Laser marking and welding machine of jug bodies

A laser marking and welding machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as inability to meet production and processing requirements, eye damage, poor quality of finished products, etc., to reduce labor costs and error rates , Guarantee the accuracy and stability of conveying, improve the safety factor and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

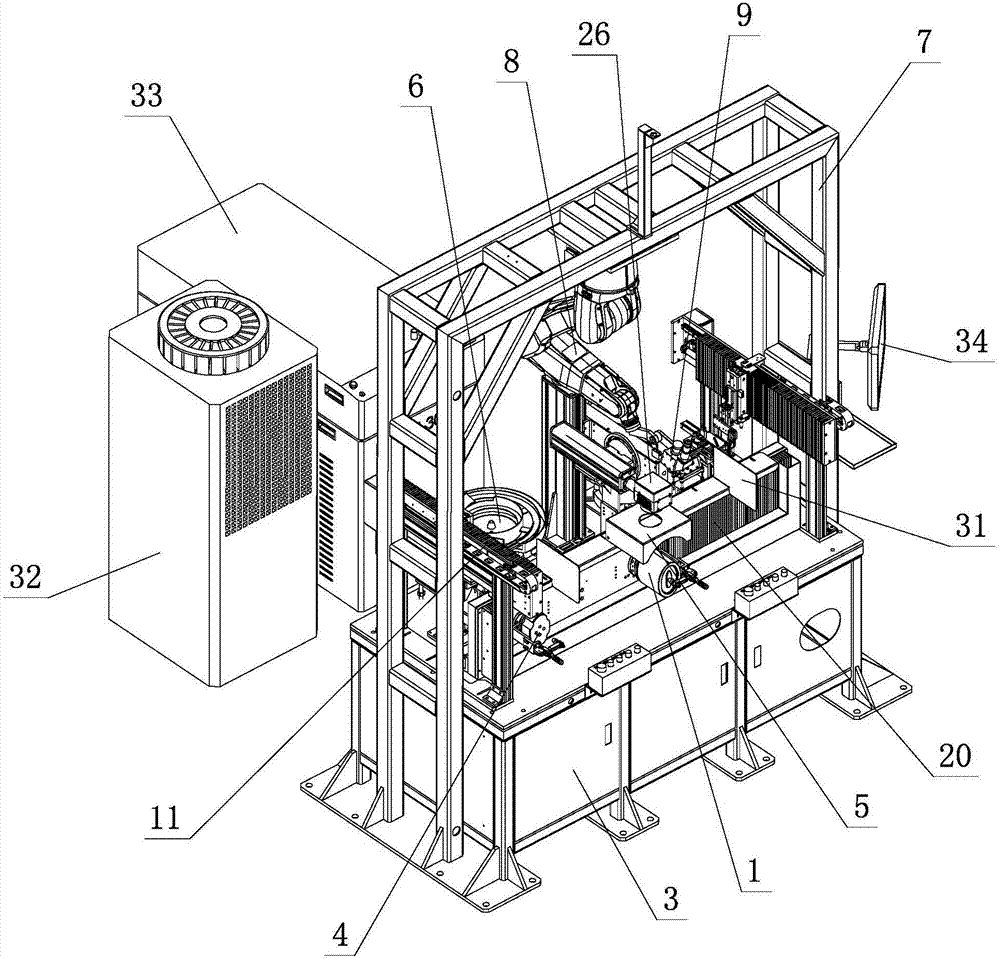

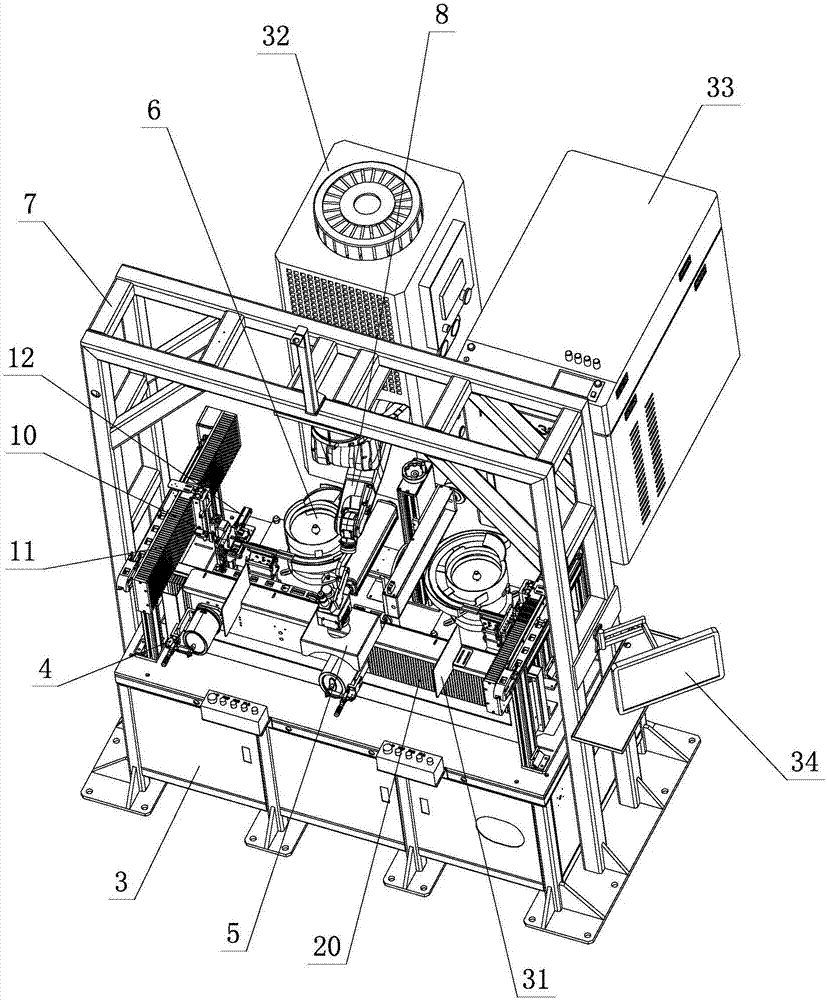

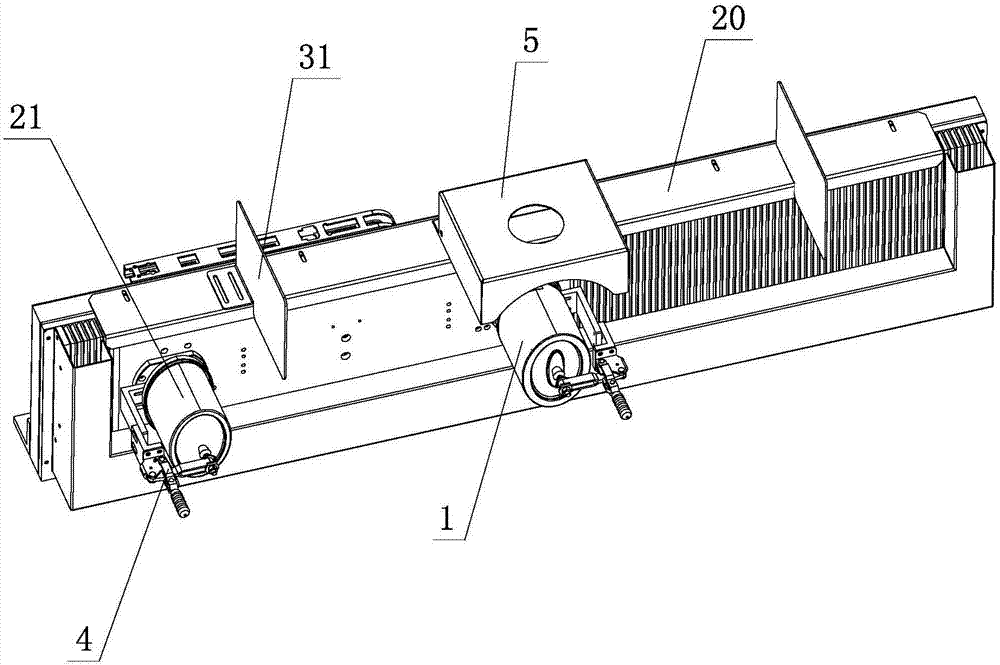

[0032] see Figure 1-Figure 11 , the pot body laser marking welding machine, including the processing pot body 1, buckle ear 2 and workbench 3, the workbench 3 is provided with at least two welding stations 4 for welding the processing pot body 1 and buckle ear 2 , and at least one marking station 5 for marking on the surface of the processing pot body 1, at least one marking station 5 is located above at least two welding stations 4, and at least two welding stations 4 are respectively A vibrating plate 6 is provided on which the buckle ear 2 is placed, and the processing pot body 1 is placed on the welding station 4; a robot hanger 7 is also arranged on the workbench 3, and a robot 8 is arranged on the robot hanger 7, The robot 8 is provided with a welding gun clamp 9, and the robot 8 moves back and forth on at least two welding stations 4 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com