Connector contact pin bending trimming device

A connector and pin technology, which is applied in the field of connector pin bending and edge removal devices, can solve the problems of error-prone operation, danger-prone, low work efficiency, etc., so as to improve safety, reduce labor intensity, and ensure folding. The effect of bending stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

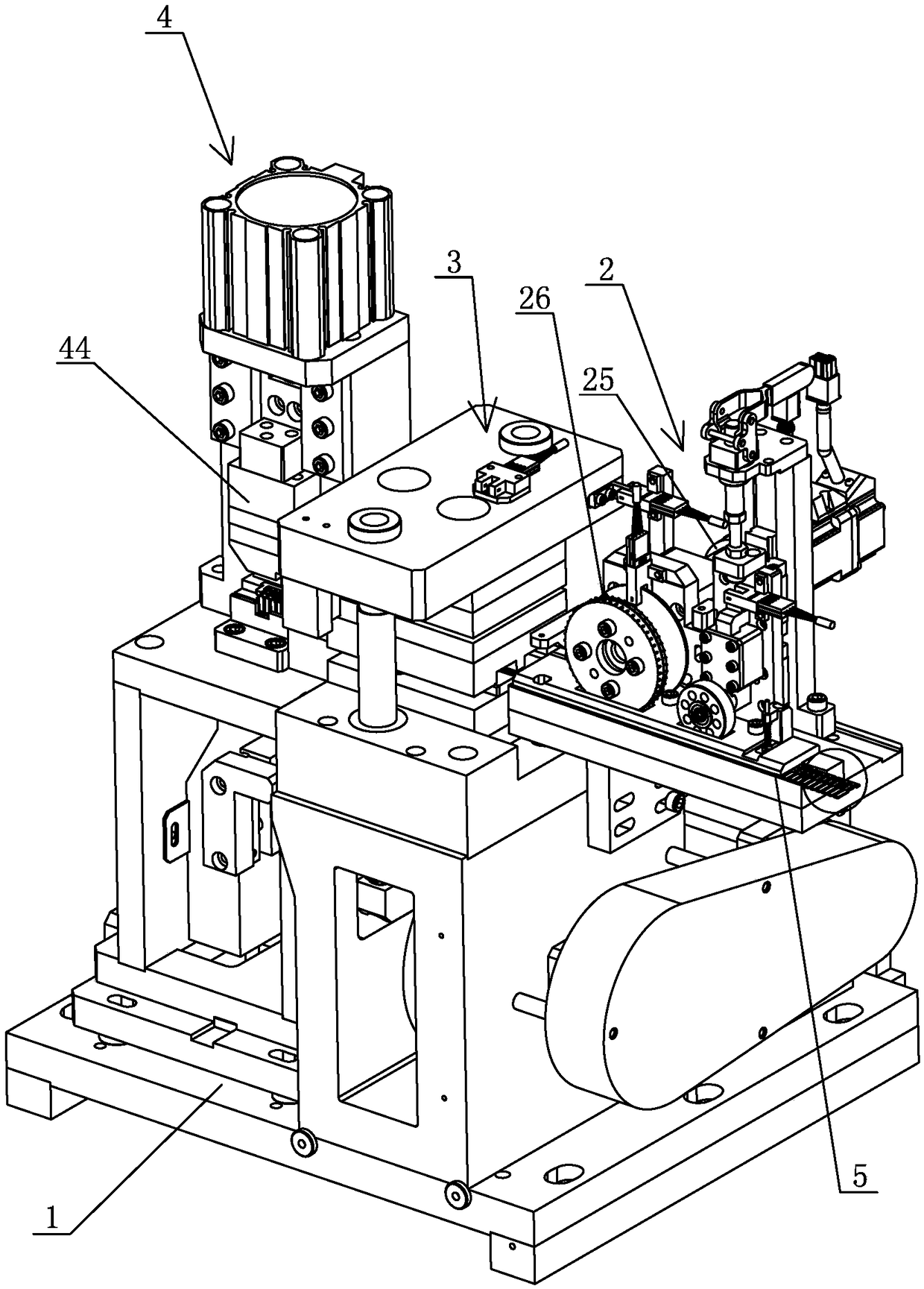

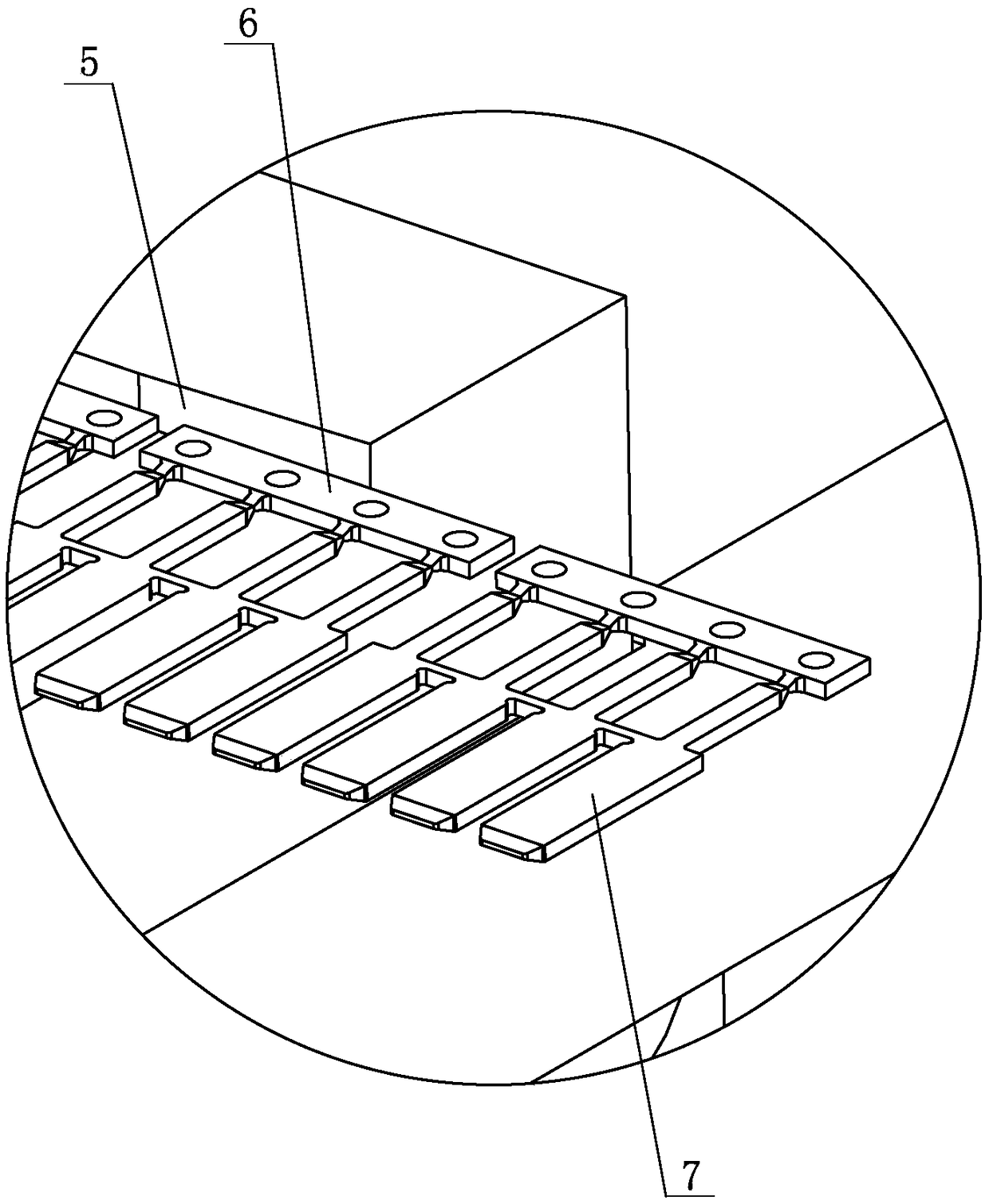

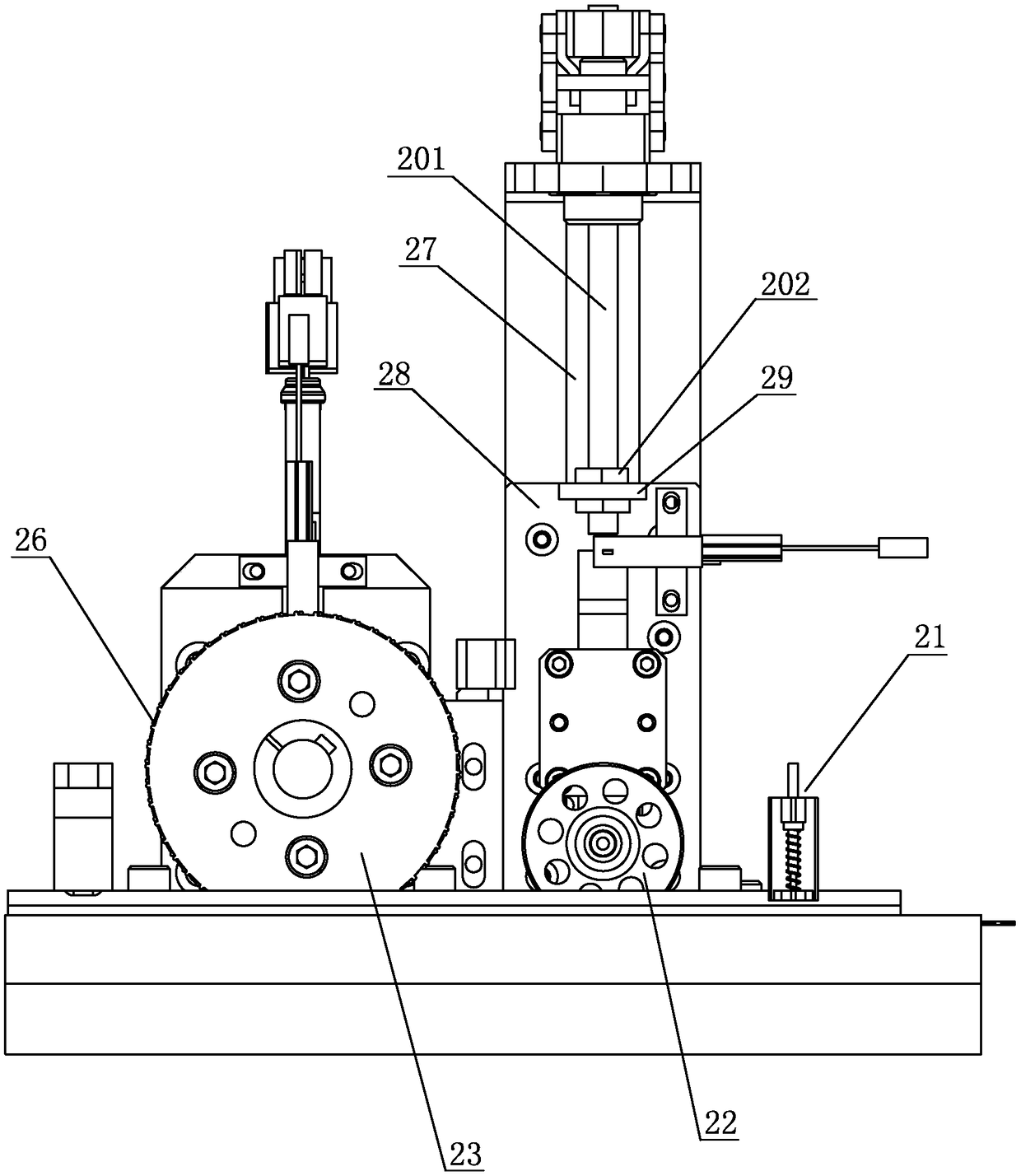

[0028] Embodiment one: see Figure 1-7 As shown, a connector pin bending device includes a frame 1, a feeding mechanism 2 arranged on the frame 1, a bending mechanism 3 and a edge removing mechanism 4, and the bending mechanism 3 is arranged on the between the feeding mechanism 2 and the edge removing mechanism 4; the frame 1 is provided with a feeding slide 5, and the feeding slide 5 passes between the feeding mechanism 2, the bending mechanism 3 and the edge removing mechanism 4 .

[0029] In this embodiment, the pins 7 are placed directly on a material belt 6 and put directly into the feeding chute, the product is conveyed through the feeding mechanism, and then the product is bent by the bending mechanism, and the product after bending Send it into the edge-removing mechanism to remove the edge of the product, which can realize the automatic processing of the product, effectively reduce the labor intensity of the operator, ensure the safety of the operation, and improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com