Concrete conveying process for high steep and big drop height landform

A concrete, large drop technology, applied in construction, infrastructure engineering and other directions, can solve the problems of limited construction site, high construction cost, tight construction period, etc., and achieve the effect of saving cost and transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

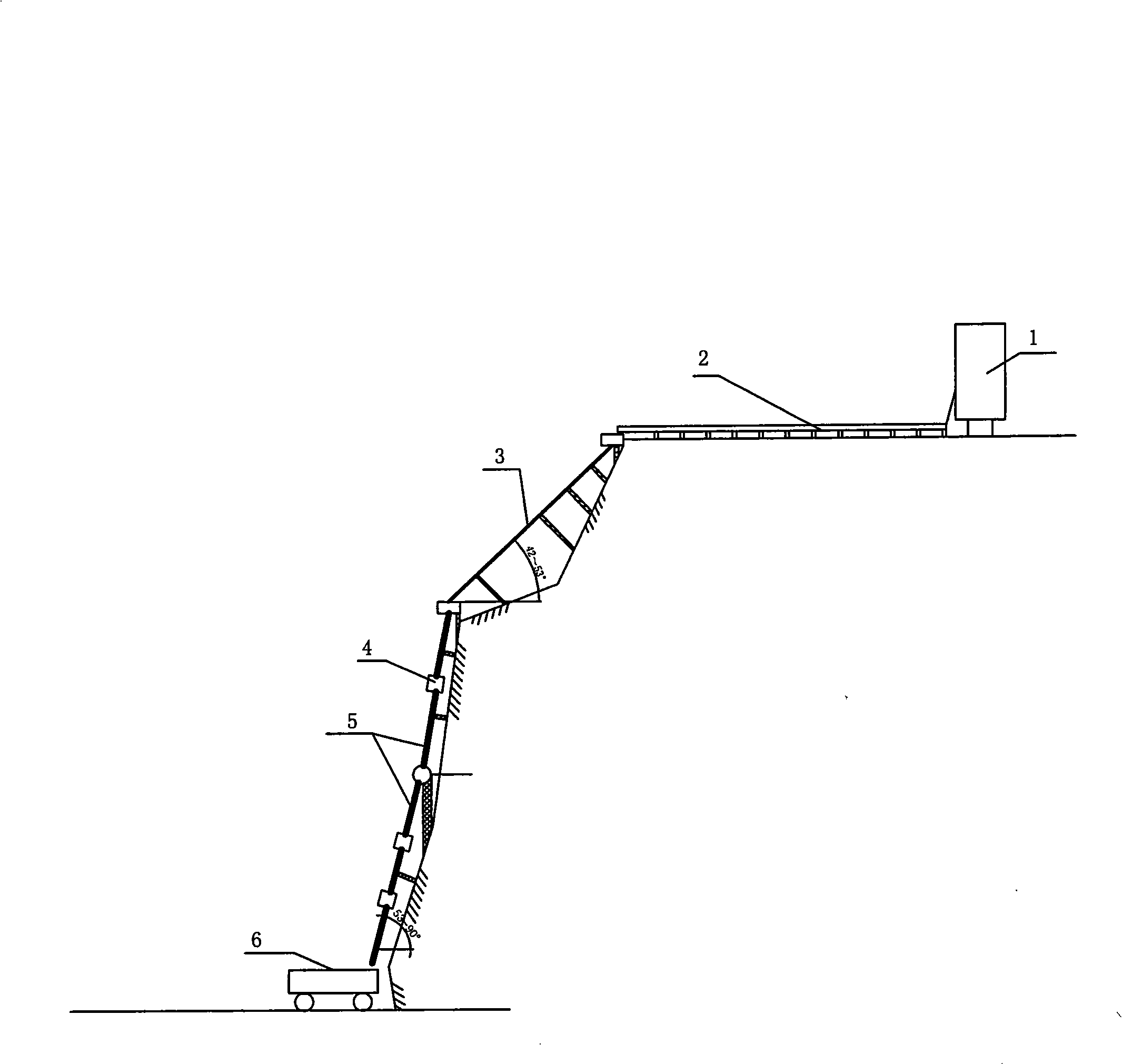

[0018] Such as figure 1 Shown, a kind of concrete conveying method of high and steep slope big drop terrain, it comprises the following steps:

[0019] a. Topographic field survey and measurement;

[0020] After topographic field surveys, parameters such as the length, elevation, slope and rock surface characteristics of the horizontal section from the dam surface to the dam bottom pouring warehouse surface are fully grasped;

[0021] b. Formulate the layout plan of concrete conveying equipment

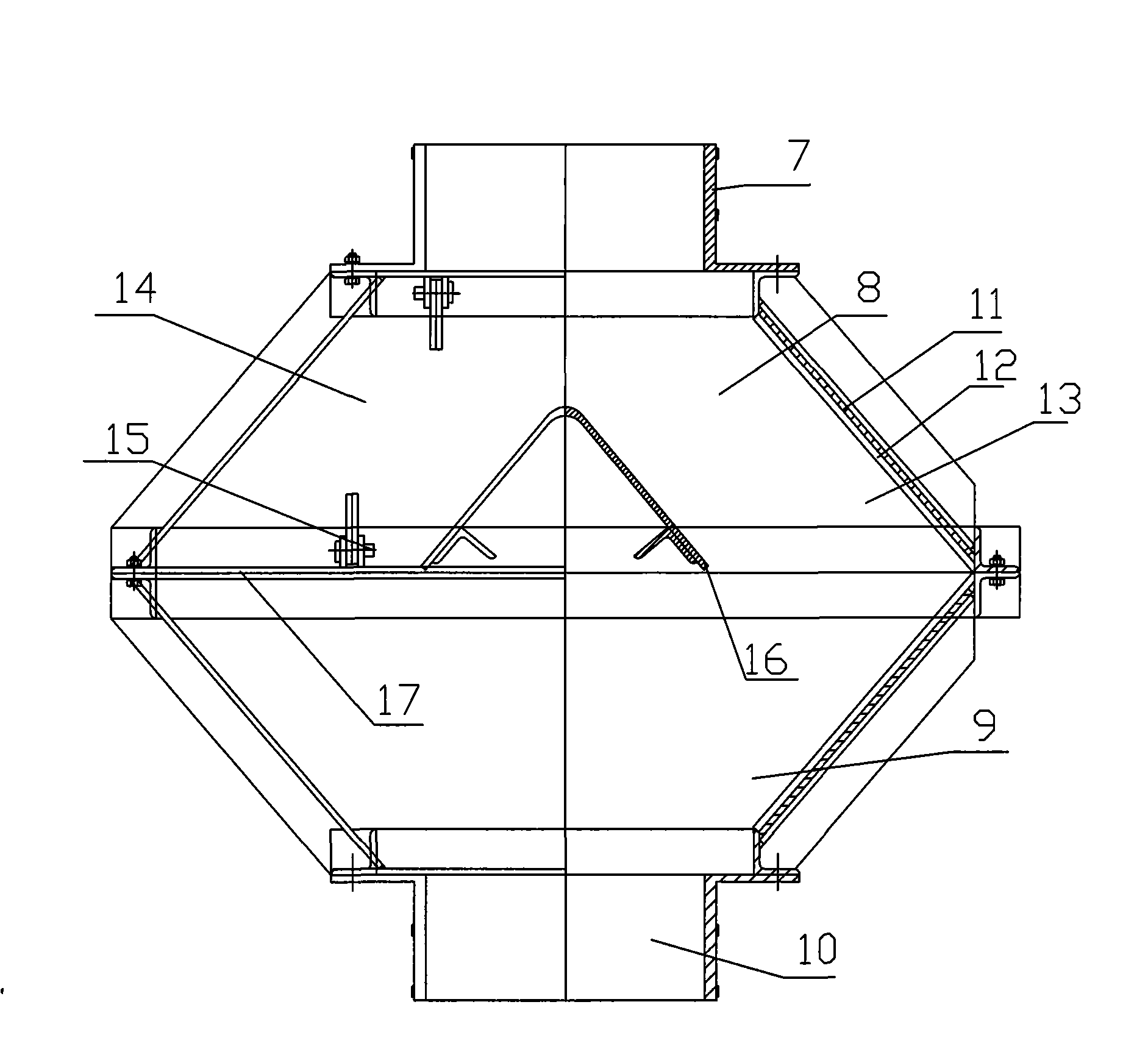

[0022] Concrete is conveyed horizontally by belt conveyor 2; when the slope angle is greater than 42° and less than 53°, it is conveyed by negative pressure chute 3; when the slope angle is greater than 53° and less than 90°, it is conveyed by combination of chute 5 and slow-down mixer 4 .

[0023] c. Program implementation

[0024] According to the actual topography of the site and the layout plan of the conveying equipment, the concrete belt conveyor 2, the negative pressure chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com