Patents

Literature

51results about How to "Ensure delivery stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

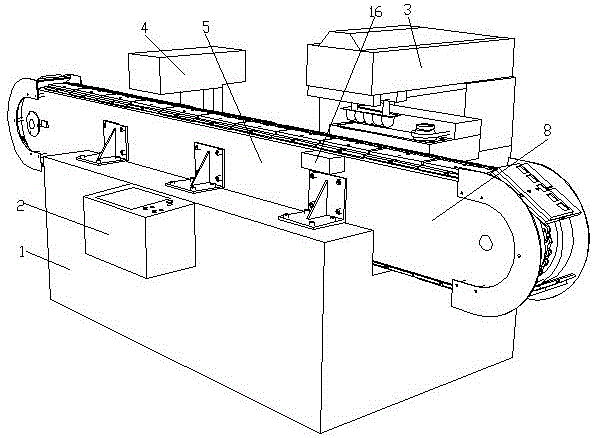

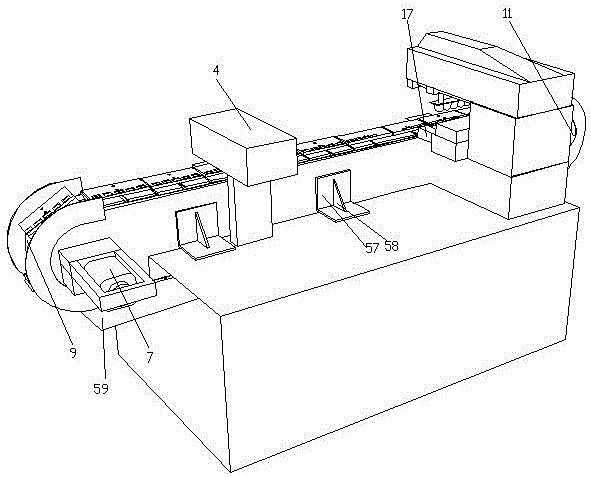

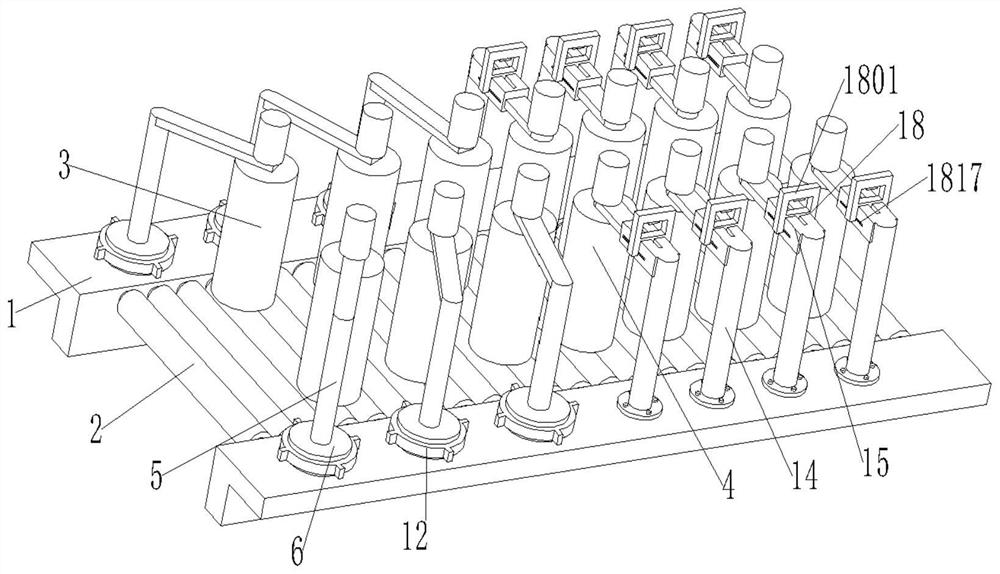

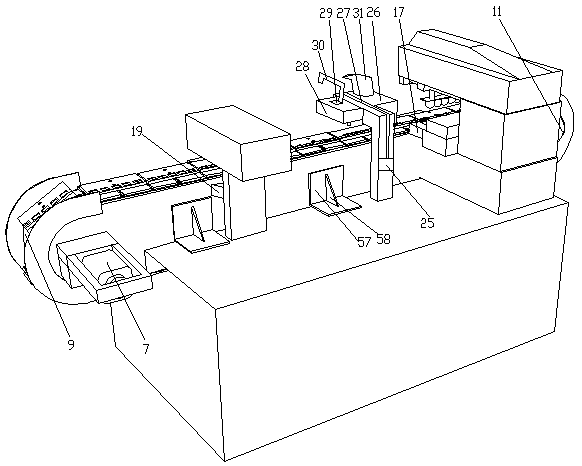

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

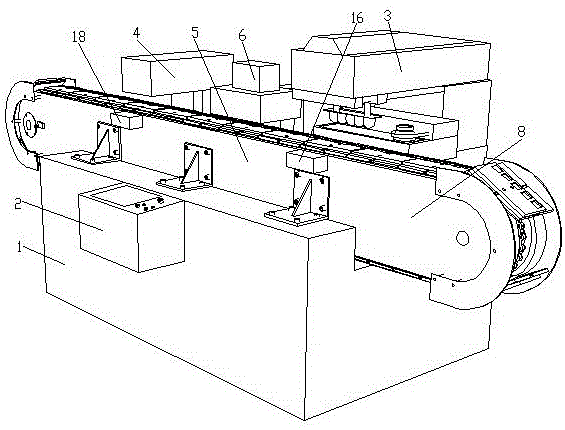

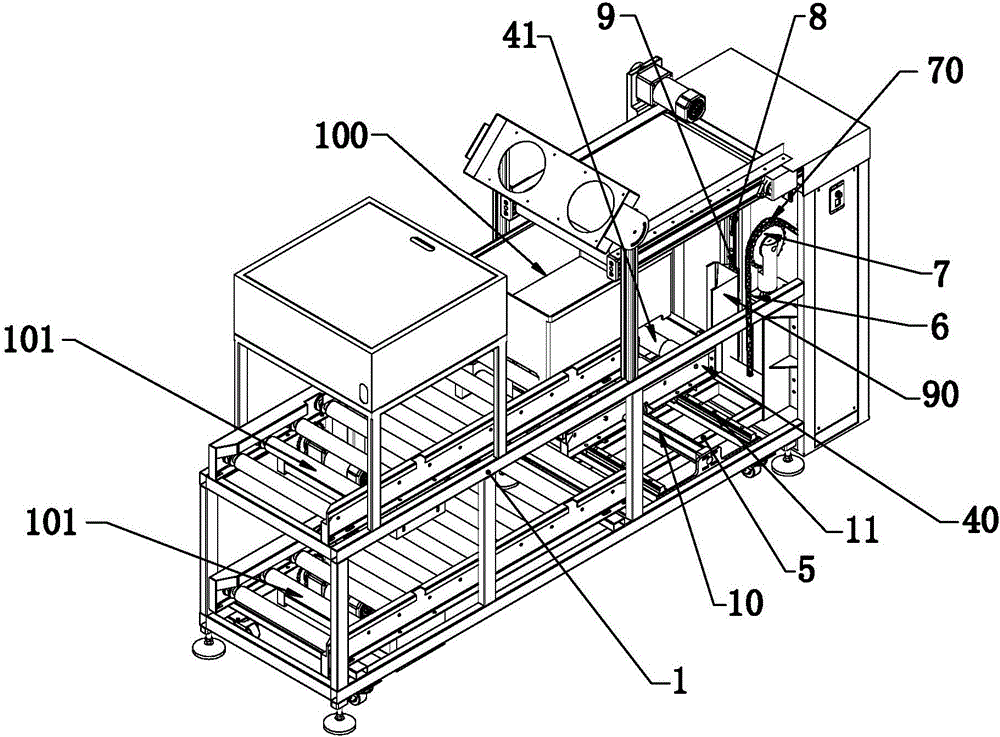

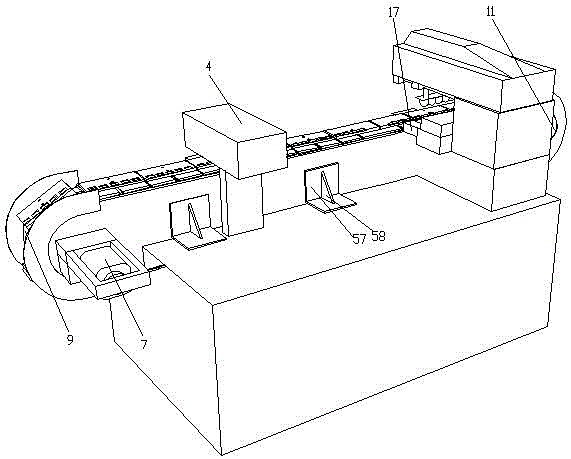

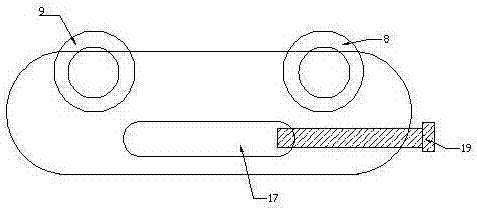

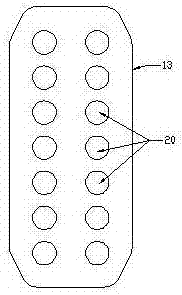

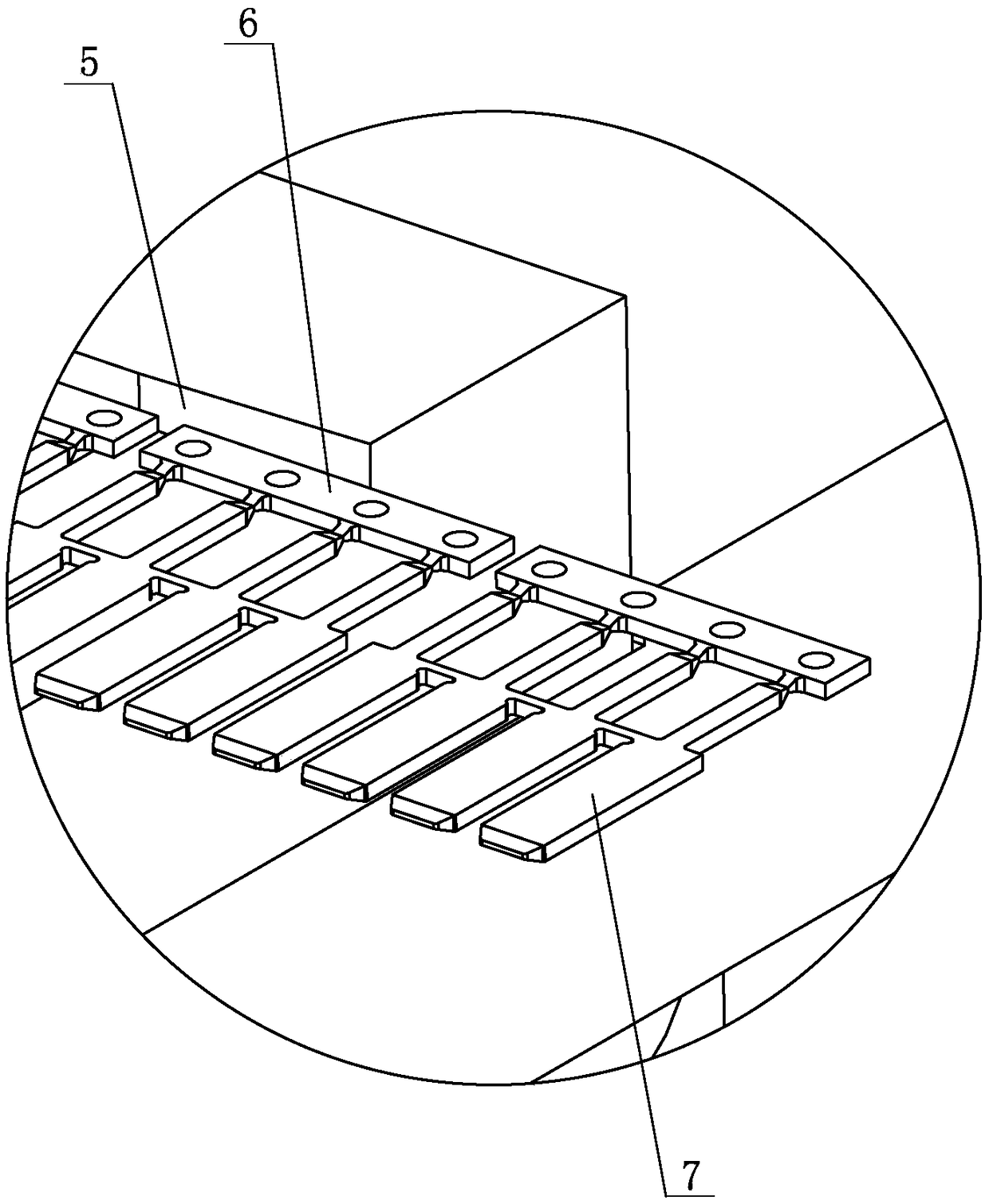

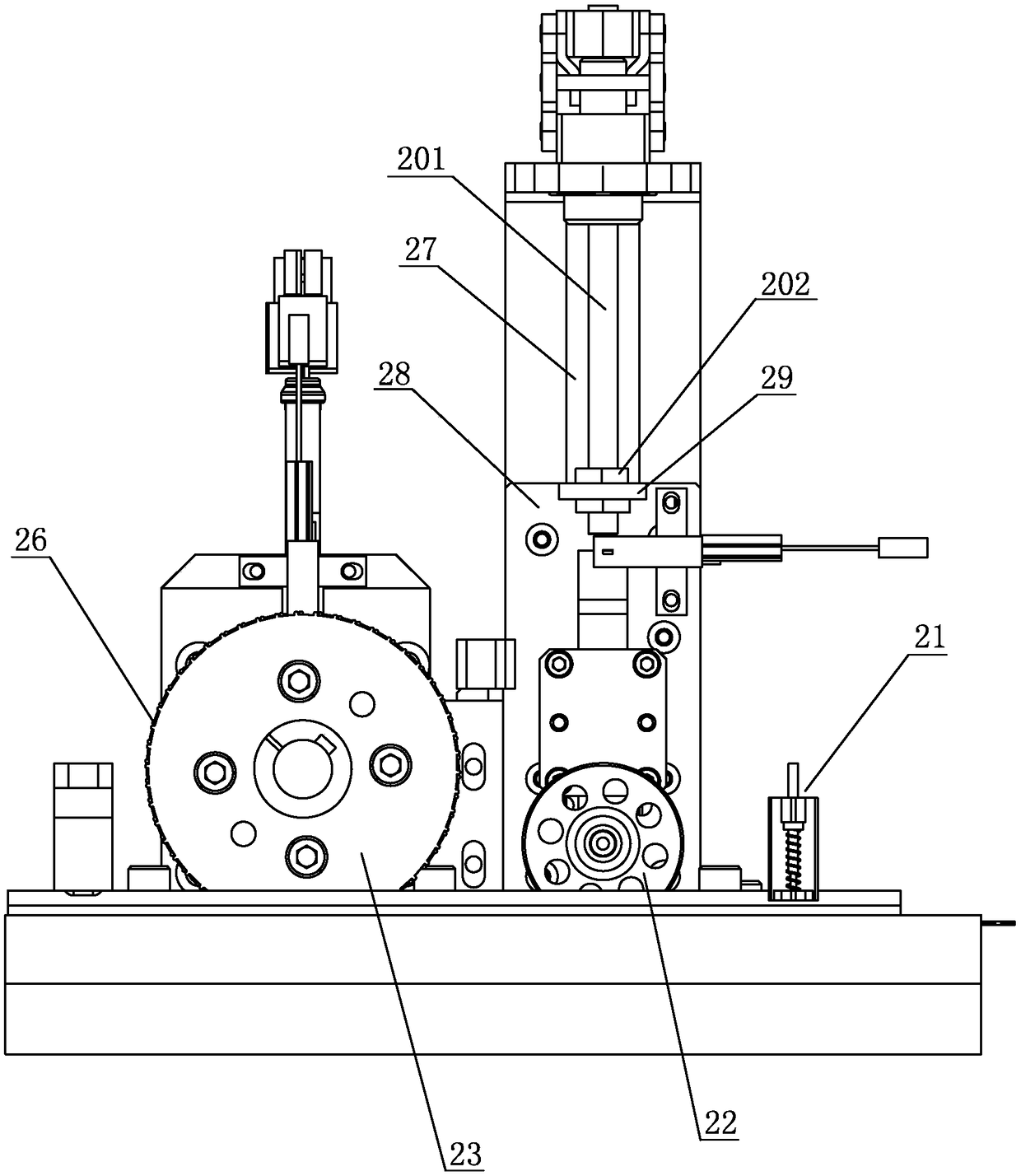

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

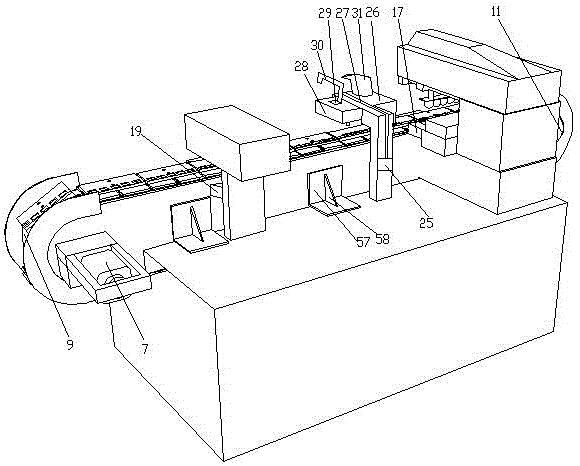

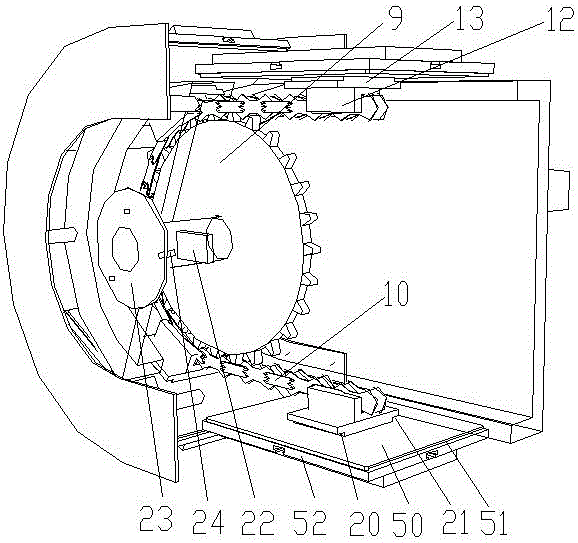

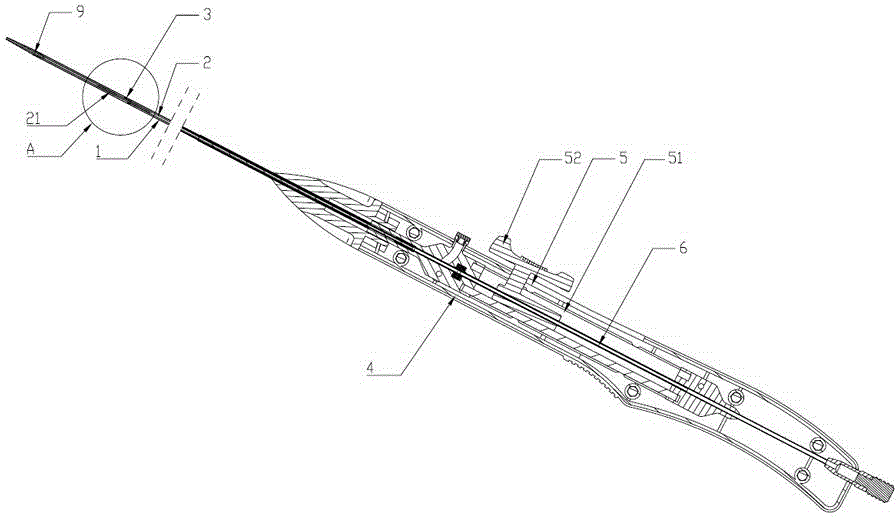

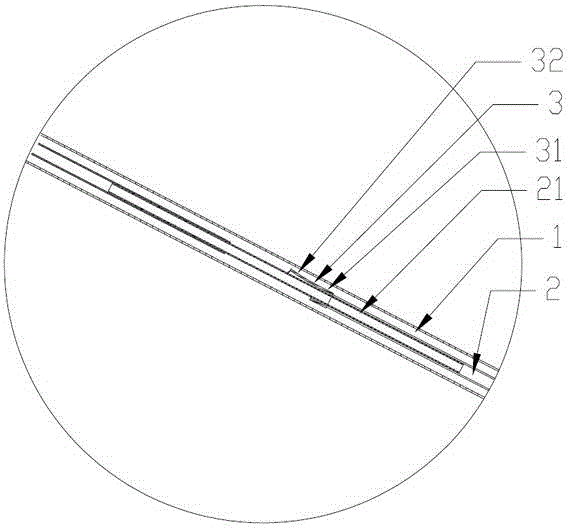

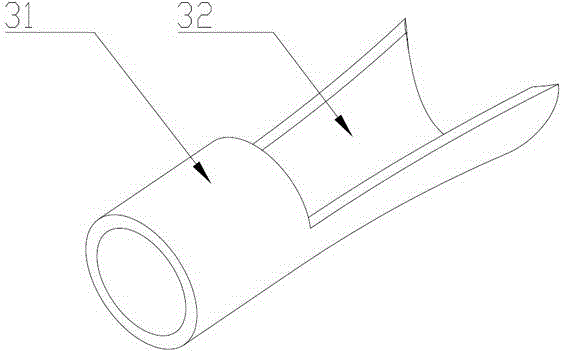

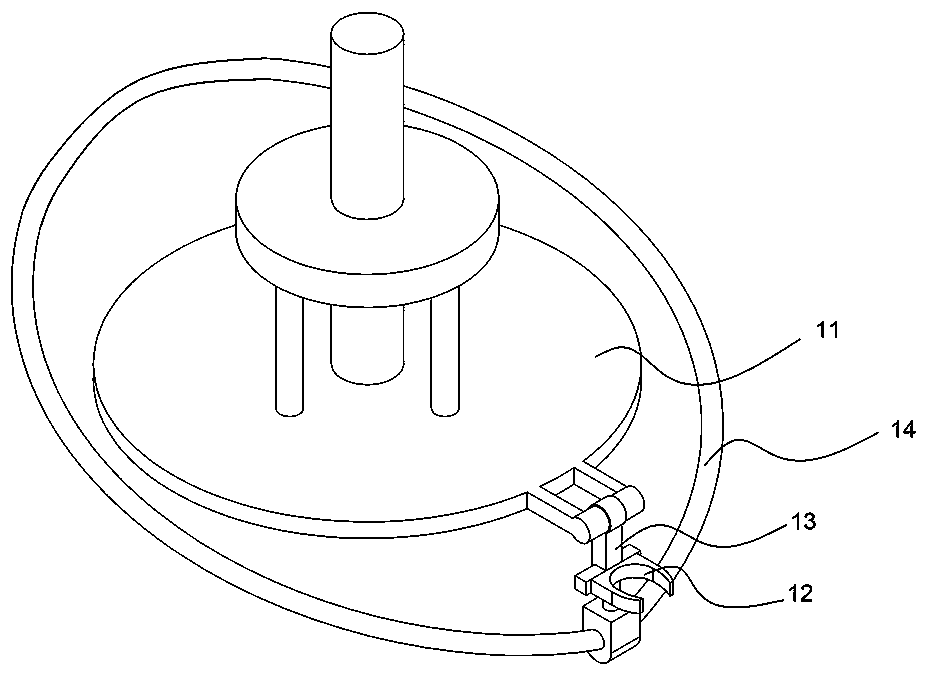

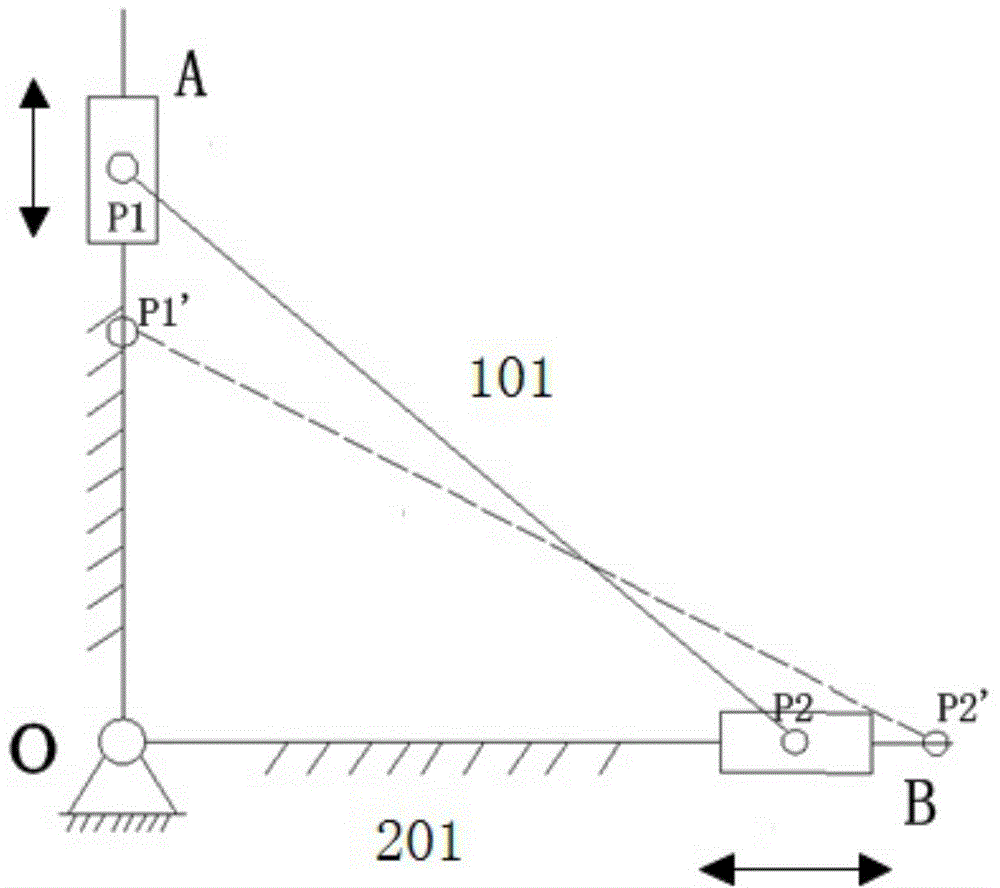

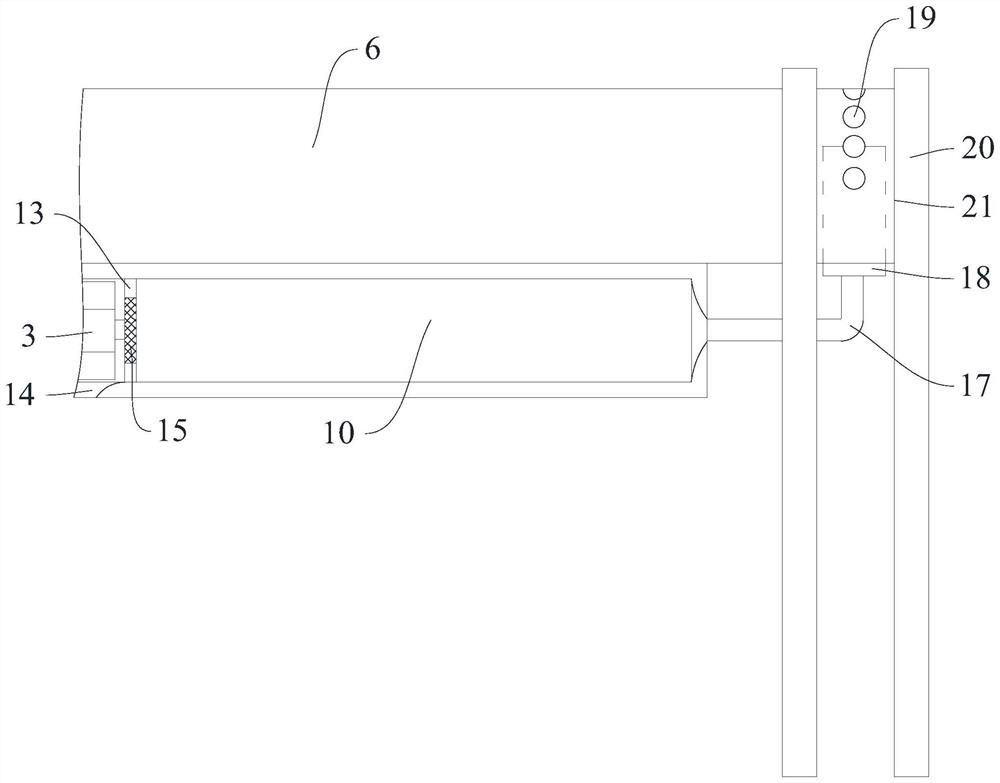

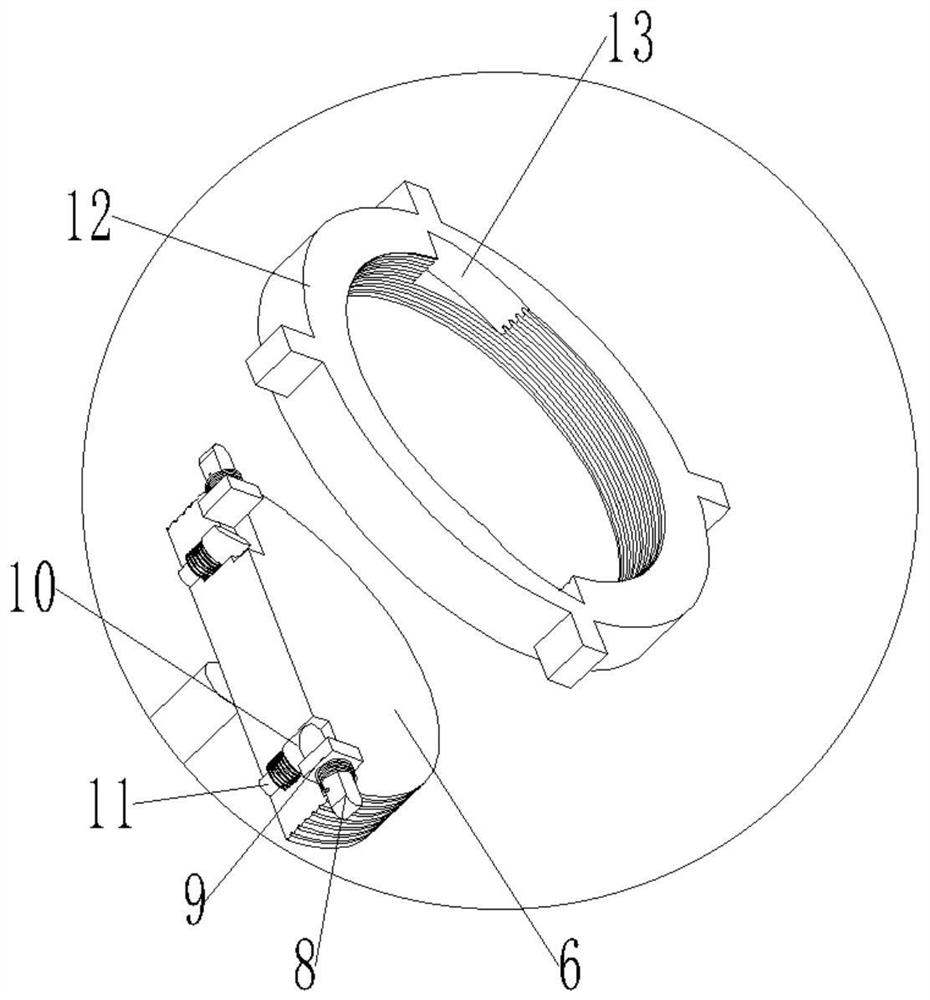

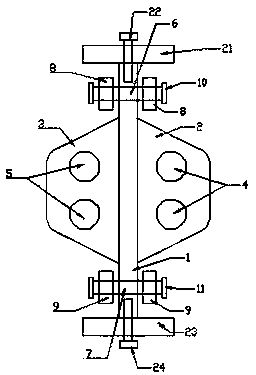

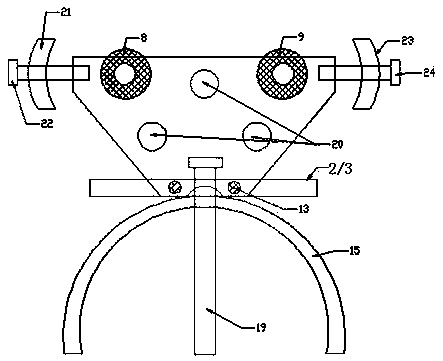

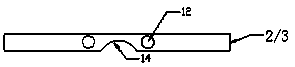

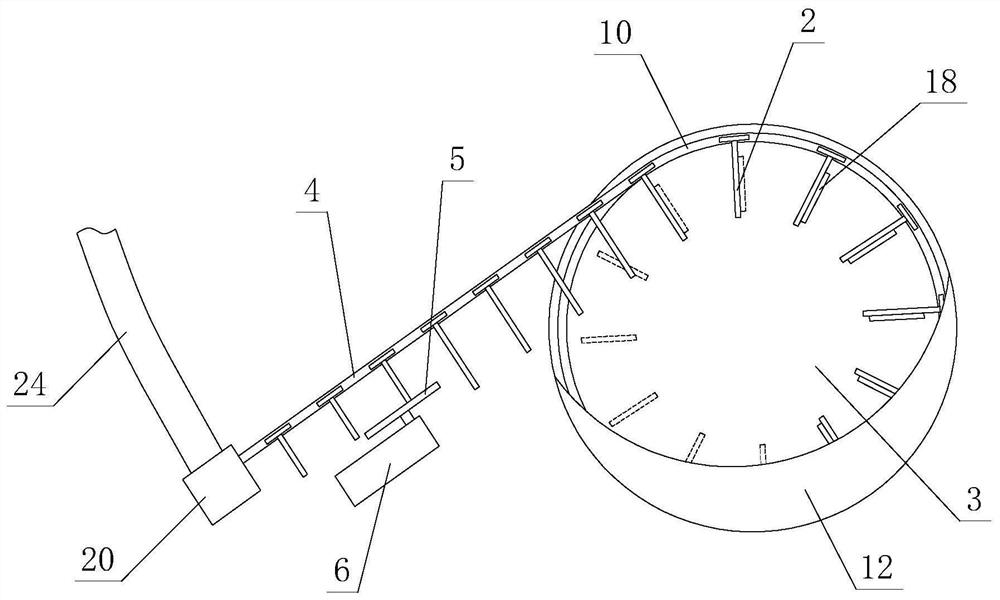

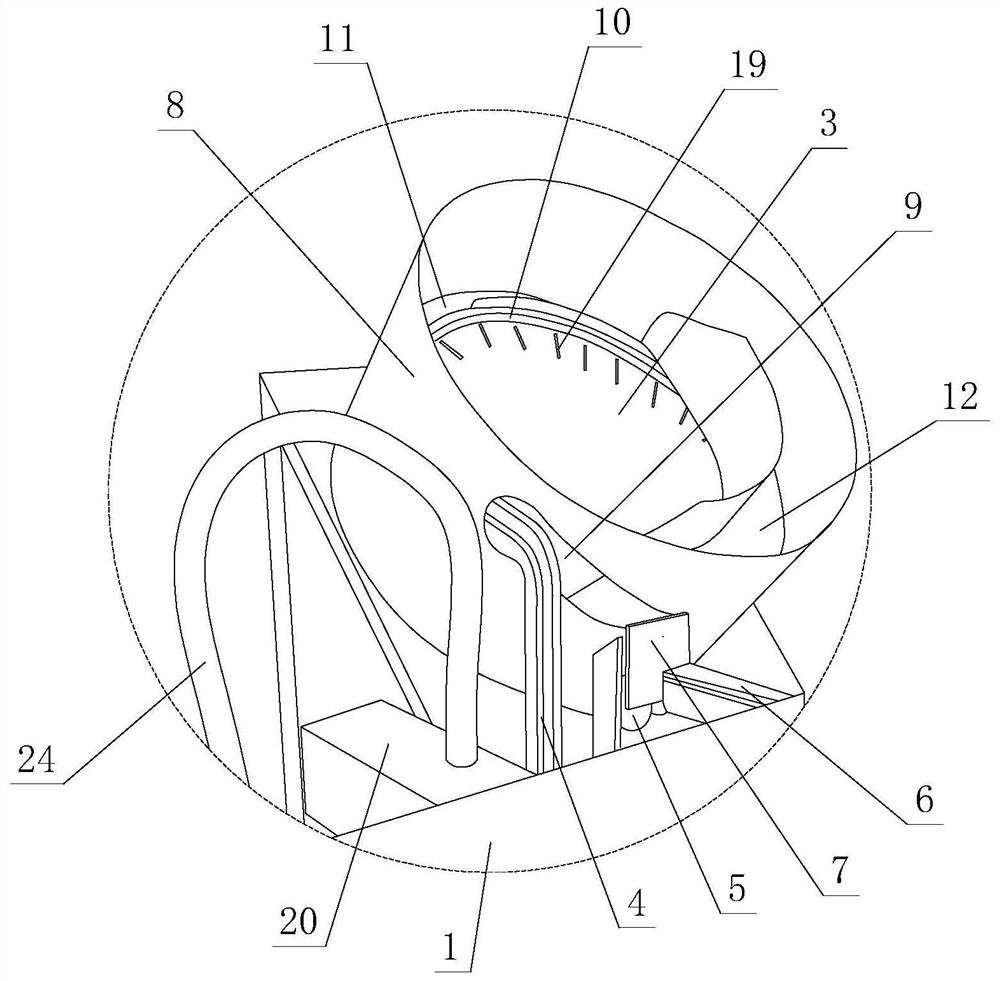

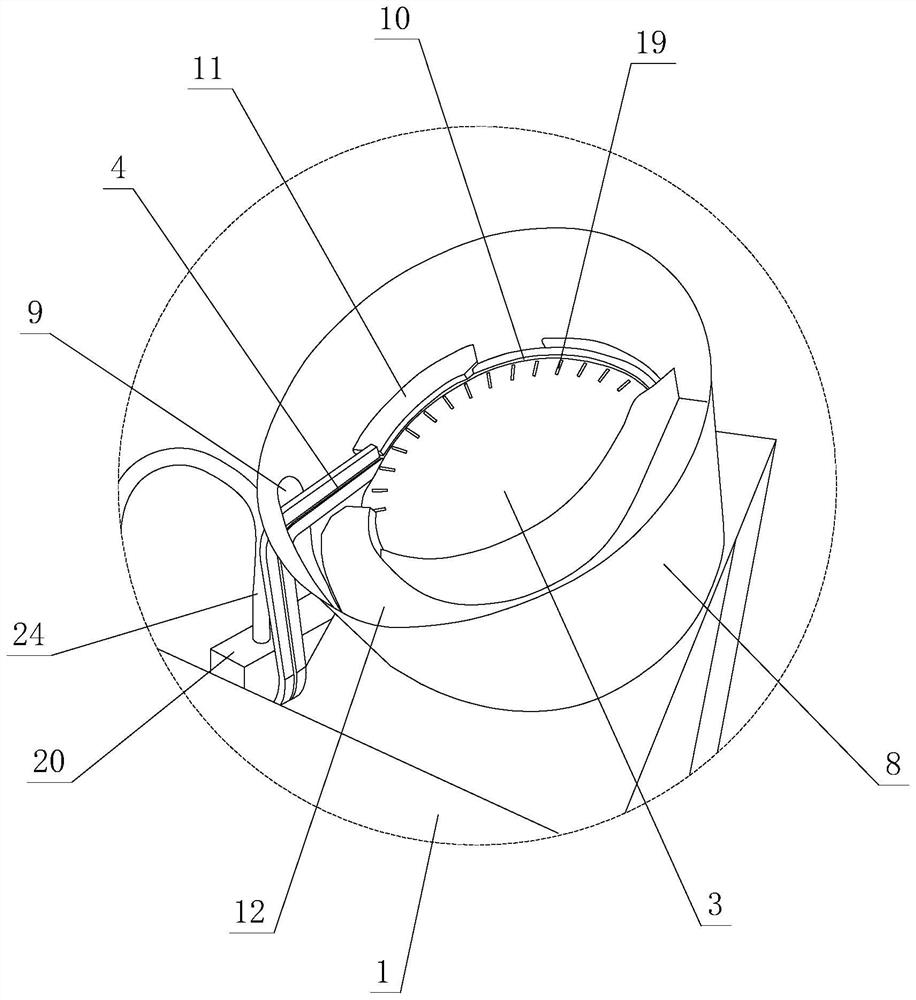

Vascular stent conveying system and conveying method thereof

The invention discloses a vascular stent conveying system and a conveying method thereof. The vascular stent conveying system comprises a catheter unit and a conveying device for driving the catheter unit. The catheter unit comprises an outer pipe and an inner pipe, vascular stents are arranged between the outer pipe and the inner pipe, a barb penetrating inner cavities of the vascular stents is fixedly arranged on the inner pipe and comprises a circular sleeve portion and an elastic portion, the elastic portion is abutted to the vascular stents, and the conveying device drives the barb to extend and retract through the inner pipe and pushes out the vascular stents at intervals through the inner pipe. According to the vascular stent conveying system, the catheter unit is provided with a specific barb structure, a direct pushing mode of the conveying system is changed into a reciprocating pushing mode, pushing stroke is short and not limited by the lengths of the vascular stents, the conveying system is operated by one hand conveniently and rapidly, the other hand can be released, only one hand is limited, other operations can be performed in the medical process, a reciprocating pushing mechanism is stable in pushing, conveying stability of the vascular stents is ensured, and smooth surgery is ensured.

Owner:SUZHOU INNOMED MEDICAL DEVICE

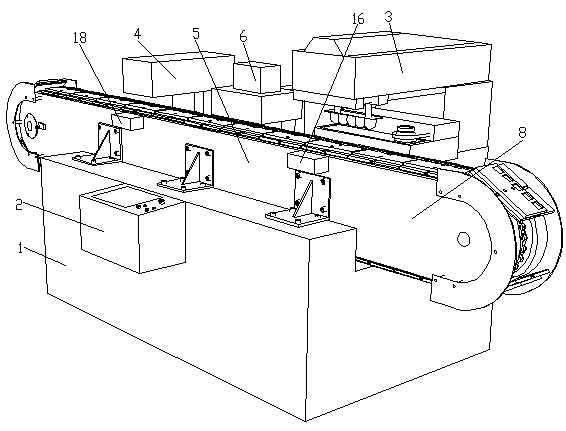

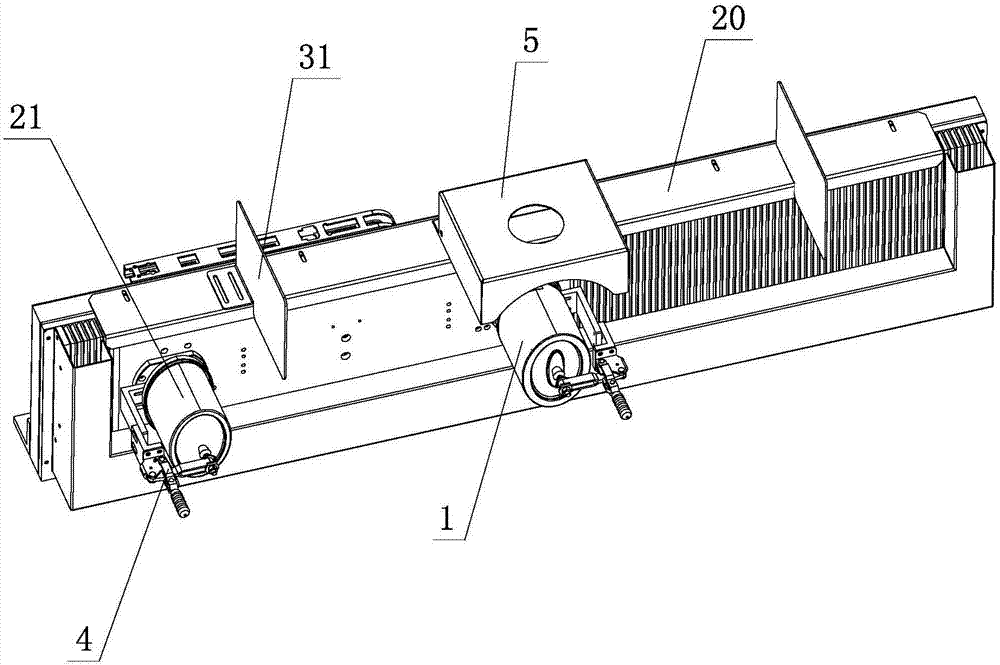

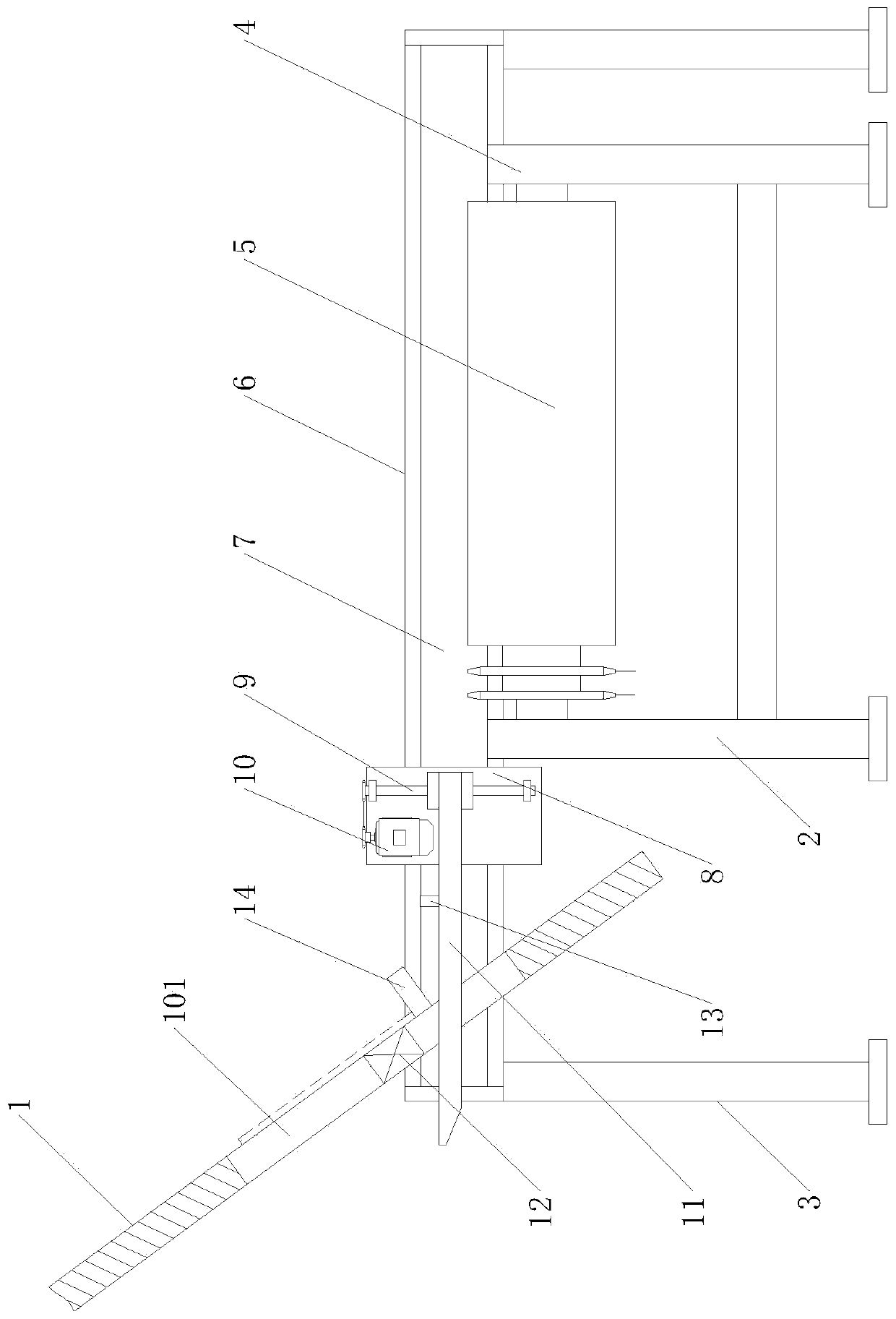

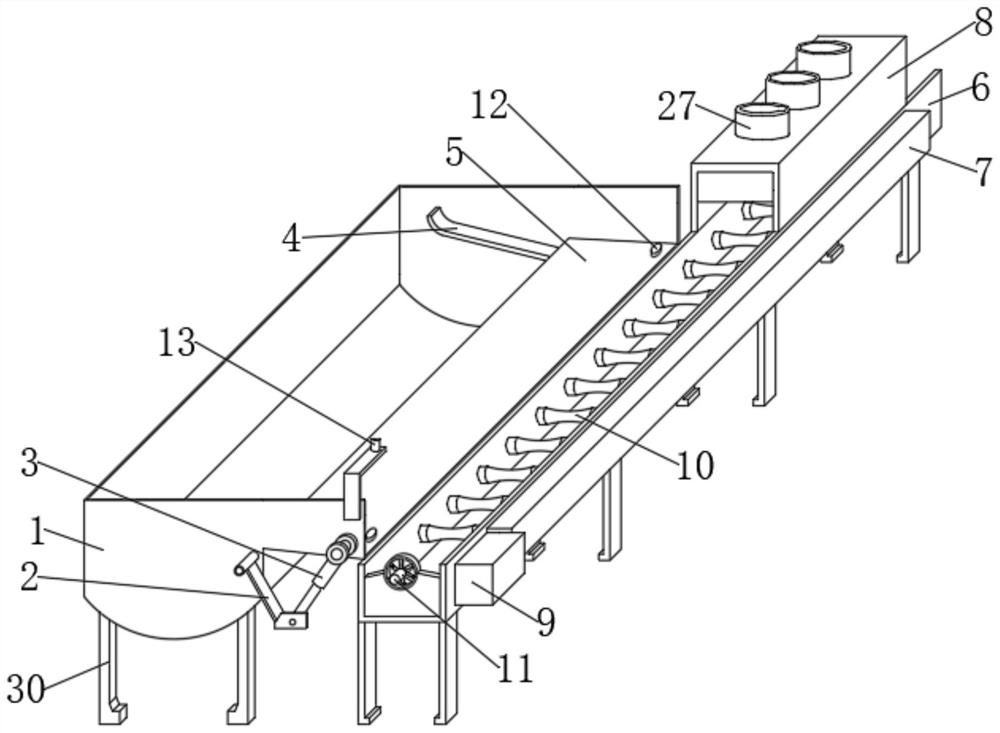

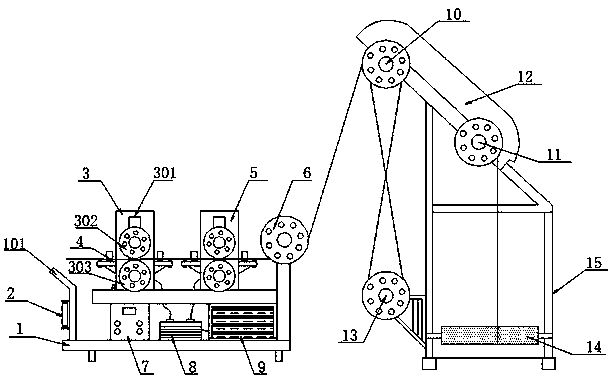

Transfer printing and coding equipment

ActiveCN106364151AEasy to clamp and positionGood pauseRotary pressesPrinting press partsElectricityFinesse

The invention discloses transfer printing and coding equipment which comprises a workbench, a PLC and a transfer printer, and further comprises a laser coding machine and a conveying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. Multiple fixing bases are fixed to the chain and connected with positioning blocks. A bracket is connected to the positioning blocks and provided with die grooves. The side wall of the transmission case is provided with a transfer printing positioning part. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disc. Three sensing columns are distributed on the wheel disc. The infrared sensor, the transfer printer and the laser coding machine are electrically connected with the PLC. By means of organic combination of transfer printing and coding, continuous transfer printing and coding operation of large batches of printed products is achieved, the production efficiency is greatly improved, transfer printing and coding are clearer, and the finesses degree is higher.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

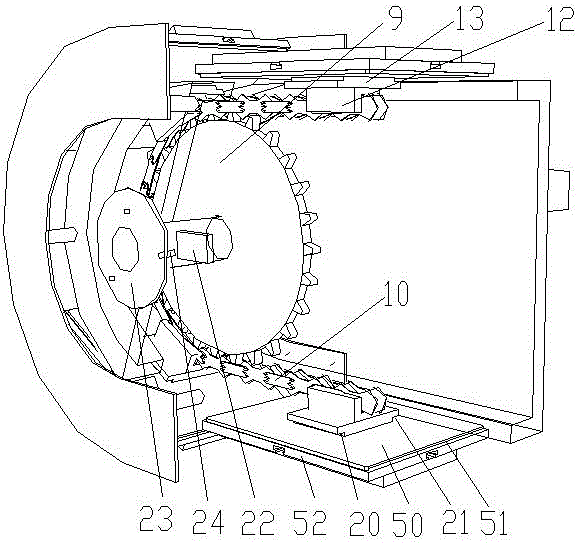

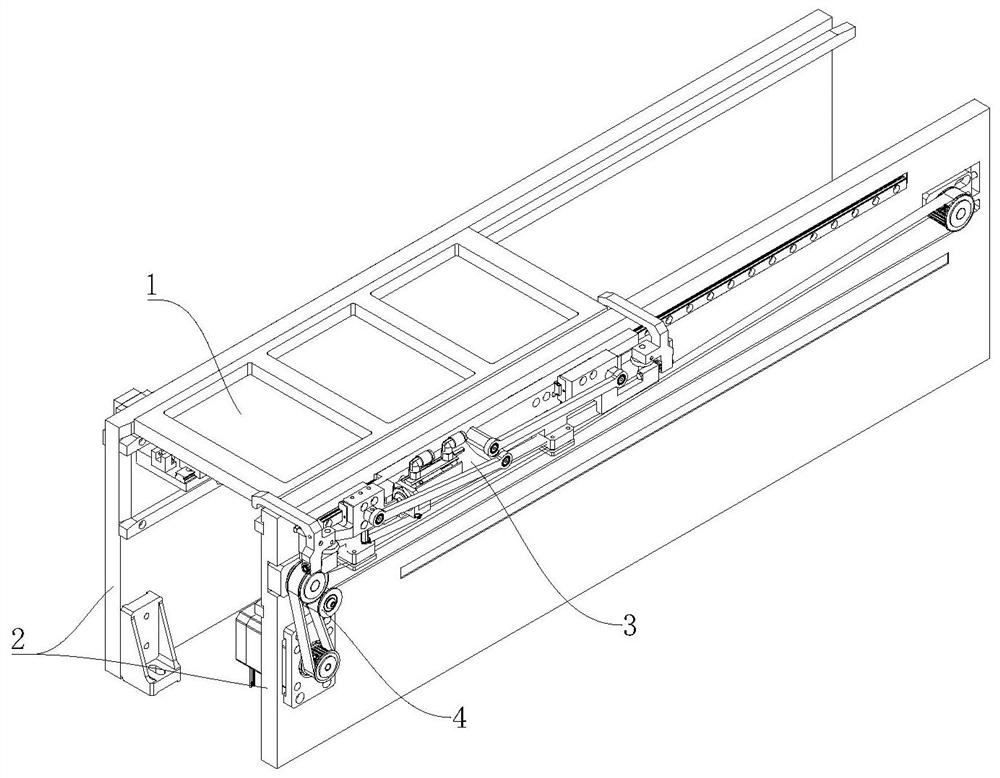

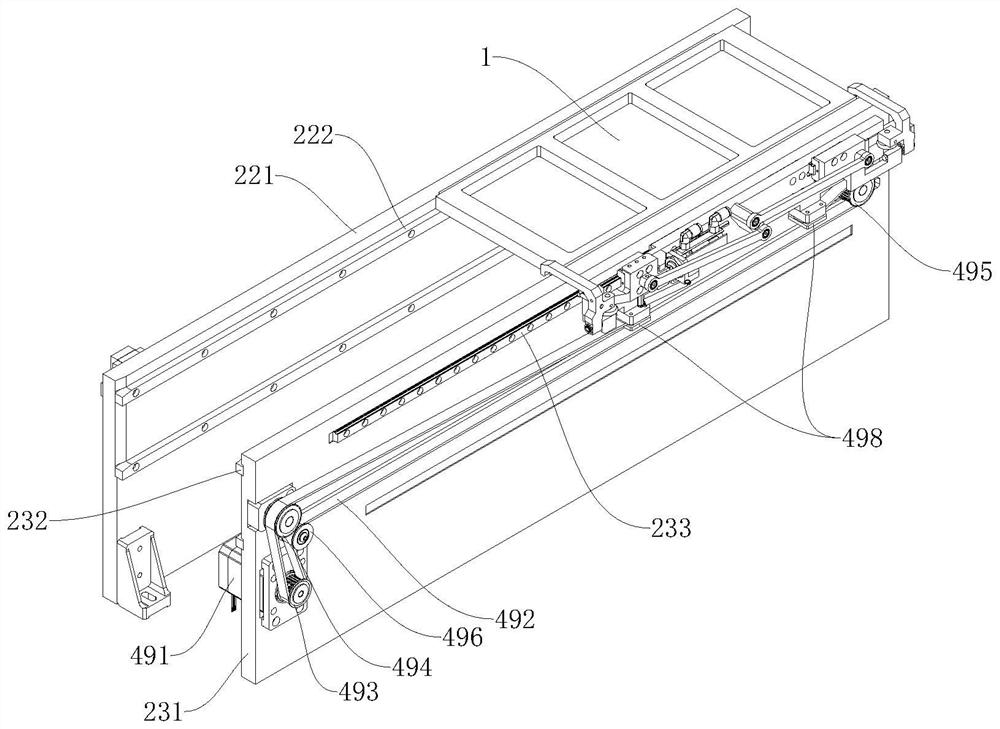

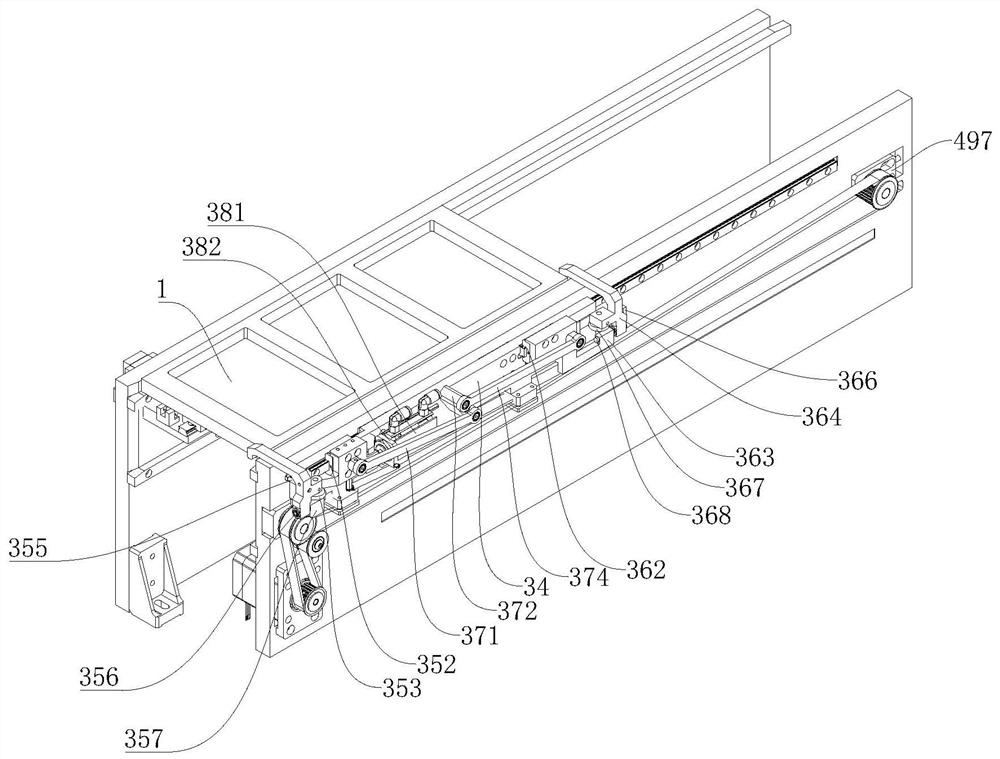

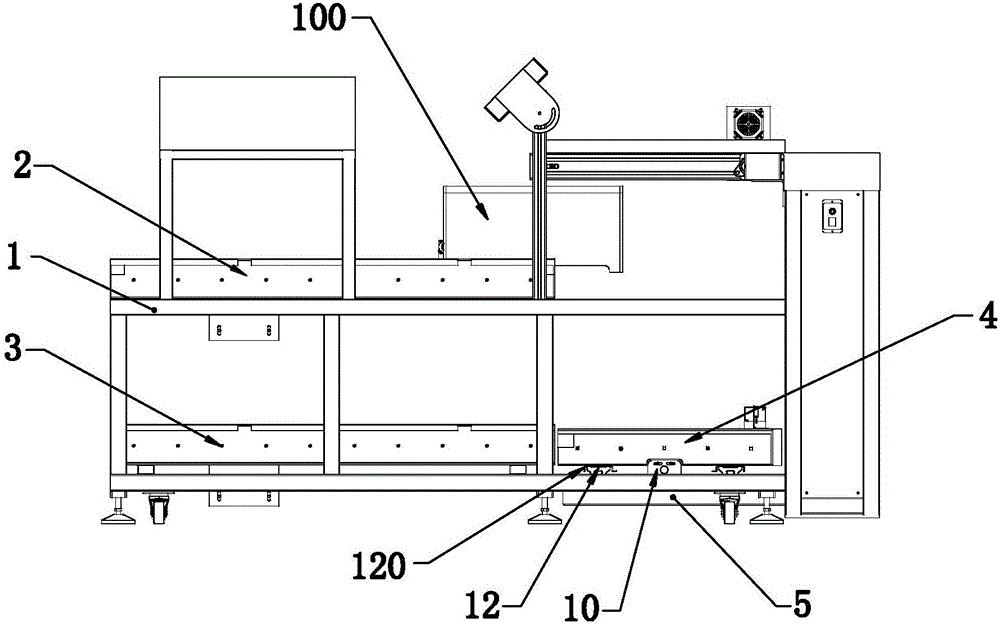

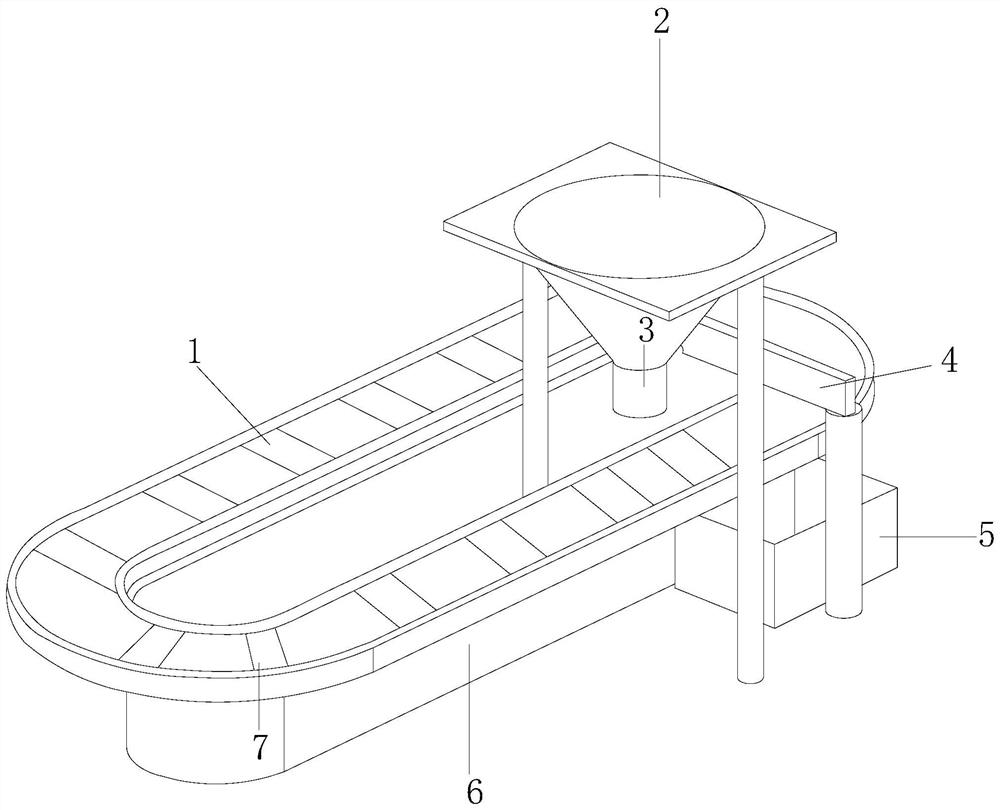

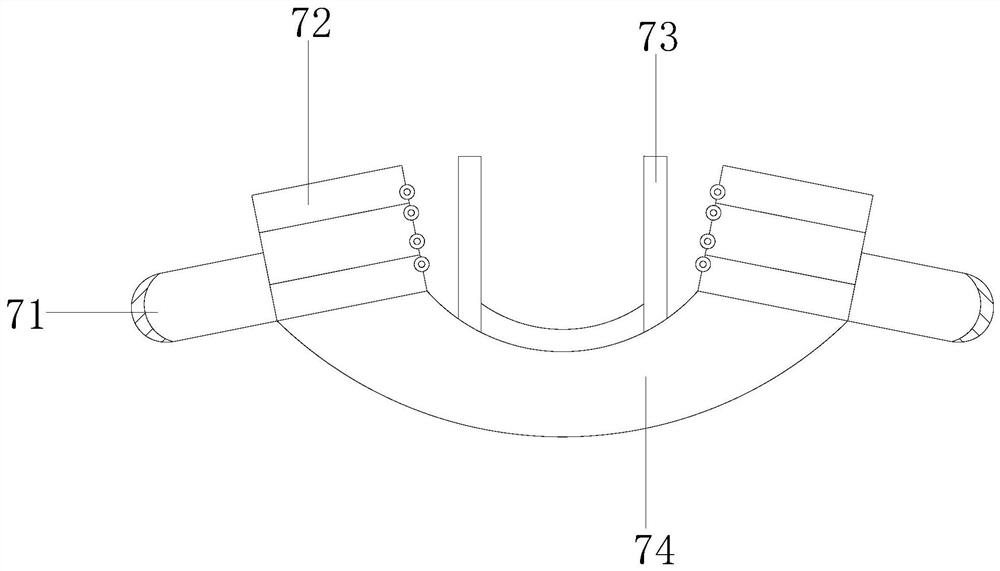

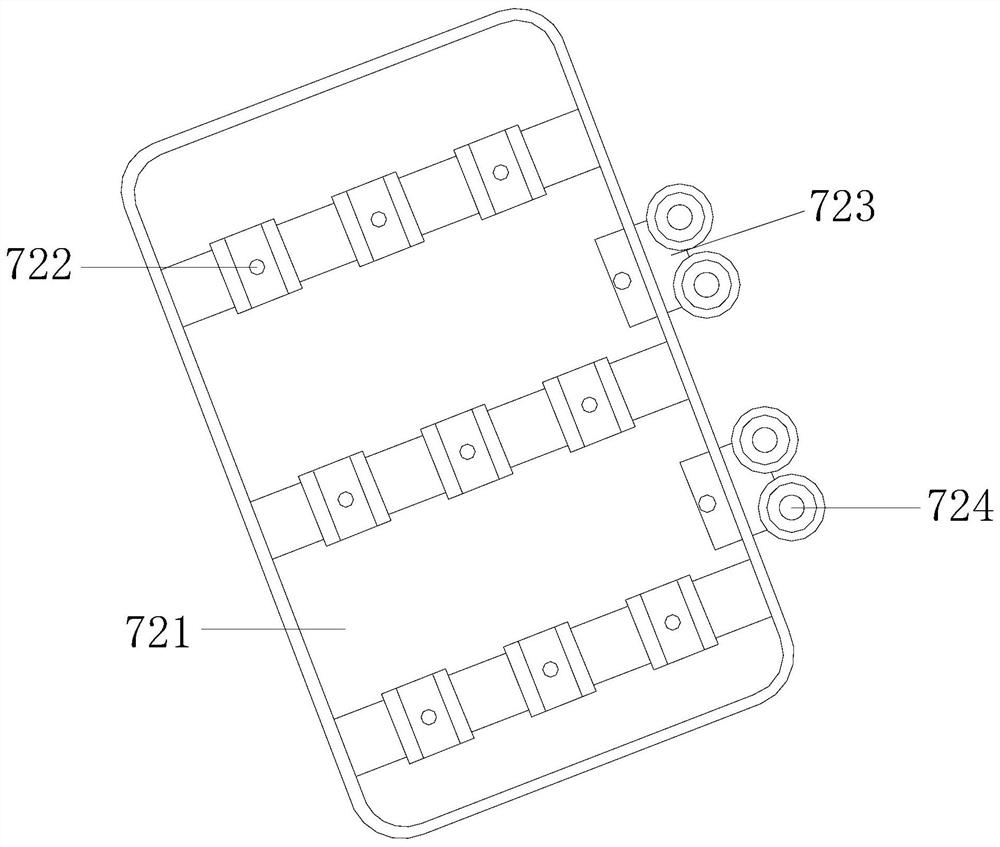

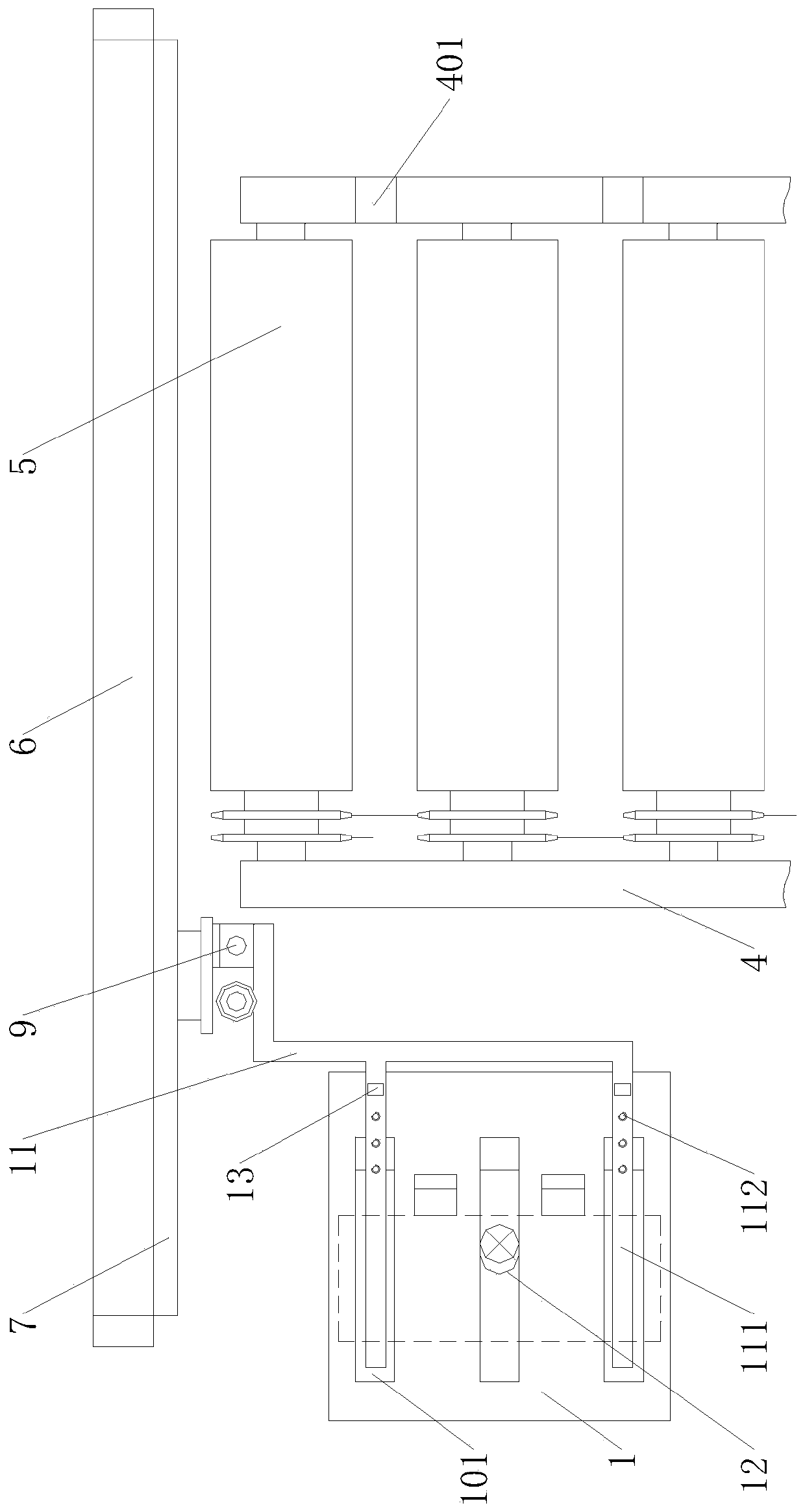

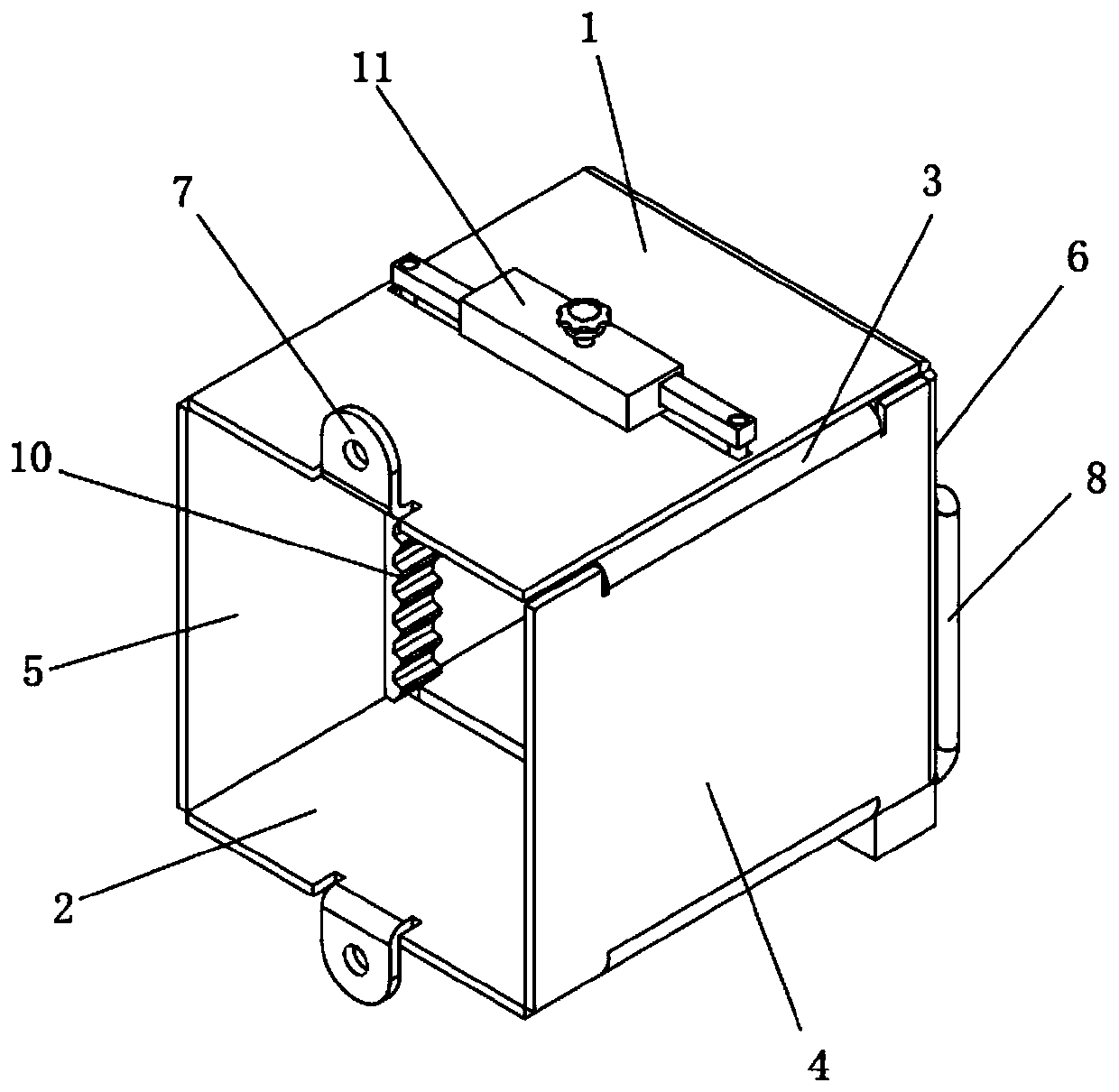

Tray conveying device

PendingCN112209089ARealize safe deliveryEnsure delivery stabilityConveyor partsEngineeringMechanical engineering

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

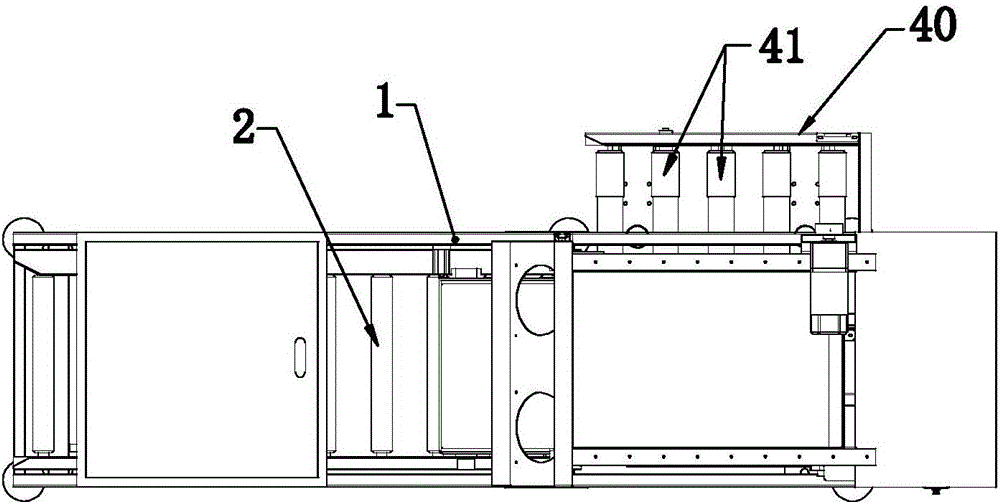

Full-automatic box changing machine

InactiveCN106743470AEnsure delivery stabilityConveyorsConveyor partsProduction lineMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a full-automatic box changing machine for a production line. The technical scheme is achieved in the manner that the full-automatic box changing machine is characterized by comprising a rack, the rack is provided with two layers of conveying assemblies including an upper conveying assembly and a lower conveying assembly which are opposite in conveying direction, and the rack is provided with a box carrying assembly used for conveying boxes on the upper conveying assembly to the lower conveying assembly; and a bottom plate is arranged at the bottom of the box carrying assembly, and the rack is provided with a longitudinal conveying assembly used for driving the longitudinal movement of the bottom plate. The full-automatic box changing machine has the beneficial effects that products can be conveyed to a next workshop to be subjected to the subsequent procedure without manual carrying of the produced products to a conveying mechanism, the manual work labor force is reduced, the production efficiency is improved, automation is achieved, and accordingly the requirements of production line enterprises are met. The full-automatic box changing machine is high in practicability and easy to popularize.

Owner:温岭市正凯自动化设备有限公司

Transfer-printing coding method

ActiveCN106394049ARealize continuous operationIncrease productivityDuplicating/marking methodsContinuous operationLaser

The invention discloses a transfer-printing coding method. The transfer-printing coding method comprises the following steps: (a) an ink feeding step, namely feeding ink to an etching plate by using a sealed type oil cup of a transfer-printing coding device; (b) an ink staining step, namely forwards pushing a rubber head of a transfer printer to a position above the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and pressing the rubber head downwards to be stained with the ink having patterns; (c) a transfer printing step, namely backwards pushing the rubber head to a position above a supporting plate of a conveying component, and then driving the rubber head to be pressed downwards, wherein the rubber is capable of printing the ink having patterns on a to-be-printed object in a mold groove; (d) a coding step, moving the transfer-printed object to a position below a laser coding machine, and performing laser coding by using the laser coding machine. According to the transfer-printing coding method disclosed by the invention, the laser coding machine is capable of coding the last transfer-printed object during transfer printing of a to-be-printed object of the next period, so continuous operation on large-batch to-be-printed objects can be realized, the production efficiency is greatly improved, and a coded product is high in fineness.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

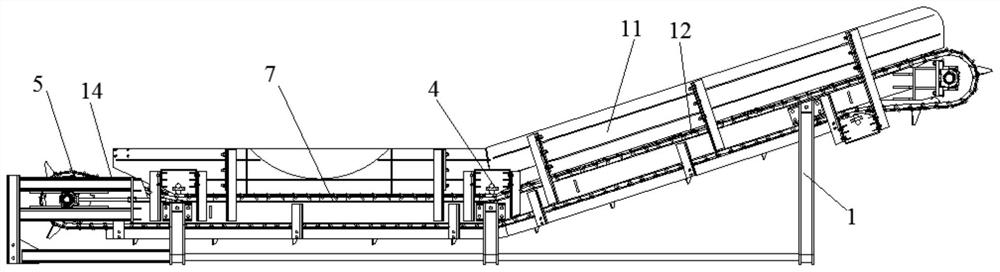

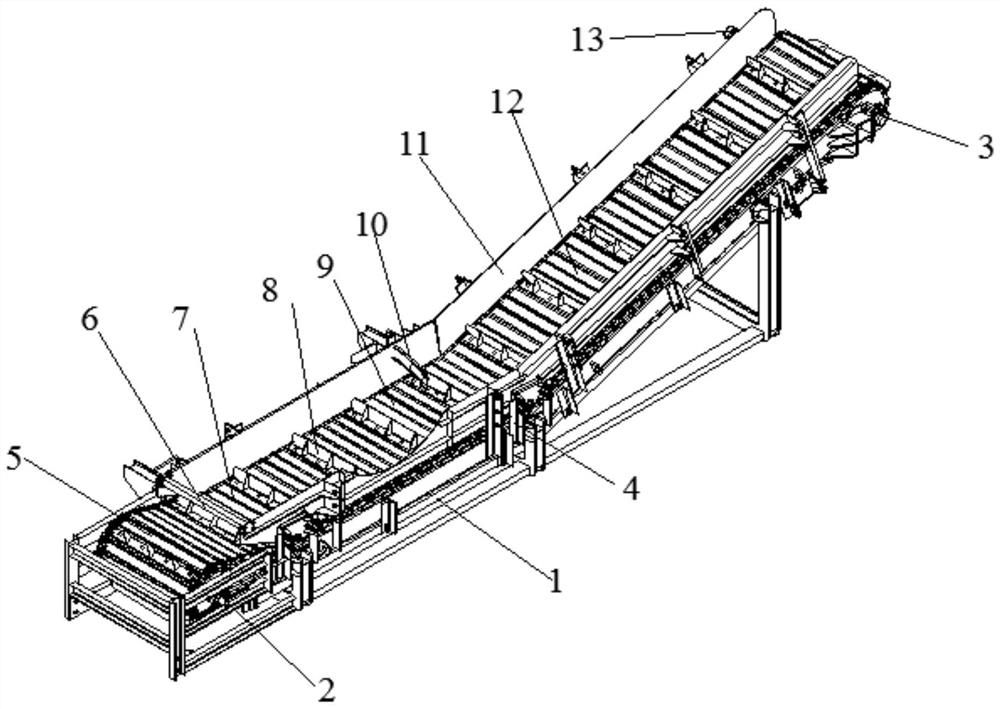

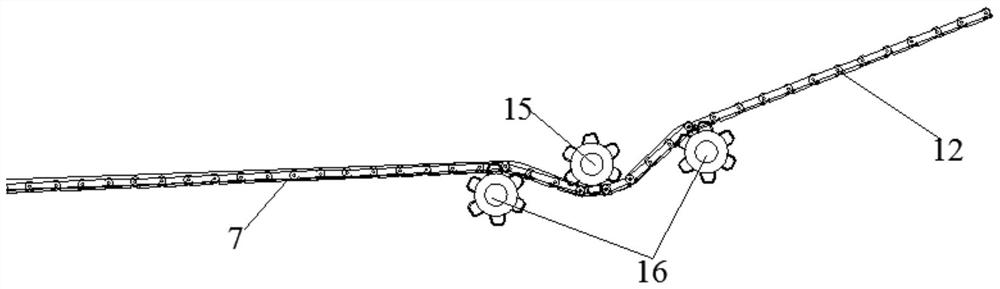

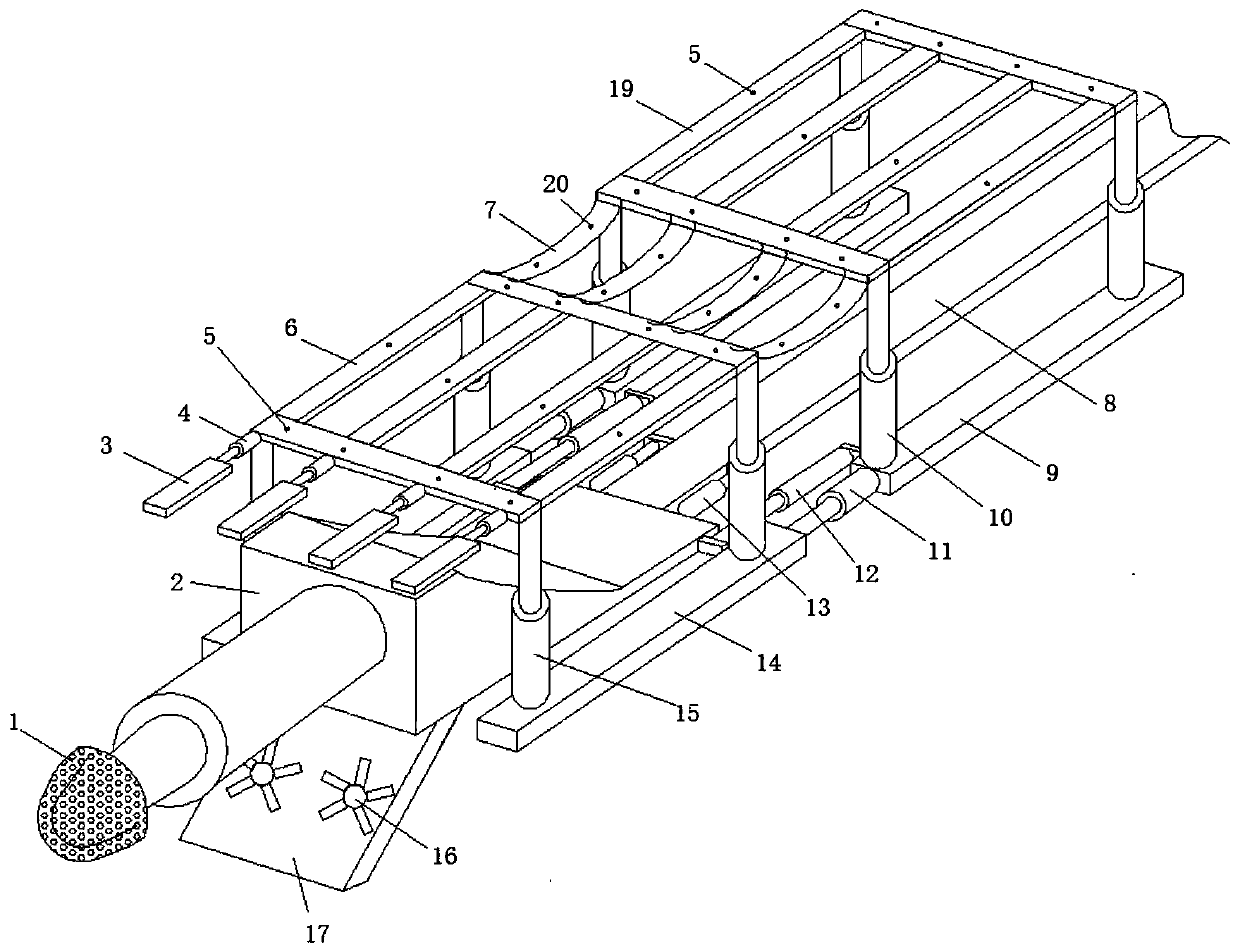

Continuous driving system for coal mine laneway

ActiveCN108194080AEasy to operateImprove working environmentSlitting machinesMine roof supportsRemote controlEngineering

The invention relates to a continuous driving system for a coal mine laneway. The continuous driving system for the coal mine laneway comprises a front frame, a rear frame, an independent cutting head, a conveyor, a plurality of alley part supporting roof bolter and a top supporting roof bolter, and a remote centralized control station, wherein the front frame comprises a pair of first sliding boots which are arranged in a horizontal mode and in parallel and first supporting frames which are arranged on the upper portion of the first sliding boots, the first sliding boots are correspondingly connected with both sides of the first supporting frames by at least one first supporting oil cylinder, the front ends of the first supporting frames are provided with a plurality of extensible oil cylinders in a horizontal mode, and an extensible end of each of the extensible oil cylinders is horizontally provided with front extension supporting beams; and the rear frame comprises a pair of secondsliding boots which are arranged in a horizontal mode and in parallel and second supporting frames which are arranged on the upper portion of the second sliding boots, the second sliding boots are correspondingly connected with both sides of the second supporting frames by at least one second supporting oil cylinder, and the front ends of the second sliding boots are connected with the rear endsof the corresponding first sliding boots through the thrust cylinder. According to the continuous driving system for the coal mine laneway, the excavating, the conveying the supporting of the roof bolter can be carried out at the same time, continuous circulation is carried out, continuous excavation is carried out, remote control is carried out, and the laneway can be formed only once.

Owner:陈新川

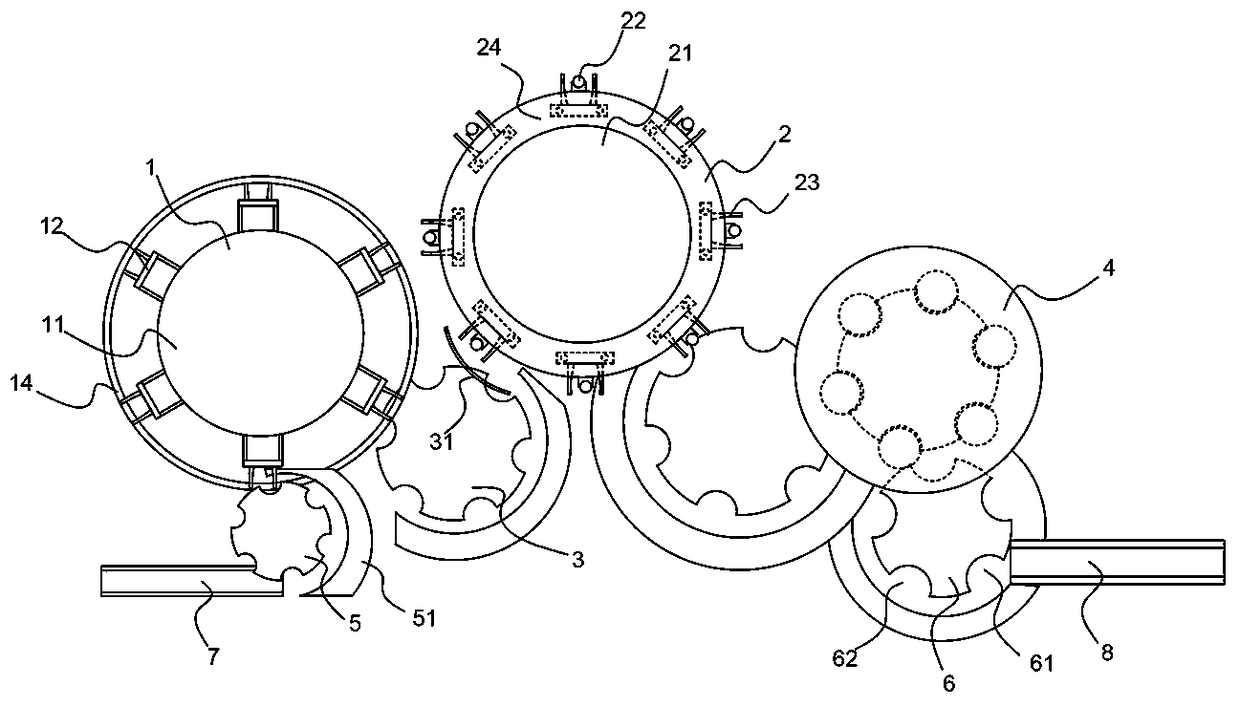

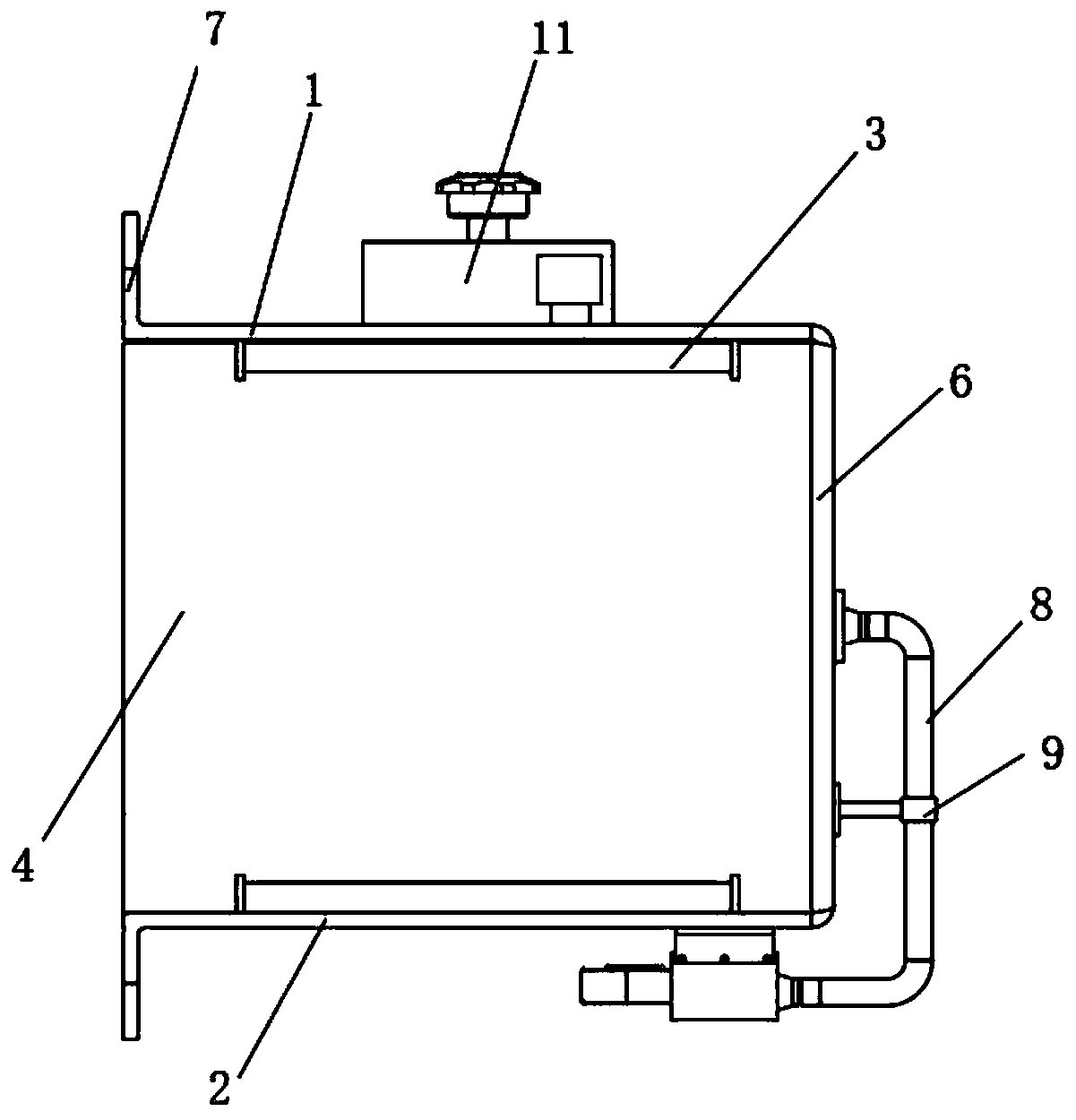

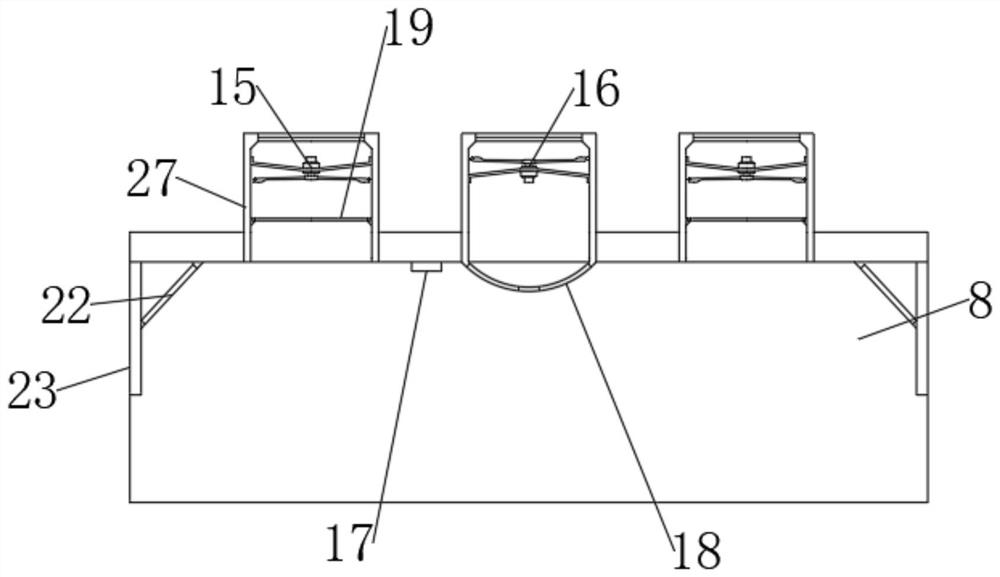

Filling method and filling equipment for fruit juice

InactiveCN109052295ACompact structureImprove stabilitySynchronising machinesConveyorsHinge jointFruit juice

The invention provides a filling method and filling equipment for fruit juice. The filling equipment comprises a bottle washing machine and a filling machine, wherein the bottle washing machine comprises a rotatable bottle washing rotating plate, first holding clips are arranged in the circumferential direction of the bottle washing rotating plate in a hinge joint manner, each holding clip is hinged with a connecting rod, guide rods are arranged at the lateral portion of the bottle washing rotating plate, and the guide rods are sleeved with one ends of the connecting rods; one part of the guide rods are located on the lower sides of the first holding clips in the circumferential direction of the bottle washing rotating plate, and the other part of the guide rods are located on the upper sides of the first holding clips; and the filling machine comprises a filling rotating plate, a storage tank is arranged on the filling rotating plate, and filling heads are arranged at the lower end ofthe storage tank. Impurities in bottles can be removed before filling, the structure is compact, and the stability is high.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

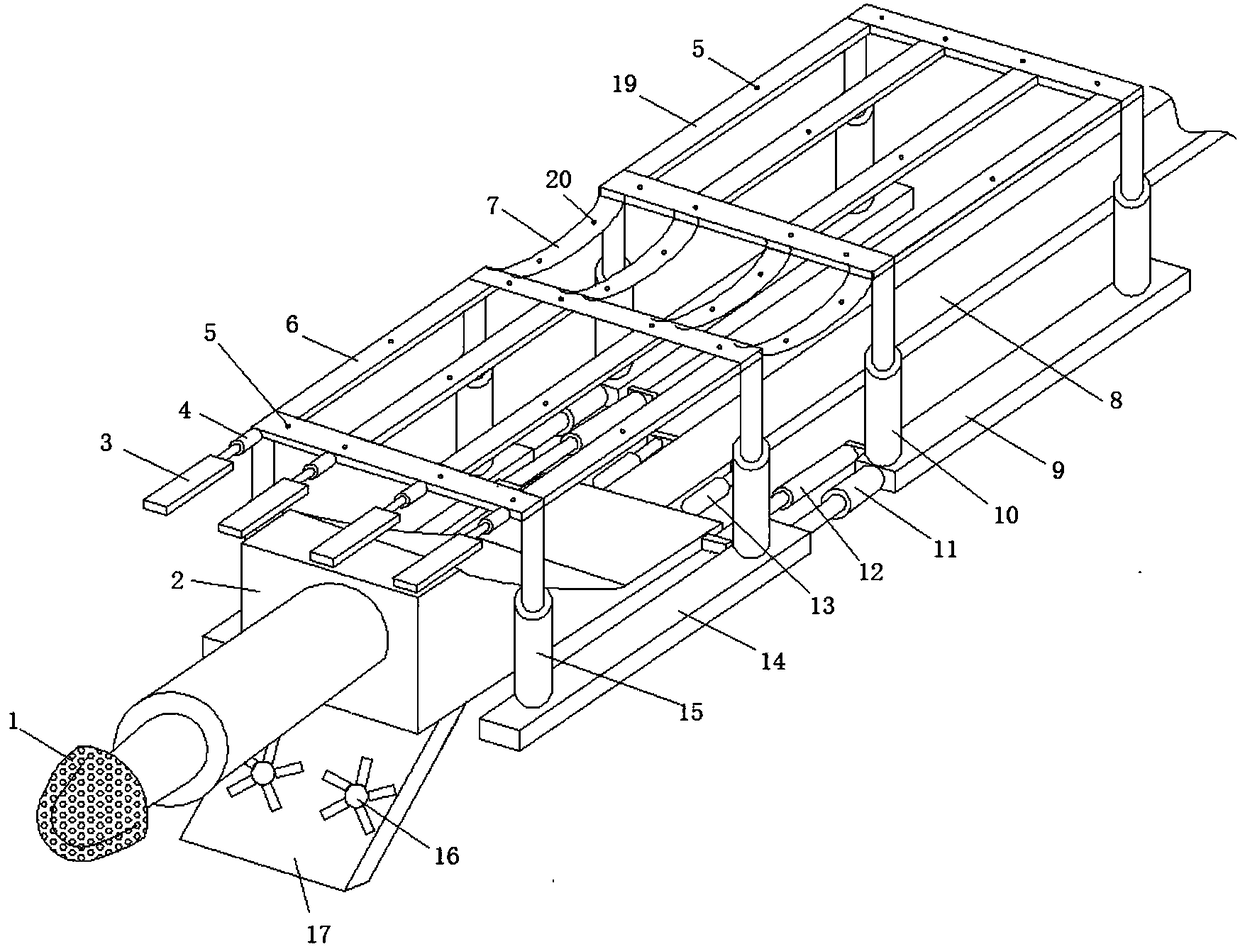

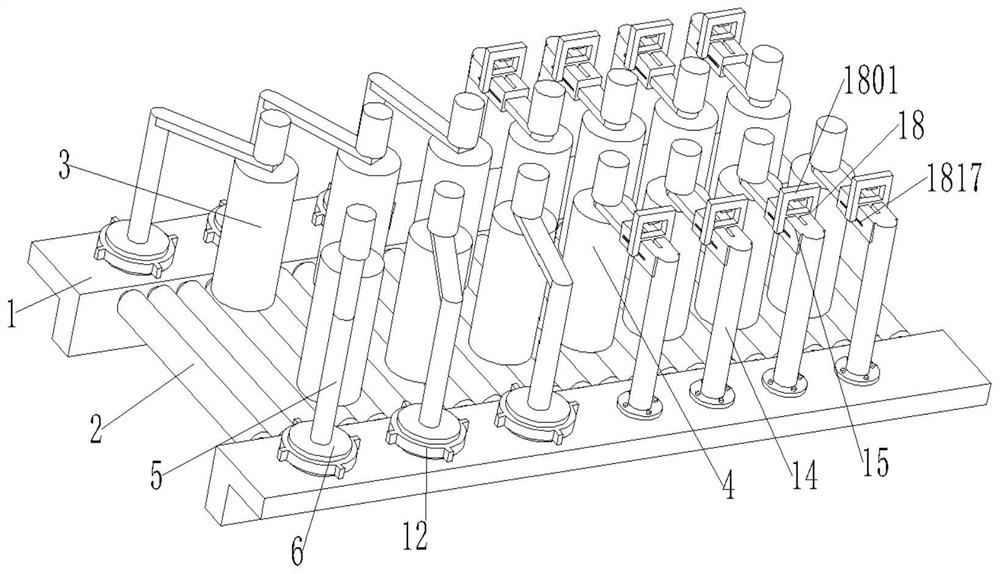

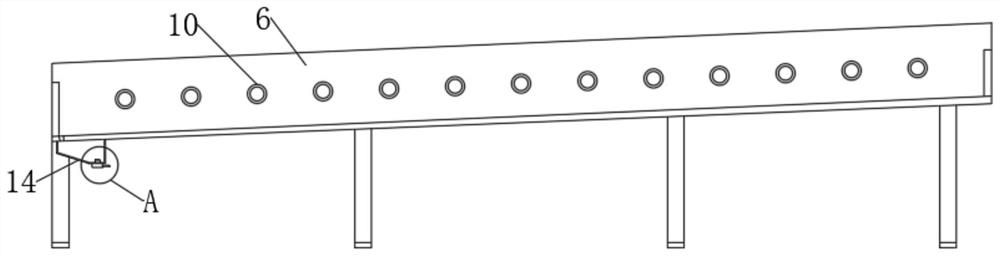

Full-automatic feeding device of industrial aluminum profile machining assembly line

ActiveCN112124841AGuarantee the quality of production and processingEnsure delivery stabilityConveyor partsRoller-waysMachine partsEconomic benefits

The invention discloses a full-automatic feeding device of an industrial aluminum profile machining assembly line. The full-automatic feeding device carries out conveying work through conveying rollers in the aluminum profile machining and production feeding process and limits the positions of aluminum profile machining raw materials through guide rollers and limiting rollers, and therefore it isensured that aluminum profiles do not deviate when being conveyed and can be conveyed to accurate positions in a next machining site without deviating, the conveying stability of aluminum profile machined parts is guaranteed, the production and machining quality of the aluminum profiles can be guaranteed, and machining and production economic benefits are guaranteed; and the positions of the guiderollers and the limiting rollers can be adjusted, adjustment can be made according to the actual sizes of the aluminum profiles, and therefore it can be better guaranteed that position guiding and limiting work can be better conducted on the aluminum profile machined parts.

Owner:JIANGXI TIAN YI ALUMINUM

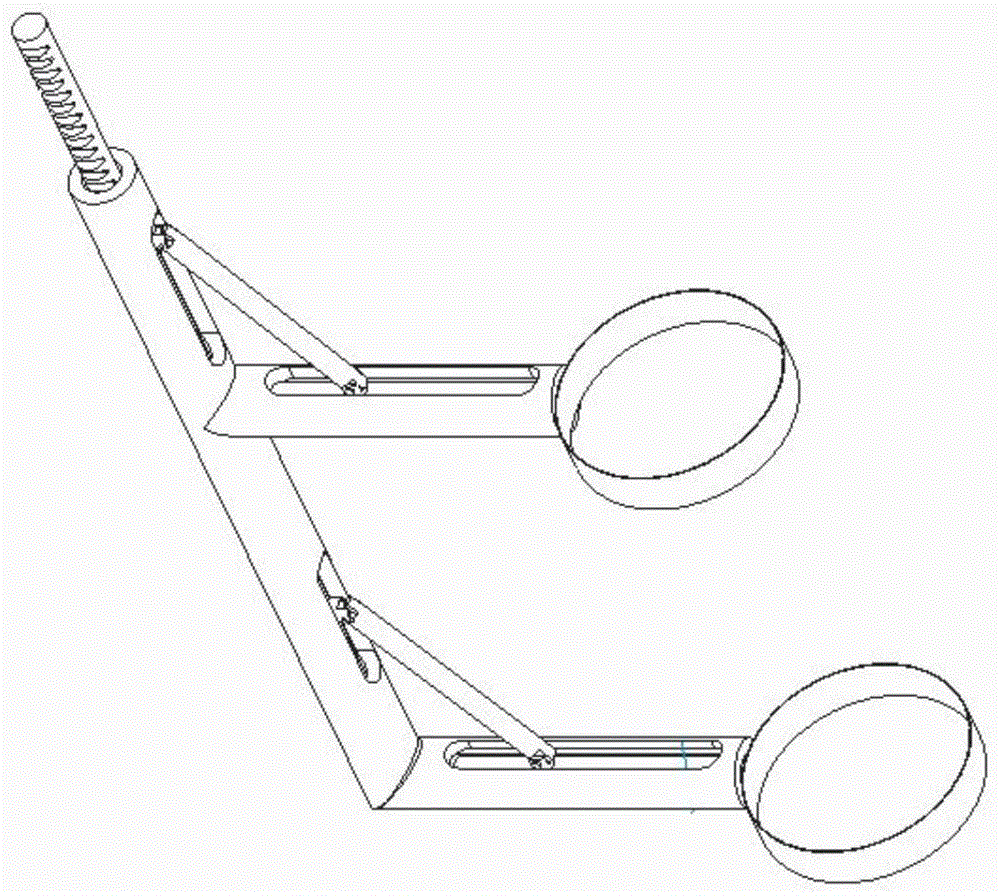

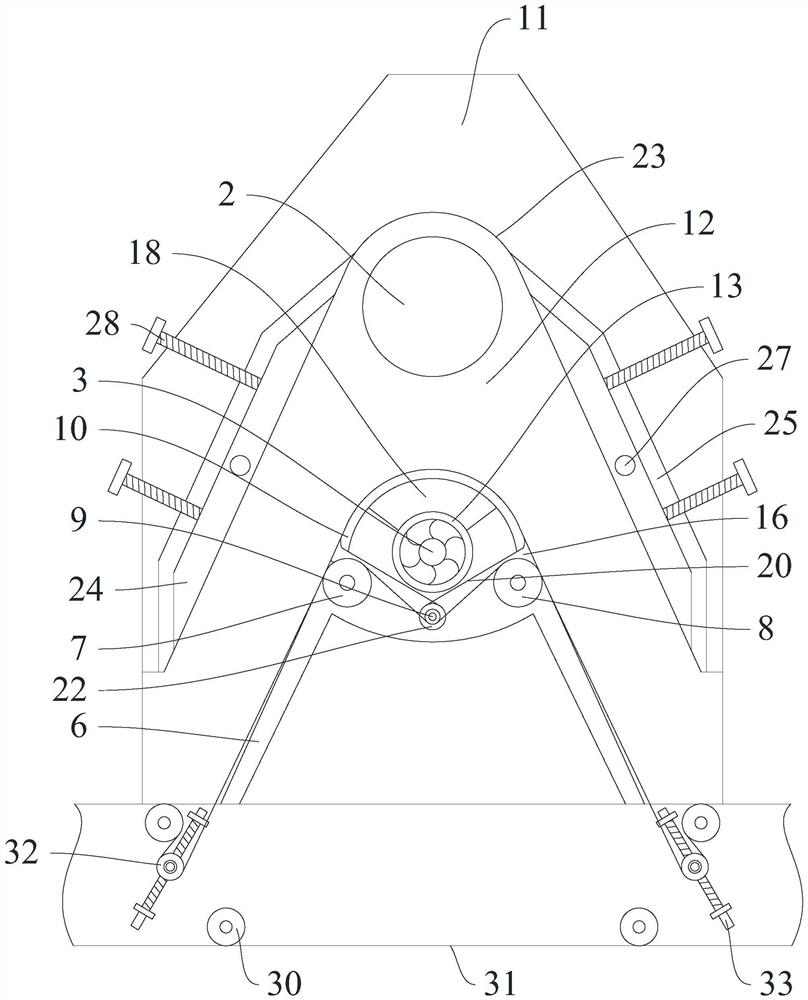

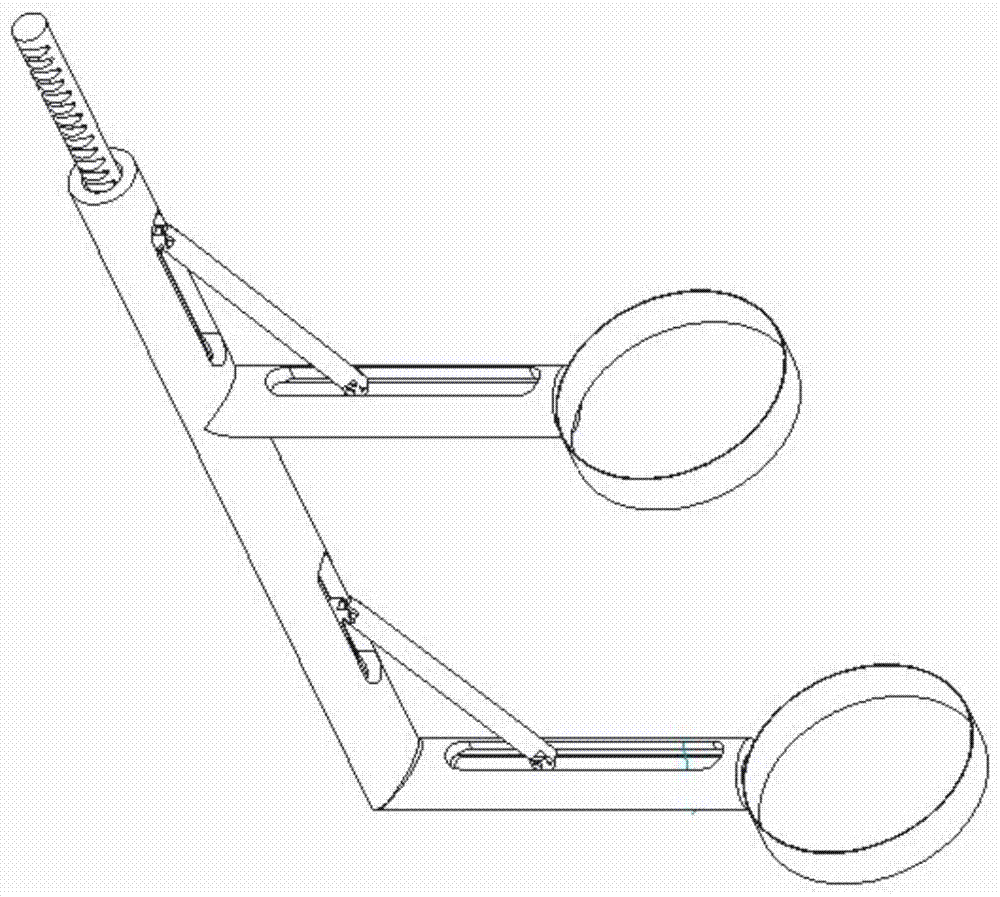

Bomb clamping device based on the principle of double-slider mechanism

The invention aims to provide a bomb clamping device based on the principle of a double-slider mechanism. When arriving at the overhead of a fire scene, a host computer sends a signal to control the rotation of a rotary motor, in order to drive a rotating shaft coaxial with the rotary motor to rotate, the rotating shaft drives a gear in key fit with the rotating shaft to move, the gear transmits the movement to a gear rack, a main piston rod moves downwards with the movement of the gear rack, meanwhile the movement is transmitted to an auxiliary piston rod I and an auxiliary piston rod II by a connecting rod, the auxiliary piston rod I and the auxiliary piston rod II advance with a straining ring, a fire extinguishing bomb fixed by the straining ring moves along a slide way along the feeding movement of the straining ring, after moving for a segment of distance, when the straining ring and the circle center of a discharge opening are approximately coaxial, the fire extinguishing bomb deviates from the tail end of the slide way, and the fire extinguishing bomb is discharged under the self-gravity environment of the fire extinguishing bomb. According to the bomb clamping device provided by the invention, a connecting rod mechanism is evolved to the double-slider mechanism, so that a series of actions of clamping, propelling and discharging the fire extinguishing bomb can be successfully completed.

Owner:HARBIN ENG UNIV

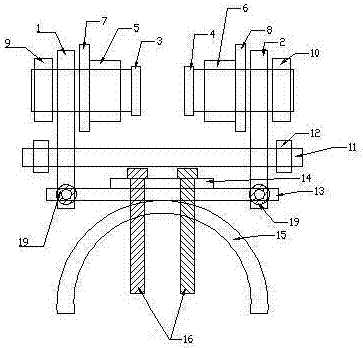

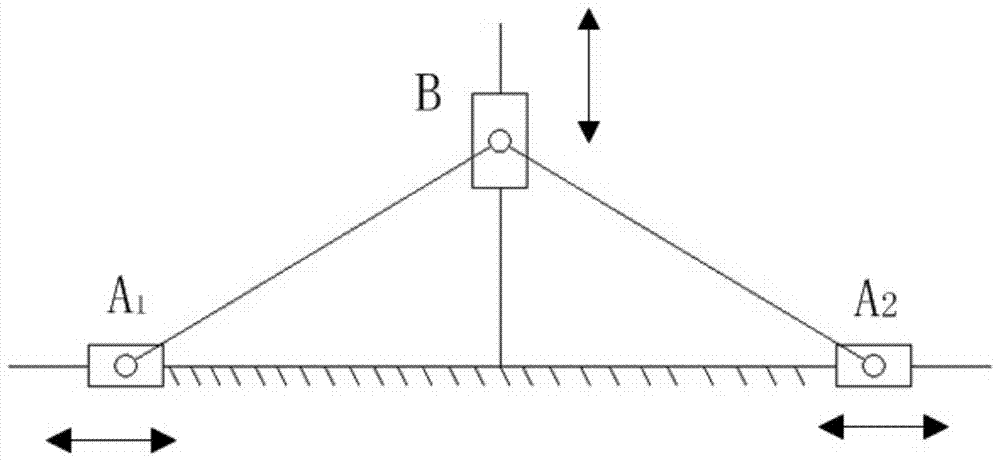

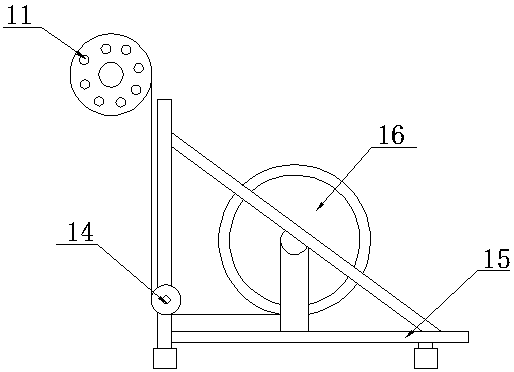

Overhead rail pulley assembly for assembling streamline

The invention belongs to the technical field of application of goods hoisting assembly accessories, and particularly discloses an overhead rail pulley assembly for assembling streamline. The overhead rail pulley assembly comprises a left supporting plate, a right supporting plate, a group of first roller assemblies, a group of second roller assemblies, horizontal supportive connecting plates, and adjusting and supporting assemblies, wherein the group of first roller assemblies and the group of second roller assemblies are respectively arranged on the left supporting plate and the right supporting plate, the horizontal supportive connecting plates are respectively connected with the left supporting plate and the right supporting plate, the adjusting and supporting assemblies are matched with the horizontal supportive connecting plates for use, porous grooves are respectively formed in the left supporting plate and the right supporting plate correspondingly, the horizontal supportive connecting plates are connected with the left supporting plate and the right supporting plate through the porous grooves. The overhead rail pulley assembly has the beneficial effects of being reasonable in an overall stainless steel structure design, strong in toughness and excellent in corrosion resistance and wear resistance, the group of first roller assembly and the group of second roller assembly can ensure the running stability and high efficiency of the overall structure, and the adjusting and supporting assembly can ensure the conveying stability of hoisted goods or products and completely eradicate the hidden production safety.

Owner:东台中海高温合金科技有限公司

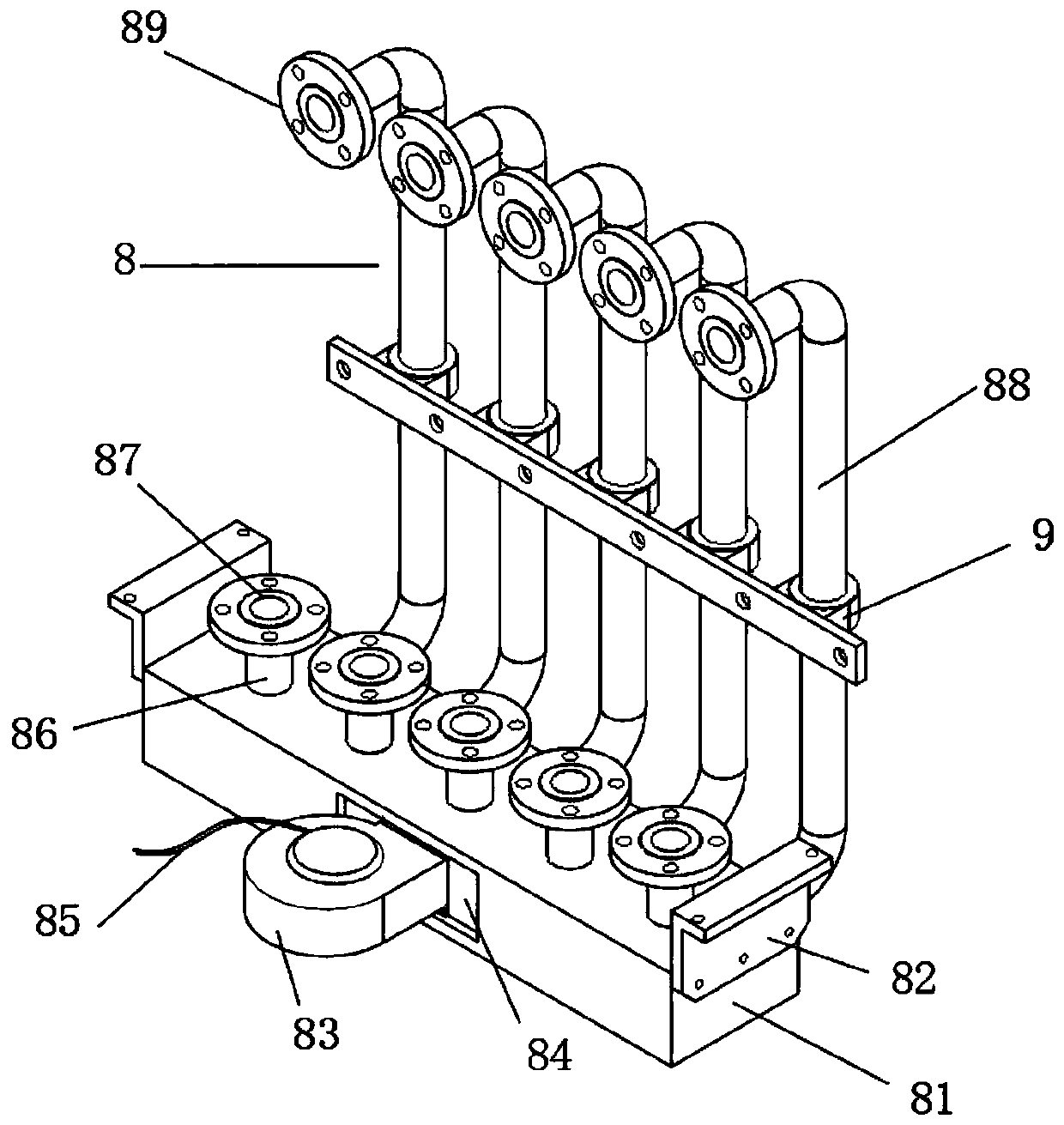

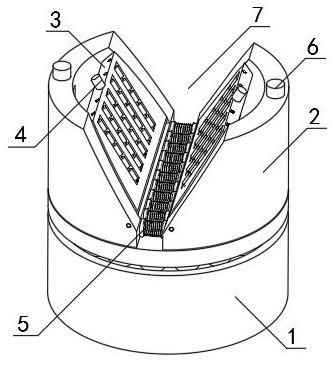

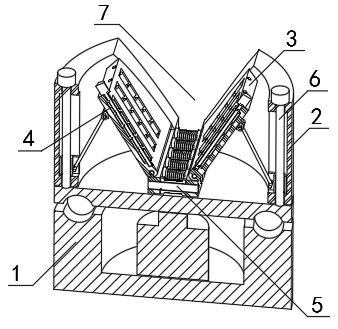

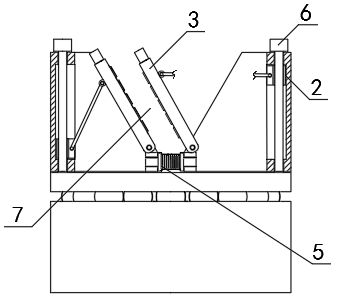

UV curing device with large irradiation range

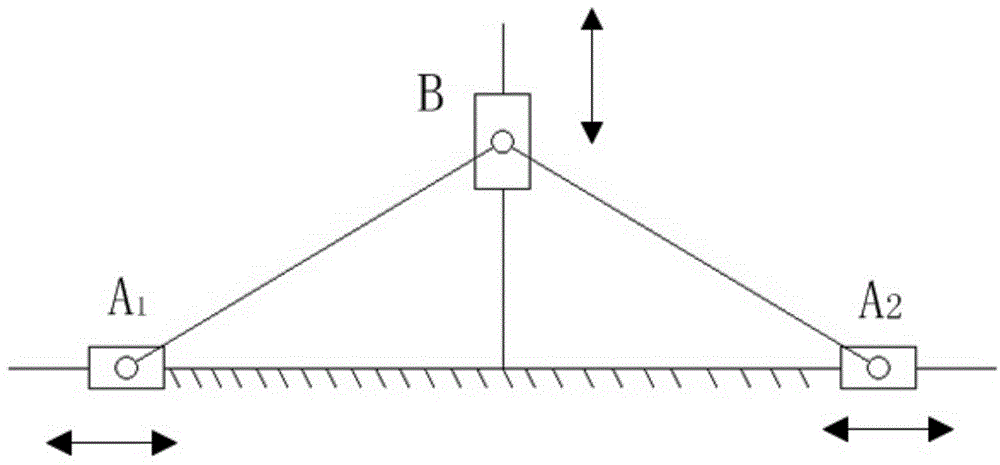

ActiveCN113894026AImprove the irradiation strokeImprove curing effectPretreated surfacesCoatingsUV curingEngineering

The invention relates to the technical field of UV curing equipment, and particularly relates to a UV curing device with a large irradiation range. The UV curing device comprises a main rack, UV curing lamps, a centrifugal fan and a driving motor. According to the UV curing device with the large irradiation range, the inverted V-shaped structural design is adopted in the UV irradiation section, through the direct irradiation and reflection phase structure, the irradiation stroke is greatly increased under the condition that the number of the UV curing lamps is not changed, and the curing effect is improved; heat generated by the irradiation section can be rapidly pumped away, and the stability and durability of the equipment are improved; the irradiation range of the UV curing device is adjustable, and the application range is wider; and an elastic lateral tensioning roller is installed between a guide roller laterally arranged on the inner side face of the main rack and an inner supporting roller, the attaching performance and tensioning degree of a belt conveying mechanism and the surface of a middle guide support can be improved, and the conveying stability is guaranteed.

Owner:JIANGSU GULIDE PRECISION PHOTOELECTRIC

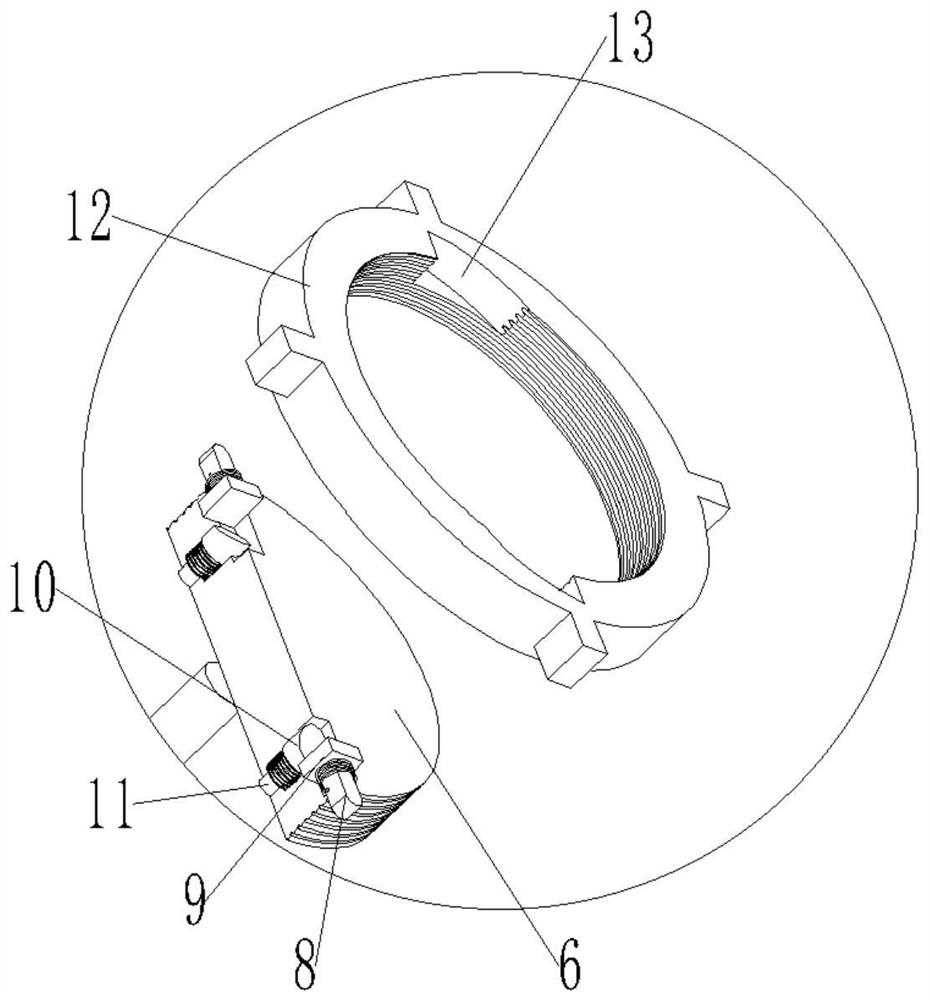

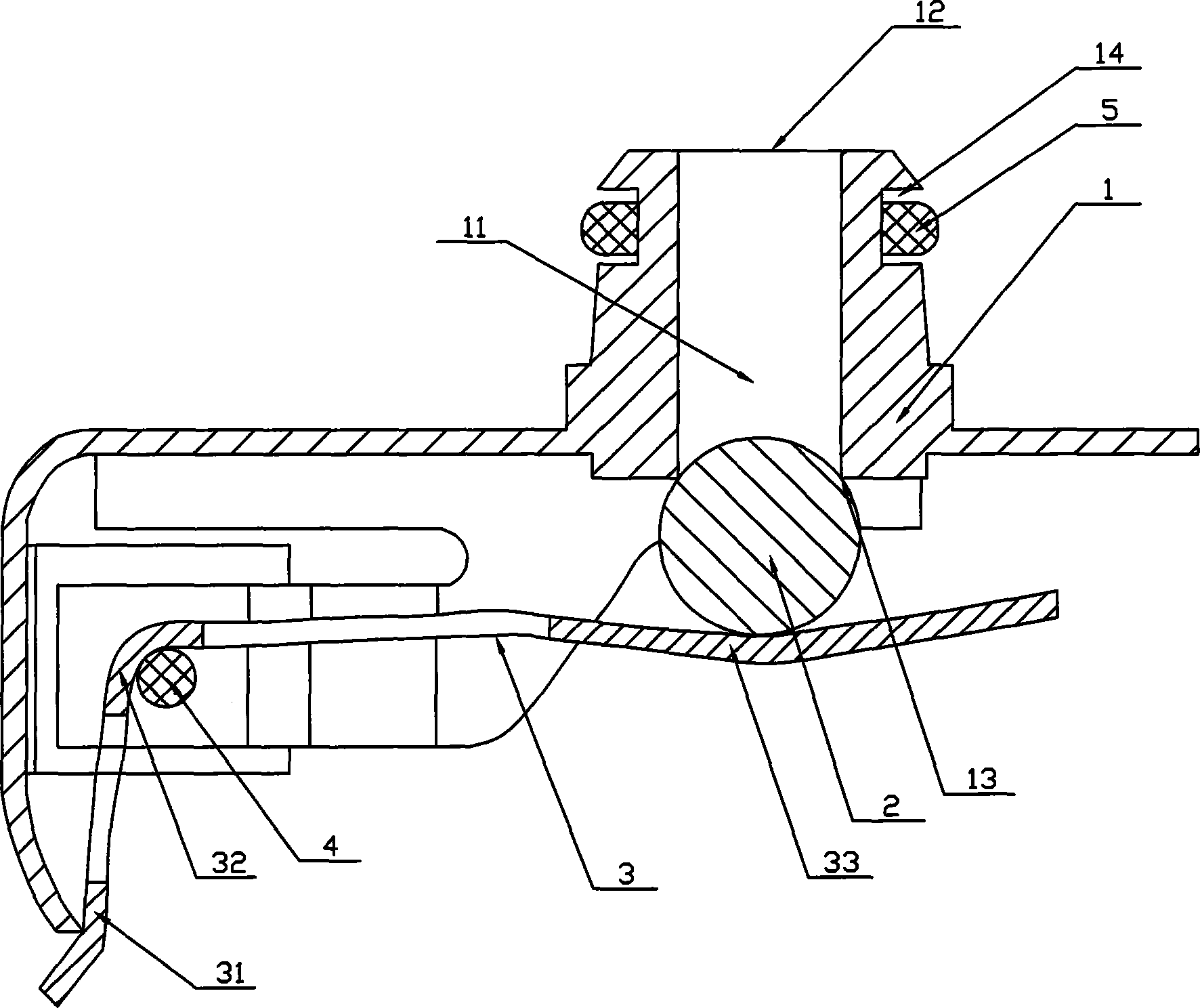

Leaf spring type constant pressure valve

InactiveCN104373650AAvoid corrosionExtended service lifeEqualizing valvesSafety valvesSteel ballEngineering

The invention discloses a leaf spring type constant pressure valve which comprises a valve base and a steel ball. A constant pressure cavity is formed inside the valve base. The two ends of the constant pressure cavity are provided with an oil inlet and an oil outlet respectively. The steel ball is arranged at the position of an oil outlet of the valve base. A bent leaf spring is installed on the valve base. The leaf spring is composed of a connecting portion, a supporting portion and an abutting pressing portion. The connecting portion of the leaf spring is fixedly connected to the valve base. The supporting portion of the leaf spring is supported on a pin shaft installed on the valve base to form a supporting point of the leaf spring. The abutting pressing portion of the leaf spring is pressed on the steel ball in an abutting mode so that the steel ball and the oil outlet of the valve base can form a sealing state. The leaf spring type constant pressure valve is simple and reasonable in structure, interference caused by the insufficient extending space will not be caused when the size of the valve is decreased, the oil conveying stability can be well kept, the service life of an engine is prolonged, and noise generated by the valve can be greatly reduced.

Owner:温州仁谦汽车油泵有限公司

A continuous pad printing coding equipment

ActiveCN106364152BPad printing stabilityPad printing precisionRotary pressesPrinting press partsElectricityPad printing

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

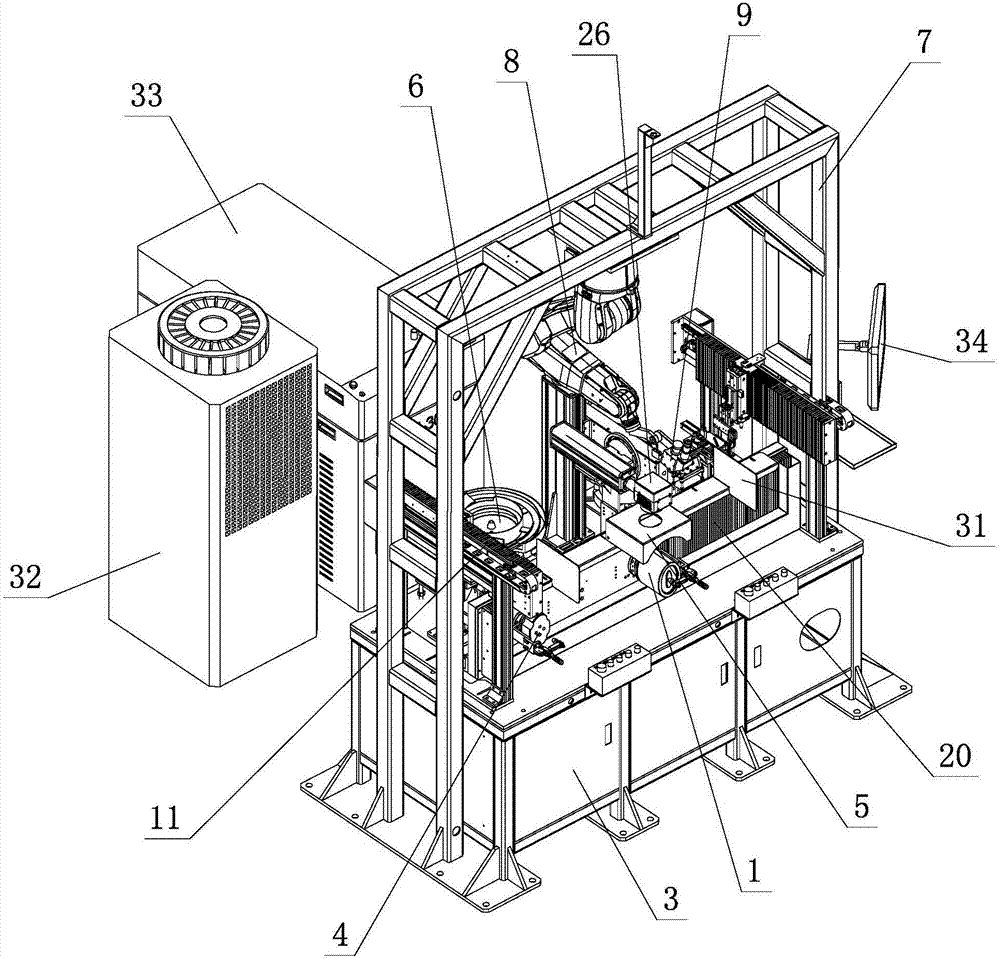

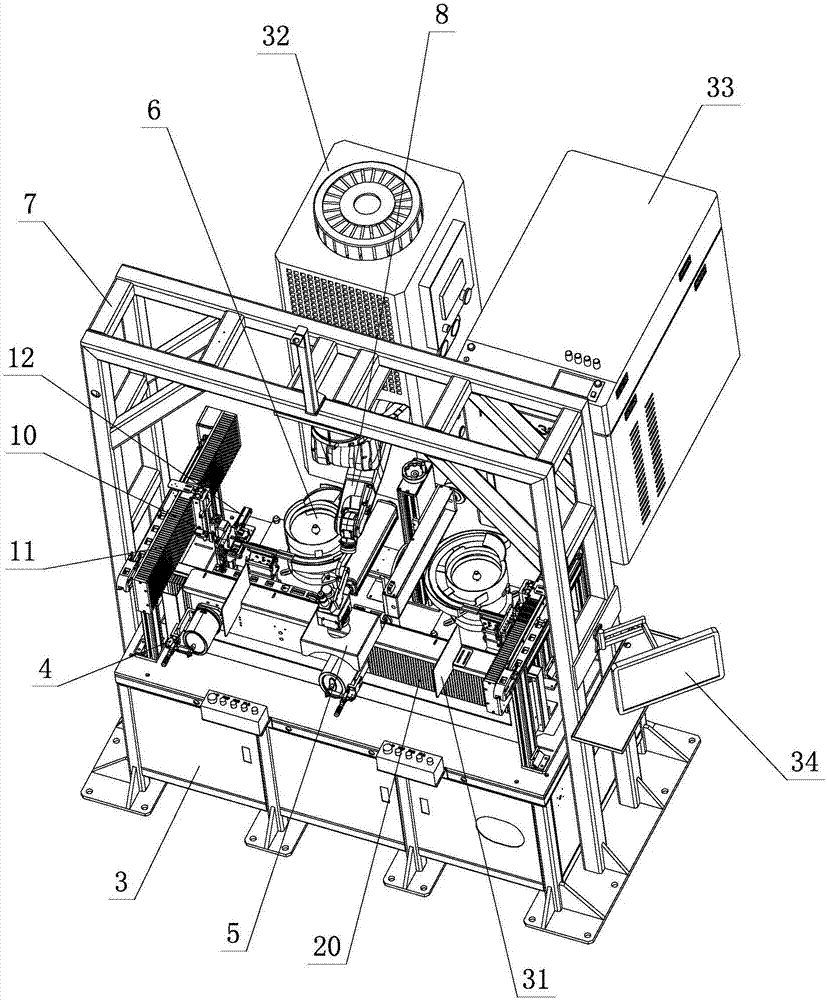

Laser marking and welding machine of jug bodies

ActiveCN107378242AImprove securityHigh precisionLaser beam welding apparatusEngineeringFully automatic

A laser marking and welding machine of jug bodies comprises the processing jug bodies, buckled lugs and a work table. At least two welding stations and at least one marking station are arranged on the work table, wherein the welding stations are used for welding the buckled lugs to the processing jug bodies respectively, the marking stations are used for printing marks on the surfaces of the processing jug bodies, and the marking stations are located above the welding stations. Vibration plates are arranged on the welding stations respectively, the buckled lugs are arranged on the vibration plates respectively, and the processing jug bodies are arranged on the welding stations respectively; the work table is further provided with a robot hanging rack, a robot is arranged on the robot hanging rack, a welding gun clamp is arranged on the robot, the robot moves on the welding stations backwards and forwards through the robot hanging rack, and each buckled lug is welded to the corresponding processing jug body through the welding gun clamp. The laser marking and welding machine has the advantages of being simple and reasonable in structure, excellent in performance, convenient to operate, low in manufacturing cost, easy to produce, easy to implement, fully automatic, intelligent, high in production efficiency, safe, reliable and the like, and the practicability is high.

Owner:GUANGDONG LXD ROBOTICS CO LTD

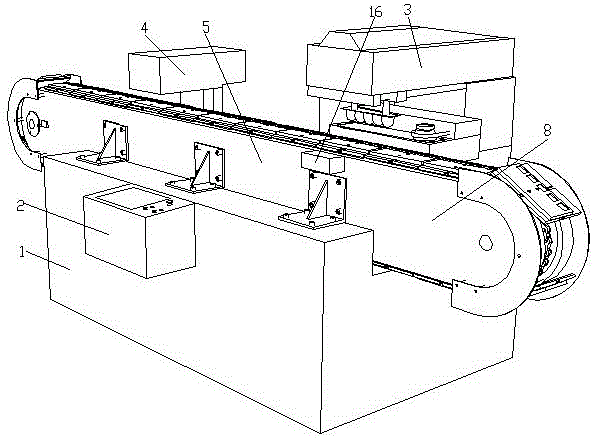

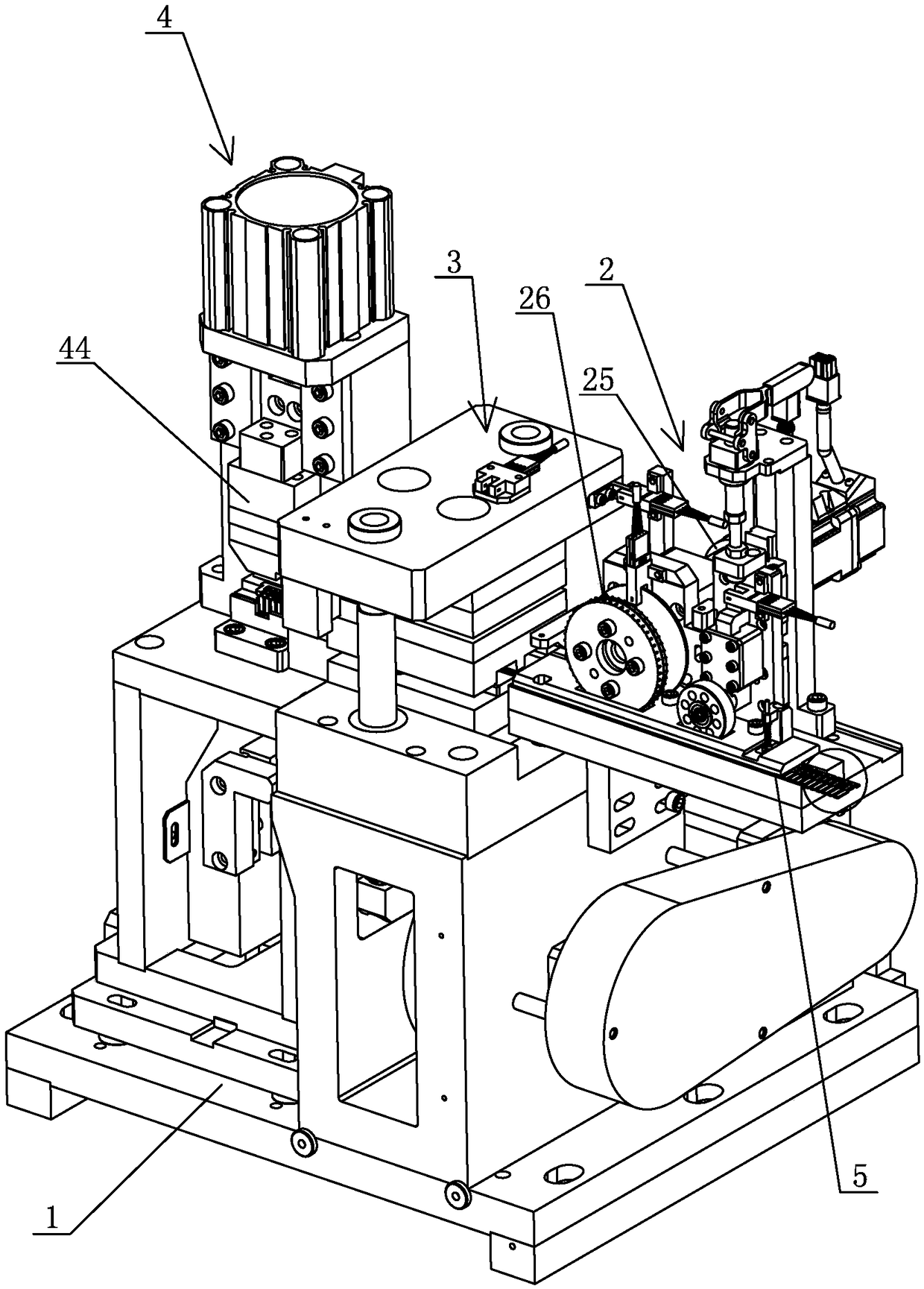

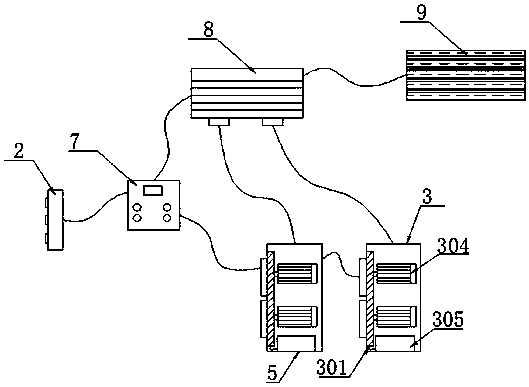

Connector contact pin bending trimming device

PendingCN109473848AReduce labor intensityImprove securityContact member manufacturingEdge surfaceEngineering

The invention discloses a connector contact pin bending trimming device. The connector contact pin bending trimming device is characterized by comprising a rack, a feeding mechanism arranged on the rack, a bending mechanism and a trimming mechanism, wherein the bending mechanism is arranged between the feeding mechanism and the trimming mechanism; a feeding sliding chute is formed in the rack, andthe feeding sliding chute is arranged among the feeding mechanism, the bending mechanism and the trimming mechanism in a penetrated manner; the feeding mechanism comprises a product positioning mechanism, a pinch roller and a conveying roller arranged above the feeding sliding chute, the pinch roller is arranged between the conveying roller and the product positioning mechanism, the rear end of the conveying roller is connected with a conveying motor, a plurality of longitudinal clamping bars are uniformly distributed on the outer edge surface of the conveying roller, the longitudinal clamping bars are arranged parallel to the axis of the conveying roller, and the conveying roller is arranged close to the bending mechanism. According to the connector contact pin bending trimming device, the product processing efficiency and quality are improved.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

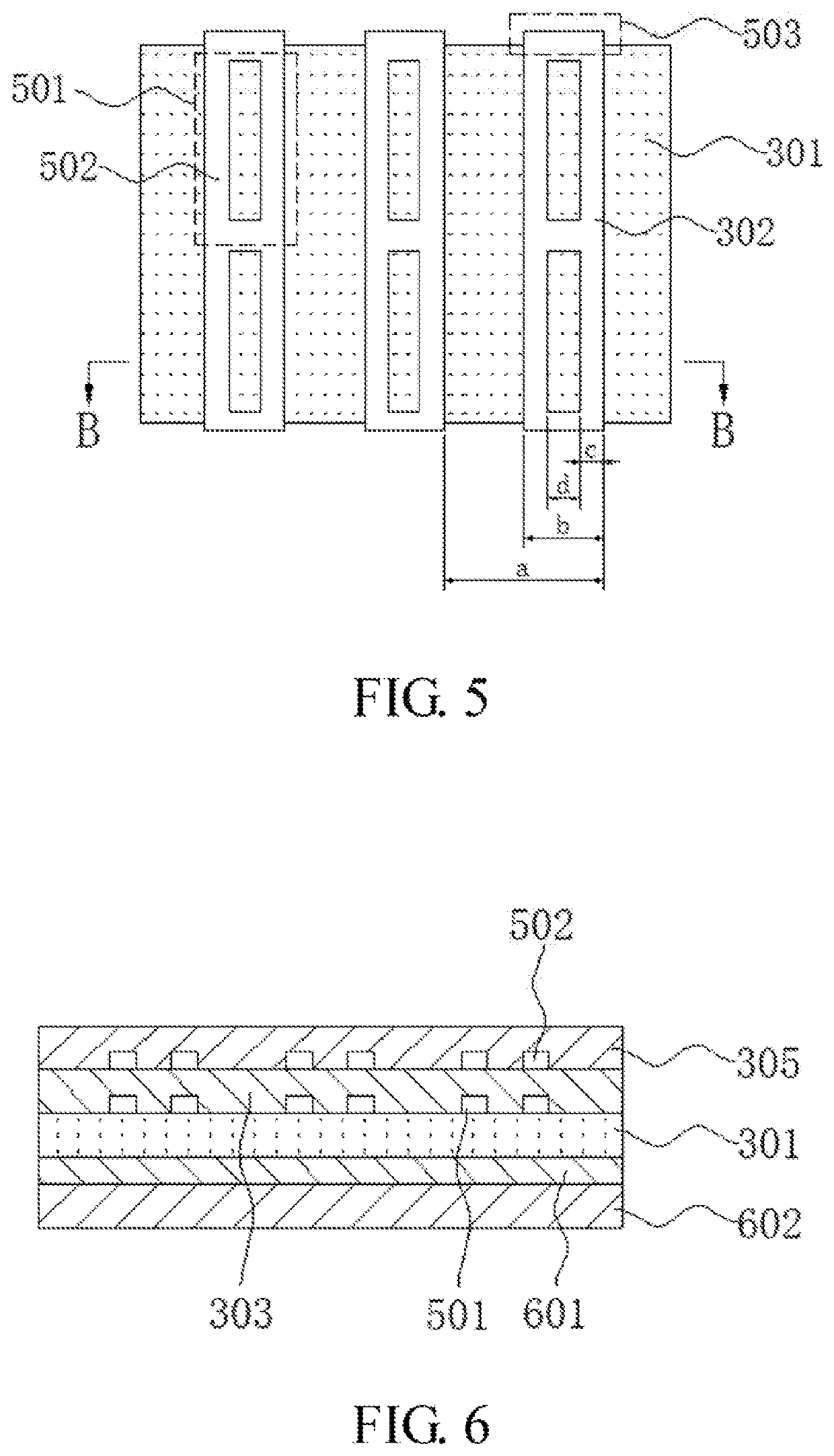

Wiring structure in bending area and display device having same

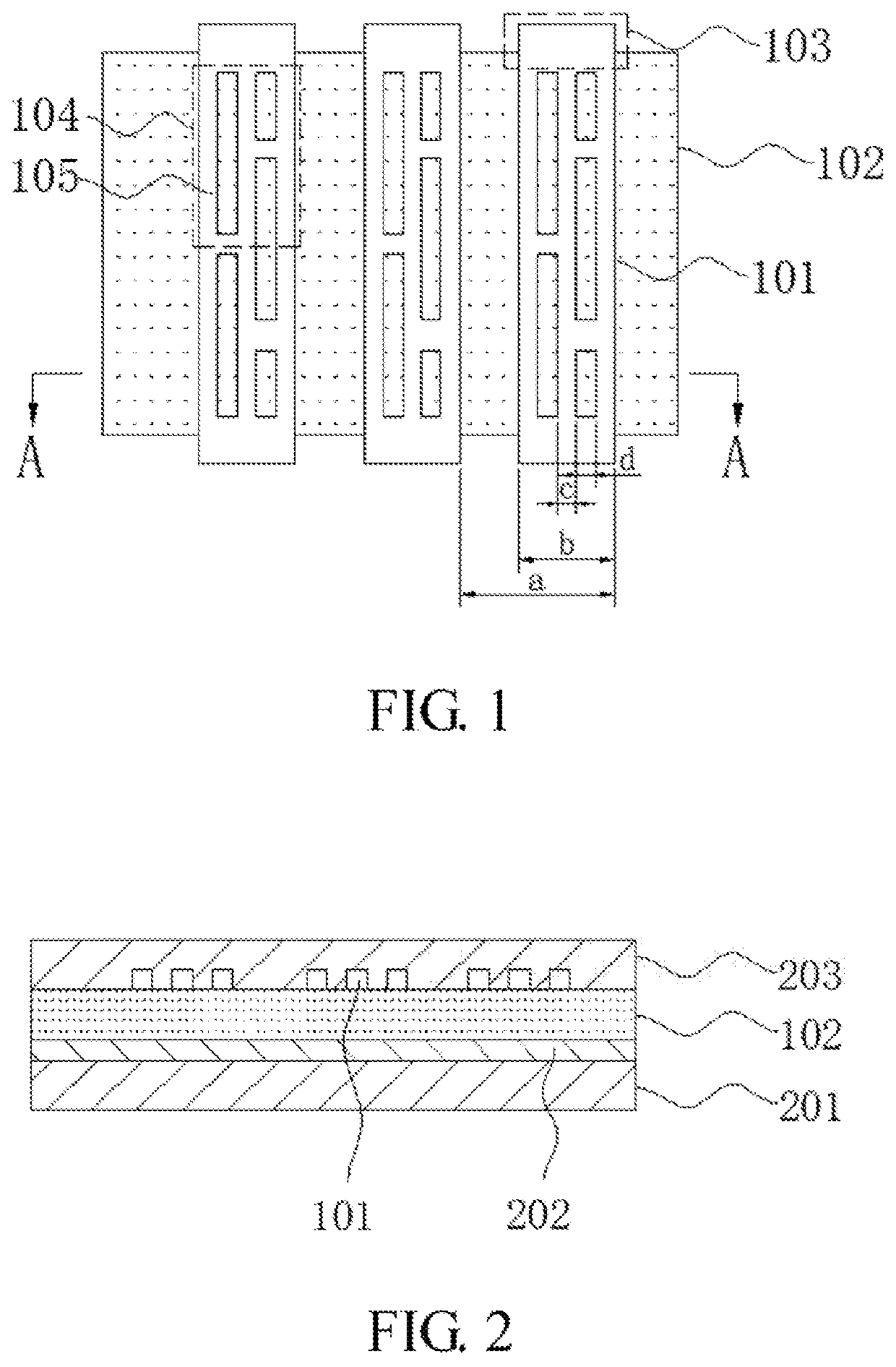

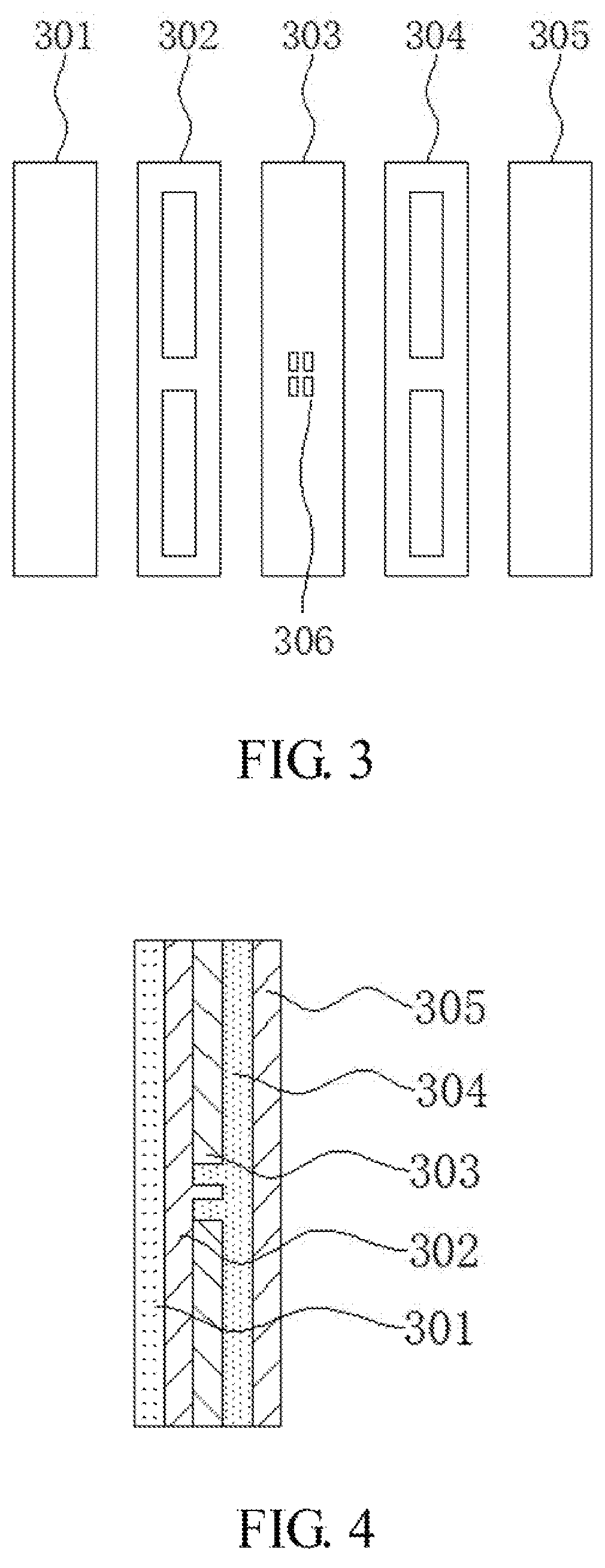

ActiveUS10811486B2Ensure delivery stabilityEnsuring property of bendingStatic indicating devicesSolid-state devicesDisplay deviceStructural engineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Tray conveying assembly line

InactiveCN113023325APrecise positioningEnsure delivery stabilityConveyor partsTransmission beltEngineering

The invention discloses a tray conveying assembly line. The assembly line structurally comprises a conveying belt, a material tray, a discharging opening, a height limiting baffle, a containing frame, a main body and an aligning device. When the tray conveying assembly line is used, the tray is stably clamped on a deformation strip through cooperation of two connecting block limiting pieces, the deformation strip is assisted by a protection support in supporting and protecting the tray, the bottom of the tray is prevented from making contact with the conveying belt, an abutting piece is positioned by moving a sliding piece, rotating wheels can be stably matched with a sliding plate to drive the tray to move along with movement of the conveying belt, the tray is not prone to inclination and clamping stagnation due to the action of the shell in the conveying process, and normal conveying of the assembly line is guaranteed.

Owner:谢美玲

A rear conveying device for a shearing machine

ActiveCN109205370BEnsure delivery stabilityImprove delivery stabilityArticle deliveryBall screwElectric machinery

The invention discloses a plate shearing machine rear conveying device. The conveying device comprises an inclined plate, a check block is arranged at the lower end of the inclined plate, multiple rectangular openings are distributed in the inclined plate at intervals, the lower ends of the rectangular openings extend to the position below the check block, a conveying device body is arranged on the outer side of the inclined plate, and a part taking device is arranged at the end of the conveying device body; the conveying device body comprises a conveying frame, multiple conveying cylinders are evenly distributed on the top of the conveying frame, and a gap is arranged between two adjacent conveying cylinders; the part taking device comprises a base located on the outer side of the end ofthe conveying frame, one side of the upper end of the base is connected with a part taking base through a pneumatic sliding table, a vertical ball screw is arranged on the part taking base, one end ofthe ball screw is connected with a driving motor through a chain wheel chain, and a part taking claw is connected with the ball screw through a screw nut. Plates can be ceaselessly collected and conveyed, the conveying efficiency is high, and stability is good.

Owner:浙江天也智能科技有限公司

A fully automatic feeding device for an industrial aluminum profile processing line

ActiveCN112124841BGuarantee the quality of production and processingEnsure delivery stabilityConveyor partsRoller-waysEconomic benefitsProcess engineering

The invention discloses a fully automatic feeding device for an industrial aluminum profile processing line. During the process of aluminum profile processing and production feeding, the conveying roller provided by the invention is used for conveying work, and the set guide roller and limit roller are suitable for aluminum profile processing. The position of the raw material is limited, that is, to ensure that the position of the aluminum profile will not be deflected during the transportation process, so as to ensure that the position of the aluminum profile can be accurately reached when it is transported to the next processing point, and there will be no position deviation, which not only ensures The conveying stability of aluminum profile processing parts can also ensure the production and processing quality of aluminum profiles, and ensure the economic benefits of processing and production; and the positions of guide rollers and limit rollers can be adjusted, and then can be adjusted according to the actual size of aluminum profiles. In this way, better position guidance and limit work for aluminum profile processing parts can be ensured.

Owner:JIANGXI TIAN YI ALUMINUM

Protection structure of inverter device for electric vehicle

InactiveCN111555589AImprove cooling efficiencyWind evenlyConversion constructional detailsModifications for power electronicsInverterElectric cars

The invention discloses a protection structure of an inverter device for an electric vehicle. The protection structure comprises a top cover plate, a bottom plate, an arc-shaped connecting piece, a right side plate, a left side plate, a rear sealing plate, an external fixing ring, a heat dissipation device, a fixing structure, a two-way clamping mechanism and a synchronous pushing mechanism. According to the invention, the heat dissipation device is arranged, a first air conveying pipe and a second air conveying pipe are used for conveying air, and the air is conveyed into a rectangular cavitystructure through a first air outlet and a second air outlet, so that heat dissipation processing can be conducted on the installed inverter from different positions, and the heat dissipation efficiency is improved; and by arranging the synchronous pushing mechanism, the left clamping plate and the right clamping plate can be driven by a telescopic left pushing rod and a telescopic right pushingrod to move synchronously, and the inverter can be conveniently and rapidly clamped and fixed.

Owner:钟新华

An aviation bomb clamping device based on the principle of double-slider mechanism

Owner:HARBIN ENG UNIV

A kind of pipe conveying equipment that is not easy to fall

The invention discloses a pipe conveying equipment that is not easy to drop, which can well realize the conveying of pipes, is convenient for detection manipulators to put down the pipes after random inspection, and effectively reduces the impact of pipes on the conveying equipment when the manipulator puts down the pipes. Adverse effects, reduce shock phenomenon, effectively ensure the reliability of pipe transportation, reduce the risk of pipe falling, effectively ensure the stability and reliability of pipe transportation, improve the safety of pipe transportation, and at the same time, it is convenient for random inspection of the pick-and-place manipulator on the pipe. Pick and place, ensure the pipe pick and place space, realize the seamless connection between the random pick and place manipulator and the pipe conveying equipment, and improve the safety of pipe conveying.

Owner:DALIAN JIAOTONG UNIVERSITY

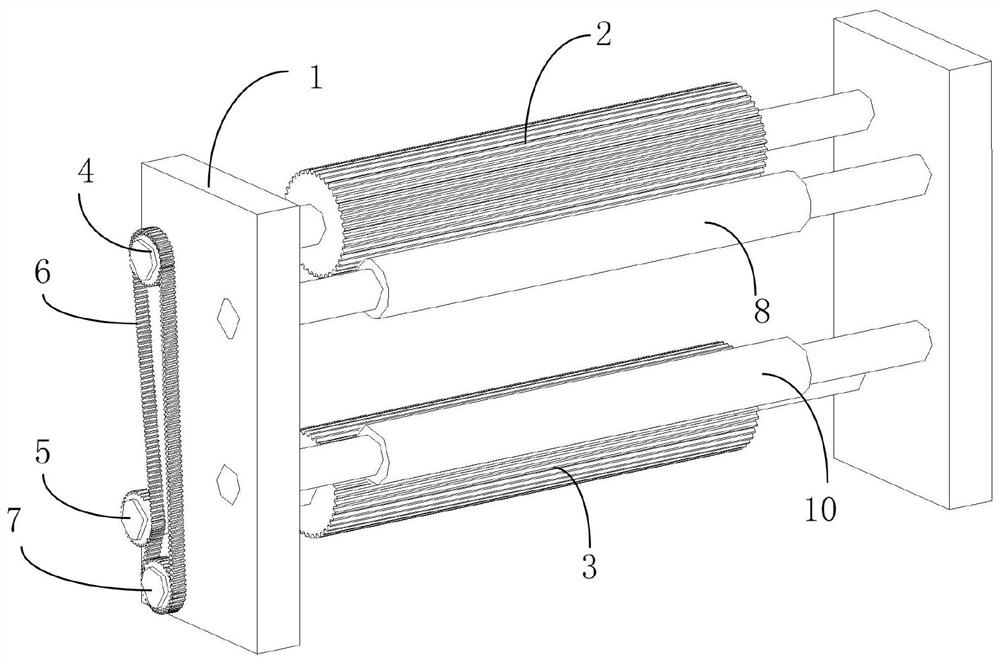

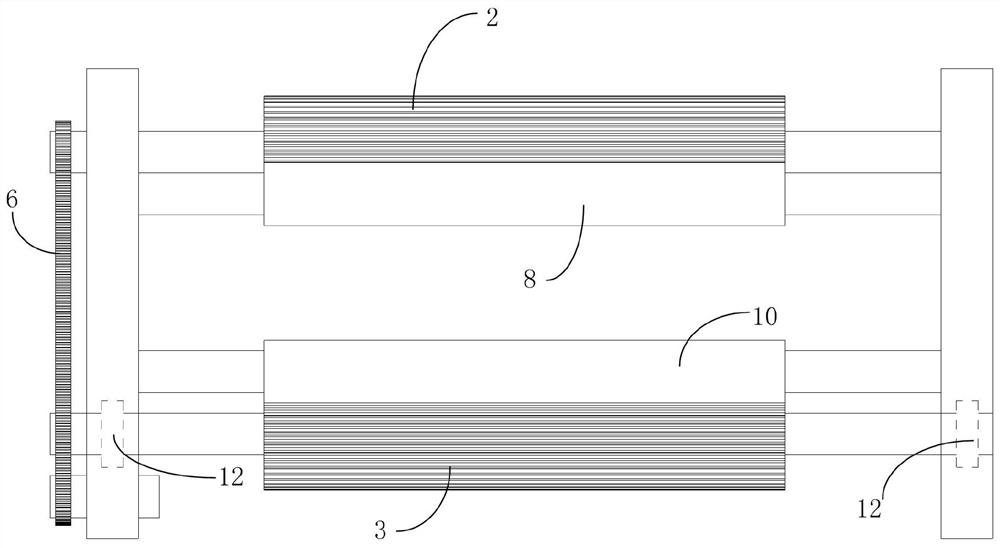

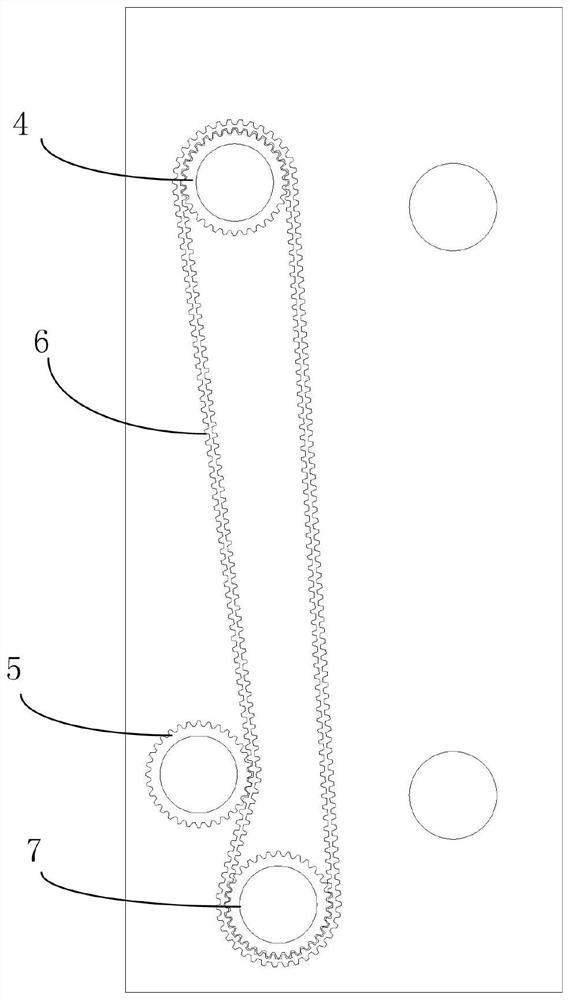

Sandwich-free double corrugated board synchronous paper feeding device and method

PendingCN112811233AEasy accessSave production raw materialsWebs handlingCorrugated fiberboardStructural engineering

The invention discloses a sandwich-free double corrugated board synchronous paper feeding device and method. The device comprises a mounting plate, an upper tooth face shaft, a lower tooth face shaft, an upper synchronous belt wheel, a lower synchronous belt wheel, a double-face tooth synchronous belt and a synchronous belt guide wheel, the upper tooth face shaft and the lower tooth face shaft are arranged in parallel, and the two ends of the upper tooth face shaft and the two ends of the lower tooth face shaft are rotationally mounted on the mounting plate; and the upper synchronous belt wheel is fixedly installed at one end of the upper tooth face shaft, the lower synchronous belt wheel is fixedly installed at one end of the lower tooth face shaft, and the inner tooth surface and the outer tooth surface of the double-face tooth synchronous belt are in meshing transmission with the upper synchronous belt wheel and the lower synchronous belt wheel respectively. The synchronous belt guide wheel is rotationally mounted at the outer side of the mounting plate. According to the sandwich-free double corrugated board synchronous paper feeding device and method, the corrugated tip of upper-layer single corrugated paper faces downwards and is matched with a tooth groove of the upper tooth face shaft, the corrugated tip of lower-layer single corrugated paper faces upwards and is matched with a tooth groove of the lower tooth face shaft, the upper tooth face shaft and the lower tooth face shaft rotate oppositely, and therefore the upper-layer single corrugated paper and the lower-layer single corrugated paper are synchronous; and tip-to-tip entering into the next process is ensured.

Owner:任英超

Air dry passivation device for processing conductive copper pipe based on air body circulation

PendingCN113981426APassivation processing efficiency guaranteeImprove skid resistanceDrying solid materials with heatDrying gas arrangementsStructural engineeringMachining

The invention discloses an air dry passivation device for processing a conductive copper pipe based on air body circulation, the air dry passivation device comprises a passivation pool, supporting legs and feeding turning plates, the supporting legs are arranged at four corners of the lower side of the passivation pool, the feeding turning plates are symmetrically arranged on the inner side of the passivation pool, and damping rubber plates are arranged on the upper side surfaces of the feeding turning plates. According to the air dry passivation device, through the arrangement of the feeding turning plate, the damping rubber plate, a rotating shaft, a feeding inclined plate, an electric telescopic rod, a laser counting sensor, a rotating arm and a hydraulic rod, when the air dry passivation device for processing the conductive copper pipe machining is used, the hydraulic rod drives the rotating arm and the rotating shaft to rotate, and then the damping rubber plate and the feeding turning plate are rotated; passivated copper pipes in the passivation pool can be rotationally fed to the feeding inclined plate, the laser counting sensor can automatically count the copper pipes rolling into a feeding groove, the electric telescopic rod controls the speed and the number of the copper pipes entering the feeding groove, and the passivation machining efficiency of the copper pipes is guaranteed.

Owner:镇江市正源智能科技有限公司

A continuous tunneling system for coal mine roadway

ActiveCN108194080BEasy to operateImprove working environmentSlitting machinesMine roof supportsRemote controlEngineering

Owner:陈新川

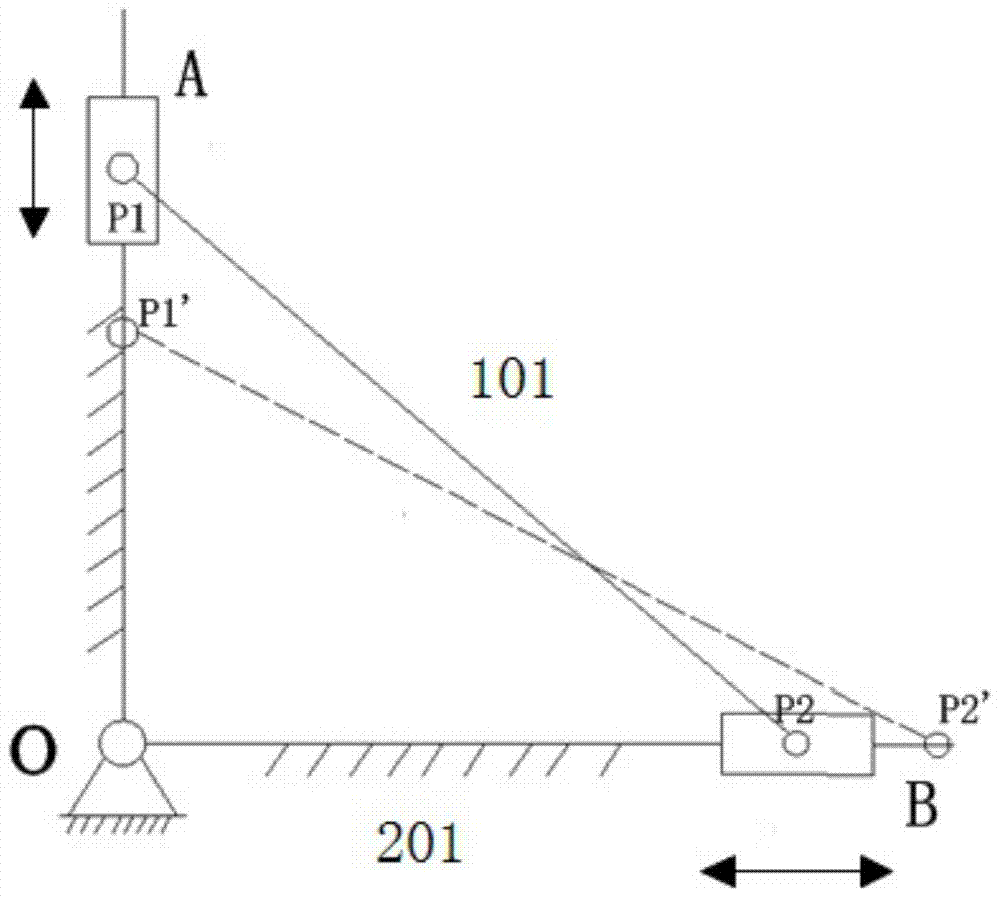

A wire pulling device for power line construction

ActiveCN106532568BReduce labor intensityMeet the needs of outdoor operationsApparatus for overhead lines/cablesEngineeringUltimate tensile strength

Owner:宿迁中江建设工程有限公司

Steering device for vacuum glass processing

PendingCN112850159AMove without manual operationImprove work efficiencyCharge manipulationConveyor partsStructural engineeringMechanical engineering

The invention belongs to the field of glass processing equipment, and particularly relates to a steering device for vacuum glass processing. The device comprises a rotating seat, fixed seats, guide seats, conveying assemblies, a bearing assembly and an adjusting assembly. The two sets of fixed seats are symmetrically arranged at the upper end of the rotating seat, the two sets of guide seats are located on the opposite sides of the two sets of fixed seats correspondingly, and the lower ends of the two sets of guide seats are rotationally connected with the lower ends of the two sets of fixed seats correspondingly. The two conveying assemblies are movably installed on the end faces of the opposite sides of the two sets of guide seats correspondingly. The two ends of the bearing assembly are movably installed on the two sets of fixed seats correspondingly. Through cooperative use of the rotating seat, the fixed seats, the guide seats, the conveying assembly, the bearing assembly and the adjusting assembly, the steering device can steer glass conveyed in a vacuum glass processing line and convey the glass to a subsequent processing procedure or a storage position, manual operation and movement are not needed, the working efficiency is higher, and use is safer.

Owner:淮北市盛文钢化玻璃有限公司

An improved stainless steel suspension rail block

ActiveCN107089594BEliminate collision hazardsReasonable designTravelling gearRunwaysMaterials scienceCorrosion

The invention belongs to the technical field of cargo lifting assembly accessories, and particularly discloses an improved stainless steel hanger rail tackle. The improved stainless steel hanger rail tackle is composed of a supporting plate body, a first lug plate, a second lug plate, a set of first positioning holes, a set of second positioning hole, an adjusting supporting assembly, a first sliding assembly and a second sliding assembly. The stainless steel hanger rail tackle has the beneficial effects that the overall stainless steel structural design is reasonable, the tenacity is high, and the corrosion resistance and abrasive resistance are excellent; by means of the first sliding assembly and the second sliding assembly, the overall structure running stability and efficiency are guaranteed; by means of the adjusting supporting assembly, the conveying stability of hoisted cargoes or products is guaranteed, and the existing production potential safety hazards are avoided; and through the structures of a first arc-shaped limiting plate and a second arc-shaped limiting plate on the two sides, it is guaranteed that collision hidden danger of external components on the hanger rail tackle is avoided in the conveying operation, and the service life of the overall structure is prolonged.

Owner:江苏天硕合金材料有限公司

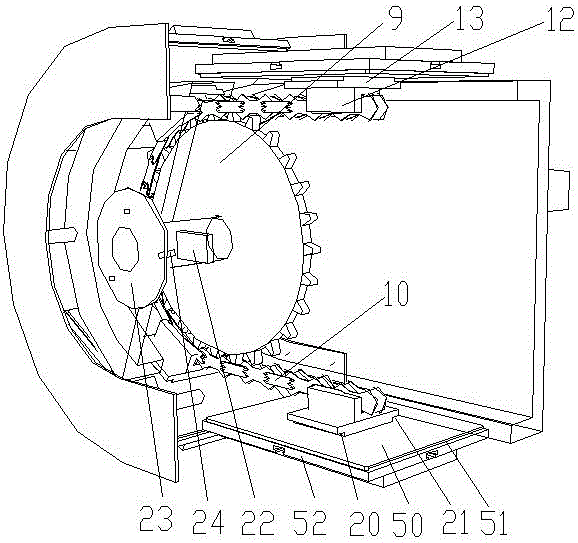

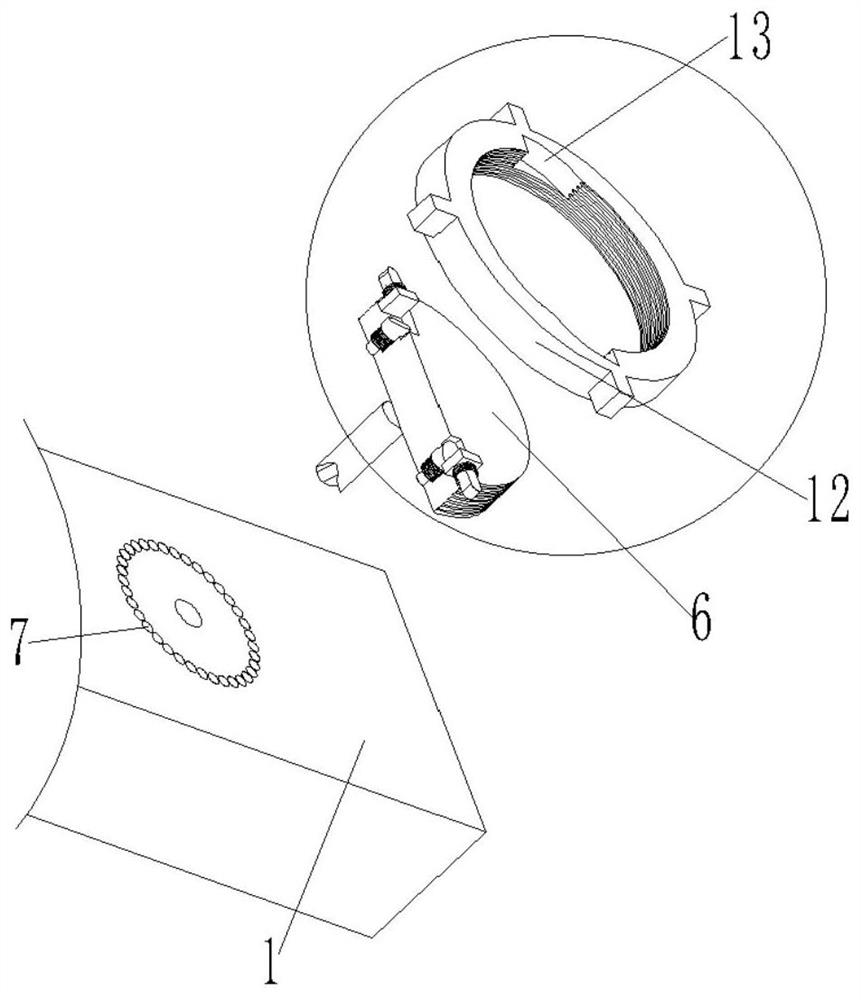

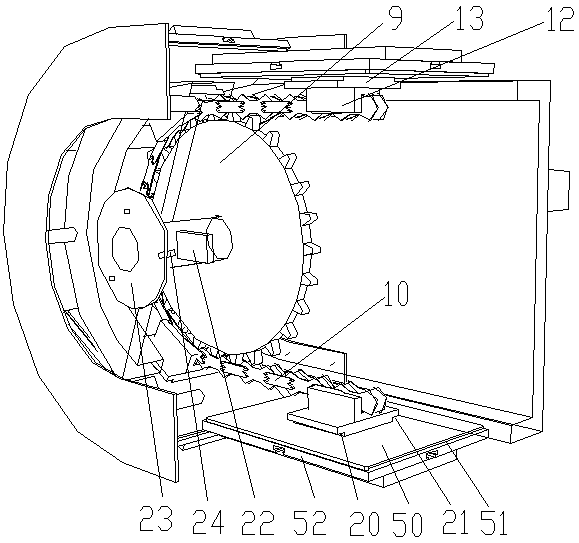

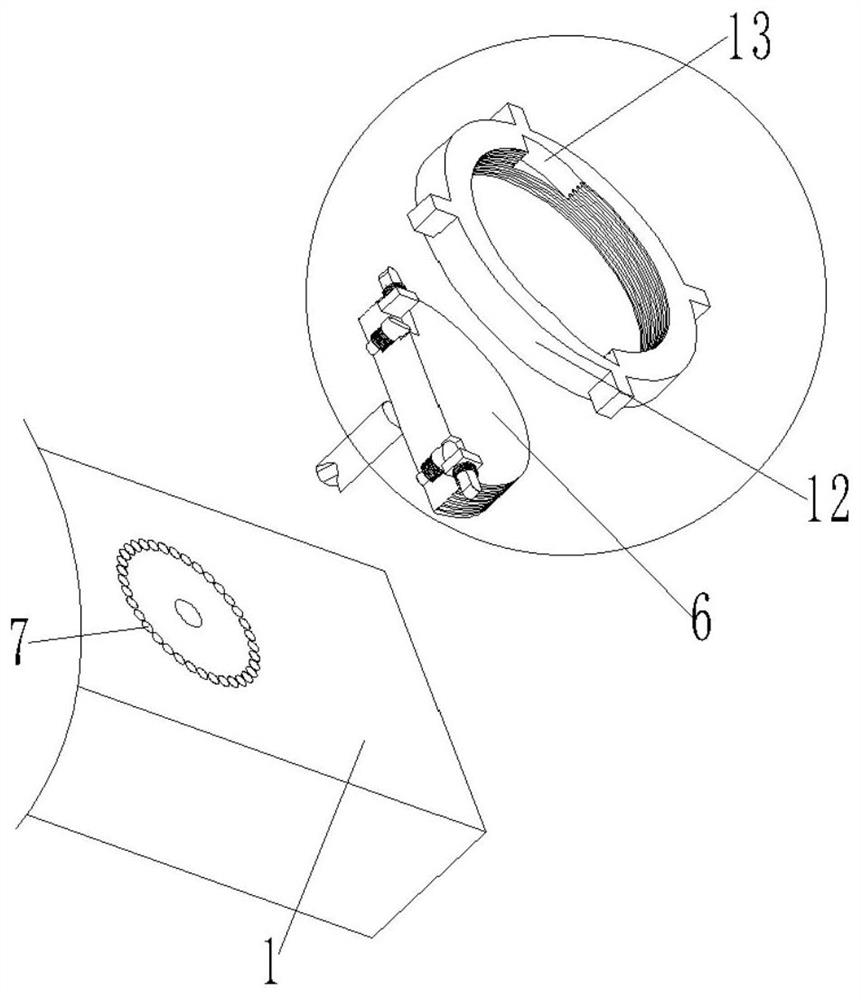

Automatic cutting equipment for aerosol can valve pipes

The invention relates to automatic cutting equipment for aerosol can valve pipes. The automatic cutting equipment for the aerosol can valve pipes comprises a support, a conveying rotating disc used for conveying the valve pipes is arranged on the support, and a conveying guide rail is arranged on the side portion of the conveying rotating disc. The support is further provided with a saw blade, and the saw blade is located on the side portion of the conveying guide rail and rotationally arranged on the support. The conveying rotating disc is obliquely and rotationally arranged on the support, and the valve pipes are conveyed to the conveying guide rail one by one during rotation. The saw blade is used for automatically cutting the length of the valve pipes conveyed on the conveying guide rail. According to the automatic cutting equipment for the aerosol can valve pipes, automatic operation of feeding, conveying, length cutting and discharging of the valve pipes can be achieved, the automation degree of the equipment is high, and therefore the production and machining efficiency is improved.

Owner:佛山市顺德区香江精细化工实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com