Air dry passivation device for processing conductive copper pipe based on air body circulation

A conductive copper tube and circulating technology, applied in the direction of drying gas arrangement, progressive dryer, drying, etc., can solve the problems of shortage, general drying effect of air drying box, and unguaranteed conveying stability of conveying rollers, etc., to achieve Guaranteed conveying stability, improved air-drying effect, and improved anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

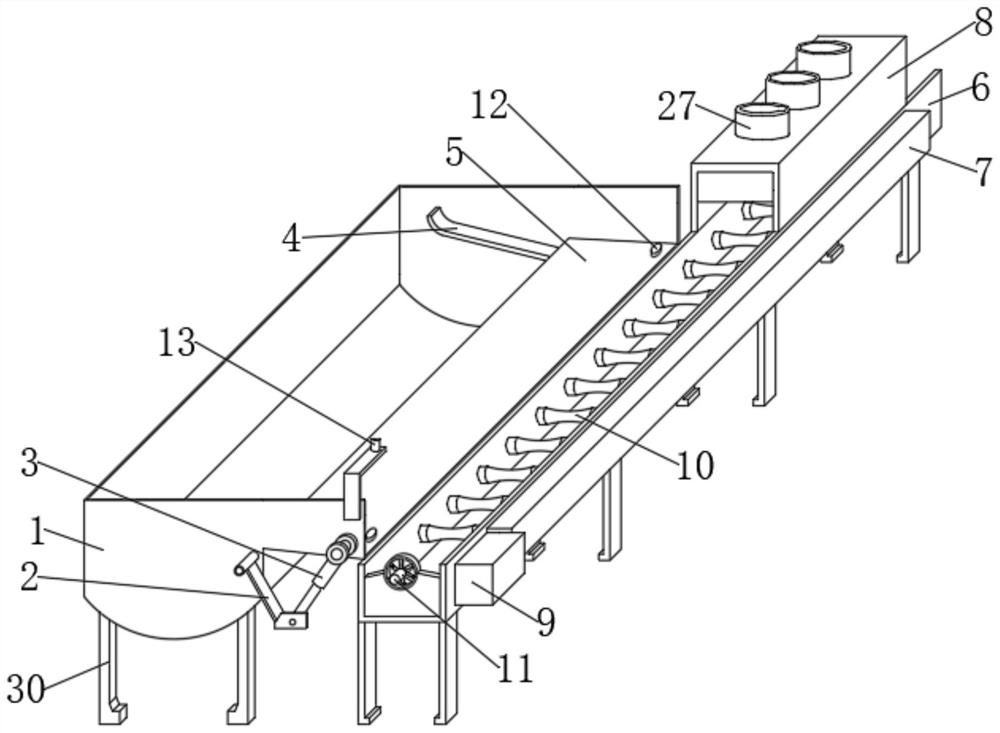

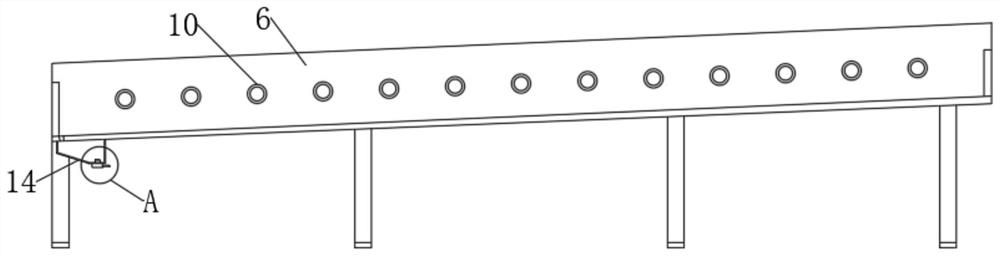

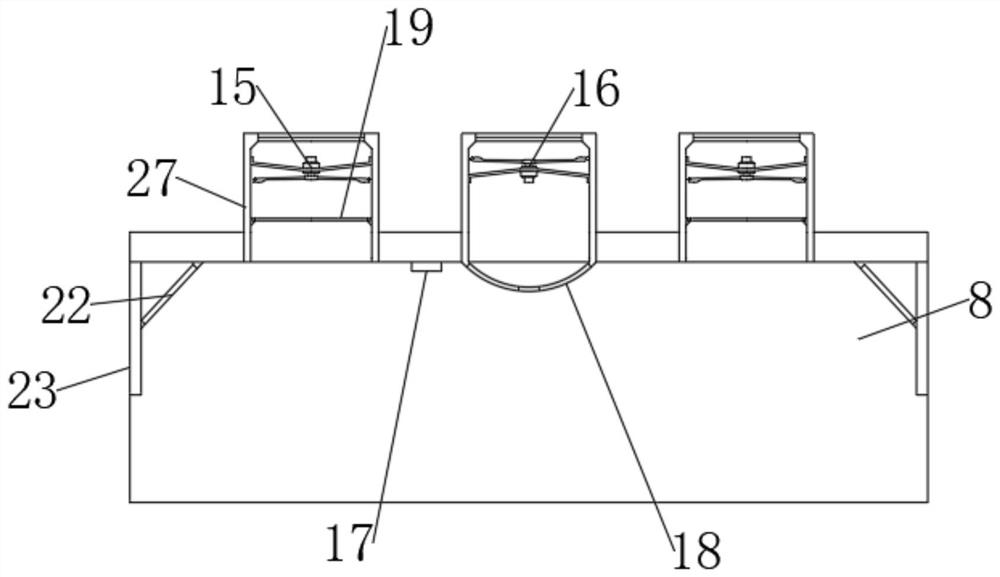

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figure 1-Figure 6 As shown, an air-dried passivation device for processing conductive copper pipes based on air body circulation includes a passivation pool 1, support legs 30 and a feeding flap 4, and the four corners of the lower side of the passivation pool 1 are provided with the support legs 30. The inner side of the passivation tank 1 is symmetrically provided with the feeding flap 4, the upper side of the feeding flap 4 is provided with a shock-absorbing rubber plate 20, and one end of the feeding flap 4 is pierced with a rotating shaft 21. The other end of the rotating shaft 21 is provided with a rotating arm 2, the lower end of the rotating arm 2 is provided with a hydraulic rod 3, and the upper side of the passivation tank 1 is provided with a feeding ramp 5, and the feeding ramp 5. An electric telescopic rod 12 is arranged symmetrically on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com