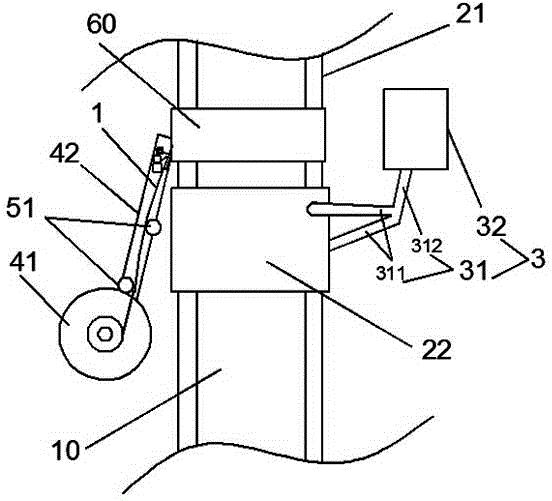

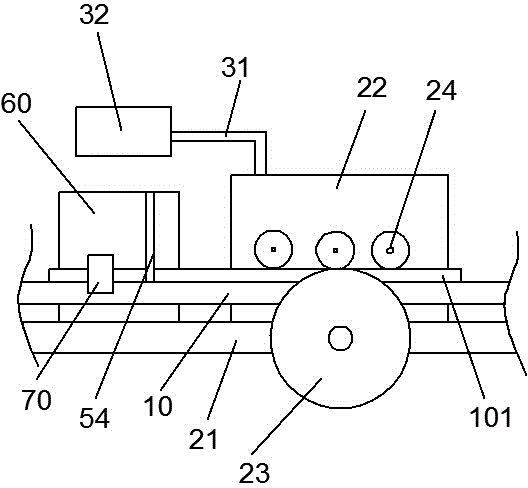

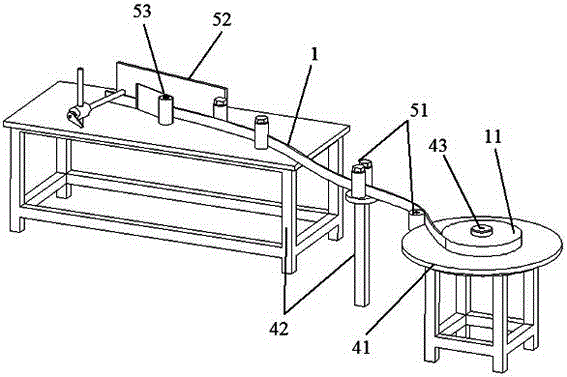

[0019] A door panel processing mechanism, as attached figure 1 , 2 , 4, including the door panel 101 conveying platform 10, along the conveying direction of the conveying platform 10, the trimming device arranged on the side of the conveying platform 10, the feeding device for providing the edge banding strip 1 for the door panel 101 and the edge banding strip Carry out extrusion to strengthen the pressing device that it is connected with door panel 101, trimming device comprises the support 21 that is arranged on the delivery platform 10 below, the trimming room 22 that is installed on the bracket 21 and is arranged on the side wall of trimming room 22 The trimming disc 23 driven by the motor, the conveying platform 10 passes through the trimming chamber 22; the conveying platform 10 in the trimming chamber 22 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com