Patents

Literature

46results about How to "Guaranteed delivery accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

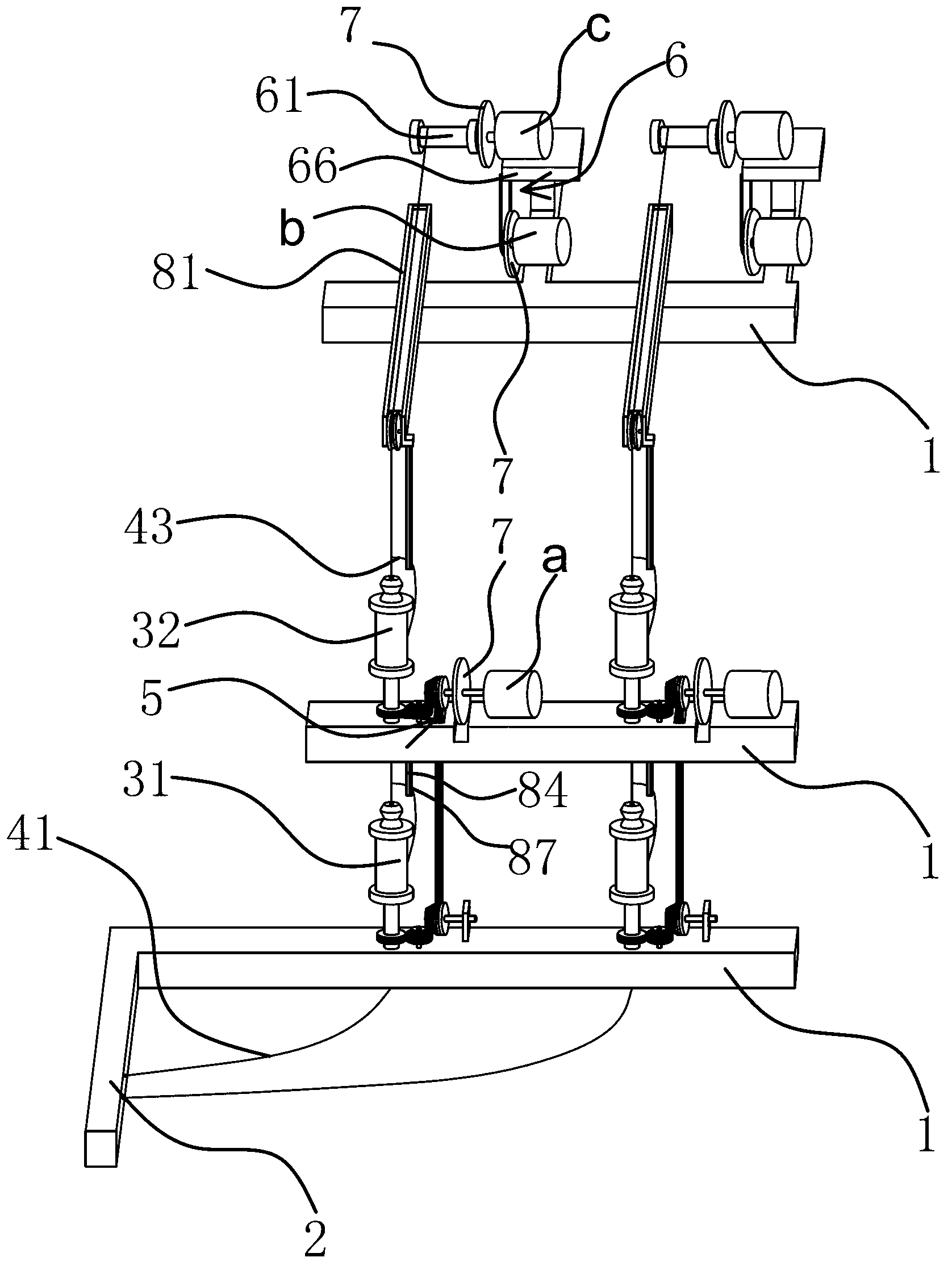

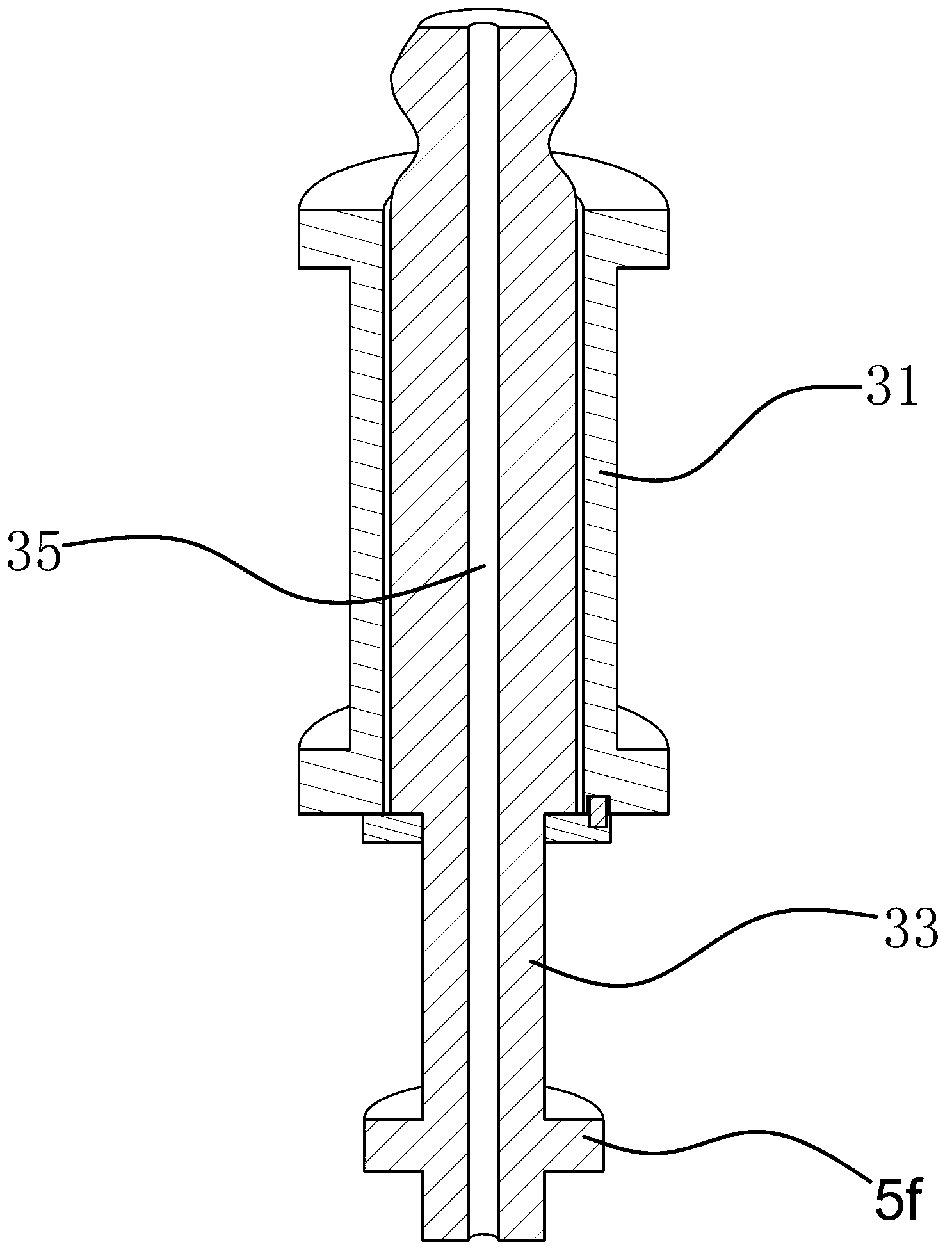

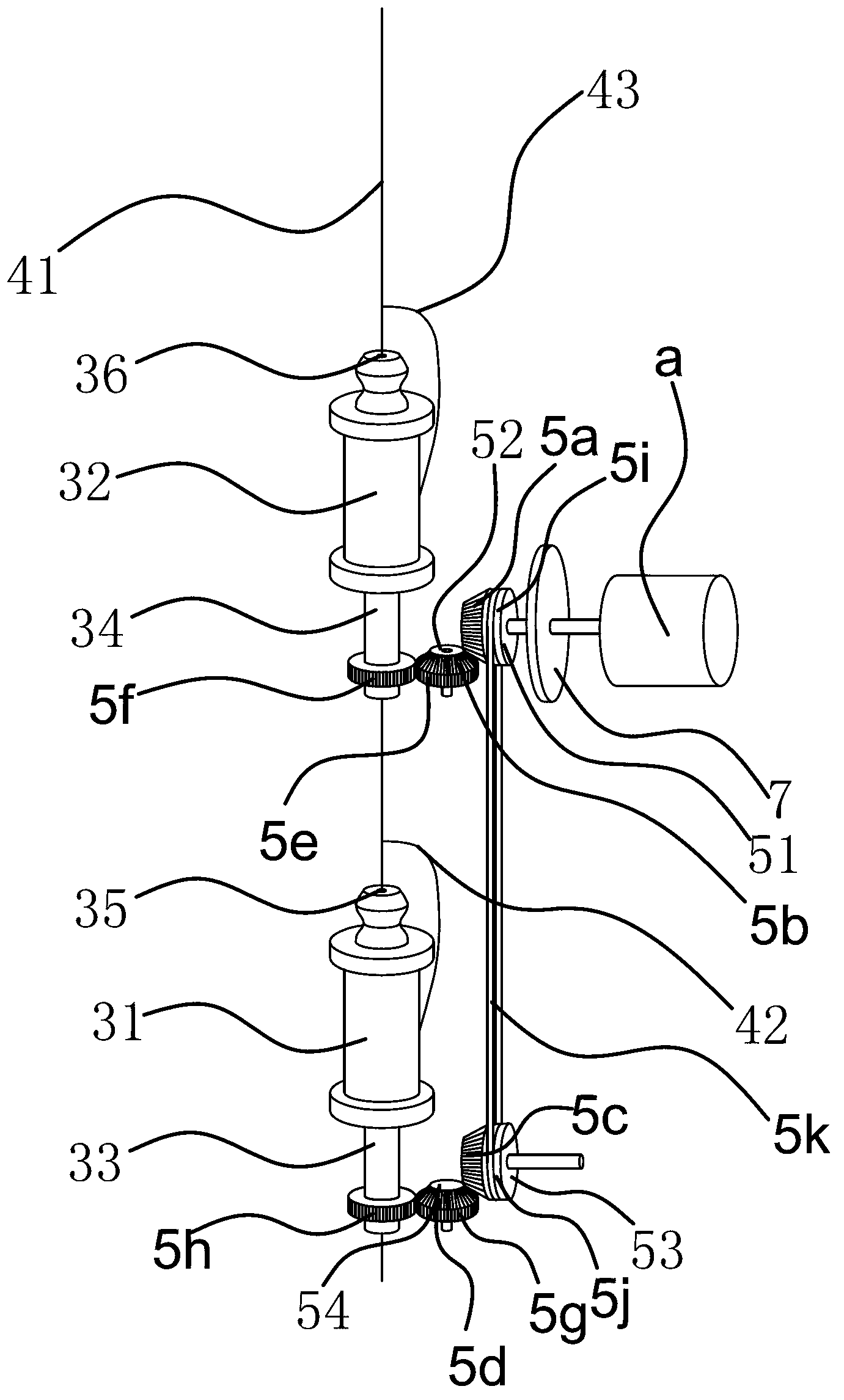

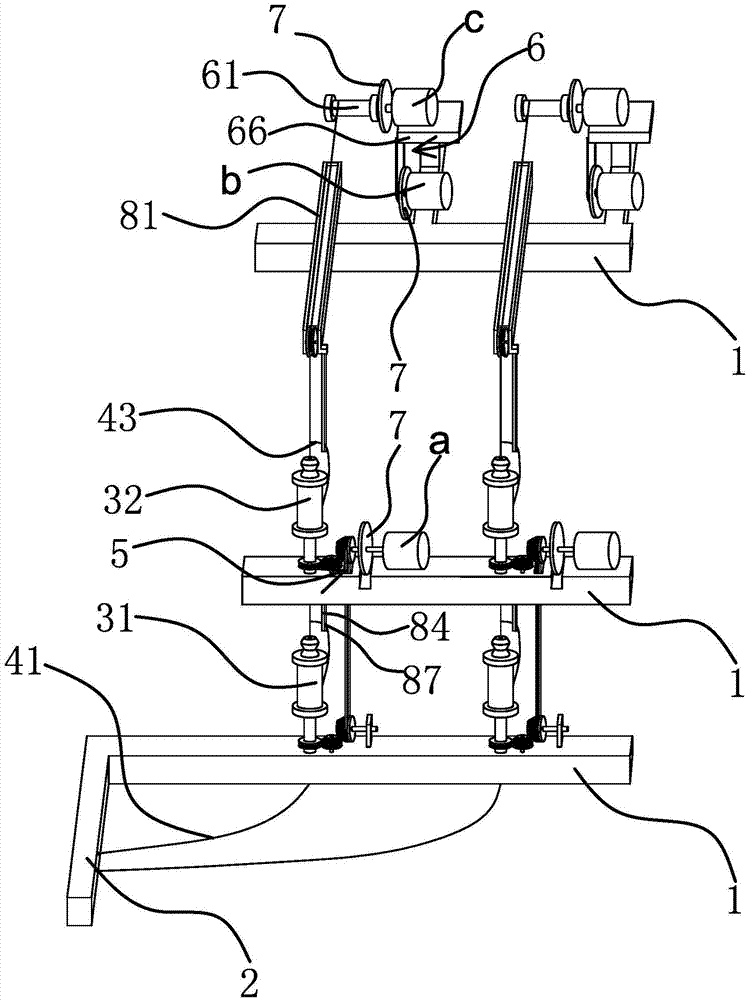

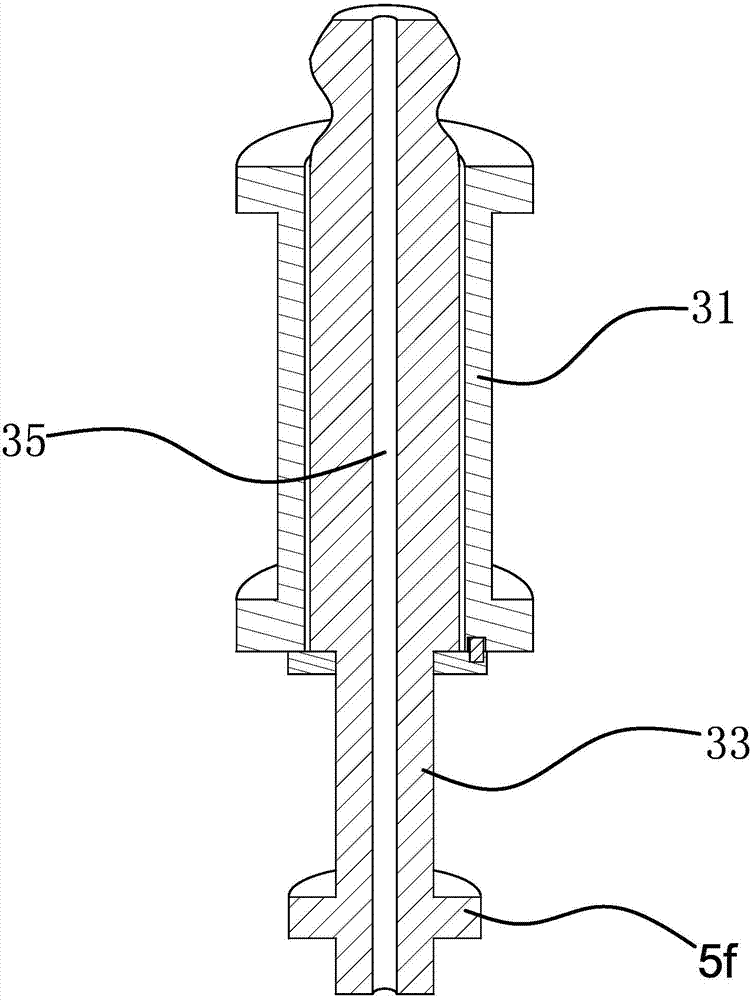

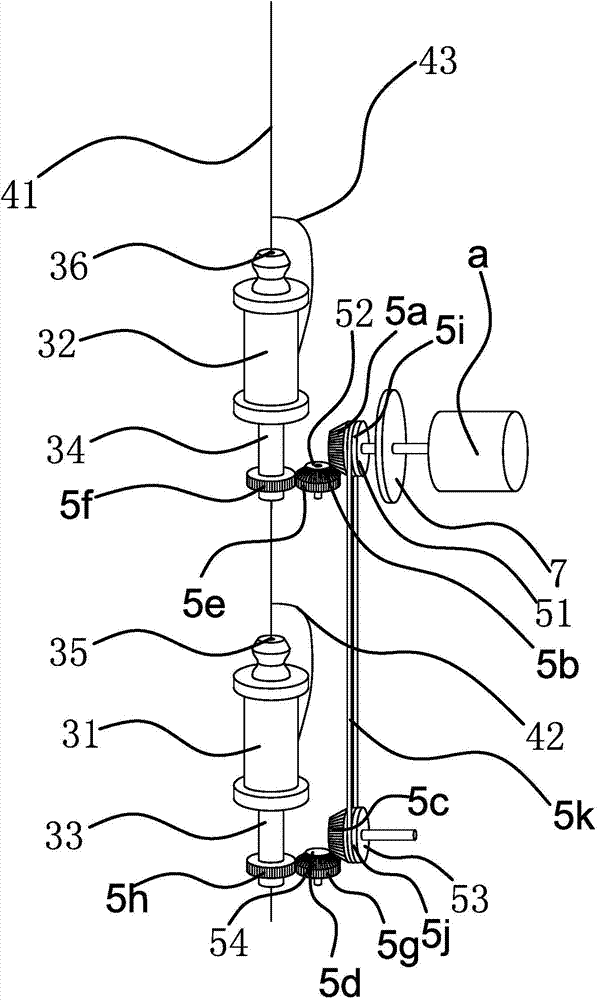

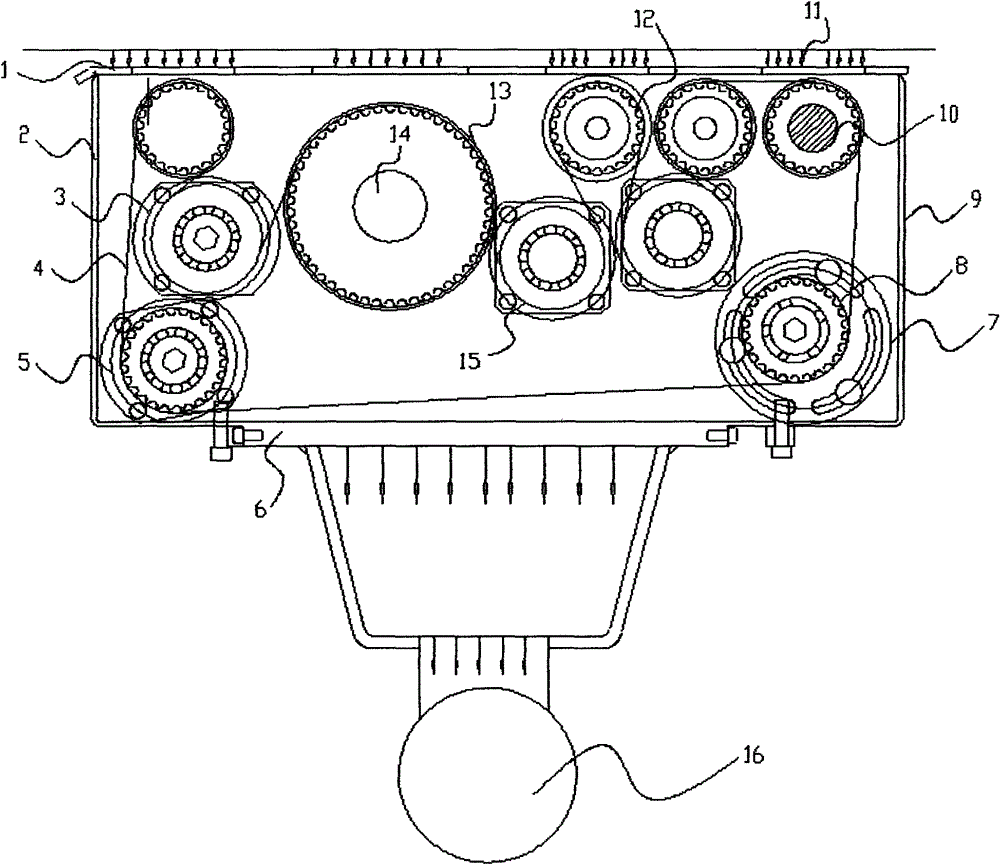

Silk covering machine

InactiveCN103290584AGuaranteed delivery accuracySmooth releaseContinuous wound-up machinesYarnYarnEngineering

The invention provides a silk covering machine, and belongs to the technical field of machines. The technical problem that two outer covering yarns can not be wound simultaneously in an existing silk covering machine is solved. The silk covering machine comprises a machine frame, wherein the machine frame is provided with a winding displacement plate, a plurality of primary covering drums and a plurality of secondary covering drums which are arranged above the primary covering drums. The winding displacement plate is provided with a plurality of yarn cores in a penetrating mode. The machine frame is further provided with a plurality of primary covering spindles and secondary covering spindles, first through holes and second through holes are formed in the primary covering spindles and the secondary covering spindles respectively, and the yarn cores sequentially penetrate through the first through holes and the second through holes. The secondary covering drums are connected with a first driving motor, and a transmission mechanism which enables the power of the first driving motor to be transmitted to the primary covering drums is arranged between the first driving motor and the secondary covering drums. The silk covering machine has the advantages of being even in yarn core covering, capable of achieving the fact that two outer covering yarns are wound simultaneously and the like.

Owner:HAINING SHENGXIANG WIRE

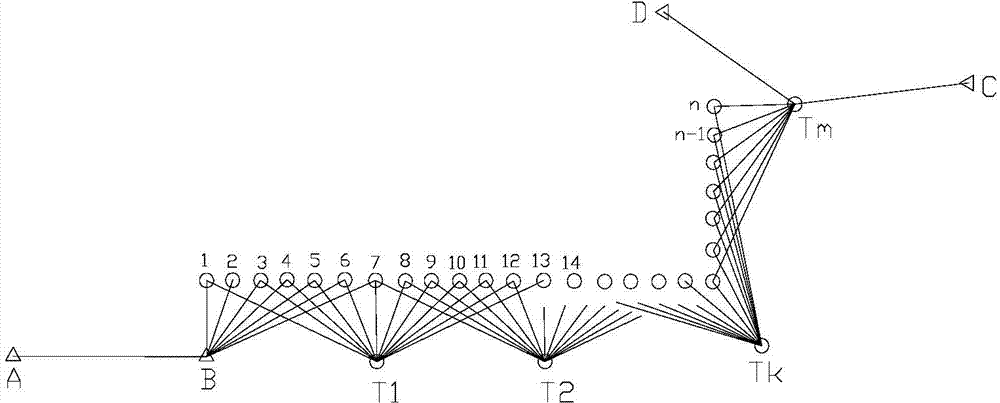

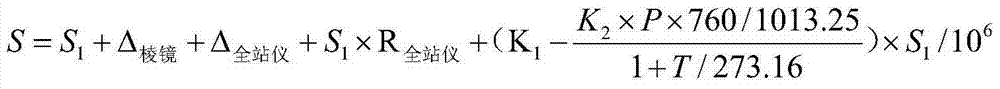

Multi-common-turning-point lateral intersection traverse surveying method

ActiveCN104729489AGuaranteed StrengthImprove reliabilitySurveying instrumentsUnderground cavernEstimation methods

The invention belongs to a multi-common-turning-point lateral intersection traverse surveying method used for narrow underground caverns short in intervisibility distance and changed in traverse extending paths in the technical field of engineering surveying. The multi-common-turning-point lateral intersection traverse surveying method includes the steps of arranging at least two survey stations on a traverse extending path, arranging a plurality of public survey turning points on the other sides of connection lines among the survey stations uniformly, and adopting a high-precision total station for automatic observation; correcting surveyed slope distance and using the same to compute an independent coordinate for each survey station; computing three converting parameters between the independent coordinate and an integral coordinate of each public turning point between adjacent survey stations by the aid of a least-square indirect adjustment method and a robust estimation method, and converting the independent coordinates into integral coordinates. The multi-common-turning-point lateral intersection traverse surveying method has the advantages that enough redundant observation objects for traverse transferring and high precision are achieved, influence of lateral refraction is avoided, influence of error of centralization of an instrument and a prism during traverse transferring is eliminated, influences of gross observation error on an adjustment result are reduced, and the multi-common-turning-point lateral intersection traverse surveying method is suitable for places in difficult conditions, such as narrow underground caverns, curve paths and visualizing obstacles, and capable of improving precision and reliability of traverse transferring.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

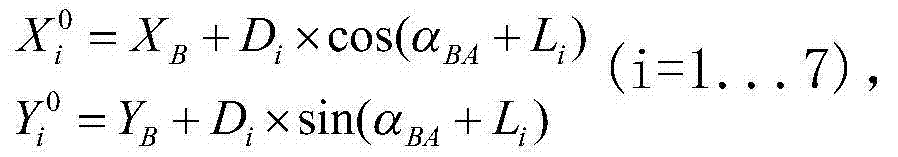

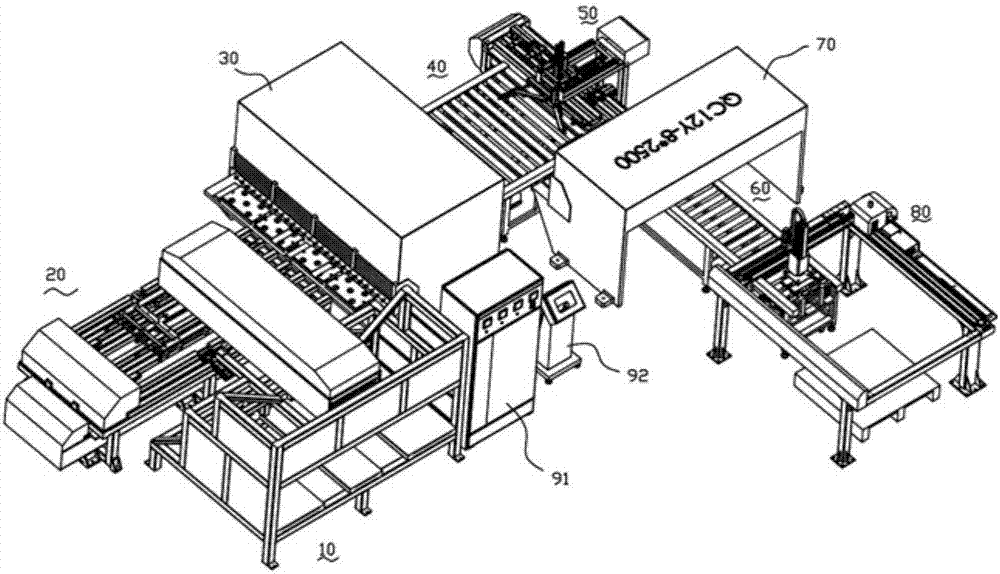

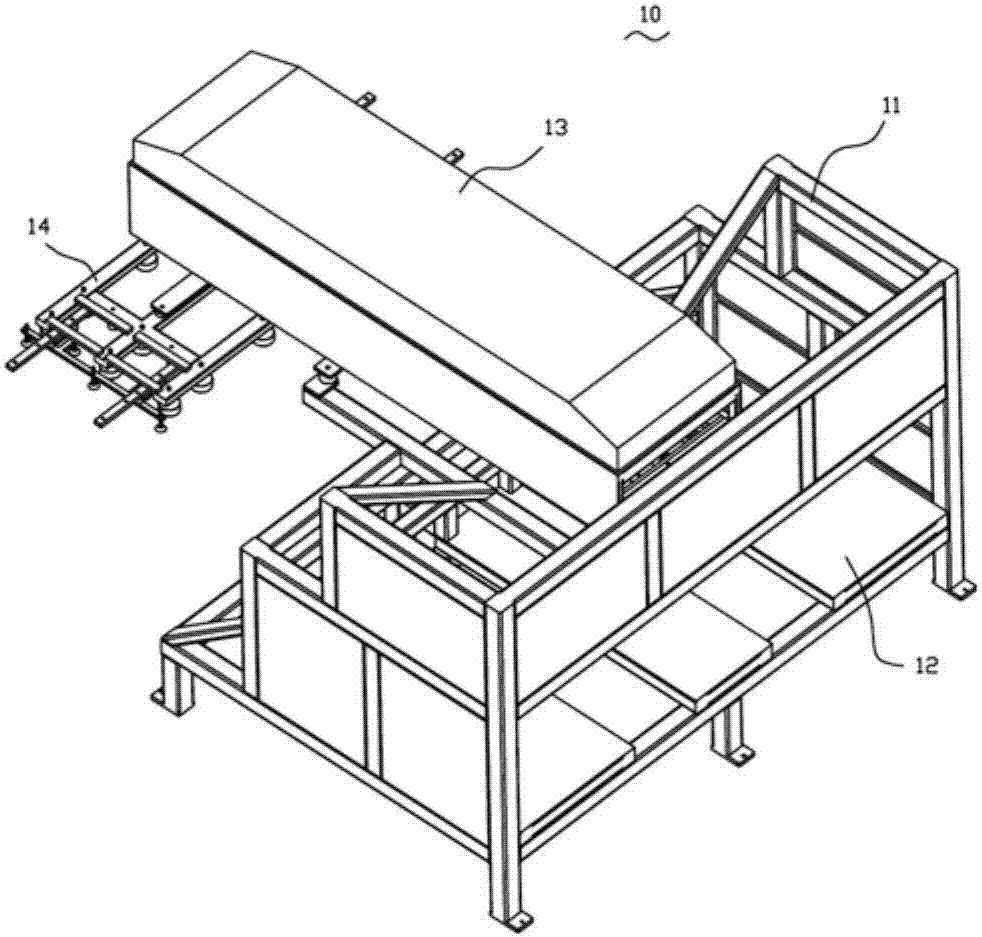

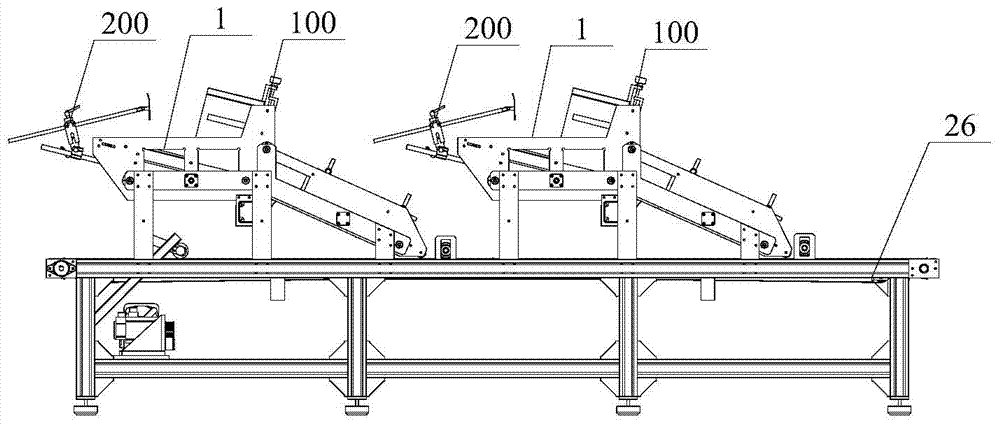

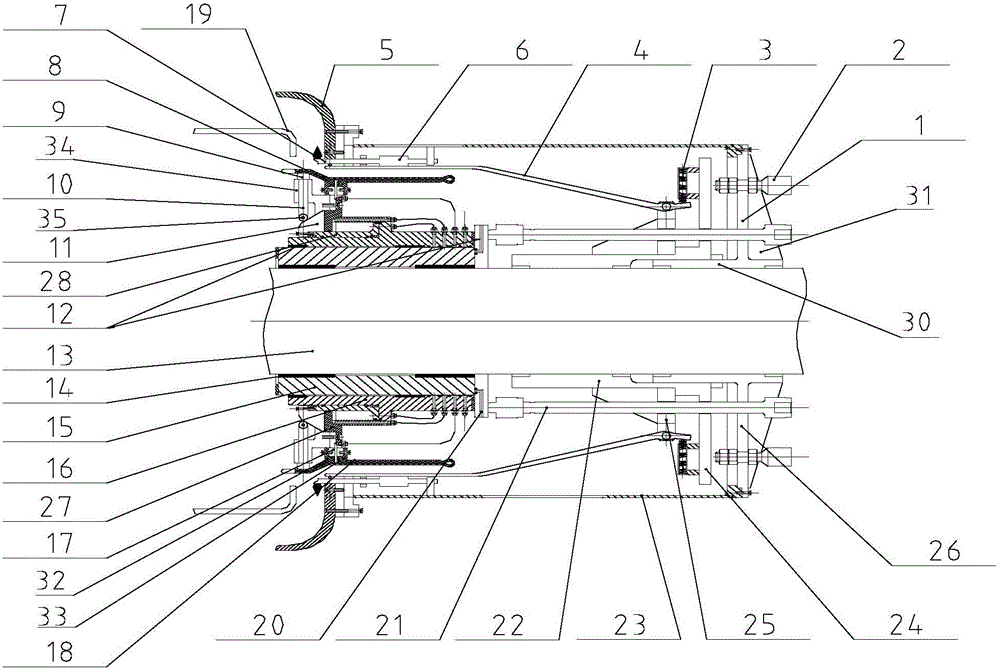

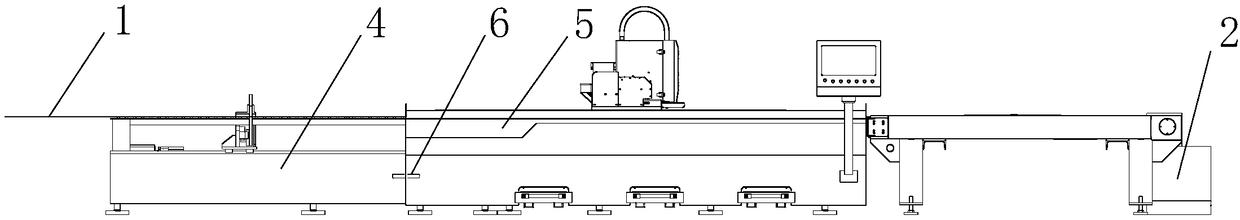

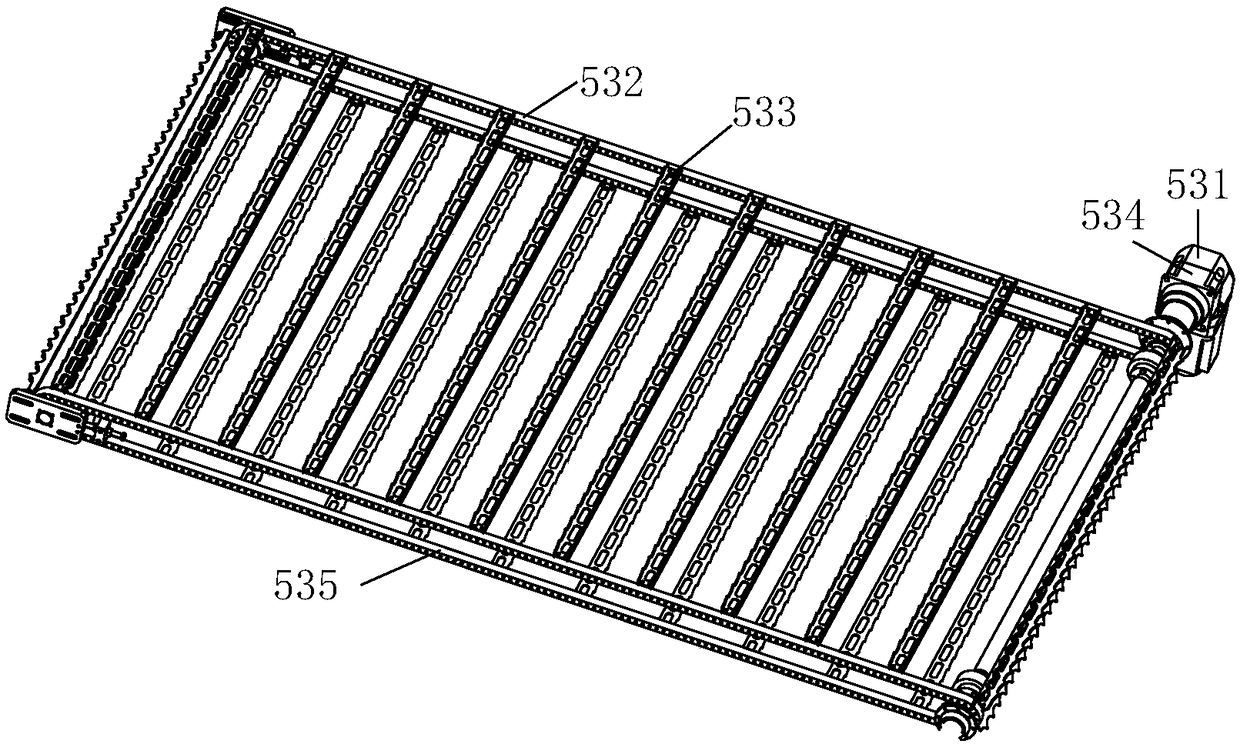

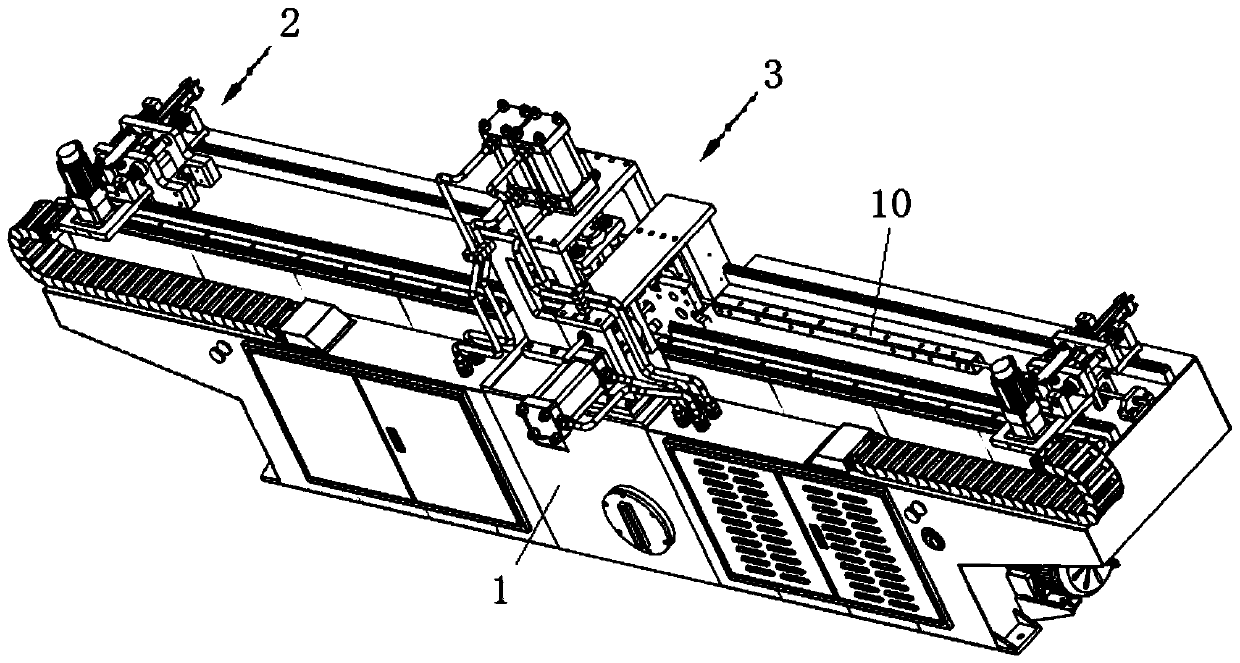

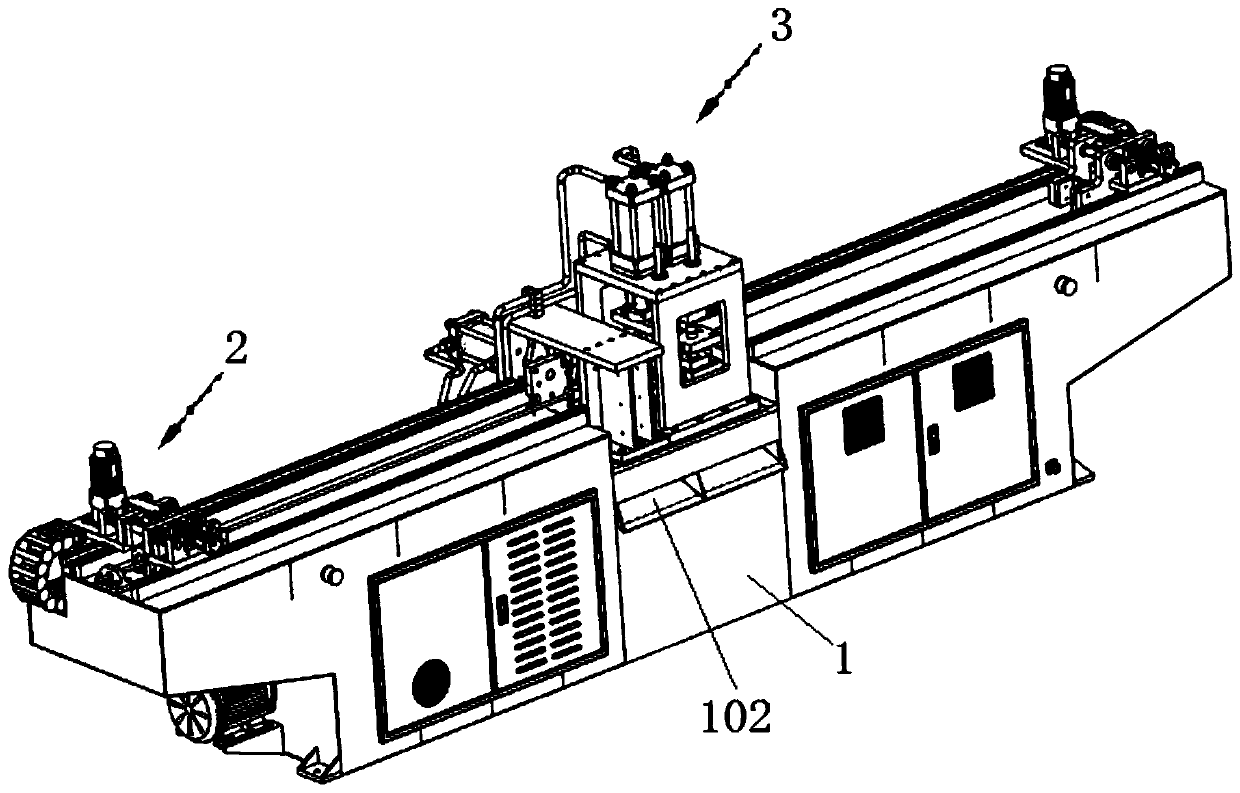

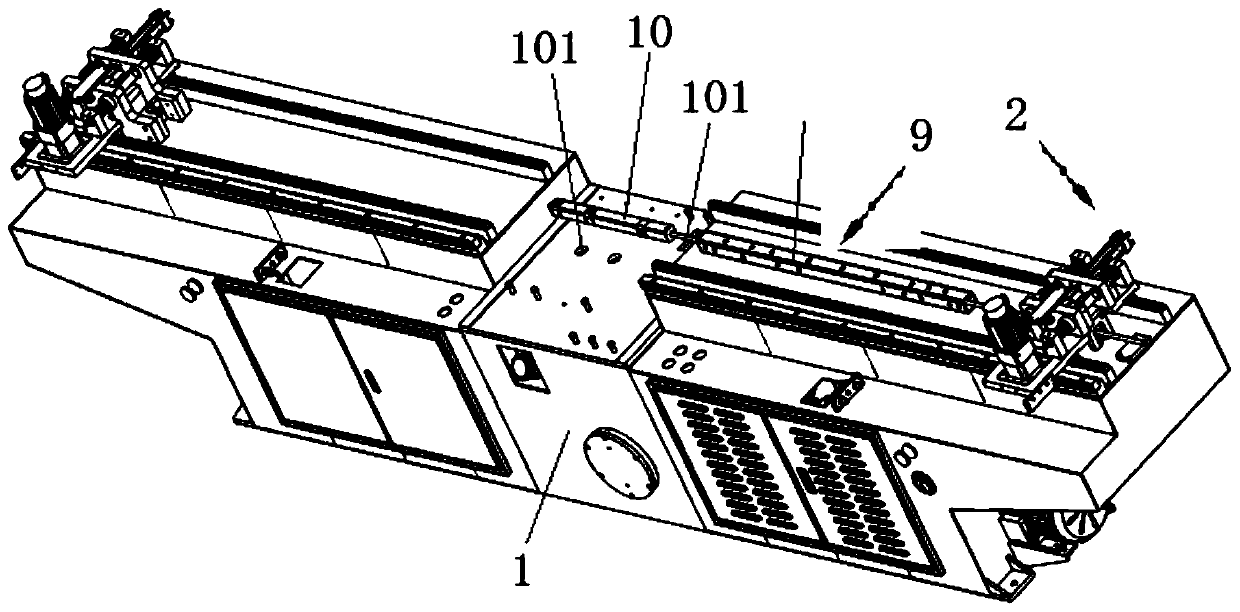

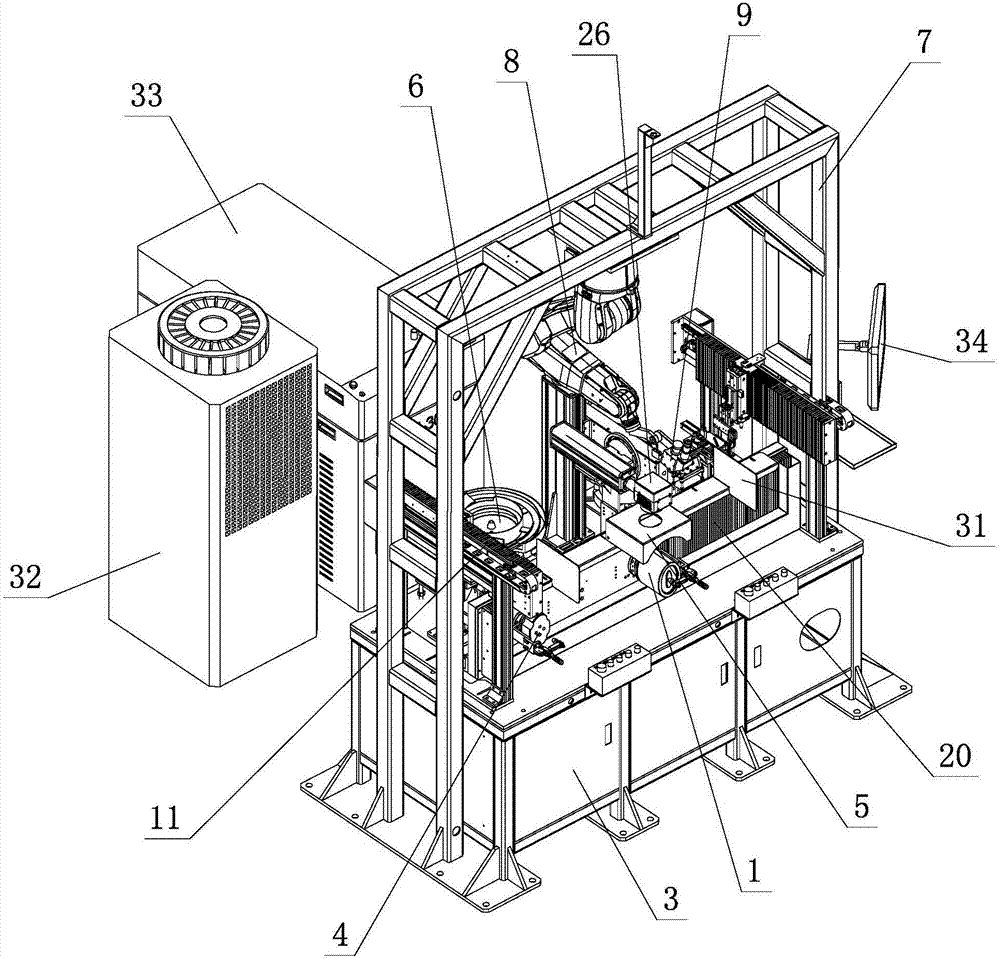

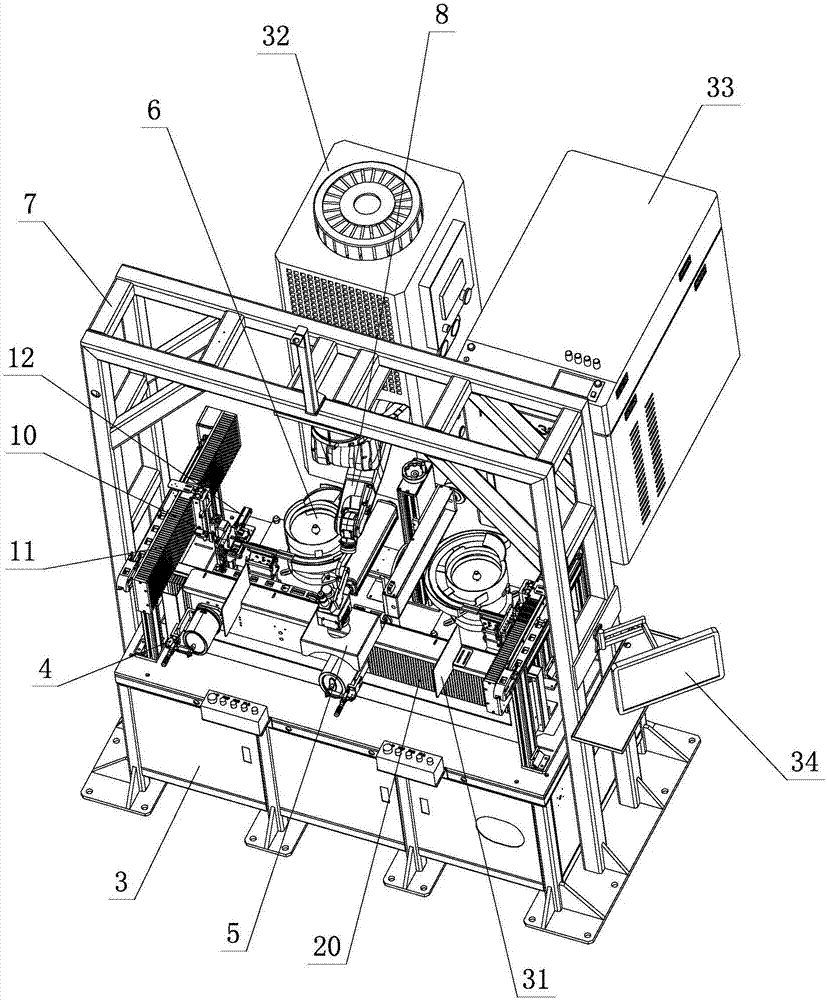

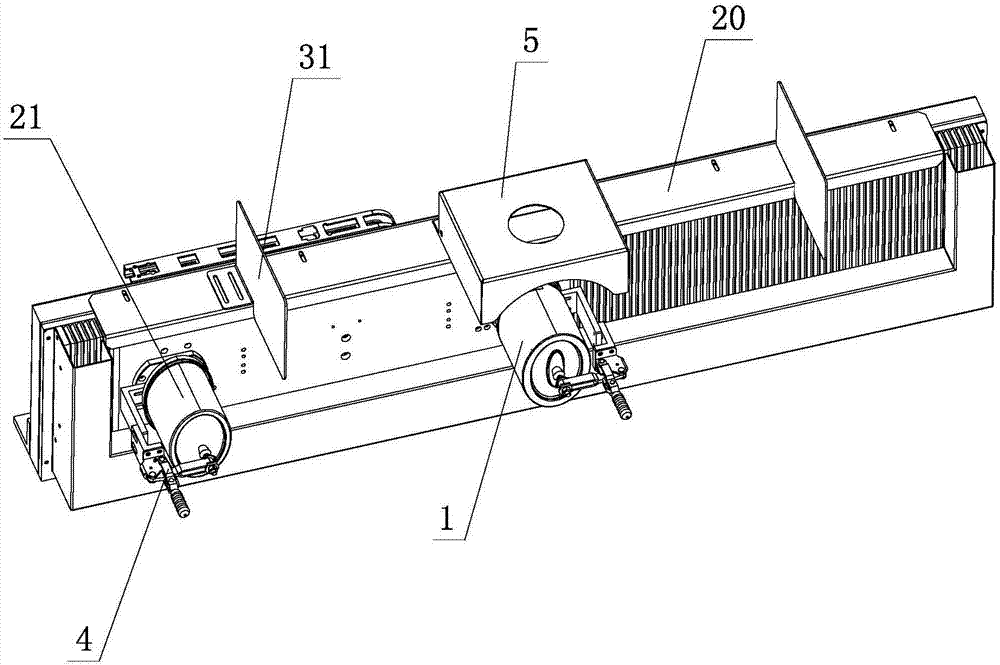

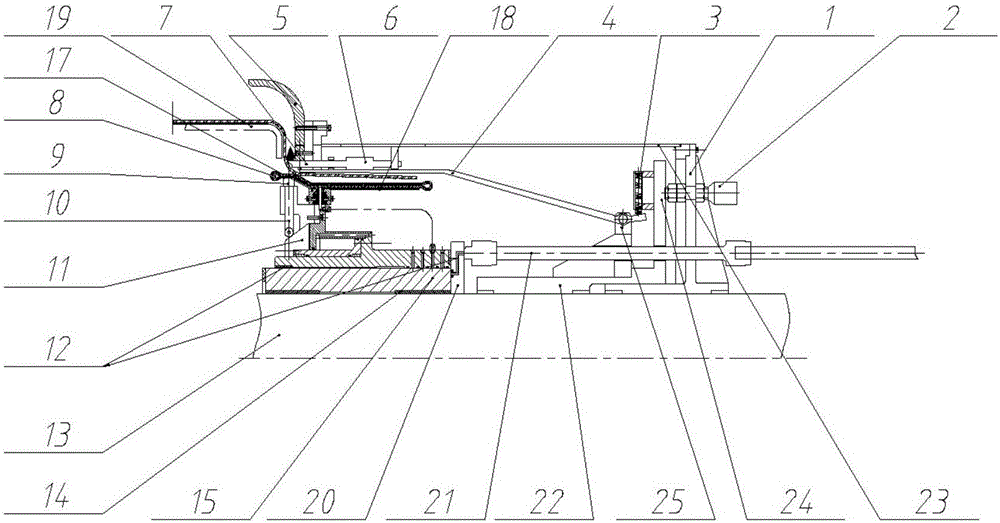

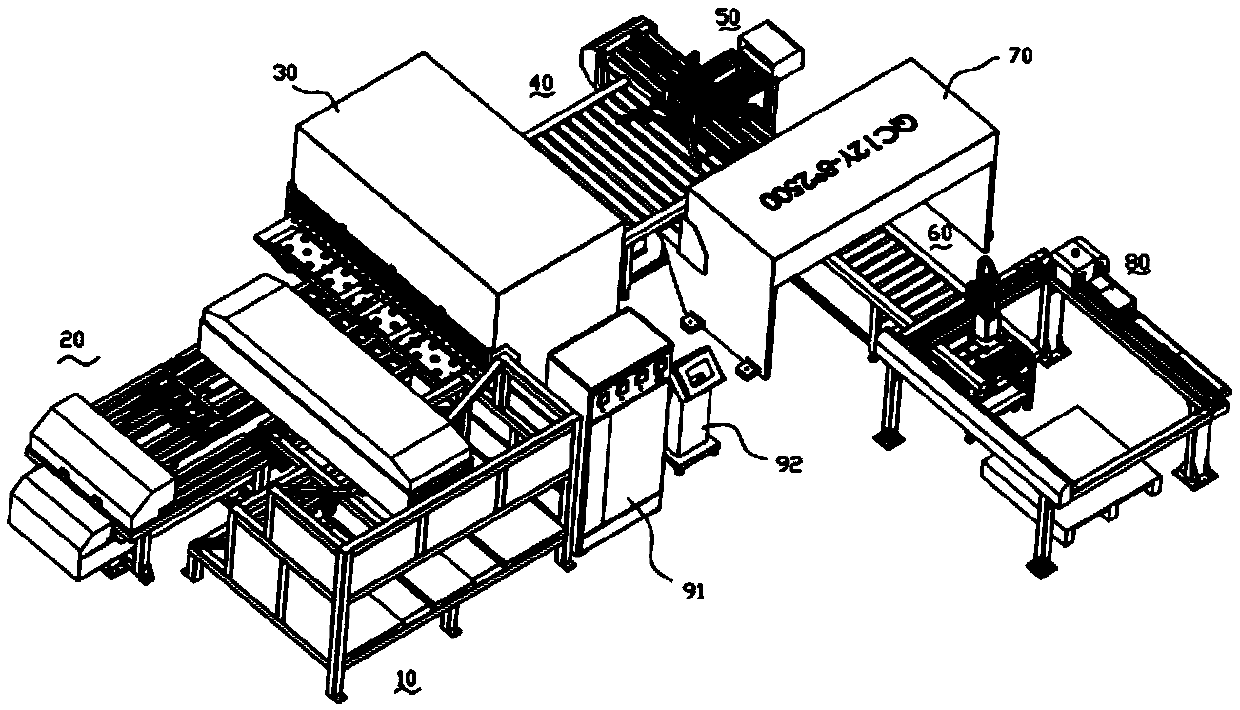

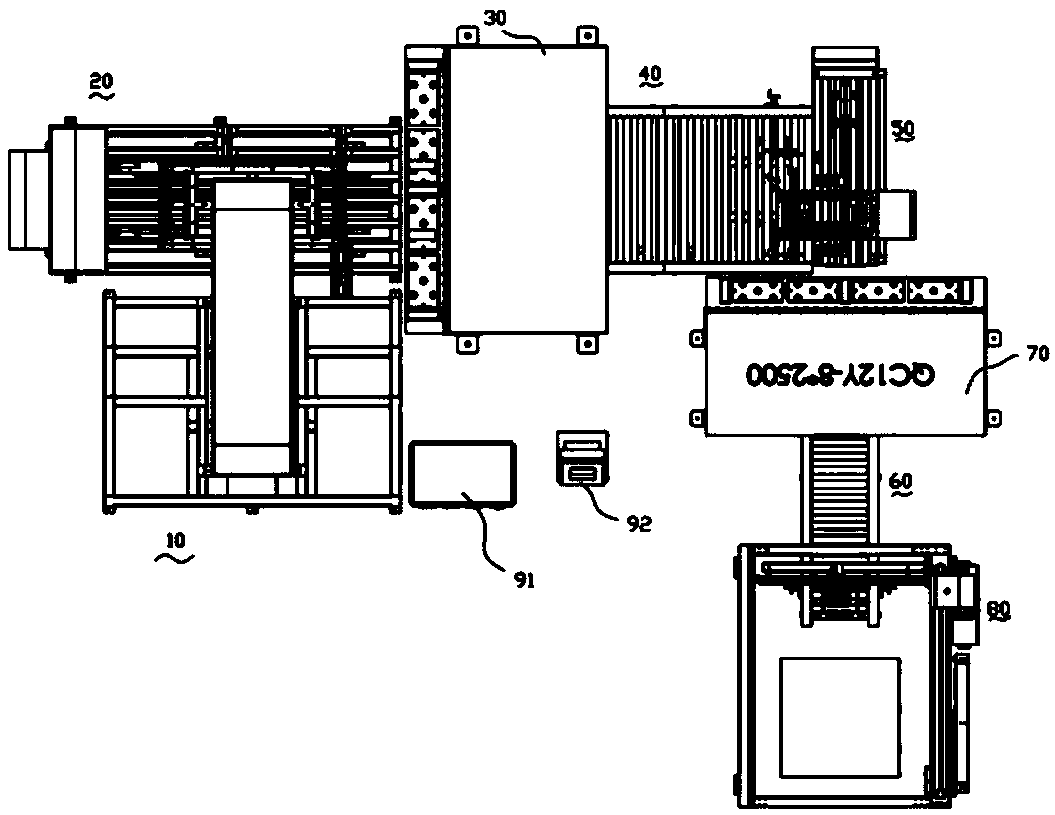

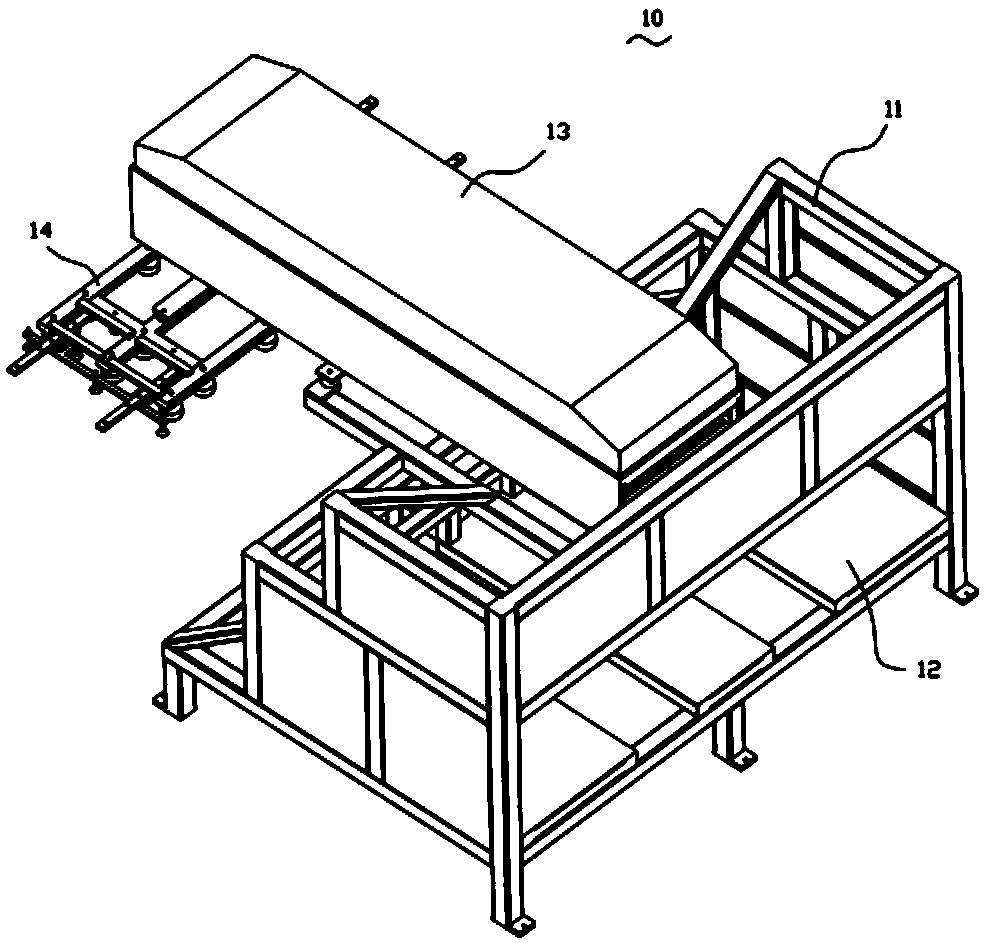

Automatic plate shearing system

InactiveCN107252922AReduce work intensityGuaranteed delivery accuracyMetal-working feeding devicesShearing machinesEngineeringManipulator

The invention discloses an automatic plate shearing system. The automatic plate shearing system comprises a raw material feeding carrying assembly, a raw material servo supplying assembly, a first shearing machine, a strip fixed-point conveying assembly, a strip supplying carrying assembly, a second shearing machine, a finished product fixed-point conveying assembly and a stacking carrying assembly. The feeding carrying assembly comprises a raw material carrying rack and raw material carrying manipulators. The raw material carrying manipulators are located above the raw material servo supplying assembly. The first shearing machine is arranged at the tail end of the raw material servo supplying assembly. The strip fixed-point conveying assembly is arranged on the side of the first shearing machine. The strip supplying carrying assembly is arranged on the side of the strip fixed-point conveying assembly. The second shearing machine is arranged on the side of the strip supplying carrying assembly. The finished product fixed-point conveying assembly and the stacking carrying assembly are arranged on the side of the second shearing machine. According to the problem that an existing plate shearing machine is low in carrying efficiency, the improving scheme is put forward, the automatic plate shearing system is designed, and the labor intensity of staff can be effectively relieved.

Owner:DONGGUAN XINGUI IND CO LTD

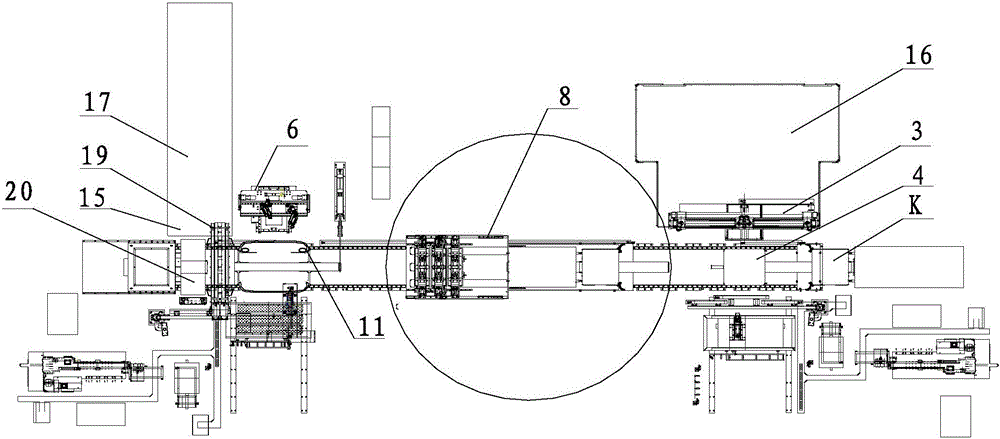

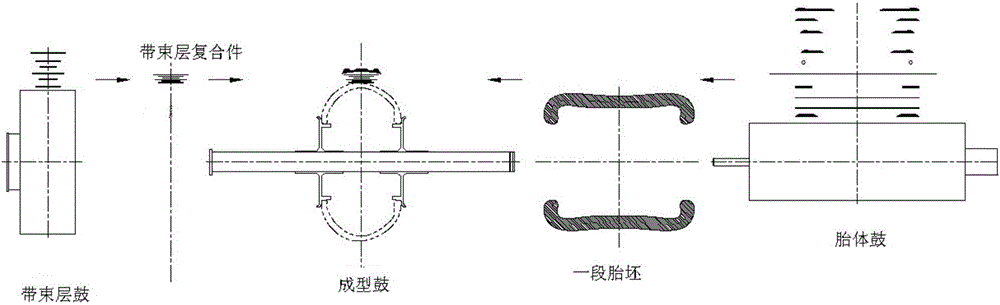

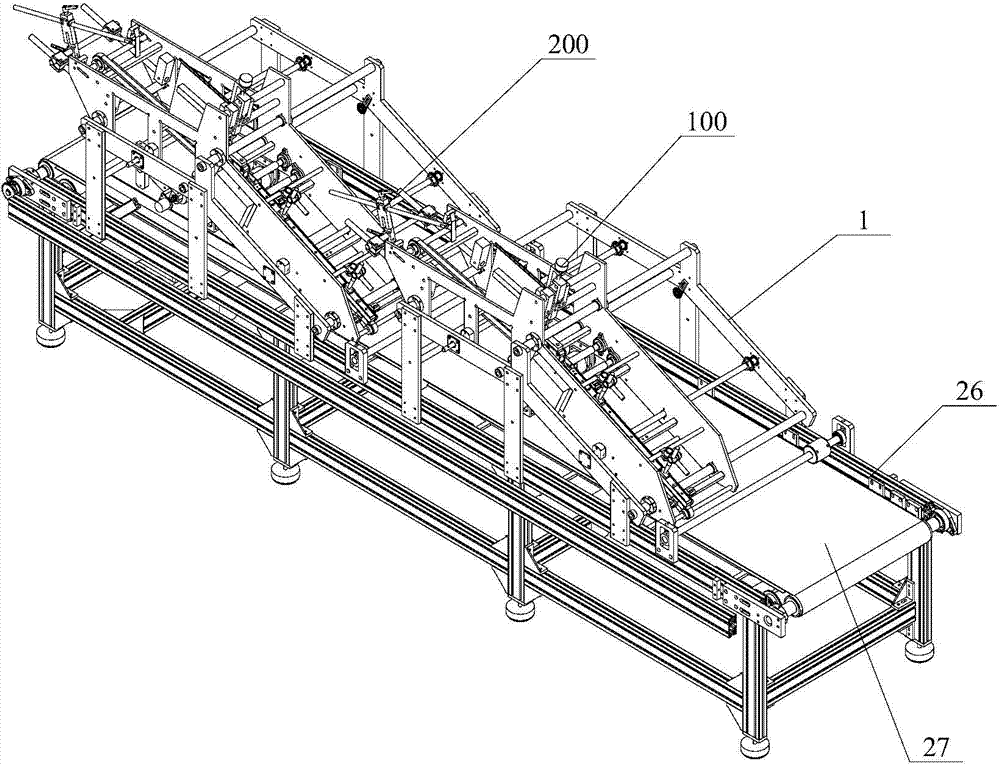

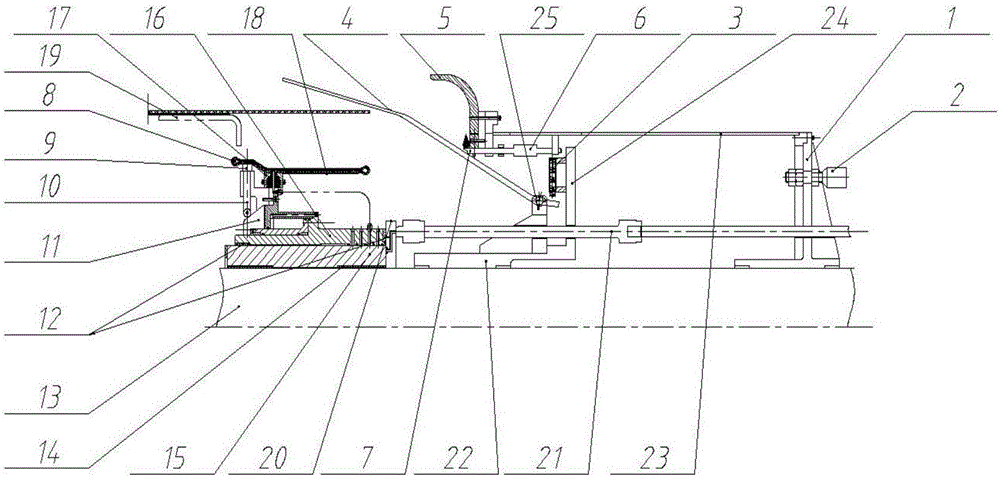

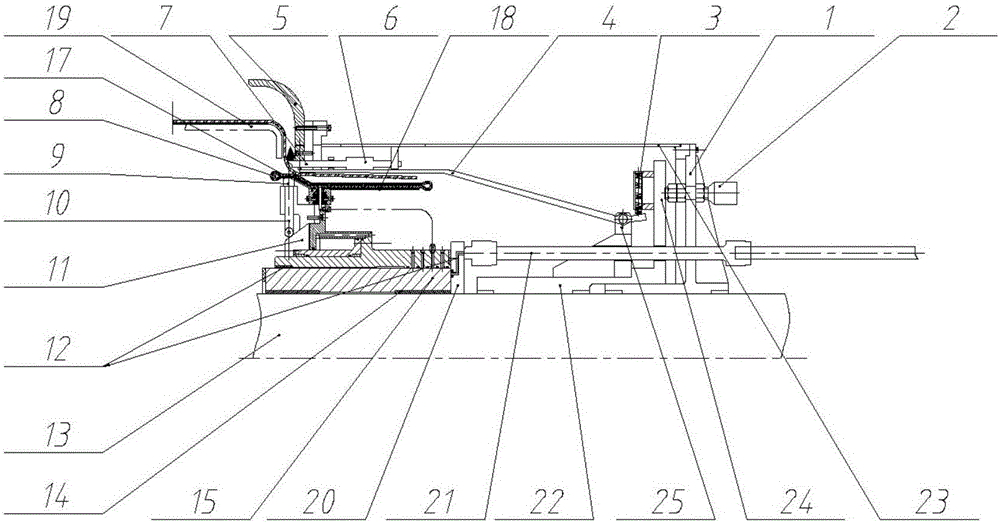

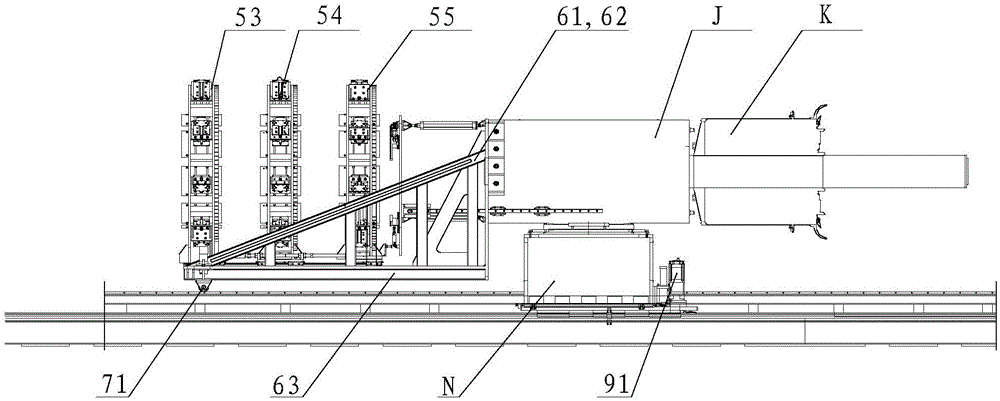

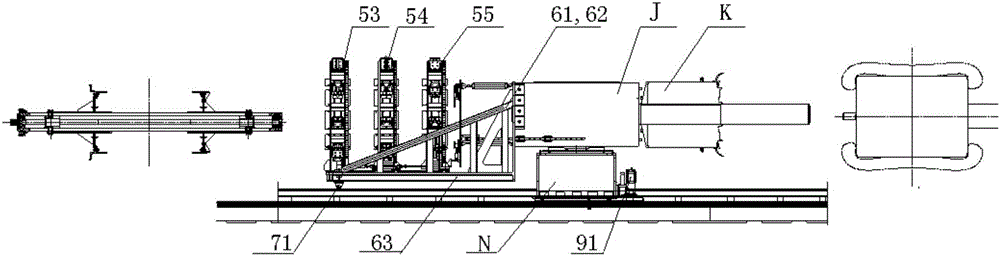

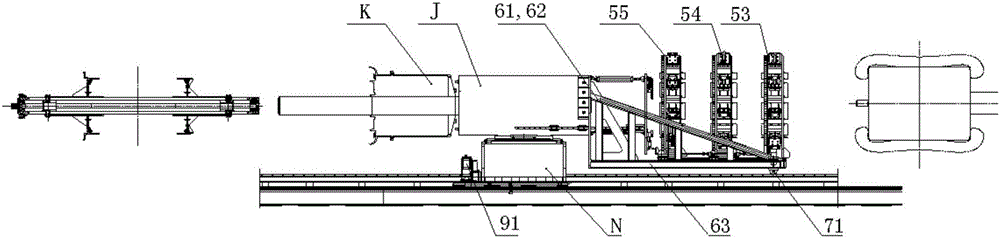

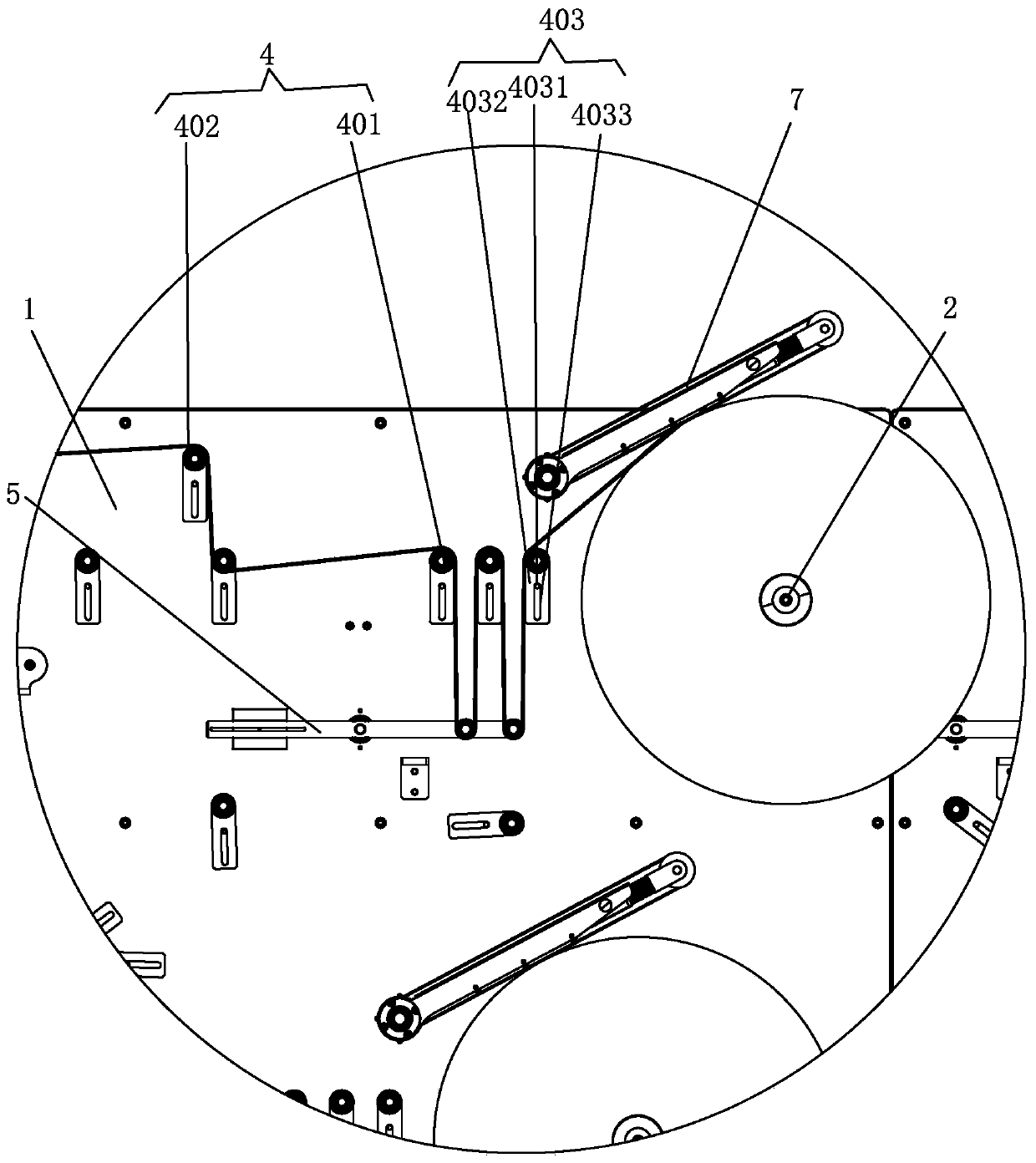

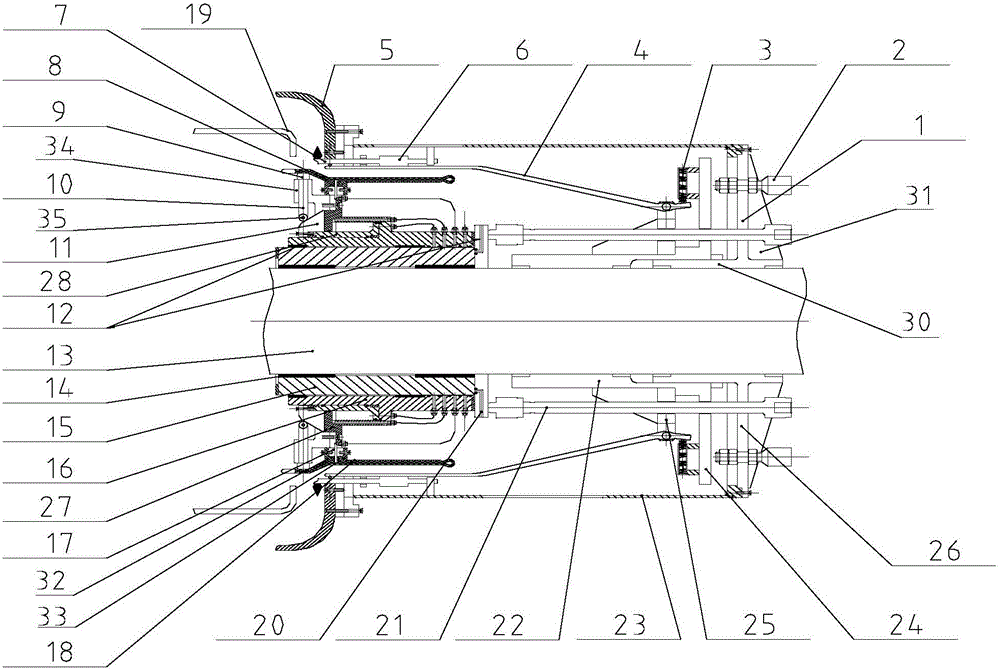

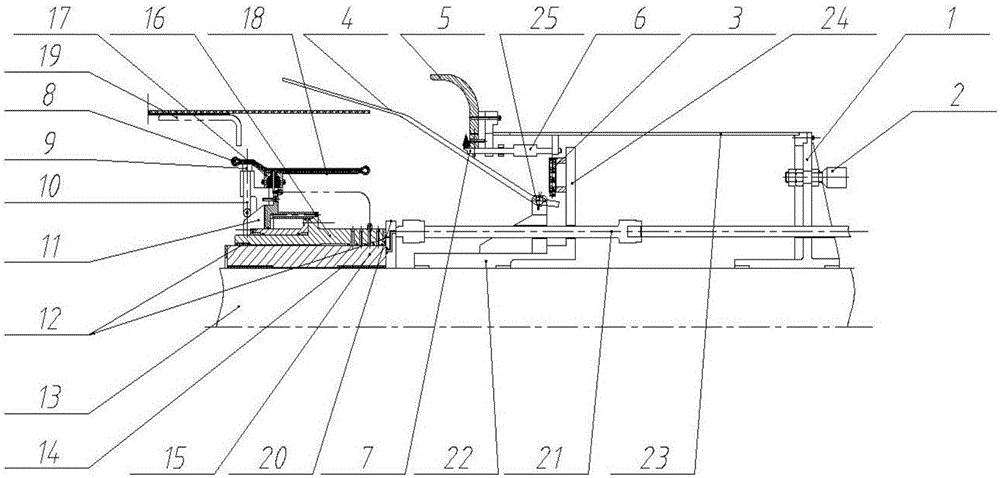

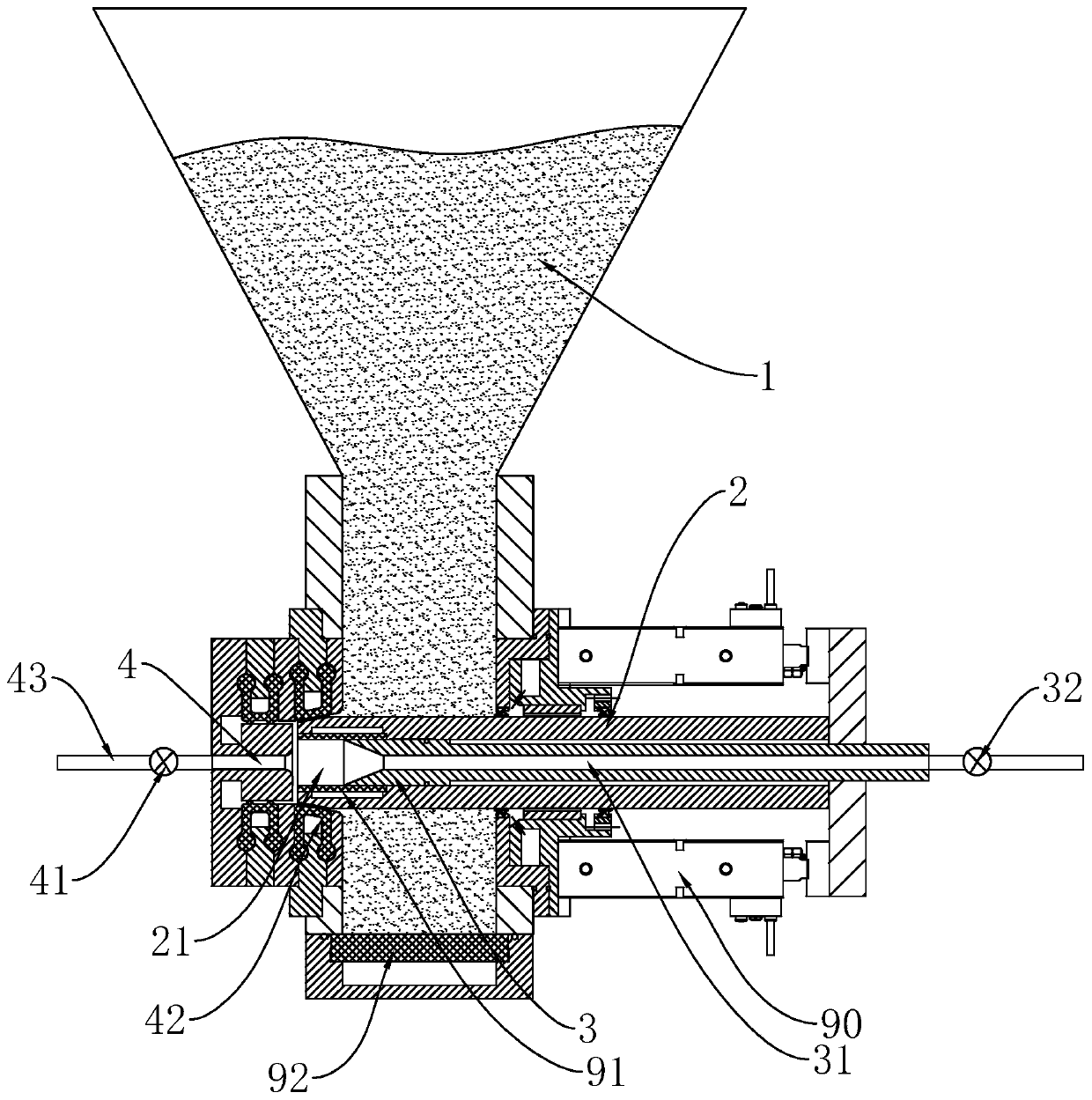

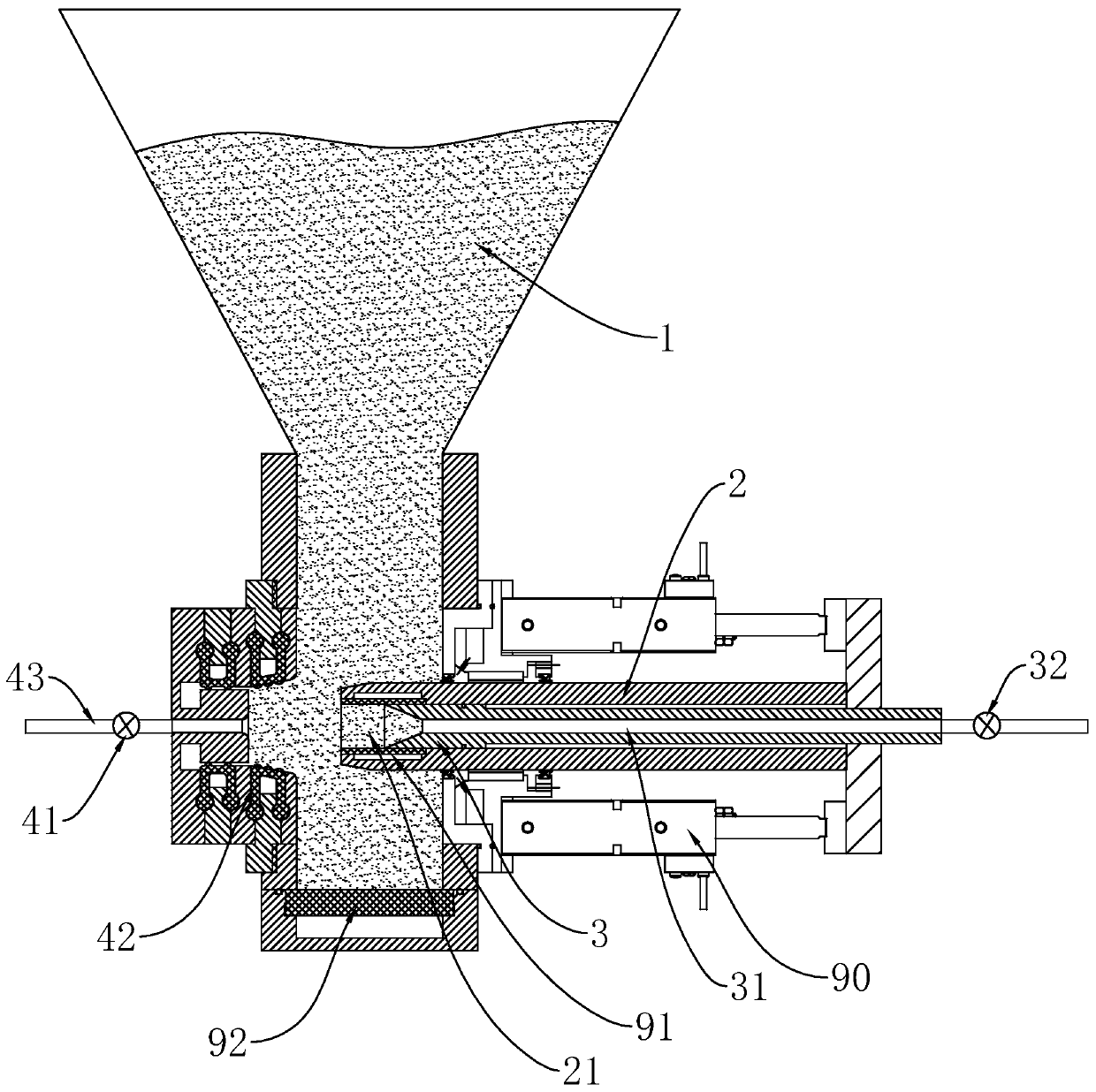

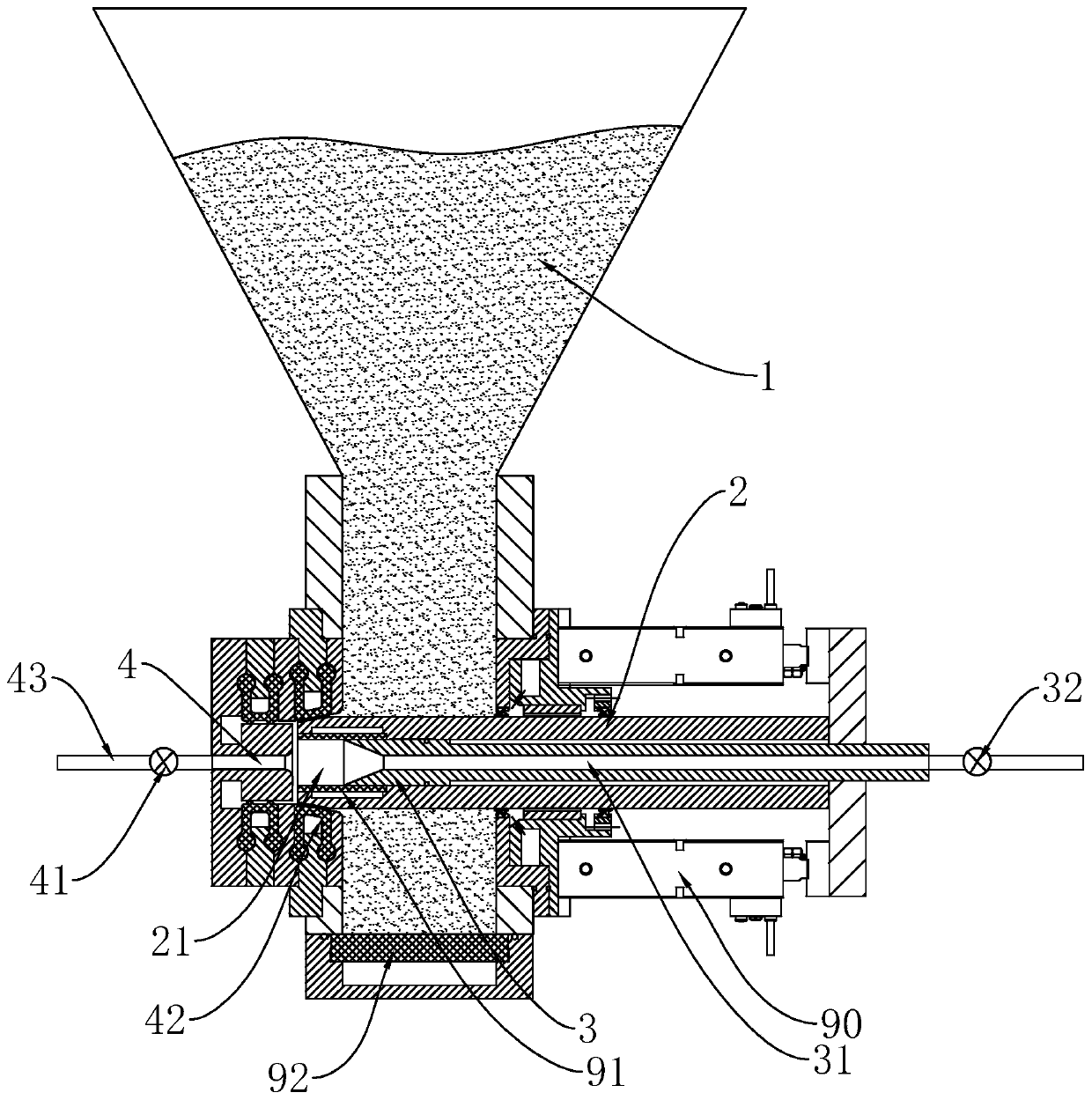

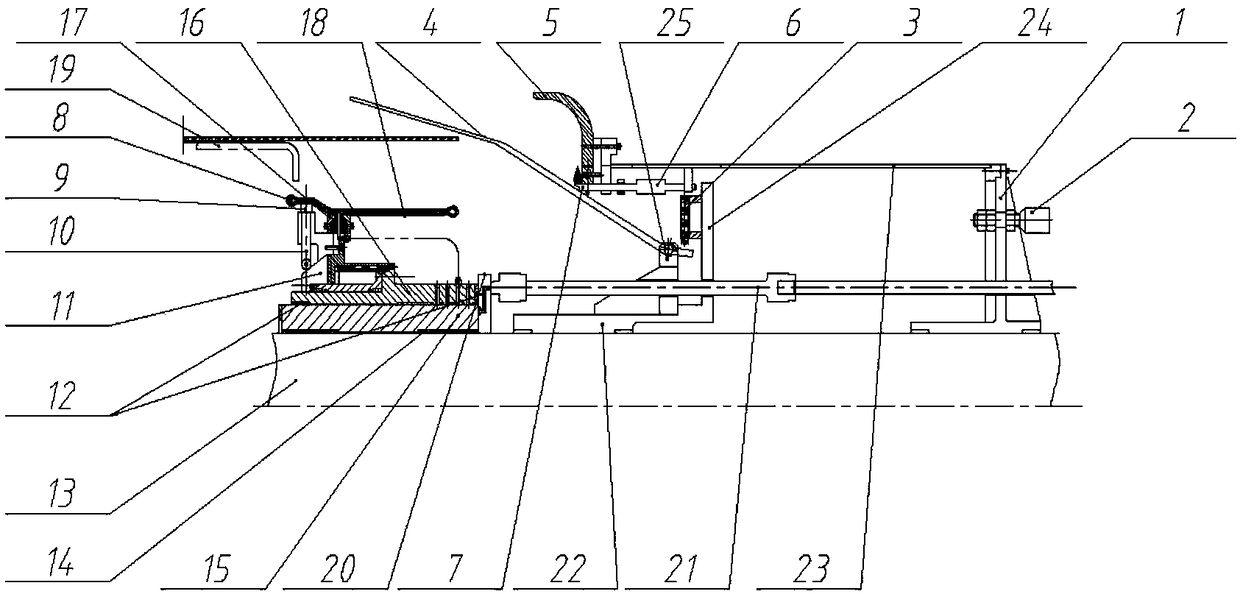

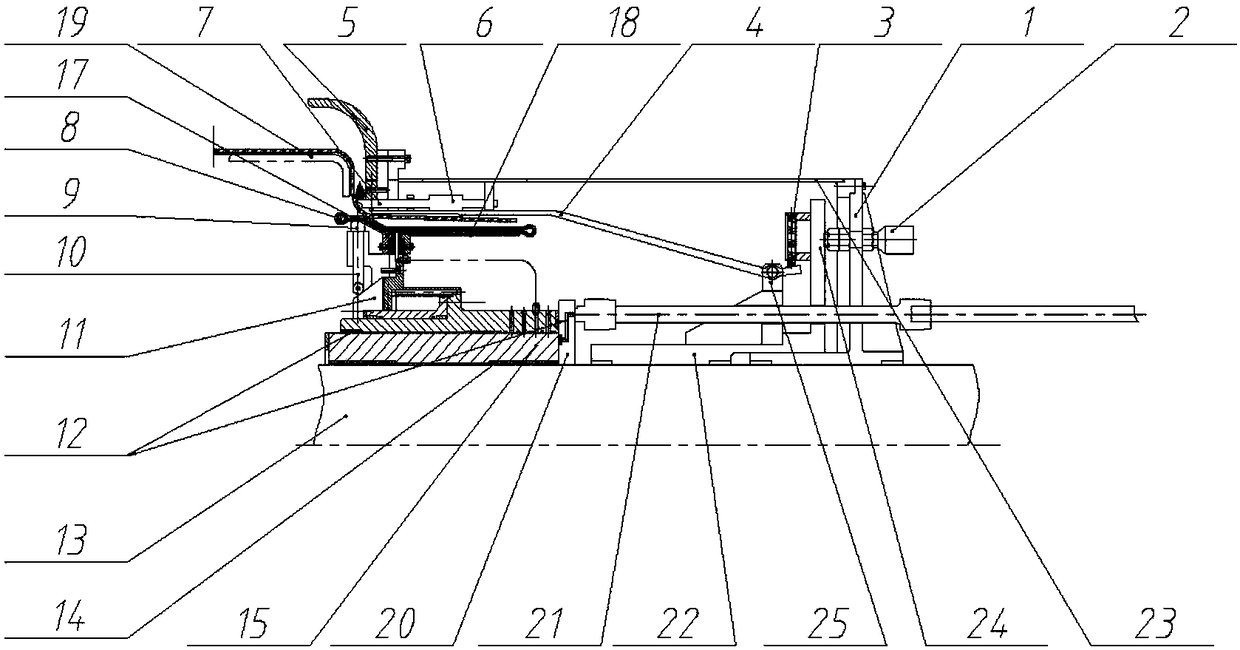

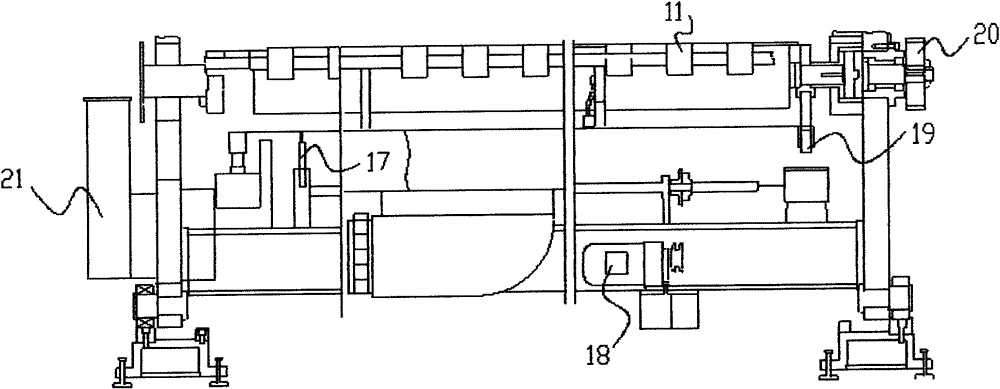

Tire forming machine

The invention discloses a tire forming machine which comprises a tire body drum, a belt layer drum and a forming drum. The tire forming machine further comprises a first tire body transmission device which is located between the tire body drum and the forming drum to achieve transmission of a first tire body assembly between the tire body drum and the forming drum, and a second tire body transmission device which is located between the forming drum and the belt layer drum to achieve transmission of a second tire body assembly between the forming drum and the belt layer drum. The first tire body transmission device can rotate. The belt layer drum, the second tire body transmission device, the forming drum, the first tire body transmission device and the tire body drum are sequentially arranged on the same axis.

Owner:EVE RUBBER RES INST +1

Data transmission device and method

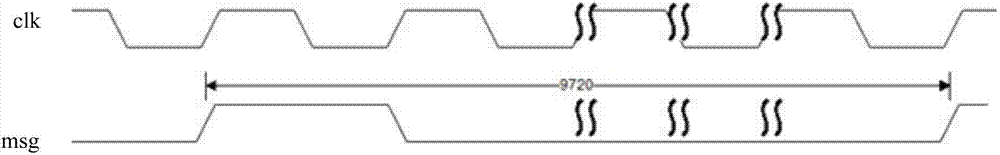

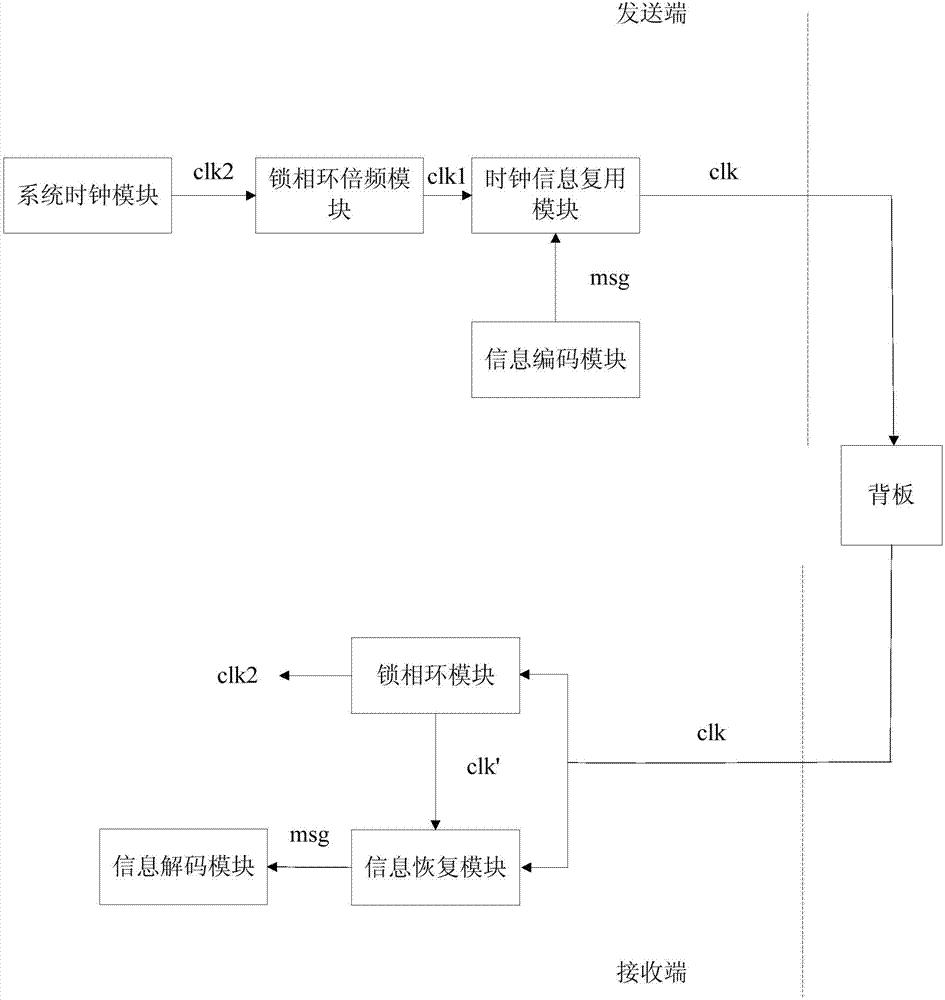

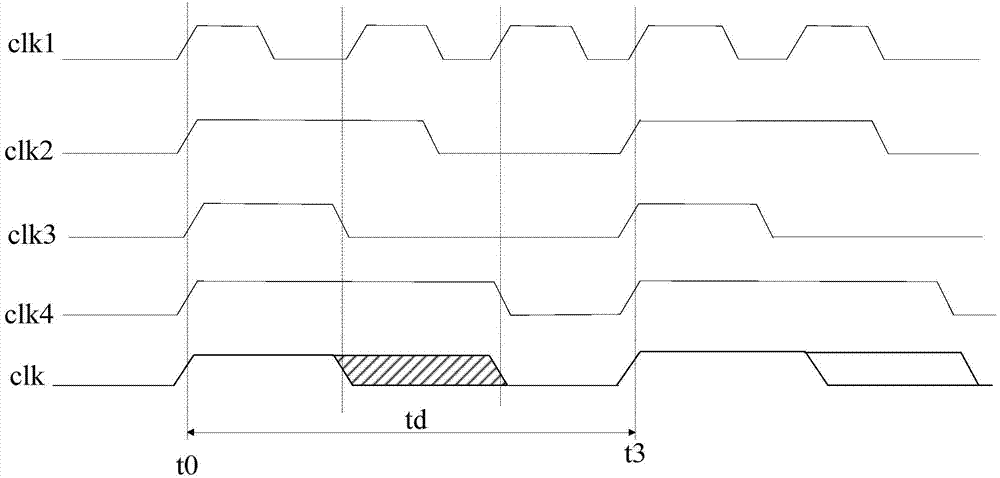

ActiveCN103763090AGuaranteed delivery accuracyRealize transmissionError preventionSynchronising arrangementCode moduleMultiplexing

The invention discloses a data transmission device. The data transmission device comprises a sending end, a system clock module, a phase-locked loop frequency doubling module, an information coding module, a clock information multiplexing module, a receiving end, a phase-locked loop module, an information recovery module and an information decoding module, wherein the system clock module is used for generating system clock signals, the phase-locked loop frequency doubling module is used for generating frequency doubling clock signals according to the system clock signals, the information coding module is used for generating discrete digital coding signals to be jointly transmitted to the clock information multiplexing module, the clock information multiplexing module is used for generating coding clock signals to be transmitted to a backplane according to the digital coding signals, the phase-locked loop module is used for generating recovery clock signals according to the received coding clock signals, the information recovery module is used for sampling the coding clock signals according to the recovery clock signals and restoring the coding clock signals to obtain the digital coding signals, and the information decoding module is used for decoding the digital coding signals to obtain digital information. In this way, transmission of the clock signals and the information signals can be achieved only through one bus, and backplane buses are saved. The invention further provides a data transmission method.

Owner:北京格林伟迪科技股份有限公司 +1

Paper bag head card machine and paper bag head card conveying device thereof

InactiveCN104260418AStable outputAccurate and stable outputPaper-makingBox making operationsProgrammable logic controllerControl system

The invention discloses a paper bag head card machine and a paper bag head card conveying device thereof. The paper bag head card conveying device comprises a fixed frame, a first control system, a first power transmission device and a second power transmission device, the first power transmission device and the second power transmission device are sequentially arranged on the fixed frame from left to right, a head card paper push device is arranged on the first power transmission device, and a paper supporting device for auxiliary conveying is arranged at the front end of the first power transmission device. By the aid of the paper bag head card conveying device, the problems of a head card of an existing traditional sticker bag are effectively solved, mechanical action replaces existing manual operation, positioning devices are arranged on two sides and at the upper end when head card paper is conveyed, and conveying accuracy is effectively ensured. In the device, a servo motor is matched with a first PLC (programmable logic controller) unit, each piece of head card paper can be accurately positioned and conveyed, mass production of the paper bag head card is achieved, production efficiency is improved, labor cost is reduced, and huge economic benefits are created.

Owner:WENZHOU ZENBO PRINTING MACHINERY

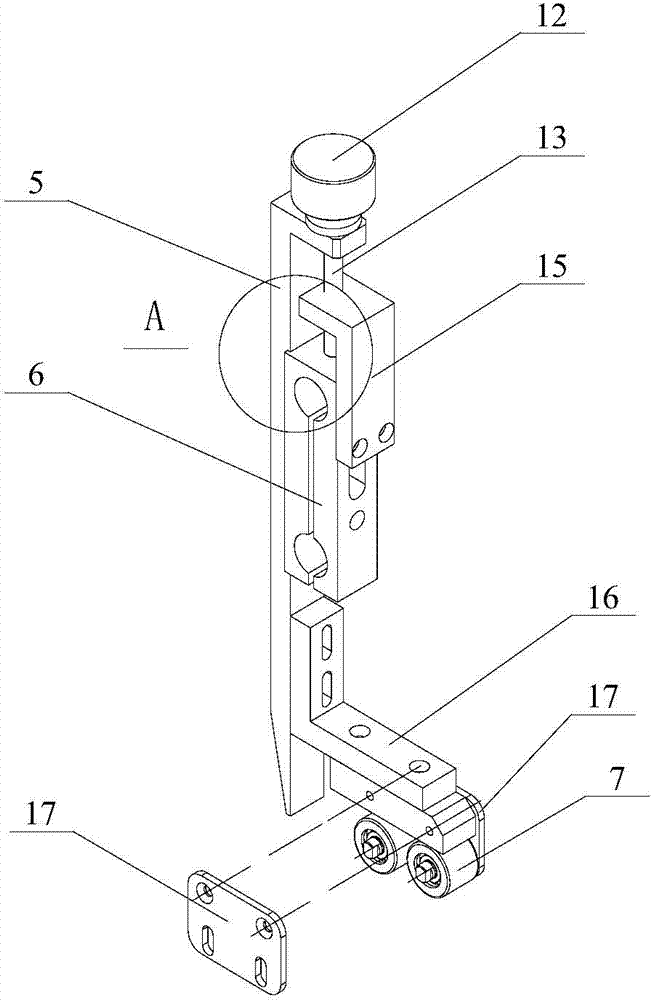

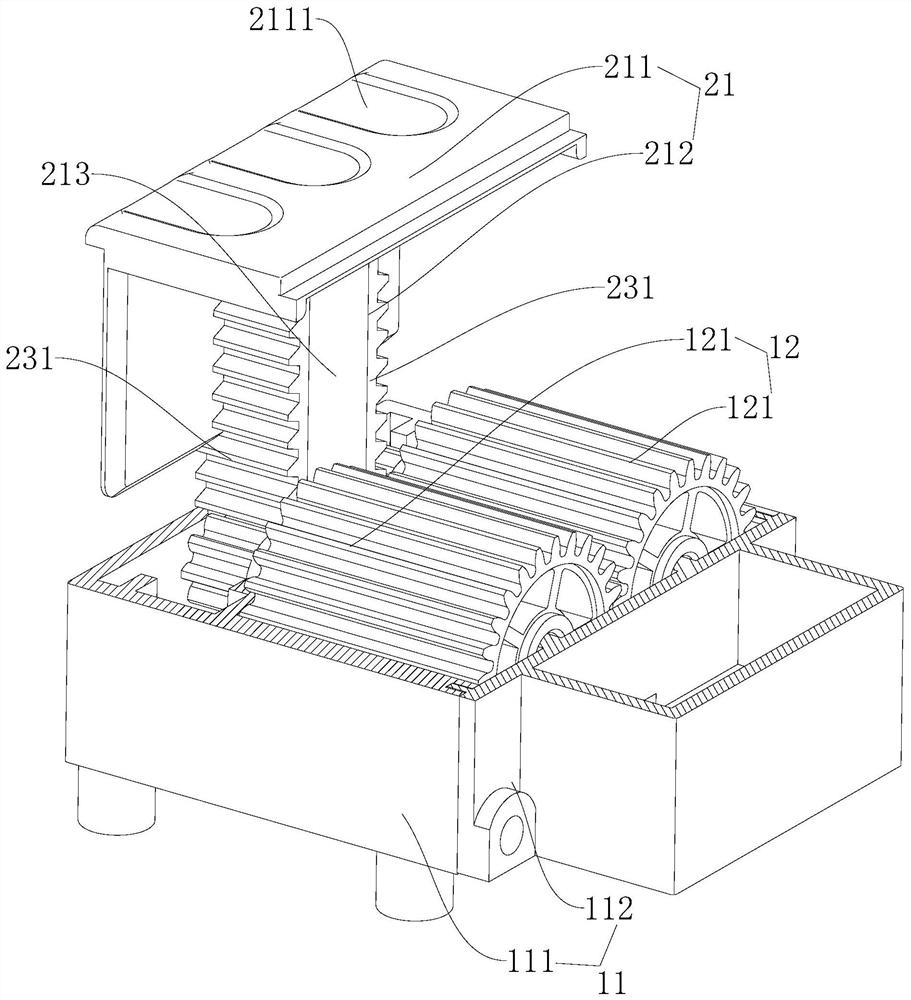

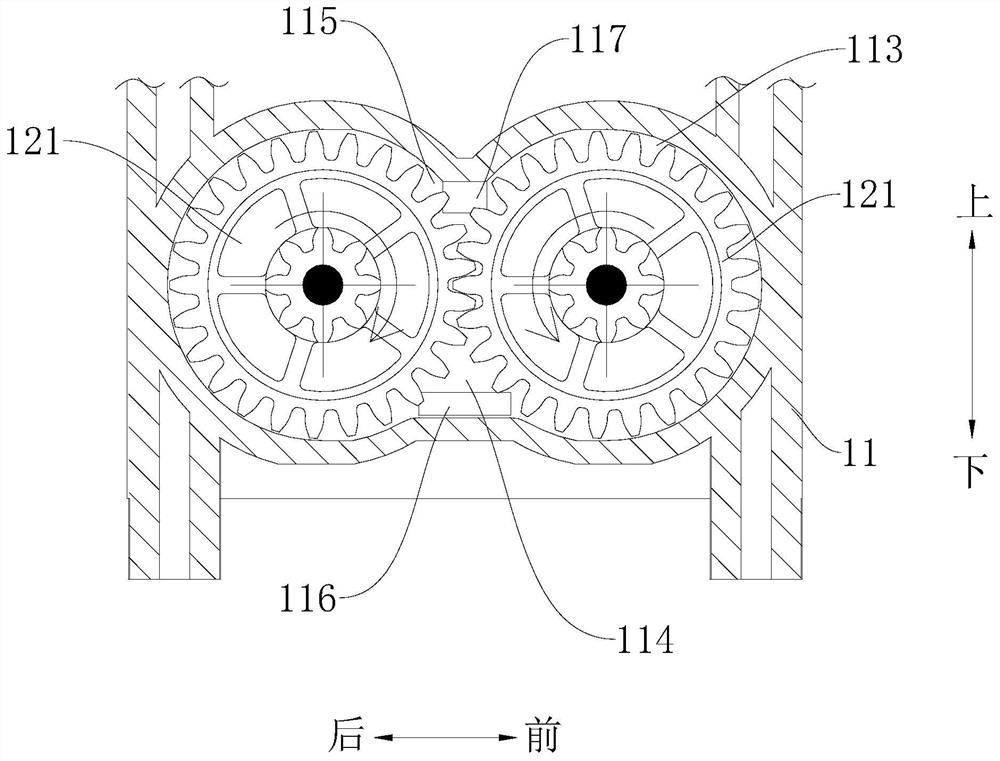

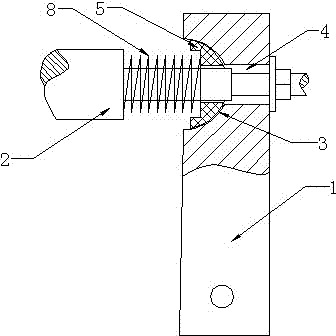

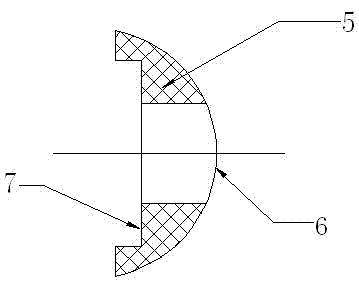

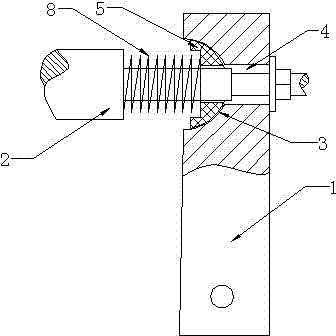

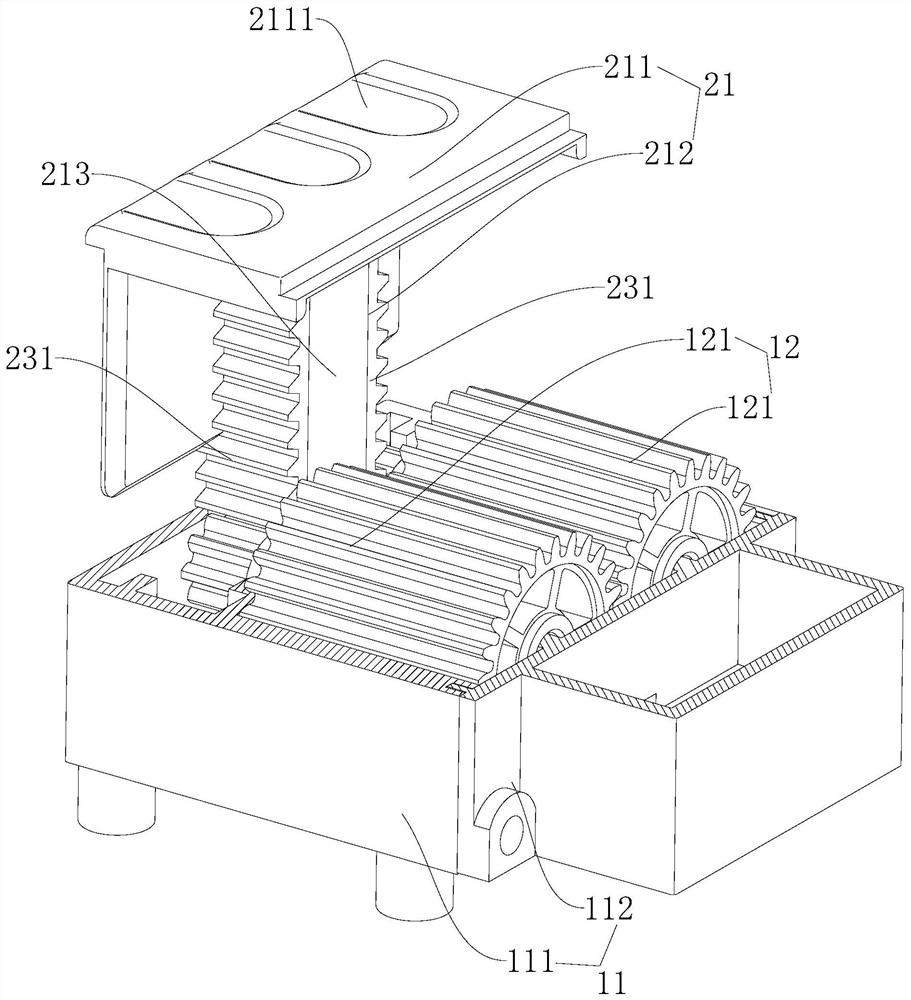

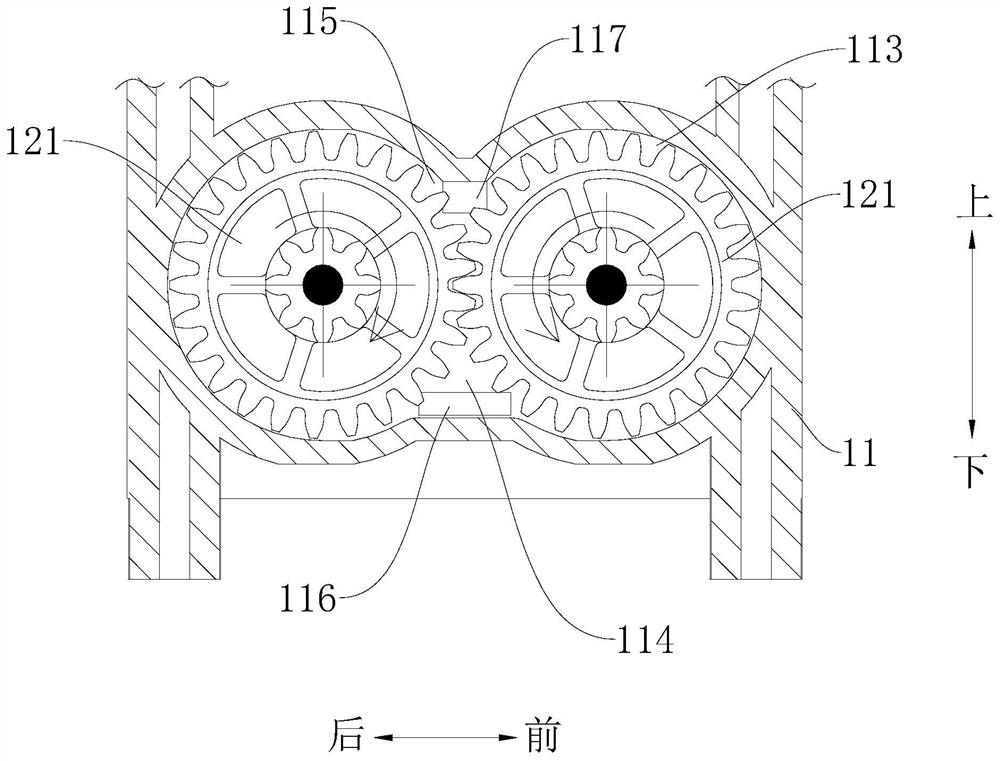

Conveying mechanism of corrugated pipe cut-off machine

InactiveCN104608180AReasonable designSimple structureMetal working apparatusEngineeringMechanical engineering

The invention relates to pipe cut-off equipment, in particular to a conveying mechanism of a corrugated pipe cut-off machine. The conveying mechanism comprises a base, a first conveying wheel and a second conveying wheel, wherein the first conveying wheel and the second conveying wheel are oppositely arranged on the base and are opposite in rotating direction, and the outer circumferential surface of the first conveying wheel and the outer circumferential surface of the second conveying wheel are provided with clamping blocks which are combined with a conveyed pipe in a clamped mode. By the adoption of the conveying mechanism of the corrugated pipe cut-off machine, the stress of the pipe is more uniform and stable in the conveying process, and the pipe is not prone to sliding even if large pull force exists at the feeding end.

Owner:SUZHOU HUISIFU AUTOMATION TECH

Tire molding method

The invention relates to a tire molding method. The tire molding method comprises the following steps: (1) a tire body component coats a tire body drum; (2) the prepared tire body component is turned down; (3) the bead setter is performed for the tire body component; (4) the tire locking is performed for the tire body component; and (5) the turned-down tire body component is turned up.

Owner:EVE RUBBER RES INST +1

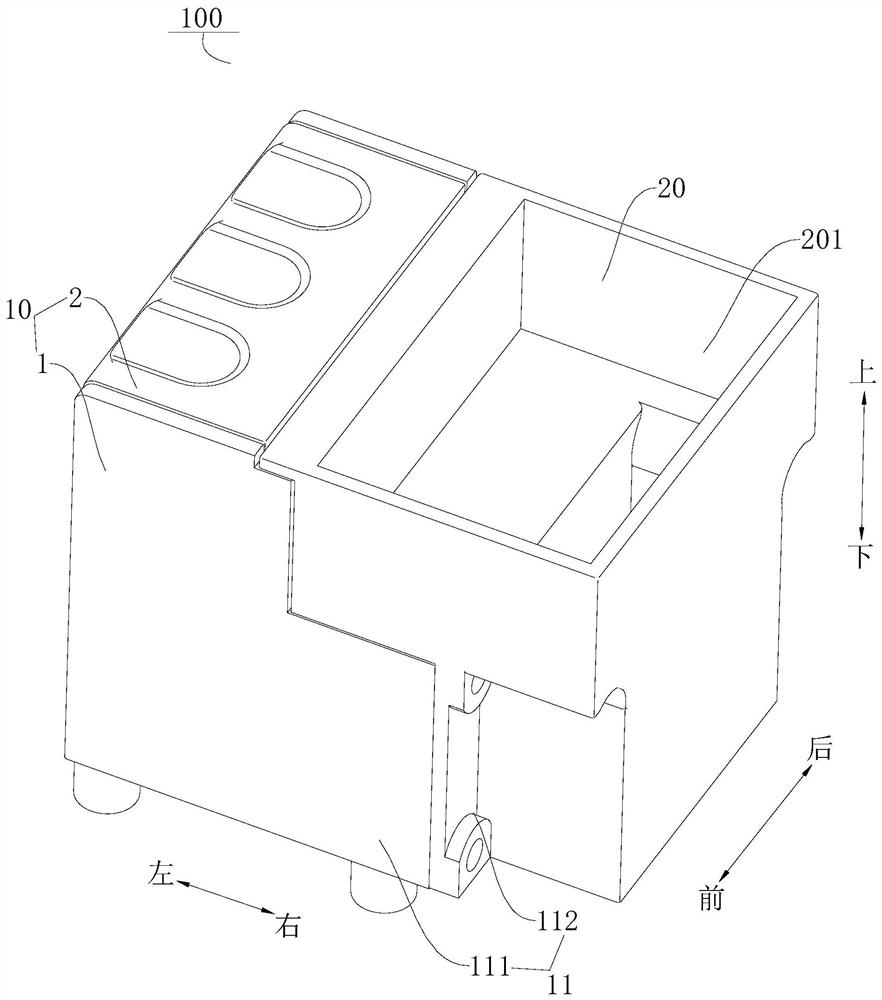

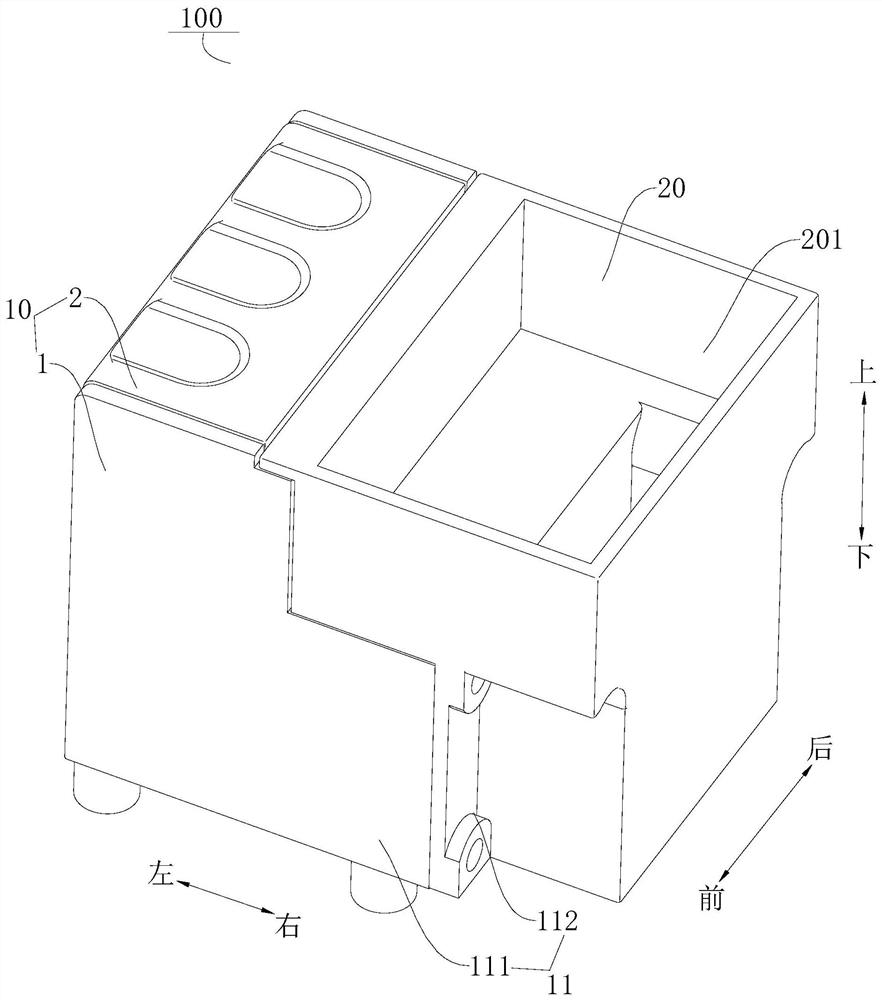

Feeding device, feeding assembly with feeding device and washing equipment

ActiveCN113249935AImprove performanceIncrease the single delivery volumeTableware washing/rinsing machine detailsOther washing machinesEngineeringMechanical engineering

The invention discloses a feeding device, a feeding assembly with the feeding device and washing equipment. The feeding device is used for feeding a washing agent and comprises a feeding pump and a driving assembly; the feeding pump comprises a pump shell and a pump body; the pump body is rotatably arranged in the pump shell, so that a liquid suction area and a liquid drainage area are formed in the pump shell; a liquid inlet corresponding to the liquid suction area and a liquid outlet corresponding to the liquid discharge area are formed in the pump shell; the driving assembly is connected with the pump body; the driving assembly comprises a driving piece; and the pump body is driven to move through movement of the driving piece. According to the feeding device provided by the embodiment of the invention, the washing agent can be fed by moving the driving piece, the liquid suction area and the liquid discharge area of the feeding pump are located in different areas in space, and when the feeding device works normally, liquid suction and liquid discharge of the feeding pump can be synchronously completed in time, so that the single-time feeding amount of the feeding device can be increased, and the feeding precision of single-time feeding is guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

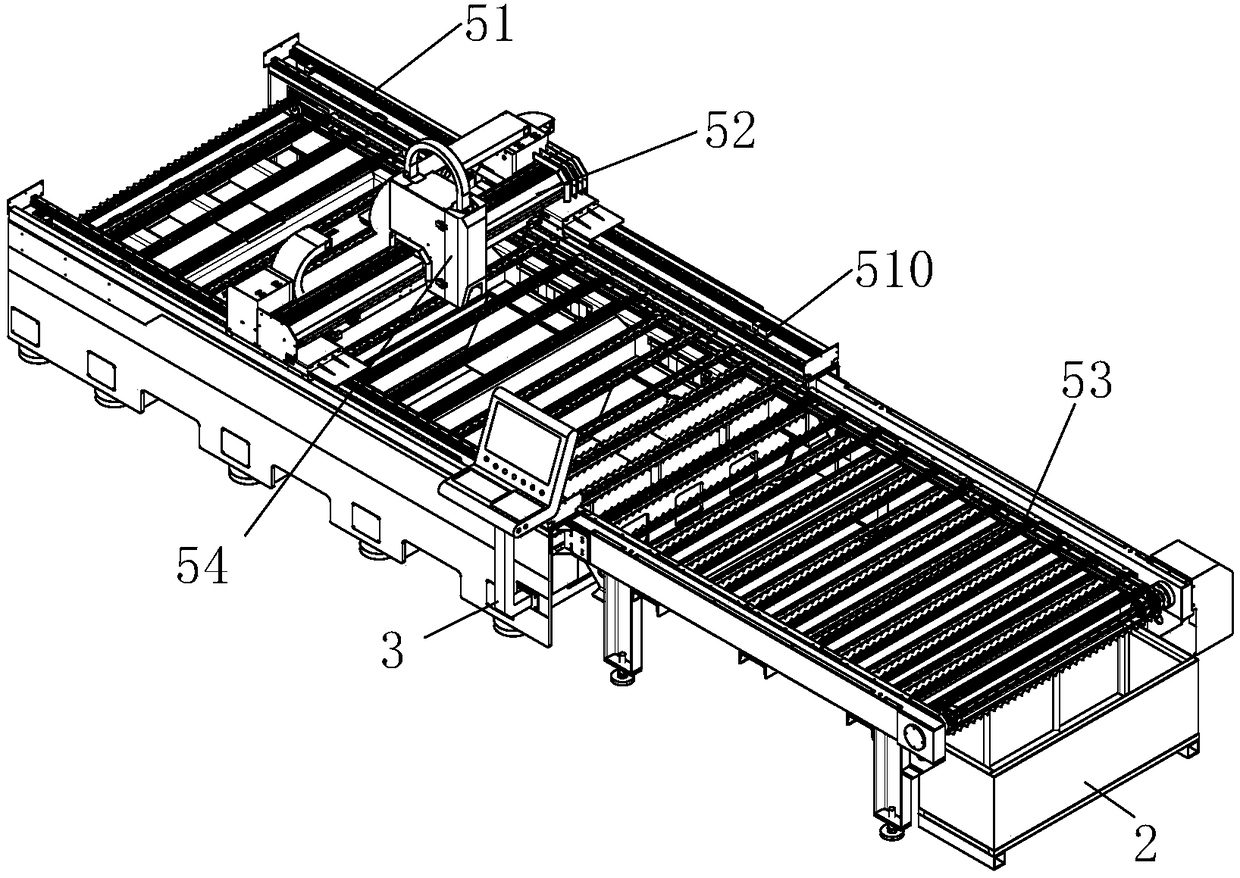

Automatic-feeding laser cutting equipment

PendingCN108406138AGuaranteed delivery accuracyGuaranteed left and right position accuracyLaser beam welding apparatusLaser cuttingEngineering

The invention relates to coil stock machining, in particular to automatic-feeding laser cutting equipment. According to the automatic-feeding laser cutting equipment, the structure is simple, the working efficiency is improved, and the cost is saved. The automatic-feeding laser cutting equipment sequentially comprises a feeding device and a laser cutting device. The feeding device is used for conveying a plate and comprises a feeding machine body, a supporting table top, a sliding block, a feeding trolley, a hydraulic oil cylinder, upper compressing blocks and lower compressing blocks; supporting columns are arranged at the four corner ends of the feeding machine body correspondingly, the supporting table top is arranged on the four supporting columns, and sliding holes are parallelly formed in the supporting table top; the sliding block is in a plate shape, a penetrating hole is formed in the middle of the sliding block, and the supporting table top is located in the penetrating hole;and a first connecting block and a second connecting block are arranged on the two sides, located on the upper portion of the penetrating hole, of the sliding block, and the upper compressing blocksare connected to the bottom faces of the first connecting block and the second connecting block. The automatic-feeding laser cutting equipment has the efficient production capability, and the plate utilization rate is increased by a large margin.

Owner:江苏扬力数控机床有限公司

Tire building machine

The invention relates to a tire building machine. The tire building machine comprises a transfer ring device, a supporting device, a rotating device, an encapsulation device, a balance device and a base device, wherein the rotating device is mounted above the base device; the encapsulation device is mounted on one side of the rotating device; the supporting device is mounted on the other side of the rotating device; the transfer ring device is mounted on the supporting device; the transfer ring device, the supporting device, the rotating device and the encapsulation device can rotate together; the balance device is mounted on the supporting device; a balance base is mounted on the base device; and the balance device is supported on the balance base in a separable manner.

Owner:EVE RUBBER RES INST +1

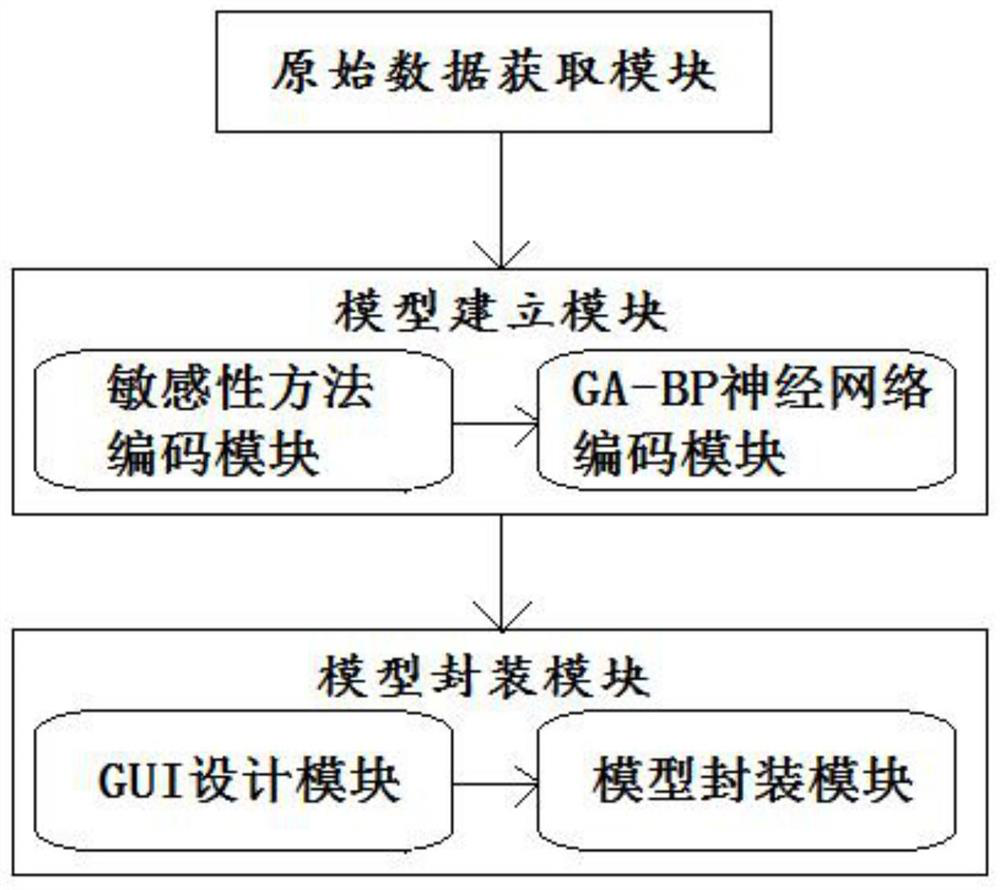

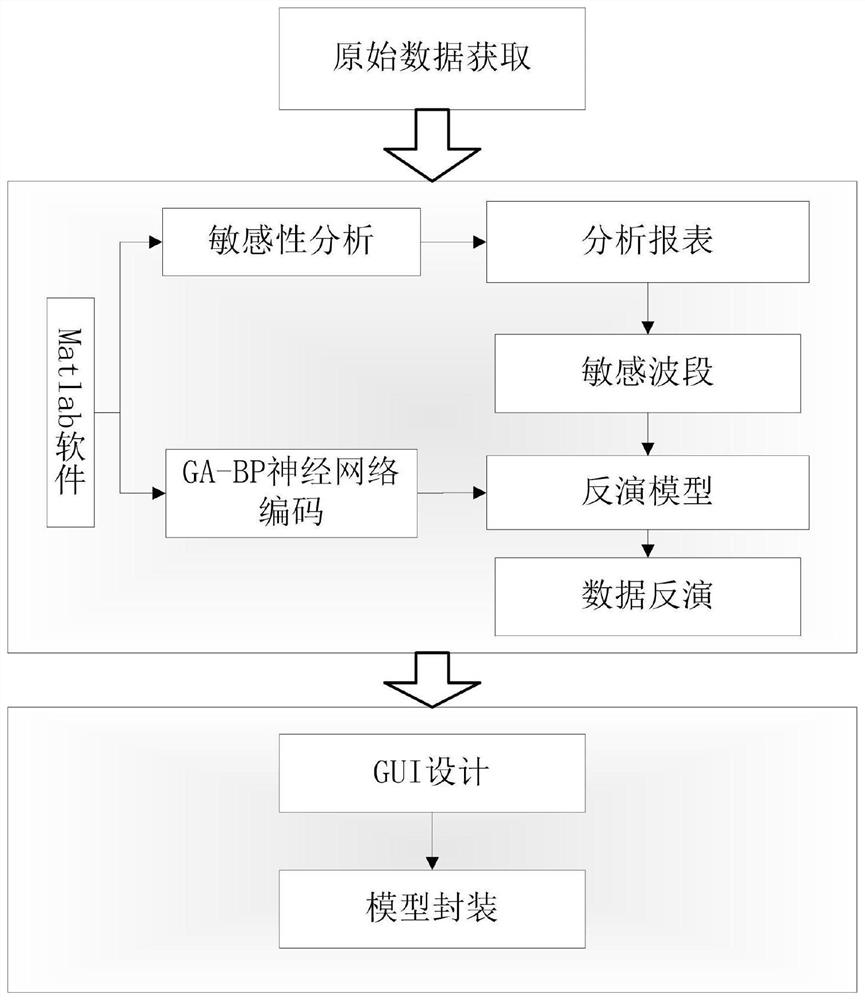

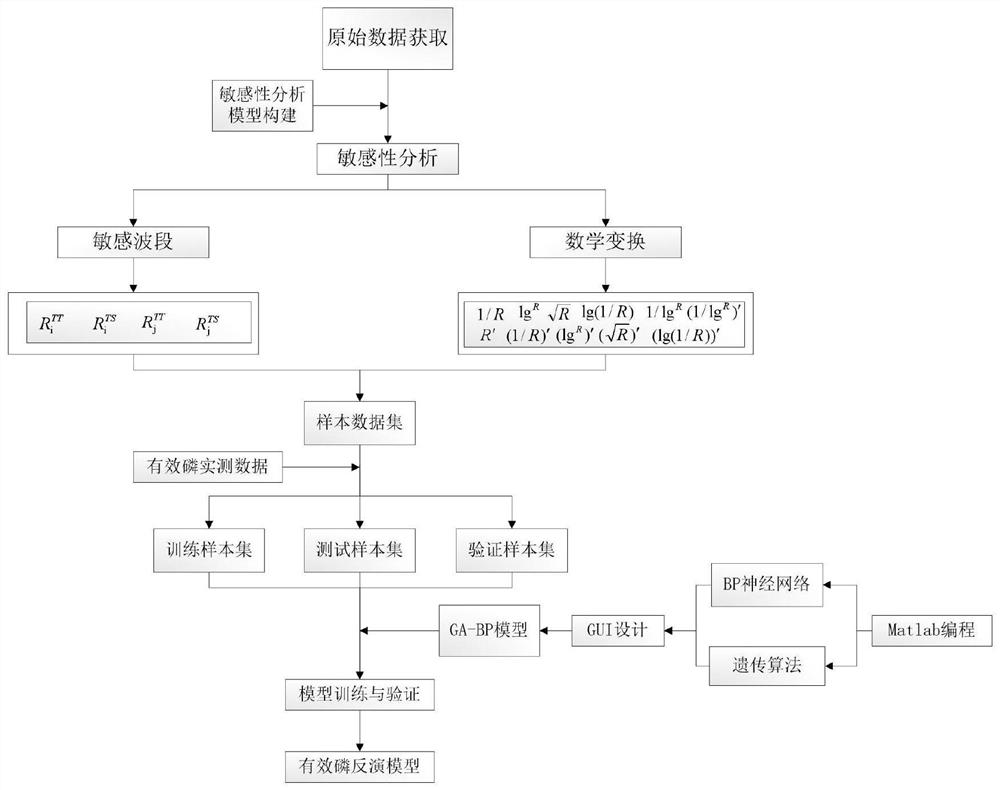

System and method for constructing soil available phosphorus analysis model based on satellite images

InactiveCN112733780AHigh precisionAccurate valueScene recognitionNeural learning methodsWave bandSatellite image

The invention discloses a system and a method for constructing a soil available phosphorus analysis model based on a satellite image, and aims to solve the problems that time and labor are consumed, the cost is high and accurate and comprehensive fertilization cannot be realized when the soil available phosphorus content is used for guiding fertilization. According to the invention, a Spearman sensitive analysis technology and a GA + BP neural network algorithm are adopted, a soil available phosphorus inversion model is established by applying matlab programming and GUI design, pixel-by-pixel fine analysis technologies are carried out by applying multiple parameters such as sensitive wave bands, sensitive wave band mathematical transformation and field soil sample acquisition data, quantitative analysis is carried out on available phosphorus of soil fertilization, and thus obtaining soil available phosphorus content distribution raster data of the target area before sowing; compared with a traditional method, the remote sensing technology is used for processing satellite image data, the Matlab technology is used for completing model construction, the GIS technology is combined for completing correlation and grid vectorization of reflectivity information and soil sample data and guiding fertilization prescription map making, the production cost can be saved, the production efficiency is improved, and the purpose of farmland protection is achieved.

Owner:哈尔滨航天恒星数据系统科技有限公司

Multi-angle punching machine

PendingCN110280651AGuaranteed fixed effectGuaranteed accuracyMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a multi-angle punching machine which comprises a machine body, wherein raw material clamping and feeding mechanisms are installed on two ends of the machine body in a sliding manner; a multi-angle punching machine head is disposed on the machine body located between the two raw material clamping and feeding mechanism; a raw material positioning and transport guiding mechanism is disposed inside the multi-angle punching machine head; a core rod is disposed inside the raw material positioning and transport guiding mechanism; a core rod supporting mechanism is disposed between one end of the core rod and a rack; and the core rod supporting mechanism passes through one of the raw material clamping and feeding mechanism. The machine has the beneficial effects that multi-direction punching of a raw material can be completed with one time of feeding, feeding of multiple times is not needed, feeding processes are simplified, working efficiency is increased, and precision of positioning and punching is high; and meanwhile, online punching of a clamped area of the raw material is realized through alternate clamping of the raw material by the two raw material clamping and feeding mechanism, the raw material do not need to be sawn and cut in comparison with traditional tools, the raw material is not wasted, processes of sawing and cutting are saved, production efficiency of a finished material is greatly increased, and processing precision of the finished material is effectively ensured.

Owner:张家港市诺恩机械有限公司

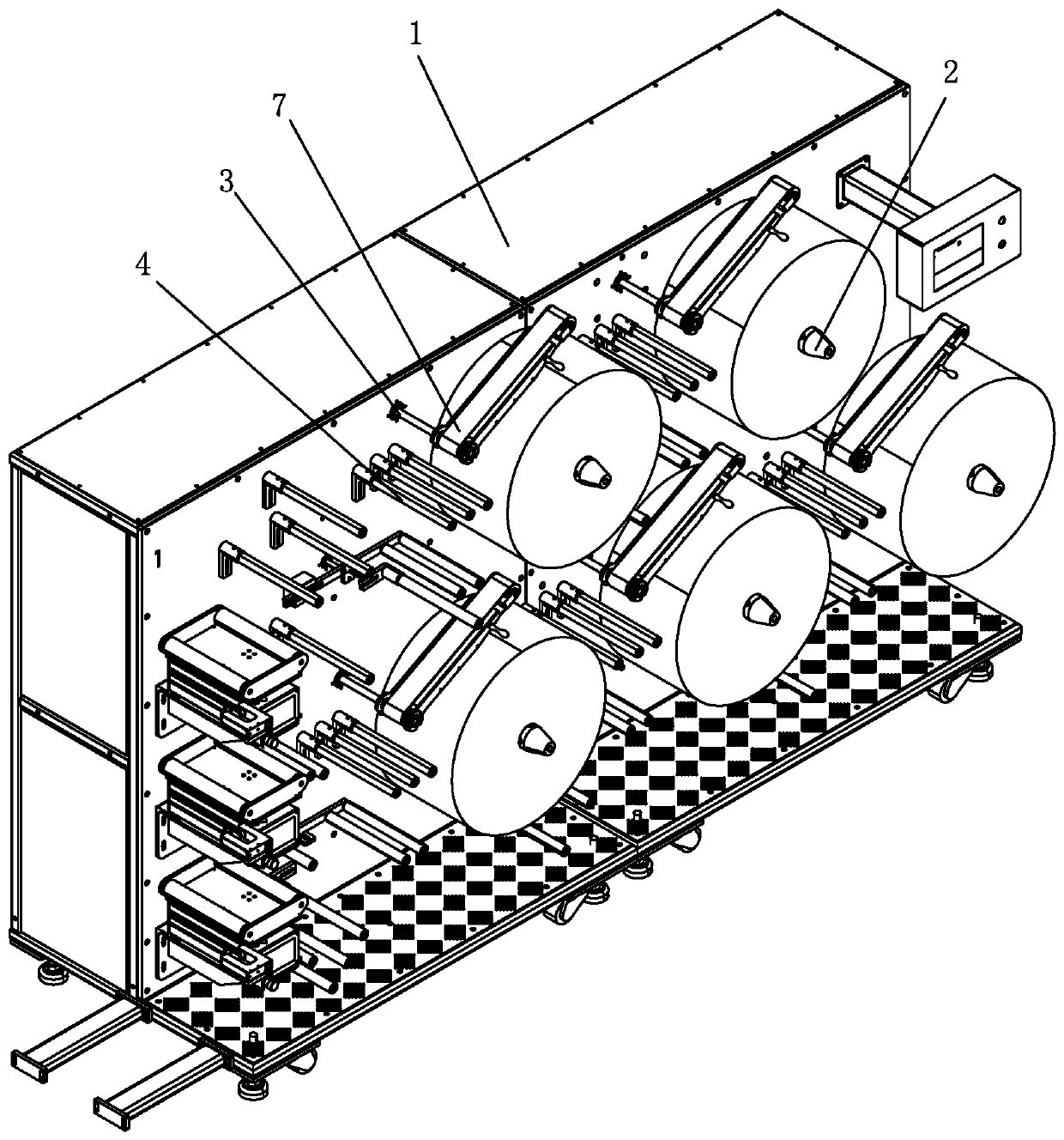

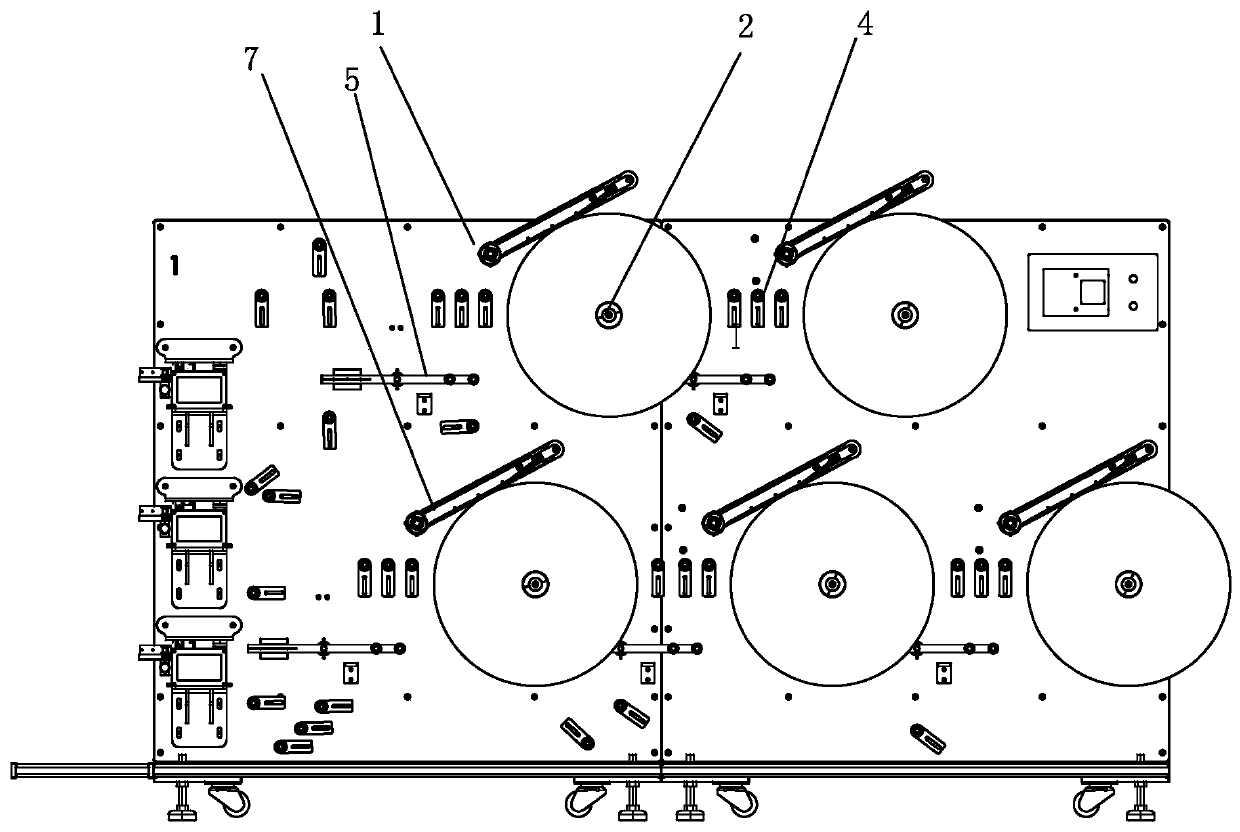

Constant tension conveying mechanism of material unit

InactiveCN111573371AGuaranteed delivery accuracyQuality assuranceWebs handlingTransmission beltEngineering

The invention discloses a constant tension conveying mechanism of a material unit. The mechanism comprises an equipment body, a free swing transmission belt, a belt rotating speed controller, a material conveying roller unit and a tension detection controller, wherein a roll material rotating shaft for mounting a roll material is arranged on the equipment body; the free swing transmission belt isarranged on one side of the roll material rotating shaft and clings to the surface of the material to deliver and drive the material; the belt rotating speed controller is connected to the free swingtransmission belt and is used for controlling the belt rotating speed of the free swing transmission belt; the material conveying roller unit is arranged on one side of the roll material rotating shaft and is connected to the material to assist in material output; and the tension detection controller is arranged on one side of the material conveying roller unit and is connected to and conveys thematerial and detects the tension of the material. The constant tension conveying mechanism can adjust the tension automatically to guarantee smooth conveyance without adjusting the tension manually, so that the conveying precision and the conveying quality of the material are guaranteed. The constant tension conveying mechanism is simple in structure and convenient to use.

Owner:中山达远智造有限公司

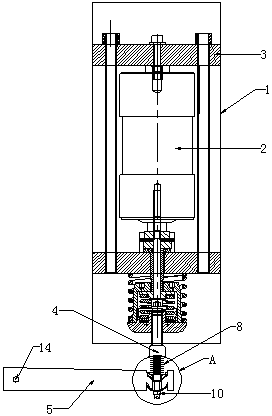

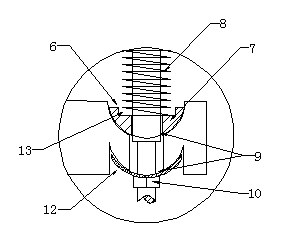

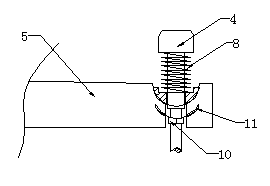

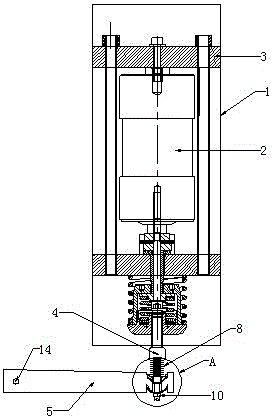

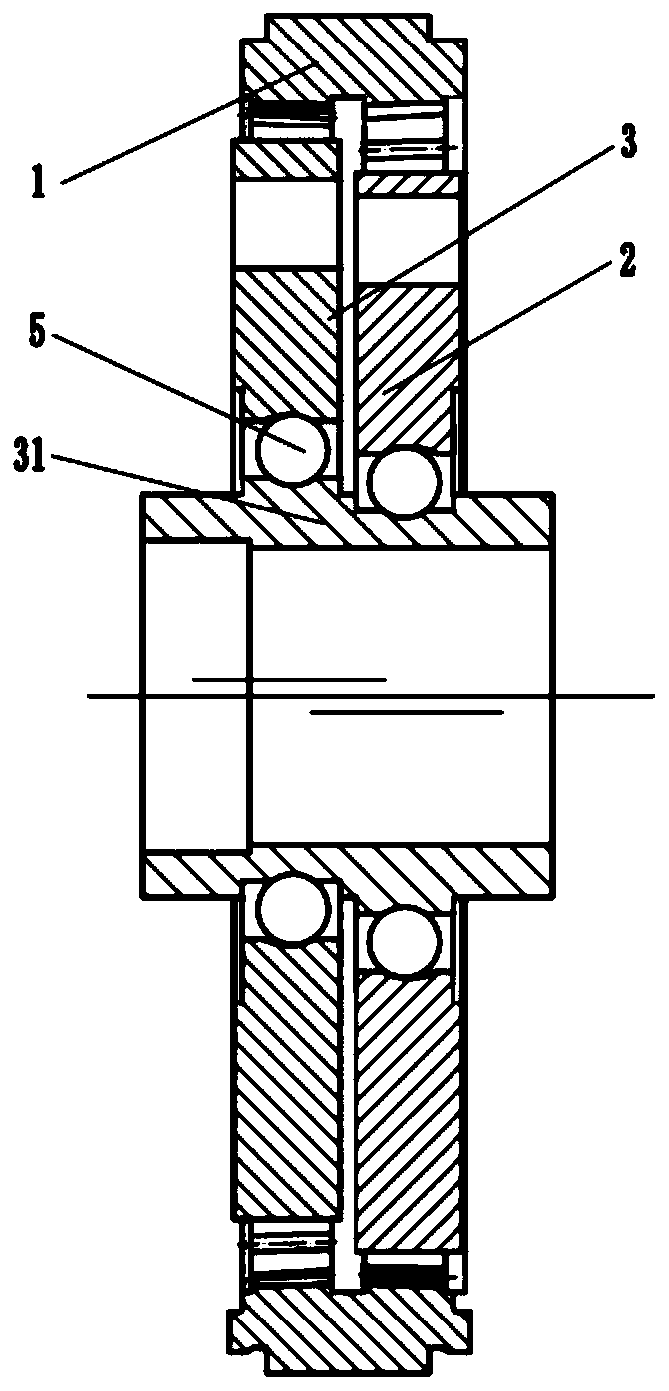

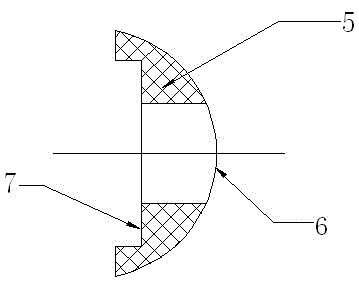

Vacuum circuit breaker

ActiveCN103700538AStable working parametersReduce wearHigh-tension/heavy-dress switchesAir-break switchesStress concentrationWear resistant

The invention discloses a vacuum circuit breaker, comprising a shell and a vacuum arc-extinguishing chamber, wherein the upper end of the vacuum arc-extinguishing chamber is provided with a current-conducting plate, a movable contact at the lower end of the vacuum arc-extinguishing chamber is connected with a push rod, the lower part of the push rod is provided with a driving plate, one end of the driving plate is arranged on supporting point, the upper end of the driving plate is provided with an upper groove, a wear-resistant block is arranged in the upper groove, the center of the wear-resistant block is provided with a central hole, a compressing spring is pressed between the driving plate and a step in the middle of the push rod, the rear end of the compressing spring is pressed on the front end face of the wear-resistant block, the lower half part of the driving plate is provided with an arc-shaped groove, the rear end of the push rod penetrates through piercing holes, the tail end of the push rod is provided with a limiting nut which is adapted to the arc-shaped groove in contour shape, the area of the limiting nut is smaller than the area of the arc-shaped groove, and the limiting nut is enabled to be positioned in the arc-shaped groove. After the structure is adopted, stress concentration caused by complete rigid vertical connection between the driving plate and the push rod traditionally is completely changed, and wear is effectively reduced.

Owner:北京交通大学长三角研究院

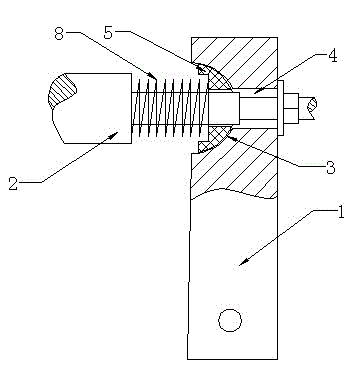

Breaker manipulator

ActiveCN102412088AStable working parametersReduce wearHigh-tension/heavy-dress switchesAir-break switchesEngineeringSupport point

The invention discloses a part of a breaker, and particularly relates to a breaker manipulator. The breaker manipulator comprises a manipulator and a push rod connected with a vacuum arcing chamber moving contact part, wherein the manipulator swings around an installation supporting point; the upper end of the manipulator is provided with a semispherical indentation, the rear end of the push rod passes through a cross-under hole arranged at the center of the semispherical indentation and is a spacing nut, and a compression spring is pressed between the manipulator and a step at the middle part of the push rod; and a wear-resistant block is arranged on the semispherical indentation and matched with the semispherical indentation, the center of the wear-resistant block is provided with a center hole through which the push rod can pass, and rear end of the compression spring is pressed on the front end face of the wear-resistant block. By utilizing the structure, the compression spring iscontacted with the manipulator through the wear-resistant block in a breaker manipulator swinging process so as not to generate friction on the manipulator, the abrasion is effectively reduced, the transferring accuracy is ensured, and the working parameter stabilization of the breaker is improved.

Owner:JIANGSU DAQO CHANGJIANG ELECTRICAL +3

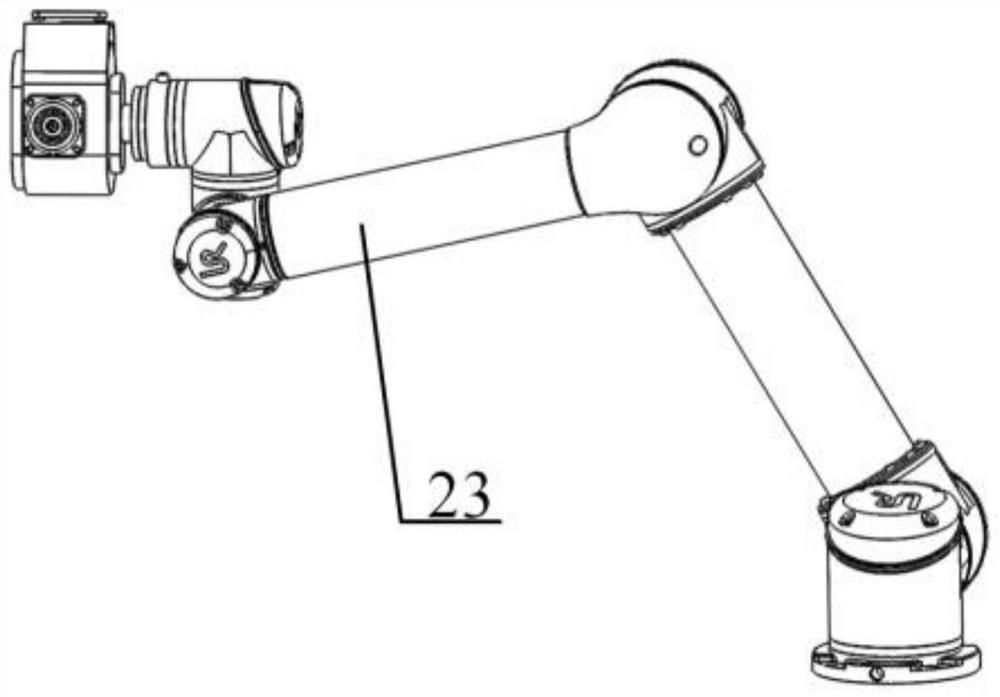

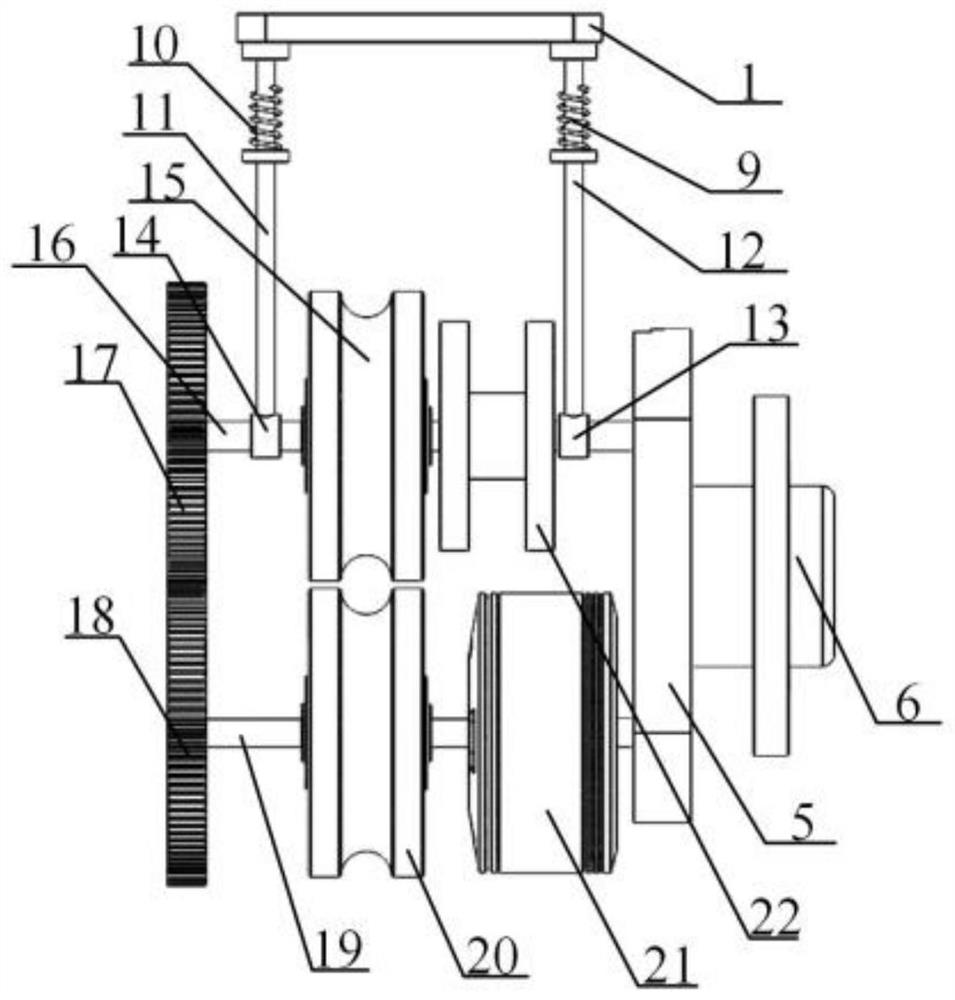

Colonoscope conveying device with force sensing function based on UR mechanical arm

PendingCN111658153ALiberate labor intensityAvoid elastic deformationRectum colonoscopesRectum signoidoscopesIntestinal wallsMechanical engineering

The invention discloses a colonoscope conveying device with a force sensing function based on a UR mechanical arm. The colonoscope conveying device comprises a hand pull rod, a transfer disc, a sliderail frame, a shell, a fixing plate, a hanging rod, a spring, a roller, a gear, a torque sensor and a three-dimensional force sensor. The mode that a doctor manually pushes a colonoscope and rotates acolonoscope body to observe the focus of the intestinal cavity for colon examination is improved, the doctor is liberated from tedious and repeated labor, the colonoscope conveying device can be matched with the doctor to complete the whole process of colon examination operation on a patient, and the torque sensor and the force sensor are arranged on the device to sense the force effect between the colonoscope and the intestinal wall, and a guarantee is provided for intestinal perforation. Compared with a traditional doctor colon examination operation mode, the colonoscope conveying device assists the doctor in colon examination, positioning is accurate, flexibility is high, reliability is high, the diagnosis efficiency can be improved and the pain of the patient can be reduced when the colonoscope conveying device is applied to clinic, and meanwhile a safer operation mode is provided for the doctor.

Owner:HARBIN UNIV OF SCI & TECH

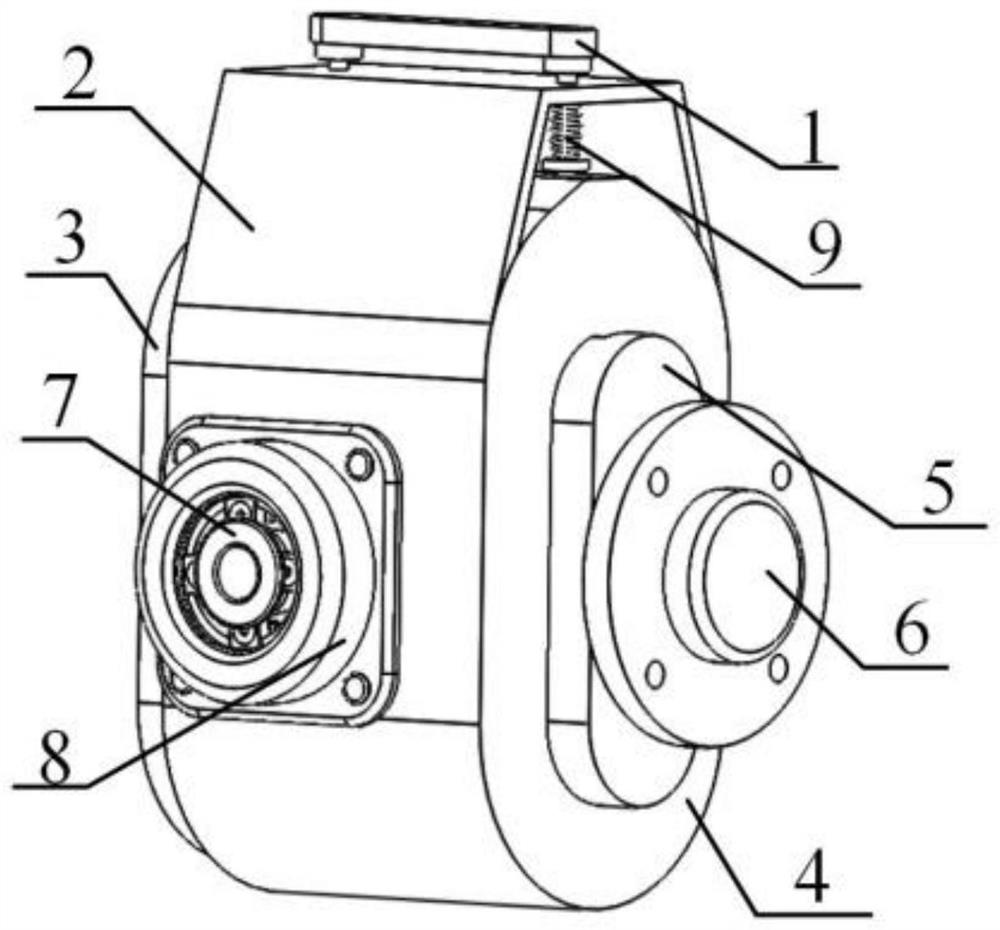

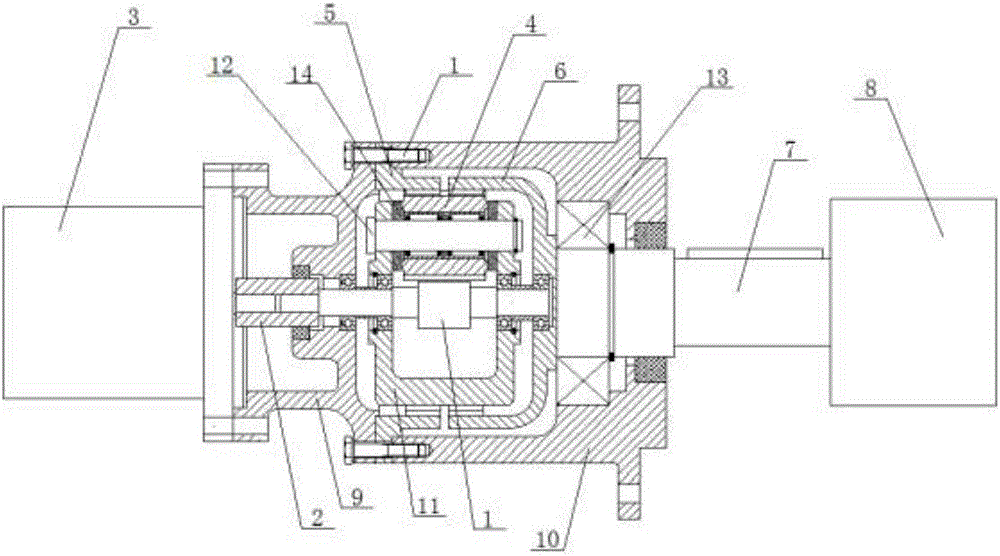

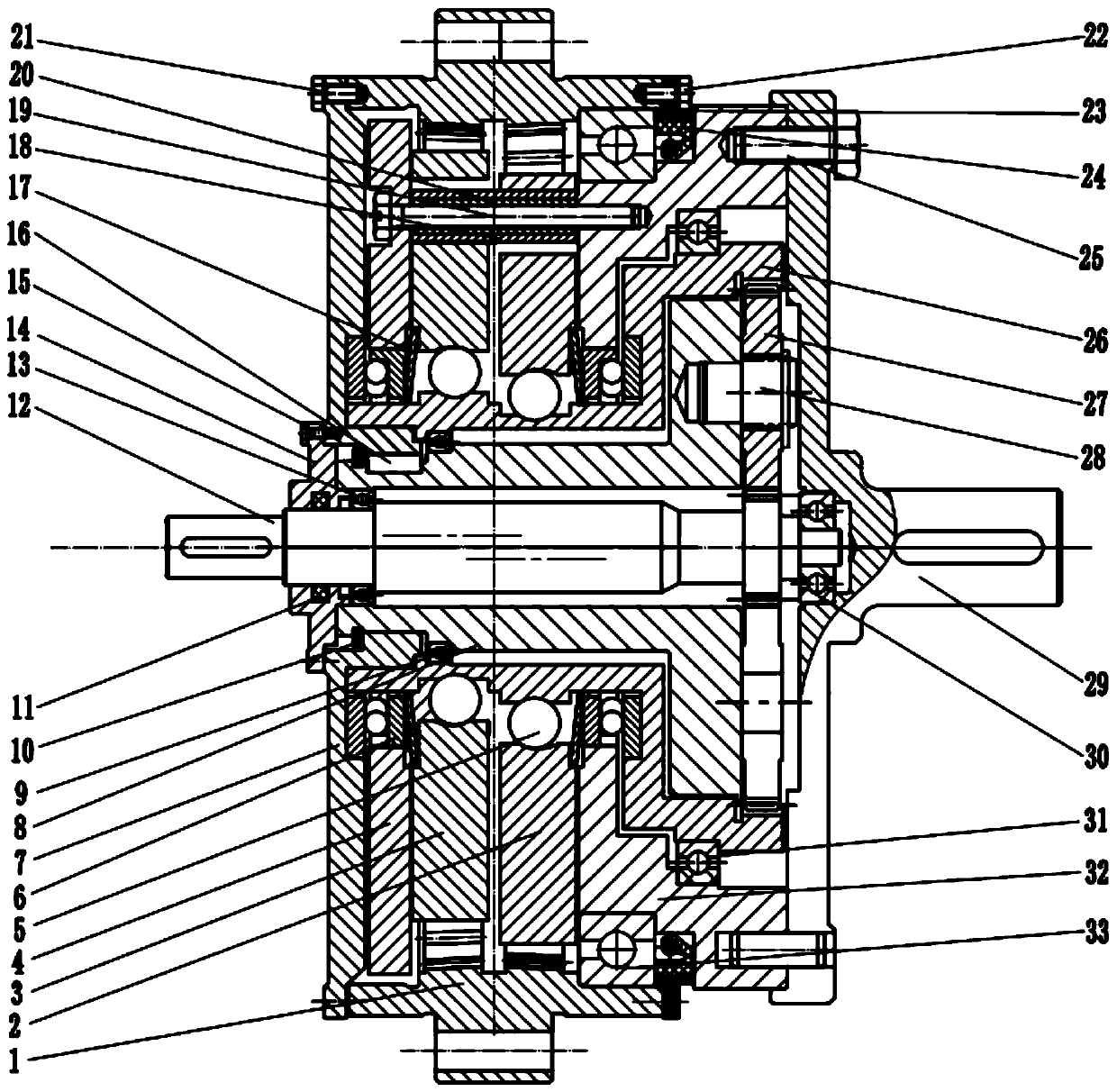

Speed reducer for solar thermal electric power generation

InactiveCN106641114AExpand the range of optionsReduce in quantityToothed gearingsGearing detailsCouplingReduction drive

The invention discloses a speed reducer for solar thermal electric power generation. The speed reducer comprises a box, an input shaft gear is arranged in the box and can be connected with an external motor through a coupler, the input shaft gear is connected with a planet gear which is in meshed connection with a first inner gear ring and a second inner gear ring, and an output shaft is fixedly connected to the second inner gear ring and connected with an external working machine. The planet gear is driven by the input shaft gear, and the output shaft is driven to rotate through the first inner gear ring and the second inner gear ring so as to convert high rotation speed of the motor into plane change movement of mirror planes to make rotation angular rate of the mirror planes accord with solar moving angular rate. Coaxial rotation of an input shaft and the output shaft is realized by the input shaft gear, the first inner gear ring and the second inner gear ring, and widening of a speed ratio selectable range, reduction of parts, lowering of machining difficulty and guarantee of transmission precision and power generation efficiency are realized.

Owner:苏州吾纳德传动技术有限公司

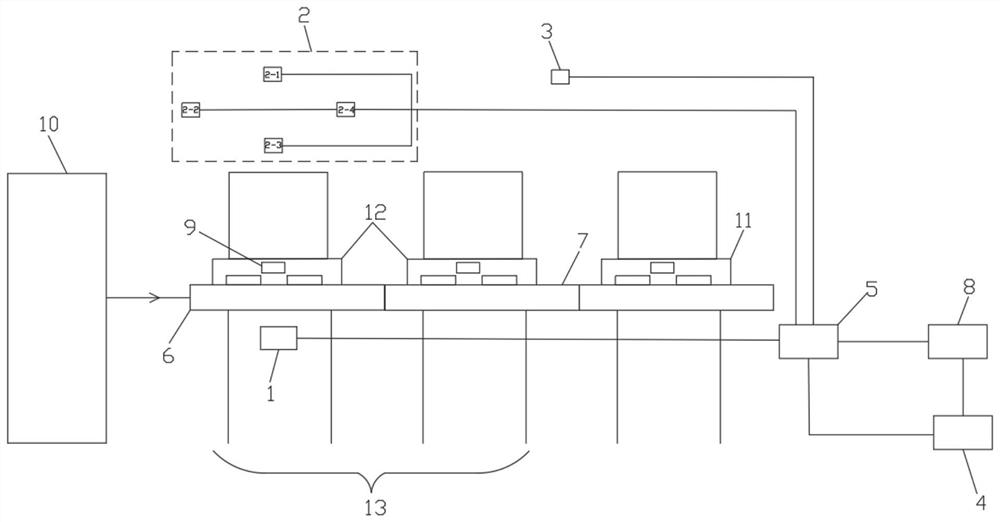

Automatic cigarette material warehouse-out detection device

PendingCN112918978AGuaranteed delivery accuracyQuality assuranceConveyorsControl devices for conveyorsInformation transmissionChain conveyor

The invention provides an automatic cigarette material warehouse-out detection device. According to the automatic cigarette material warehouse-out detection device, a pallet code scanner scans a pallet two-dimensional bar code on a cigarette material pallet passing through a warehouse-out chain conveyor and transmits two-dimensional bar code information to a monitoring computer, the monitoring computer performs information interaction with a cigarette material pallet warehouse system, and the monitoring computer acquires pallet distribution information of the types, specifications and quantity of cigarette materials on the cigarette material pallet through the two-dimensional bar code information; an industrial automatic zoom camera and an intelligent camera identify material object information of the types, specifications and quantity of the cigarette materials on the cigarette material pallet passing through the warehouse-out chain conveyor and send the material object information to the monitoring computer; and the monitoring computer compares and analyzes the acquired information and then judges whether the cigarette materials on the cigarette material pallet are the cigarette materials required by a cigarette material warehouse-out station. According to the scheme, the automatic cigarette material warehouse-out detection device has the advantages that it is guaranteed that the distribution accuracy of the cigarette materials can be 100%, the hidden danger that wrong cigarette materials are distributed to a roll-packing unit can be thoroughly eliminated, and the final product quality of cigarettes is guaranteed.

Owner:CHINA TOBACCO SHAANXI IND

Laser marking and welding machine of jug bodies

ActiveCN107378242AImprove securityHigh precisionLaser beam welding apparatusEngineeringFully automatic

A laser marking and welding machine of jug bodies comprises the processing jug bodies, buckled lugs and a work table. At least two welding stations and at least one marking station are arranged on the work table, wherein the welding stations are used for welding the buckled lugs to the processing jug bodies respectively, the marking stations are used for printing marks on the surfaces of the processing jug bodies, and the marking stations are located above the welding stations. Vibration plates are arranged on the welding stations respectively, the buckled lugs are arranged on the vibration plates respectively, and the processing jug bodies are arranged on the welding stations respectively; the work table is further provided with a robot hanging rack, a robot is arranged on the robot hanging rack, a welding gun clamp is arranged on the robot, the robot moves on the welding stations backwards and forwards through the robot hanging rack, and each buckled lug is welded to the corresponding processing jug body through the welding gun clamp. The laser marking and welding machine has the advantages of being simple and reasonable in structure, excellent in performance, convenient to operate, low in manufacturing cost, easy to produce, easy to implement, fully automatic, intelligent, high in production efficiency, safe, reliable and the like, and the practicability is high.

Owner:GUANGDONG LXD ROBOTICS CO LTD

vacuum circuit breaker

ActiveCN103700538BStable working parametersReduce wearHigh-tension/heavy-dress switchesAir-break switchesStress concentrationWear resistant

The invention discloses a vacuum circuit breaker, comprising a shell and a vacuum arc-extinguishing chamber, wherein the upper end of the vacuum arc-extinguishing chamber is provided with a current-conducting plate, a movable contact at the lower end of the vacuum arc-extinguishing chamber is connected with a push rod, the lower part of the push rod is provided with a driving plate, one end of the driving plate is arranged on supporting point, the upper end of the driving plate is provided with an upper groove, a wear-resistant block is arranged in the upper groove, the center of the wear-resistant block is provided with a central hole, a compressing spring is pressed between the driving plate and a step in the middle of the push rod, the rear end of the compressing spring is pressed on the front end face of the wear-resistant block, the lower half part of the driving plate is provided with an arc-shaped groove, the rear end of the push rod penetrates through piercing holes, the tail end of the push rod is provided with a limiting nut which is adapted to the arc-shaped groove in contour shape, the area of the limiting nut is smaller than the area of the arc-shaped groove, and the limiting nut is enabled to be positioned in the arc-shaped groove. After the structure is adopted, stress concentration caused by complete rigid vertical connection between the driving plate and the push rod traditionally is completely changed, and wear is effectively reduced.

Owner:北京交通大学长三角研究院

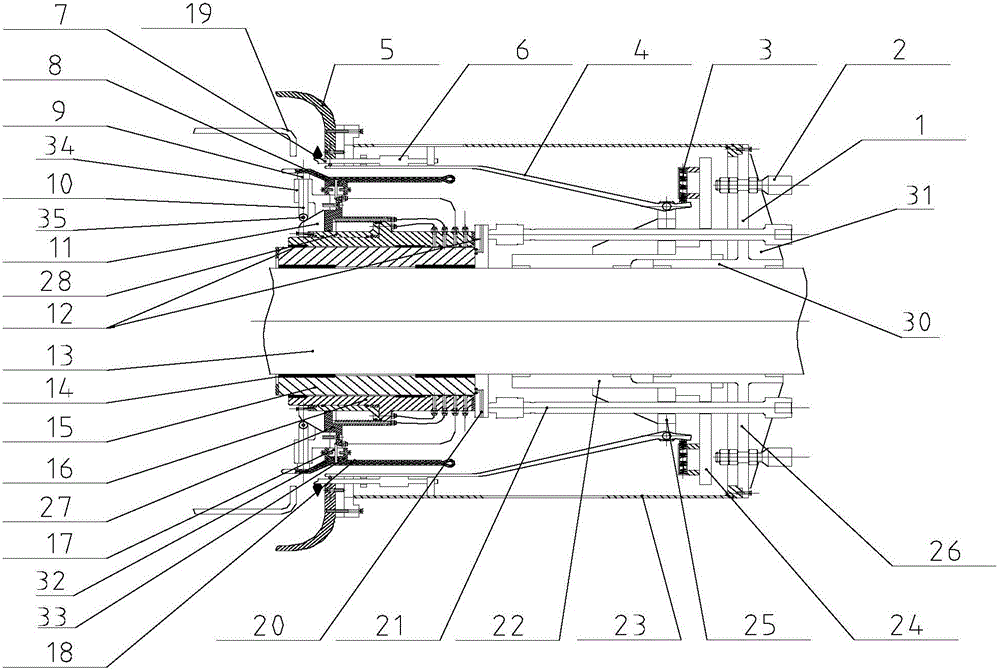

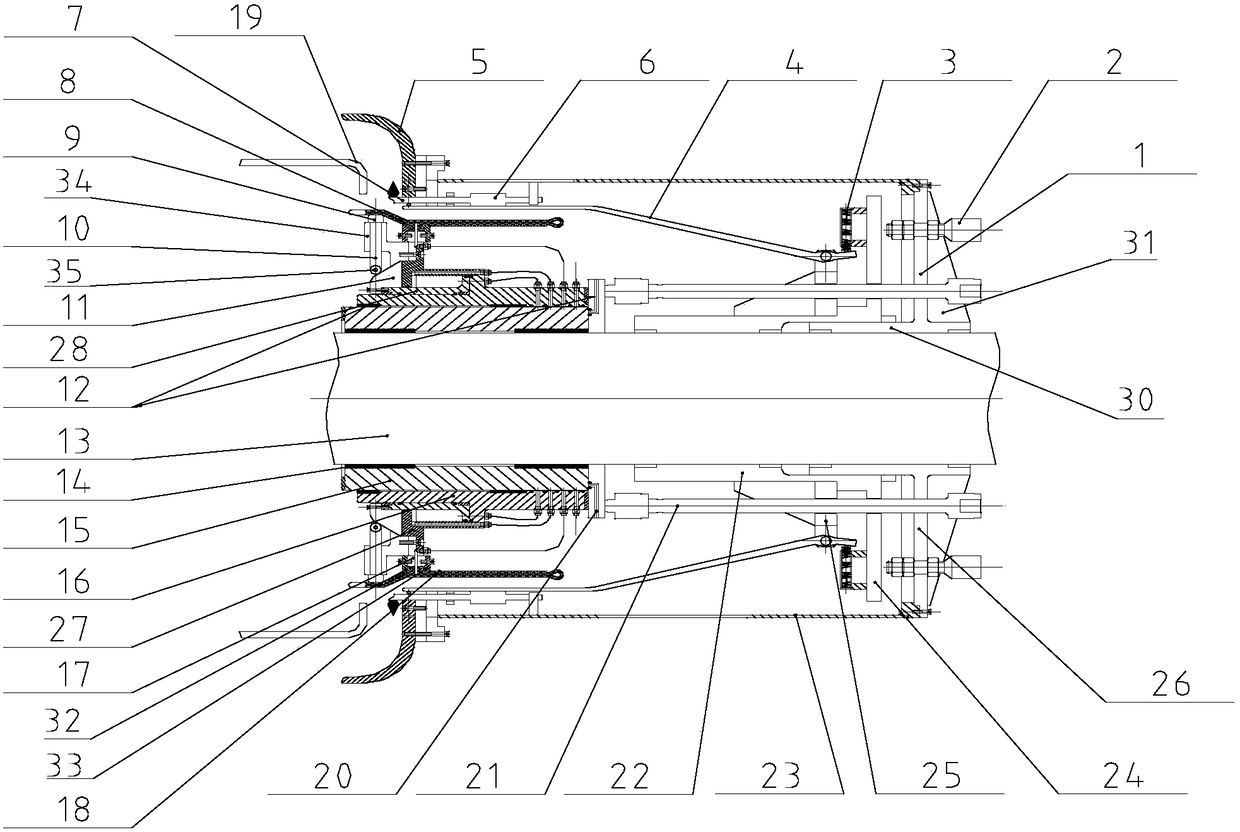

Turn-up device

The invention relates to a tire turn-up device. The tire turn-up device comprises a forming machine spindle, an outer sleeve device body, a finger-type slice device body, a capsule device body, a buckling ring device body and a locking ring device body. The outer sleeve device body, the finger-type slice device body and the capsule device body are all installed on the forming machine spindle in a sleeving mode, and the outer sleeve device body is located on the outer side of the finger-type slice device body and the outer side of the capsule device body in the radial direction of the forming machine spindle. The buckling ring device body is located on the outer sleeve device body.

Owner:EVE RUBBER RES INST +1

Quantification gas-solid two-phase flow conveying device and quantification conveying system

PendingCN110040519ARealize the function of quantitative deliveryRealize quantitative deliveryBulk conveyorsGas solidMechanical engineering

The invention discloses a quantification gas-solid two-phase flow conveying device. The quantification gas-solid two-phase flow conveying device comprises a material container, a quantification plunger, a material pushing air input port and a material output port, a material containing cavity is formed in the quantification plunger, the quantification plunger can move in a reciprocating mode in the material container, when the quantification plunger moves backwards, the material containing cavity is opened, materials in the material container can fill the material containing cavity, when the quantification plunger extends out, the material containing cavity can be sealed, the material pushing air input port and the material output port can communicate to the sealed material containing cavity, the material pushing air input port can be used for injecting compressed gas into the sealed material containing cavity so that the materials in the material containing cavity can be sent out fromthe material output port. The invention further provides a quantification conveying system. The quantification conveying system comprises one or more quantification gas-solid two-phase flow conveyingdevices, the one or more quantification gas-solid two-phase flow conveying devices can be configured according to specific output quantity requirements so as to meet different use requirements.

Owner:YU TUNG ZHONGSHAN ENG

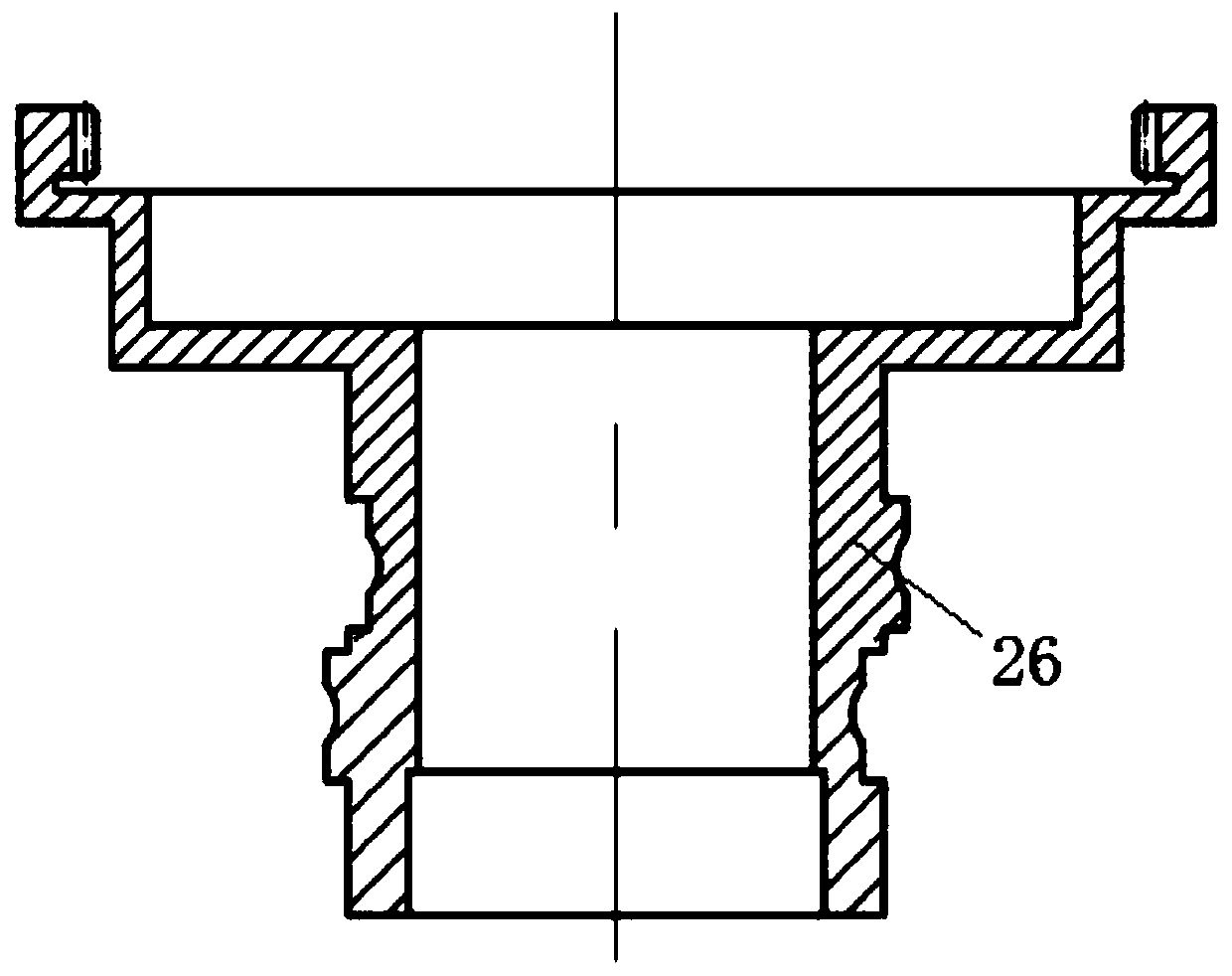

Single-crank composite small-tooth-difference speed reducer

InactiveCN110307295ADeceleration achievedRealize the second gear shiftJointsToothed gearingsReduction driveReducer

The invention belongs to the technical field of speed reducers and relates to a single-crank composite small-tooth-difference speed reducer. A first-stage fixed-shaft gear comprises an input gear shaft, an intermediate gear arranged outside the input gear shaft, an intermediate gear fixing sleeve fixed on a left large end cover through a key and a retainer ring and an inner gear sleeve sleeved outside the intermediate gear fixing sleeve. A second-stage small-tooth-difference involute variable-tooth-thickness gear comprises two involute variable-tooth-thickness outer gears and a rigid disc, wherein the two involute variable-tooth-thickness outer gears are sleeved outside an inner gear sleeve in a parallel rotating mode, the involute variable-tooth-thickness outer gears are sleeved with involute variable-tooth-thickness inner gears, and clearance adjusting devices are arranged between the involute variable-tooth-thickness outer gears and the inner gear sleeve. Single-crank integrated bearing design and involute variable-tooth-thickness gear transmission are adopted in gear transmission, the number of transmission components is reduced, the tooth side clearance of a gear pair in the meshing process is reduced through the clearance adjusting device, and the precision, the bearing capacity and the service life of the speed reducer are improved.

Owner:CHONGQING UNIV

A turn-back device

The invention relates to a tire turn-up device. The tire turn-up device comprises a forming machine spindle, an outer sleeve device body, a finger-type slice device body, a capsule device body, a buckling ring device body and a locking ring device body. The outer sleeve device body, the finger-type slice device body and the capsule device body are all installed on the forming machine spindle in a sleeving mode, and the outer sleeve device body is located on the outer side of the finger-type slice device body and the outer side of the capsule device body in the radial direction of the forming machine spindle. The buckling ring device body is located on the outer sleeve device body.

Owner:EVE RUBBER RES INST +1

Breaker manipulator

ActiveCN102412088BStable working parametersReduce wearHigh-tension/heavy-dress switchesAir-break switchesWear resistantEngineering

The invention discloses a part of a breaker, and particularly relates to a breaker manipulator. The breaker manipulator comprises a manipulator and a push rod connected with a vacuum arcing chamber moving contact part, wherein the manipulator swings around an installation supporting point; the upper end of the manipulator is provided with a semispherical indentation, the rear end of the push rod passes through a cross-under hole arranged at the center of the semispherical indentation and is a spacing nut, and a compression spring is pressed between the manipulator and a step at the middle part of the push rod; and a wear-resistant block is arranged on the semispherical indentation and matched with the semispherical indentation, the center of the wear-resistant block is provided with a center hole through which the push rod can pass, and rear end of the compression spring is pressed on the front end face of the wear-resistant block. By utilizing the structure, the compression spring is contacted with the manipulator through the wear-resistant block in a breaker manipulator swinging process so as not to generate friction on the manipulator, the abrasion is effectively reduced, the transferring accuracy is ensured, and the working parameter stabilization of the breaker is improved.

Owner:JIANGSU DAQO CHANGJIANG ELECTRICAL +3

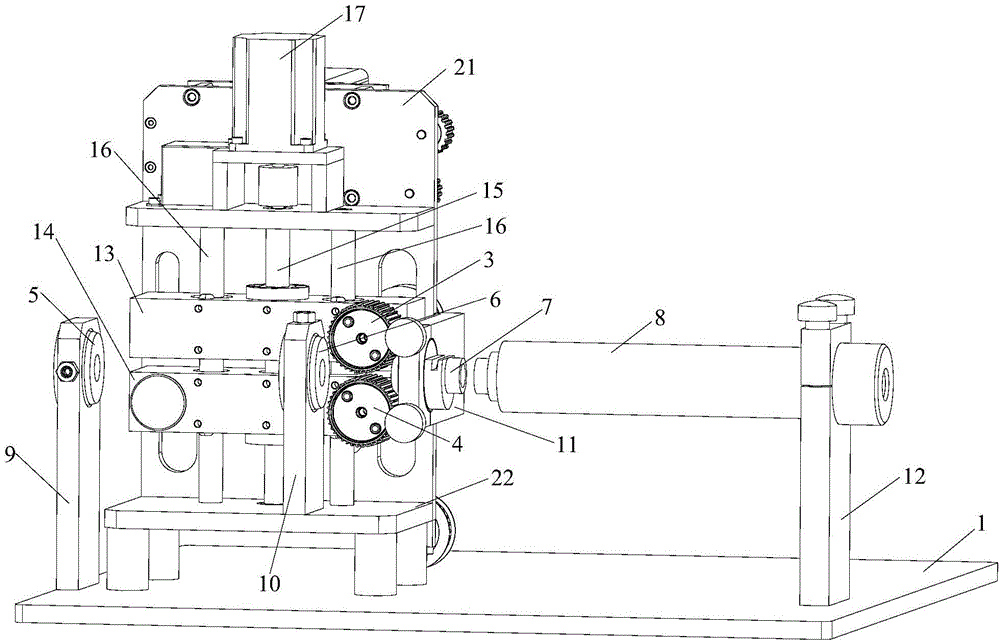

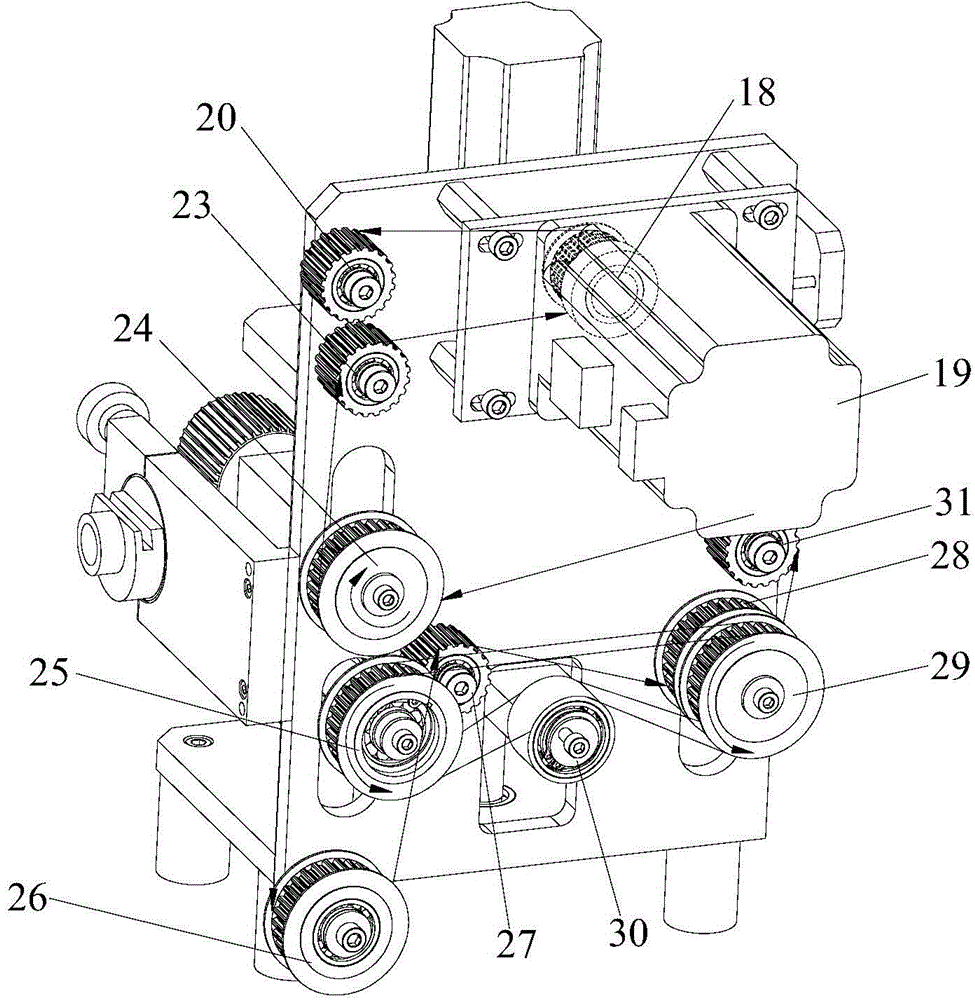

Yarn covering machine with winding mechanism

InactiveCN104514060AGuaranteed delivery accuracySmooth releaseContinuous wound-up machinesYarnYarnTransmitted power

The invention provides a yarn covering machine with a winding mechanism, belongs to the technical field of machinery and solves the technical problems that an existing yarn covering machine cannot simultaneously wind two covered yarns and the like. The yarn covering machine comprises a frame, a winding displacement plate, a plurality of primary covering cylinders and a plurality of secondary covering cylinders are arranged on the frame, the secondary covering cylinders are arranged above the primary covering cylinders, a plurality of yarn cores penetrate the winding displacement plate, a plurality of primary covering rotation shafts and secondary covering rotation shafts are arranged on the frame, first through holes and second through holes are formed in the primary covering rotation shafts and the secondary covering rotation shafts, the yarn cores sequentially penetrate the first through holes and the second through holes, the secondary covering cylinders are connected with a first driving motor, and a transmission mechanism capable of transmitting power of the first driving motor to the primary covering cylinders is arranged among the first driving motor and the secondary covering cylinders. The yarn covering machine has the advantages that the yarn cores are uniformly covered, two covered yarns can be simultaneously wound and the like.

Owner:HAINING SHENGXIANG WIRE

Dosing device and its dosing components, washing equipment

ActiveCN113249935BImprove performanceIncrease the single delivery volumeTableware washing/rinsing machine detailsOther washing machinesMedicineSingle injection

The invention discloses a dosing device, its dosing assembly and washing equipment. The dosing device is used for dosing lotion and includes: a dosing pump, the dosing pump includes a pump casing and a pump body, and the pump body is rotatable It is arranged in the pump casing so that a liquid suction area and a liquid discharge area are formed in the pump casing, and a liquid inlet corresponding to the liquid suction area and a liquid inlet corresponding to the liquid discharge area are formed on the pump casing. The liquid outlet corresponding to the area; the driving assembly, which is connected with the pump body, and the driving assembly includes a driving member, and the movement of the driving member is used to drive the pump body to move. According to the dispensing device of the embodiment of the present invention, the dispensing of lotion can be realized by moving the driving part. The liquid suction area and the liquid discharge area of the dispensing pump are located in different areas in space. The liquid discharge can be completed synchronously in time, which can increase the single delivery volume of the delivery device and ensure the delivery accuracy of a single delivery.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

An automatic shearing system

InactiveCN107252922BReduce work intensityGuaranteed delivery accuracyMetal-working feeding devicesShearing machinesEngineeringManipulator

The invention discloses an automatic plate shearing system. The automatic plate shearing system comprises a raw material feeding carrying assembly, a raw material servo supplying assembly, a first shearing machine, a strip fixed-point conveying assembly, a strip supplying carrying assembly, a second shearing machine, a finished product fixed-point conveying assembly and a stacking carrying assembly. The feeding carrying assembly comprises a raw material carrying rack and raw material carrying manipulators. The raw material carrying manipulators are located above the raw material servo supplying assembly. The first shearing machine is arranged at the tail end of the raw material servo supplying assembly. The strip fixed-point conveying assembly is arranged on the side of the first shearing machine. The strip supplying carrying assembly is arranged on the side of the strip fixed-point conveying assembly. The second shearing machine is arranged on the side of the strip supplying carrying assembly. The finished product fixed-point conveying assembly and the stacking carrying assembly are arranged on the side of the second shearing machine. According to the problem that an existing plate shearing machine is low in carrying efficiency, the improving scheme is put forward, the automatic plate shearing system is designed, and the labor intensity of staff can be effectively relieved.

Owner:DONGGUAN XINGUI IND CO LTD

A vacuum adsorption conveying device in a water-based printing machine

ActiveCN102267283BImprove color registration accuracyCompressive strength does not decreasePrinting press partsCardboardScreen printing

Owner:BENGBU AOTE CARTON MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com