Speed reducer for solar thermal electric power generation

A technology of photothermal power generation and reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

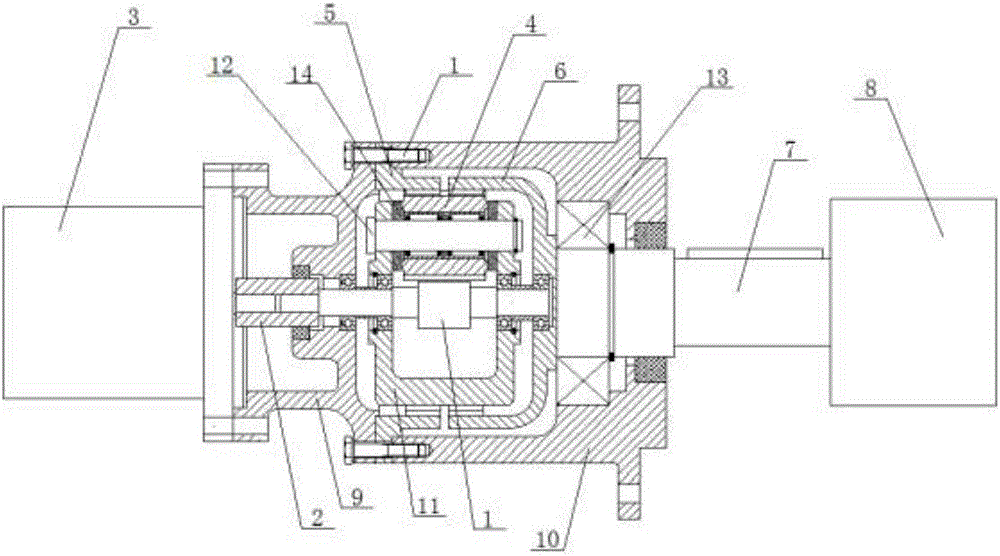

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0022] The invention provides a reducer for photothermal power generation. Its working principle is to drive the planetary gear through the input shaft gear, and then drive the output shaft to rotate through the first inner ring gear and the second inner ring gear, so as to convert the high speed of the motor into The face-changing movement of the mirror makes the angular rate of rotation of the mirror conform to the angular rate of movement of the sun, and the coaxial rotation of the input shaft and the output shaft is realized by using the input shaft gear, the first internal ring gear and the second internal ring gear to increase the speed ratio The optional range, reduce the number of parts, reduce the difficulty of processing, ensure the transmission accuracy and ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com