Automatic-feeding laser cutting equipment

A technology of laser cutting and automatic feeding, which is applied in the field of coil material processing, can solve the problems of high cost of sheet material procurement, many intermediate transfer processes, and low utilization rate of sheet materials, and achieve the goals of saving labor costs, improving utilization rate, and high-efficiency production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

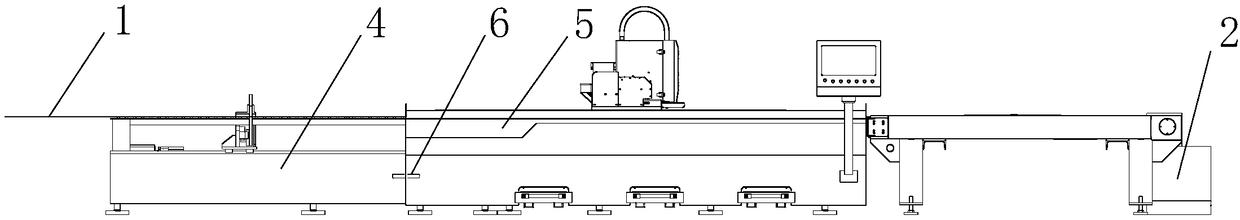

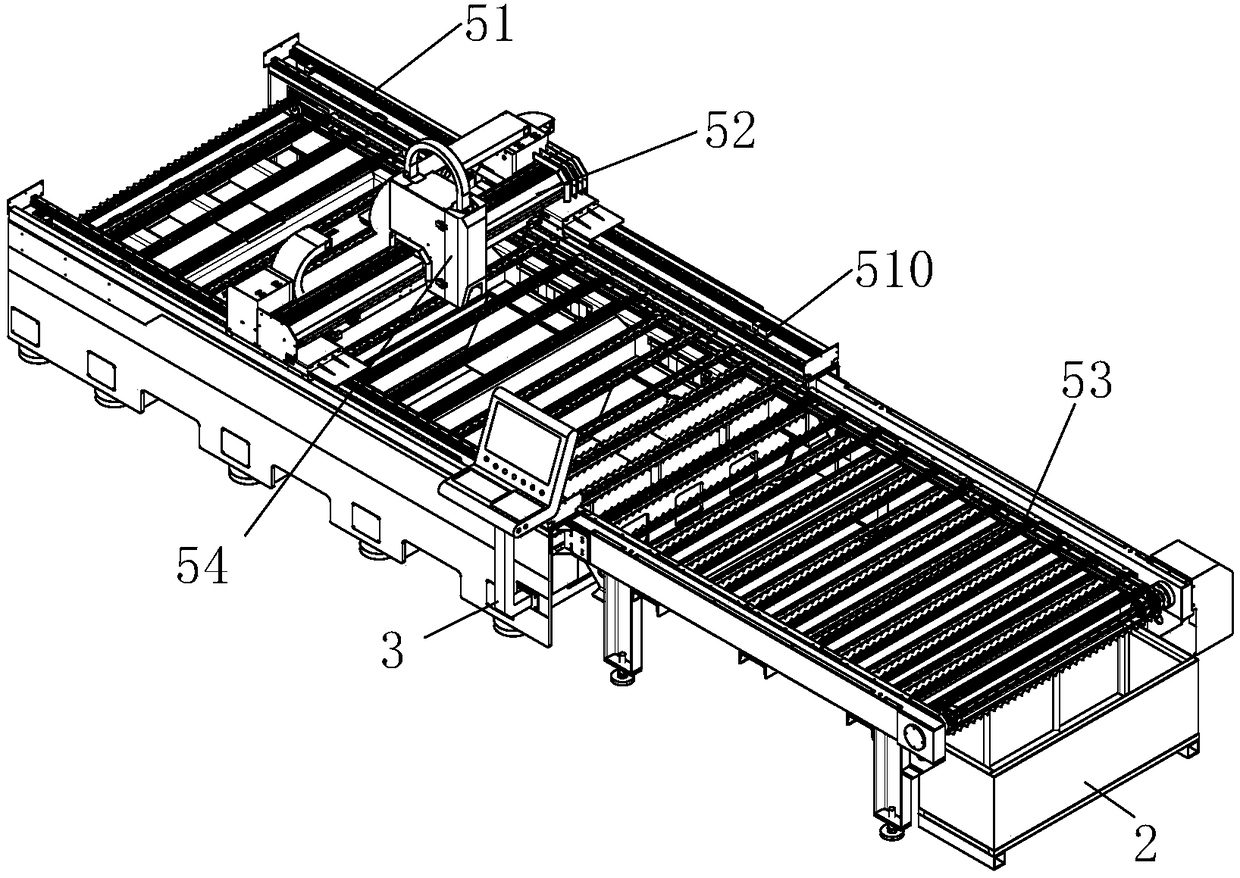

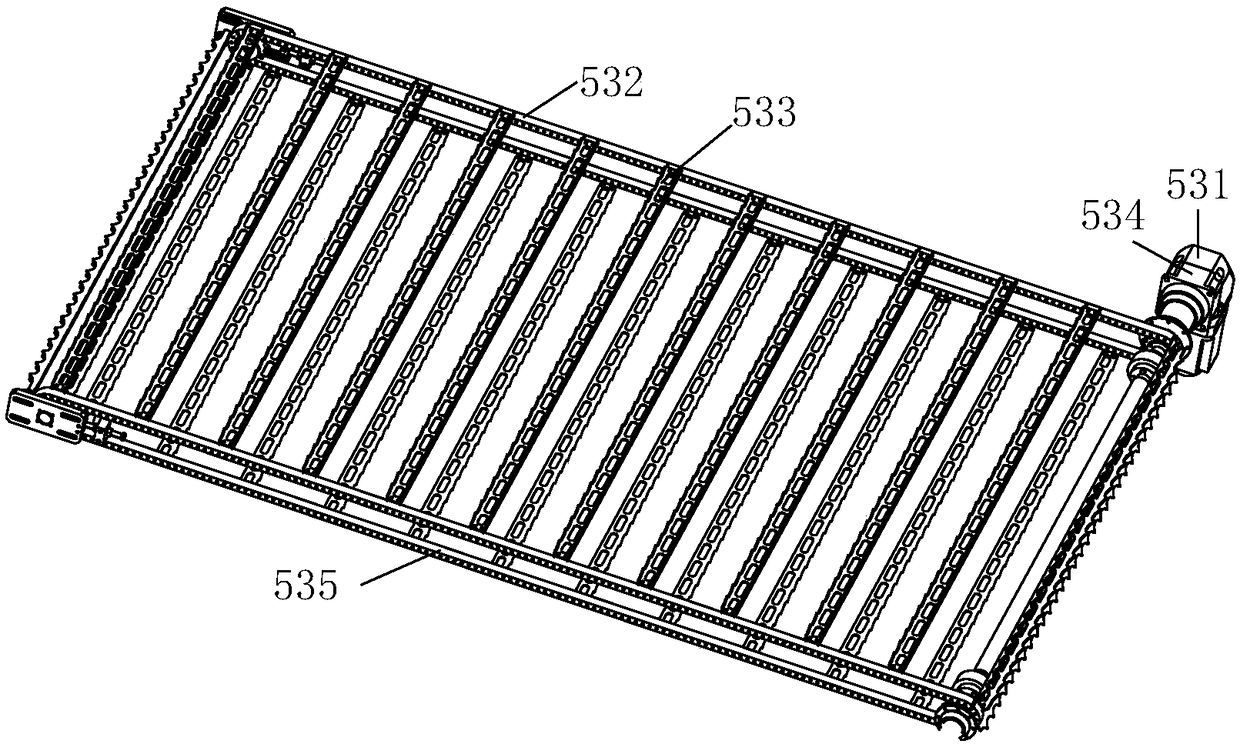

[0039] The present invention as Figure 1-9 As shown, it includes a feeding device 4 and a laser cutting device 5 in turn,

[0040] The feeding device is used to transmit the sheet material 1, and the feeding device includes a feeding body 41, a support table 42, a slider 43, a feeding trolley 410, a hydraulic cylinder 413, an upper pressing block 47 and a lower pressing block 48, the Show that the four corners of the feeding fuselage are respectively provided with pillars 414, the support table is located on the four pillars, and the support table is provided with sliding holes 420 arranged in parallel;

[0041] The slider 43 is plate-shaped, and the middle part of the slider is provided with a perforation 430, and the support table is located in the perforation,

[0042] The sliding block 43 is located on both sides of the upper part of the perforation to be respectively provided with a first connecting block 46 and a second connecting block 411, and the upper pressing bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com