Leaf spring type constant pressure valve

A technology of constant pressure valve and shrapnel, which is applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of unstable pressure in the oil delivery line, abnormal engine fuel, harsh vibration and noise of the valve, etc., and achieve stable delivery, durability Improves corrosion resistance and prolongs service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the content of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

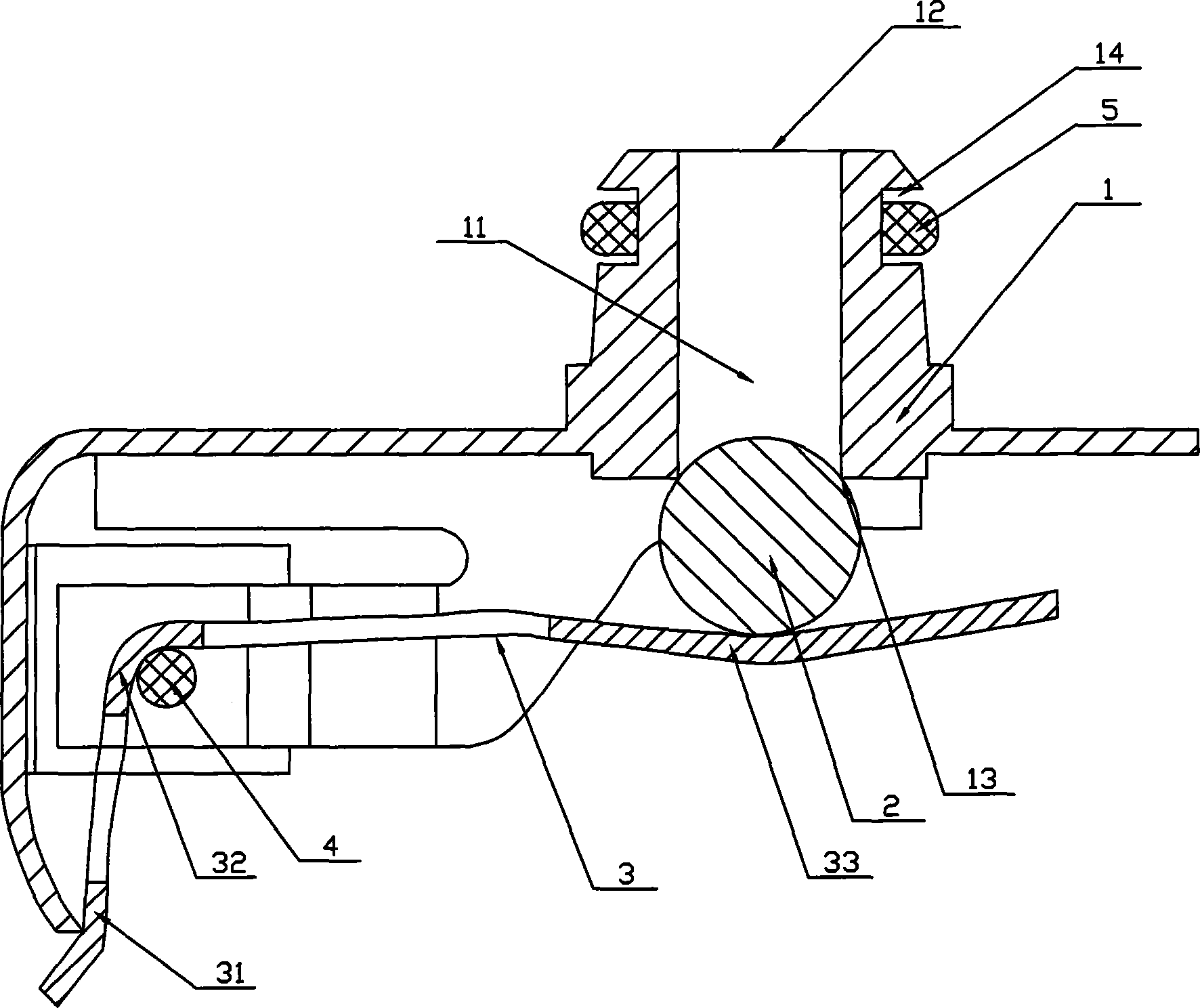

[0015] Such as figure 1 As shown, a shrapnel type constant pressure valve according to the embodiment of the present invention includes a valve seat 1 and a steel ball 2. A constant pressure chamber 11 is provided in the valve seat 1, and the two ends of the constant pressure chamber 11 are oil inlets 12 respectively. And the oil outlet 13, the steel ball 2 is set at the oil outlet 13 of the valve seat 1, further, a curved shrapnel 3 is installed on the valve seat 1, the shrapnel 3 is formed by the connecting part 31, the supporting part 32 and the abutment The pressing part 33 is composed of the connecting part 31 of the elastic piece 3 fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com