Sulfolane based binary sodium ion electrolyte and preparation method thereof

A technology of sulfolane and sodium ions, applied in electrolytes, secondary batteries, circuits, etc., can solve problems such as poor heat dissipation, potential safety hazards, and low boiling point, and achieve the effects of low price, good compatibility, and high cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The whole preparation process of the binary sodium ionic liquid is completed in a glove box filled with high-purity argon to ensure an environment of oxygen <0.1ppm and water <0.1ppm.

[0032] The assembly sequence of the CR2032 button battery is as follows: sequentially compress the negative electrode case, sodium sheet, fiber diaphragm, 4 to 5 drops of binary sodium ion electrolyte, stainless steel gasket, stainless steel shrapnel and positive electrode case; wherein, the fiber diaphragm Produced by Waterman (Whatman), its model is GF / D,

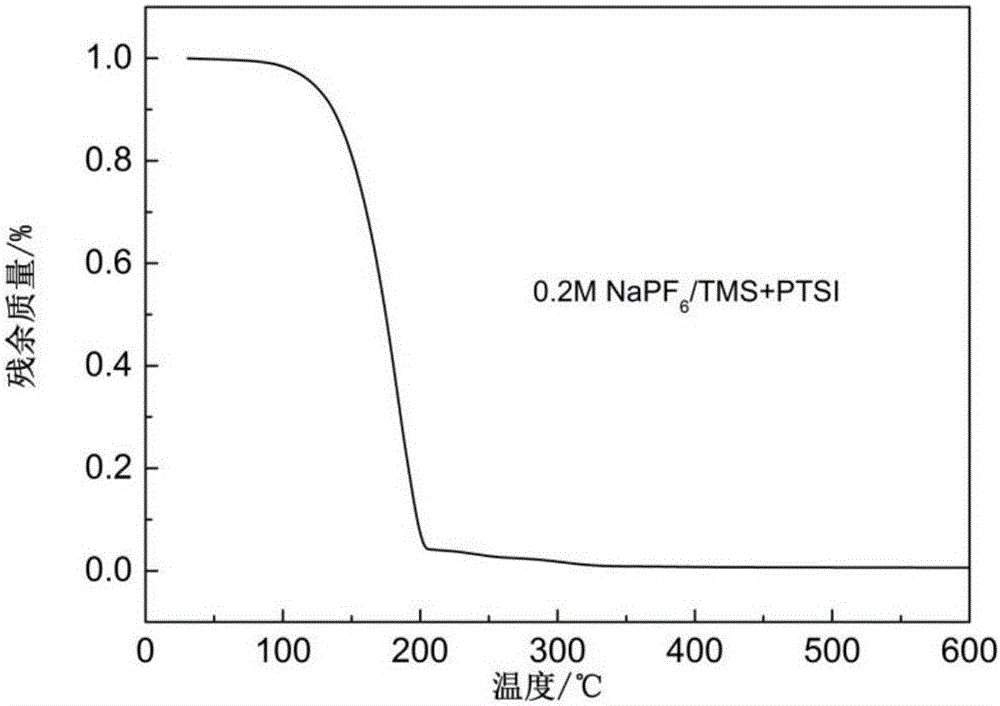

[0033] The thermal analysis adopts a thermogravimetric analyzer (TGA / SDTA851 / Swiss Mettler company), the sample quality is 5 mg, the protective gas atmosphere is nitrogen, and the heating rate is 10 °C min -1 , the final temperature is 600°C.

Embodiment 1

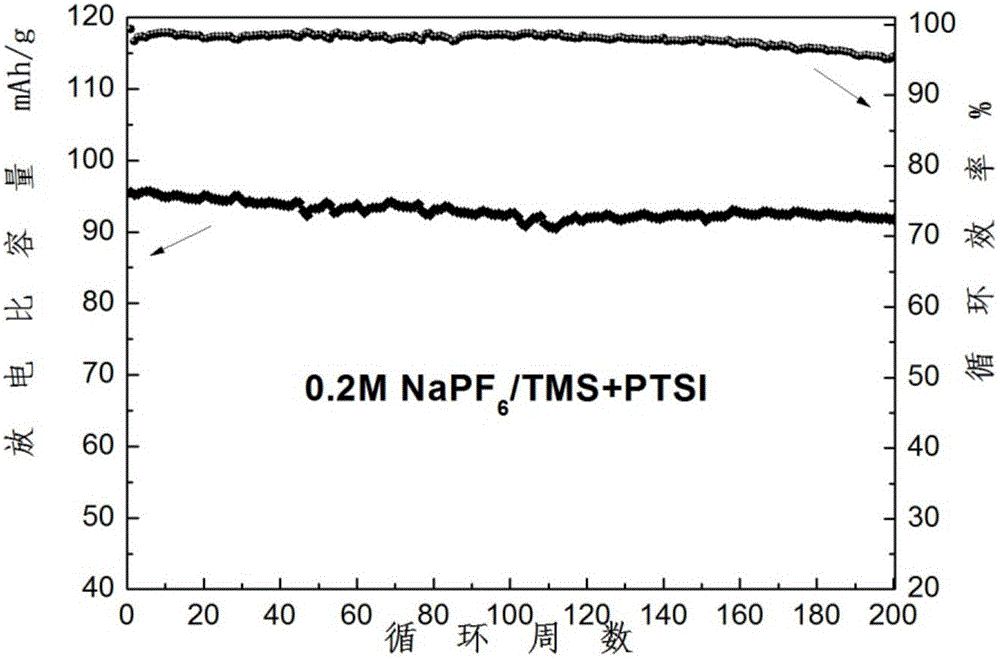

[0035] A sulfolane-based binary sodium ion electrolyte 0.2MNaPF 6 Preparation method and application of / TMS+PTSI:

[0036] (1) 0.5g p-toluenesulfonyl isocyanate (PTSI) and 9.164g sulfolane (TMS) are added in the reactor, mix well, obtain binary mixed solvent;

[0037] (2) 0.336g sodium hexafluorophosphate (NaPF 6 ) was added to the binary mixed solvent, stirred for 12h, and left to stand for 12h to obtain NaPF 6 Binary sodium ion electrolyte with a concentration of 0.2mol / kg, denoted as 0.2MNaPF 6 / TMS+PTSI electrolyte;

[0038] For the 0.2MNaPF 6 / TMS+PTSI electrolyte for thermal analysis, the thermogravimetric curve is as follows figure 2 It can be seen that 0.2MNaPF6 When the residual mass of / TMS+PTSI electrolyte is 90%, the temperature is higher than 120°C. Compared with the common carbonate electrolyte (50-70°C), the thermal stability is significantly improved;

[0039] The positive electrode active material Na 3 V 2 (PO4) 3 , the binder polyvinylidene fluorid...

Embodiment 2

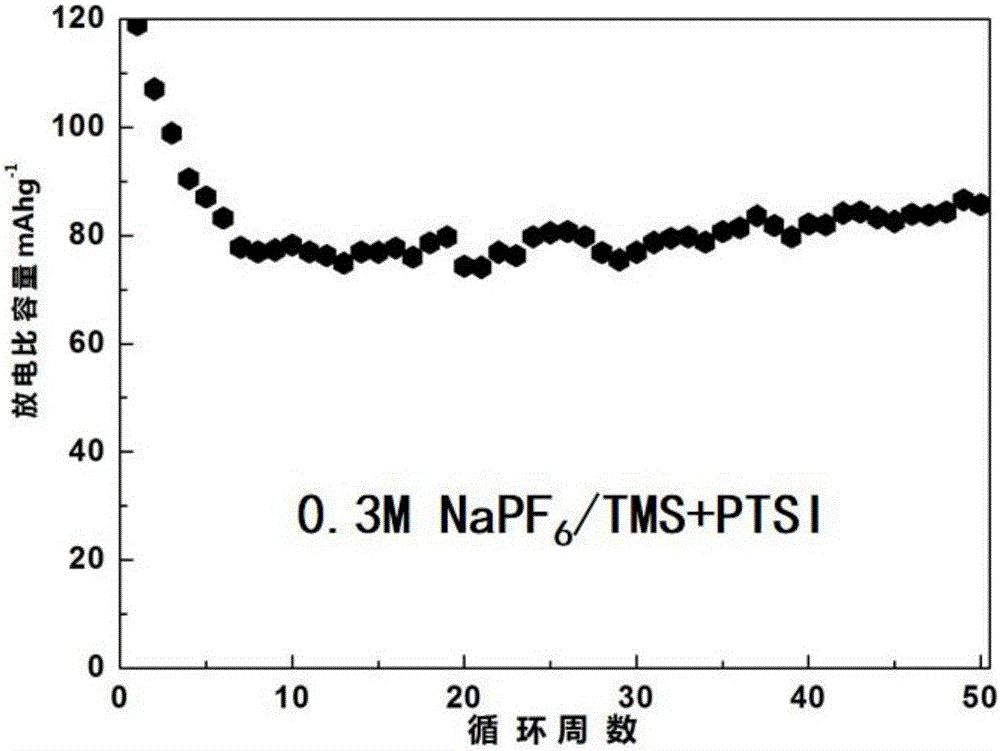

[0041] A sulfolane-based binary sodium ion electrolyte 0.3MNaPF 6 Preparation method and application of / TMS+PTSI:

[0042] (1) 0.5g of PTSI and 8.996g of TMS are added to the reactor, and mixed evenly to obtain a binary mixed solvent;

[0043] (2) Add 0.504gNaPF 6 Added to the above-mentioned binary mixed solvent, stirred for 12h, and stood for 12h to obtain NaPF 6 Binary sodium ion electrolyte with a concentration of 0.3mol / kg, denoted as 0.3MNaPF 6 / TMS+PTSI electrolyte;

[0044] For the 0.3MNaPF 6 / TMS+PTSI electrolyte for thermal analysis, from its thermogravimetric curve, 0.3MNaPF 6 When the residual mass of / TMS+PTSI electrolyte is 90%, the temperature is higher than 120°C. Compared with the common carbonate electrolyte (50-70°C), the thermal stability is significantly improved;

[0045] The positive electrode active material Na 2 TiFe(CN) 6 , the binder polyvinylidene fluoride, and acetylene black are mixed evenly in a mass ratio of 7:1:2, and evenly coated on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cycle efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com