Full-automatic box changing machine

A fully automatic, box machine technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as reducing production efficiency and increasing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

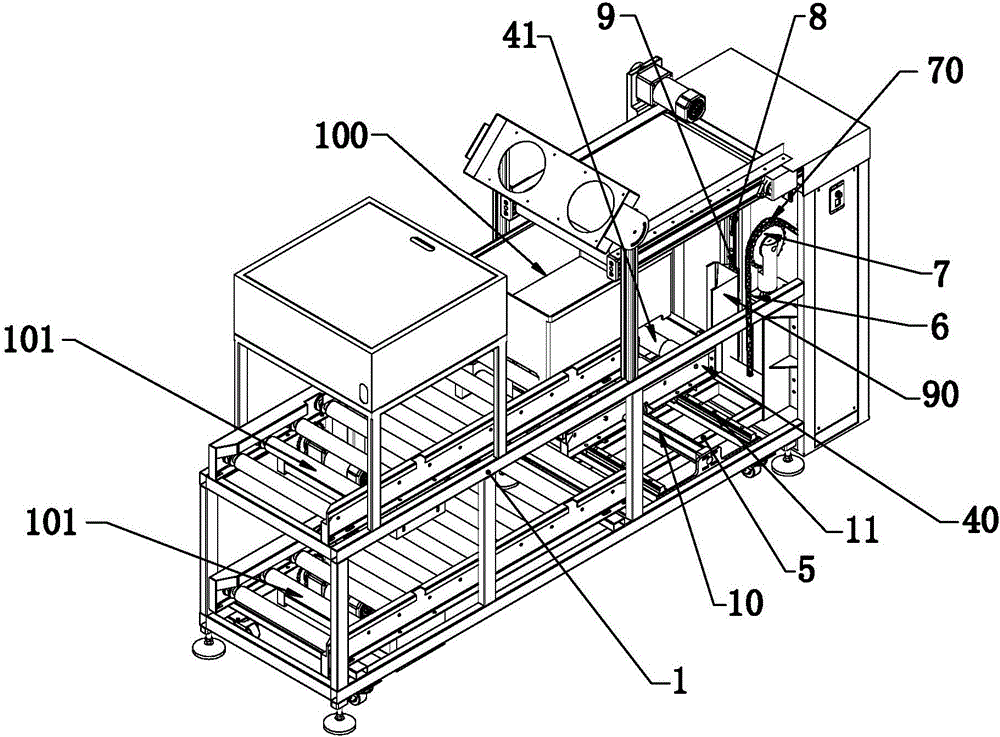

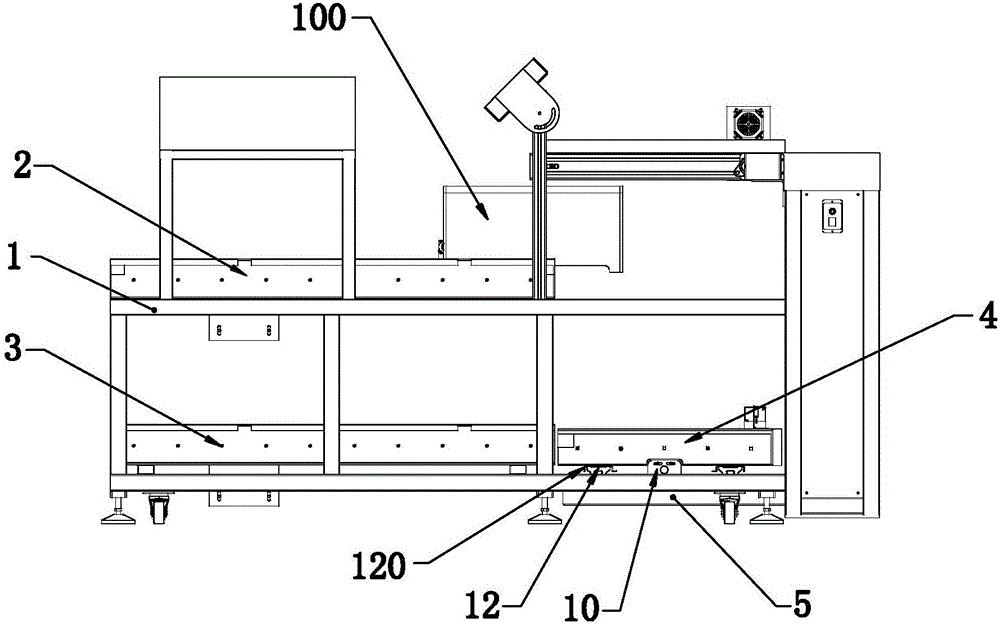

[0032] Such as figure 1 — image 3 As shown, the present invention discloses a fully automatic case changing machine. In a specific embodiment of the present invention, it includes a frame 1, and the frame 1 is provided with two layers of upper conveying components 2 and lower conveying components with opposite conveying directions. Assemblies 3, the frame 1 is provided with a case carrying assembly 4 for transporting the case 100 on the upper conveying assembly 2 to the lower conveying assembly 3, the bottom of the carrying case assembly 4 is provided with a bottom plate 5, and the frame 1 A longitudinal conveying assembly for driving the bottom plate 5 to move longitudinally is arranged on it.

[0033] In a specific embodiment of the present invention, a lateral conveying assembly for driving the container assembly 4 to move laterally is arranged between the container assembly 4 and the bottom plate 5 .

[0034] By adopting the above-mentioned technical scheme, it is not n...

Embodiment 2

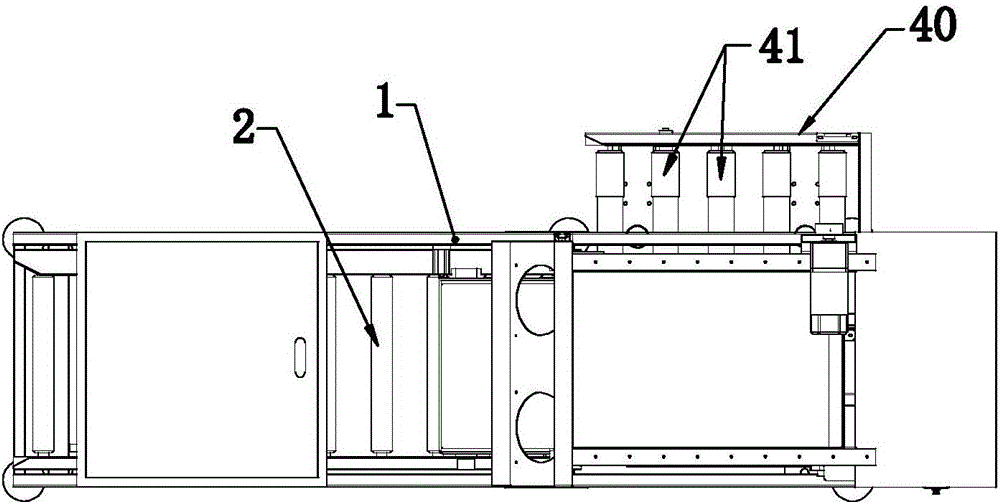

[0051] Such as Figure 4 — Figure 7 As shown, the present invention discloses a fully automatic case changing machine. In a specific embodiment of the present invention, it includes a frame 110, and the frame 110 is provided with two layers of upper conveying assemblies 200 and lower conveying assemblies with opposite conveying directions. Assemblies 300, the frame 110 is provided with a case carrying assembly 400 for transporting the boxes on the upper conveying assembly 200 to the lower conveying assembly 300, the bottom of the carrying case assembly 400 is provided with a bottom plate 500, on the frame 110 A longitudinal conveying assembly for driving the bottom plate 500 to move longitudinally is provided.

[0052] By adopting the above-mentioned technical scheme, it is not necessary to manually transport the produced products to the conveying mechanism, and the products can be transported to the next workshop for subsequent processes, which reduces manual labor, improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com