An aviation bomb clamping device based on the principle of double-slider mechanism

A clamping device and double-slider technology, which is applied in fire rescue and other fields, can solve problems such as vibration, mutual collision, and affecting the smooth operation of aerial bomb delivery, and achieve the effect of simple structure and guaranteed delivery stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

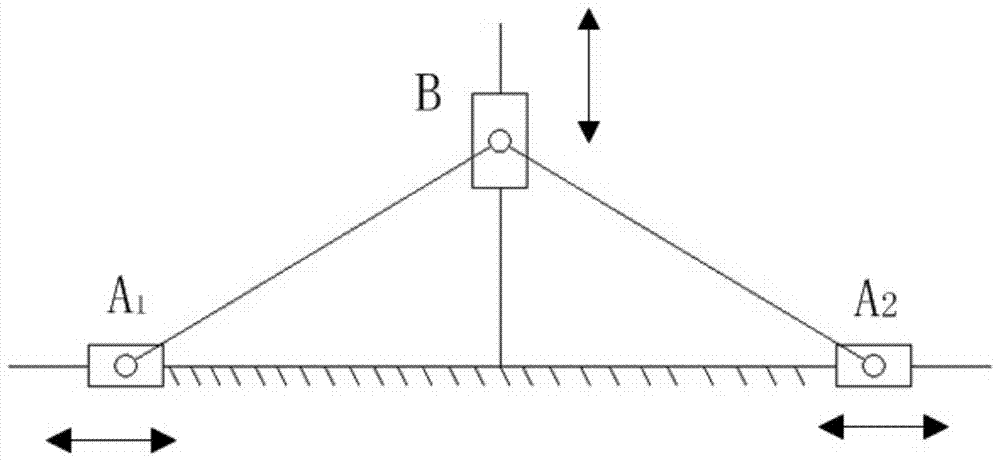

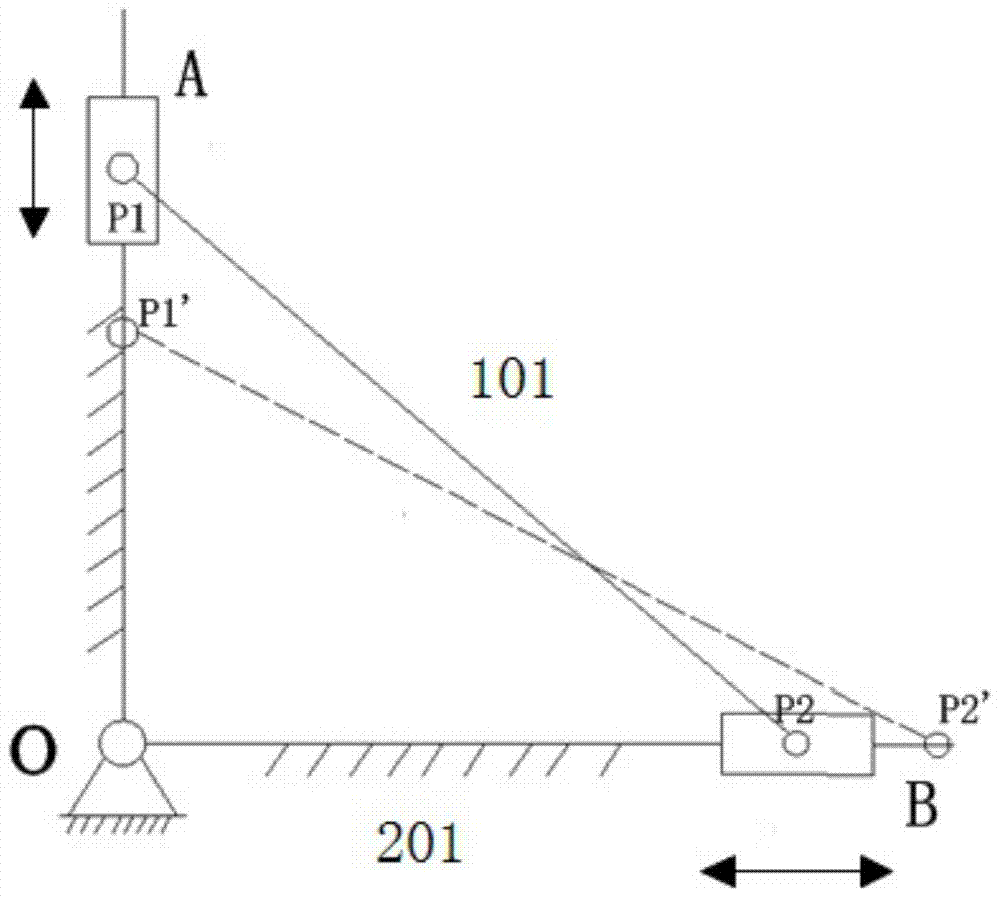

[0027] combine Figure 1-8 , the basic type of planar four-bar linkage and its evolution, see figure 1 , the figure shows a four-bar mechanism with two moving pairs, and its working principle is shown in figure 2 , is composed of double sliders A, B, connecting rod 101 and rack 201, p1 is the center of slider A, p2 is the center of slider 2, p1' is the center of slider A after moving, p2' is the center of slider A The center of block B after moving;

[0028] By the triangle theorem, op 1 2 +op 2 2 =p 1 p 2 2 、op 1 ' 2 +op 2 ' 2 =p 1 'p 2 ' 2

[0029] And it is known that the connecting rod length is constant, so p 1 p 2 =p 1 'p 2 ',

[0030] roll out: p 2 p 2 '=op 2 '-op 2

[0031] It can be seen from the formula that p 2 ' point trajectory and p 2 p 2 'The length is mainly determined by p 1 ,p 2 and p 1 'Three point parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com