Modified epoxy resin thermosetting epoxy asphalt bulking agent and preparation method thereof

A technology of epoxy resin and epoxy asphalt, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of poor compatibility and quality reduction of modified asphalt, and achieve low-temperature crack resistance Good, good anti-fatigue performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

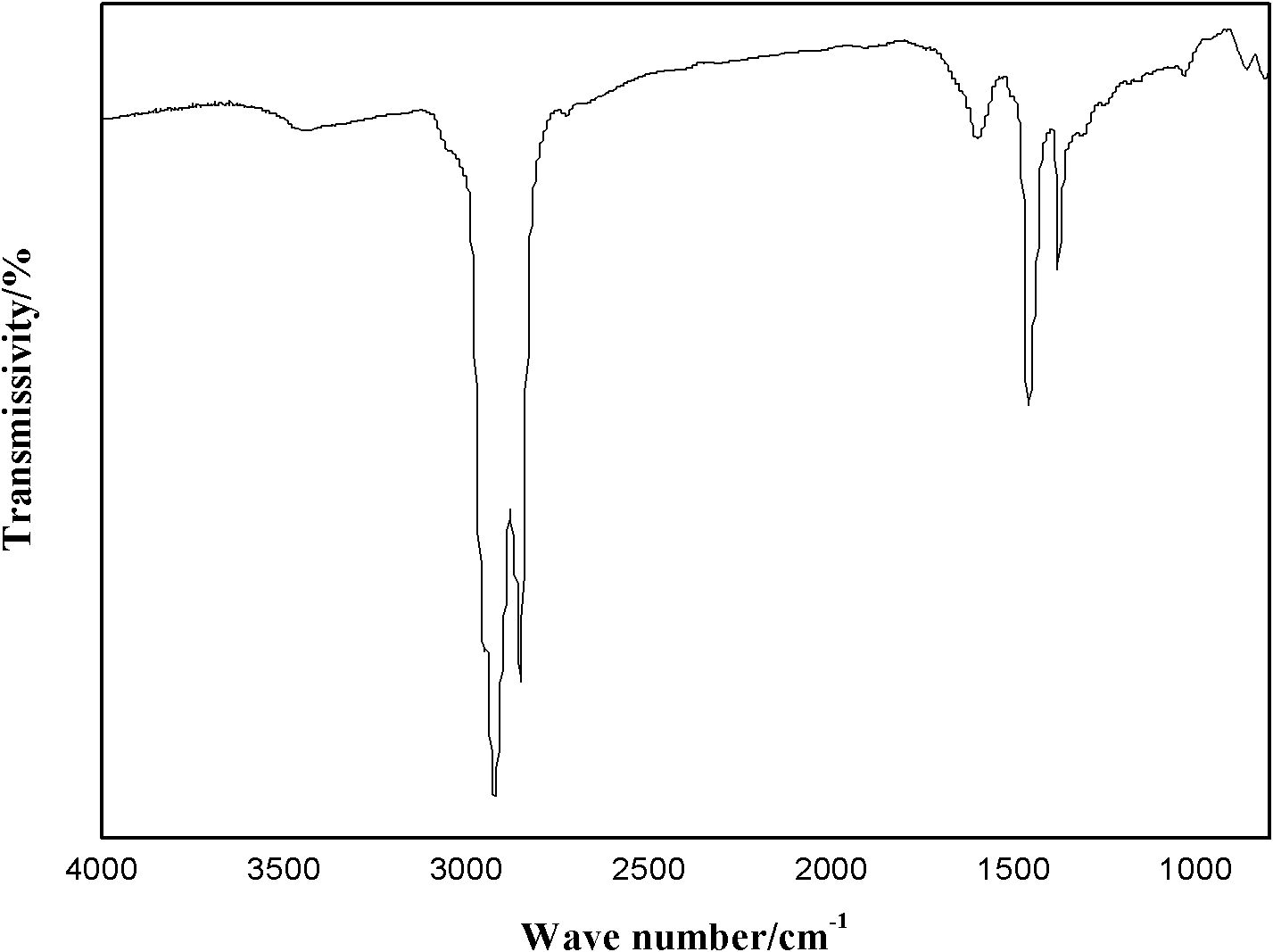

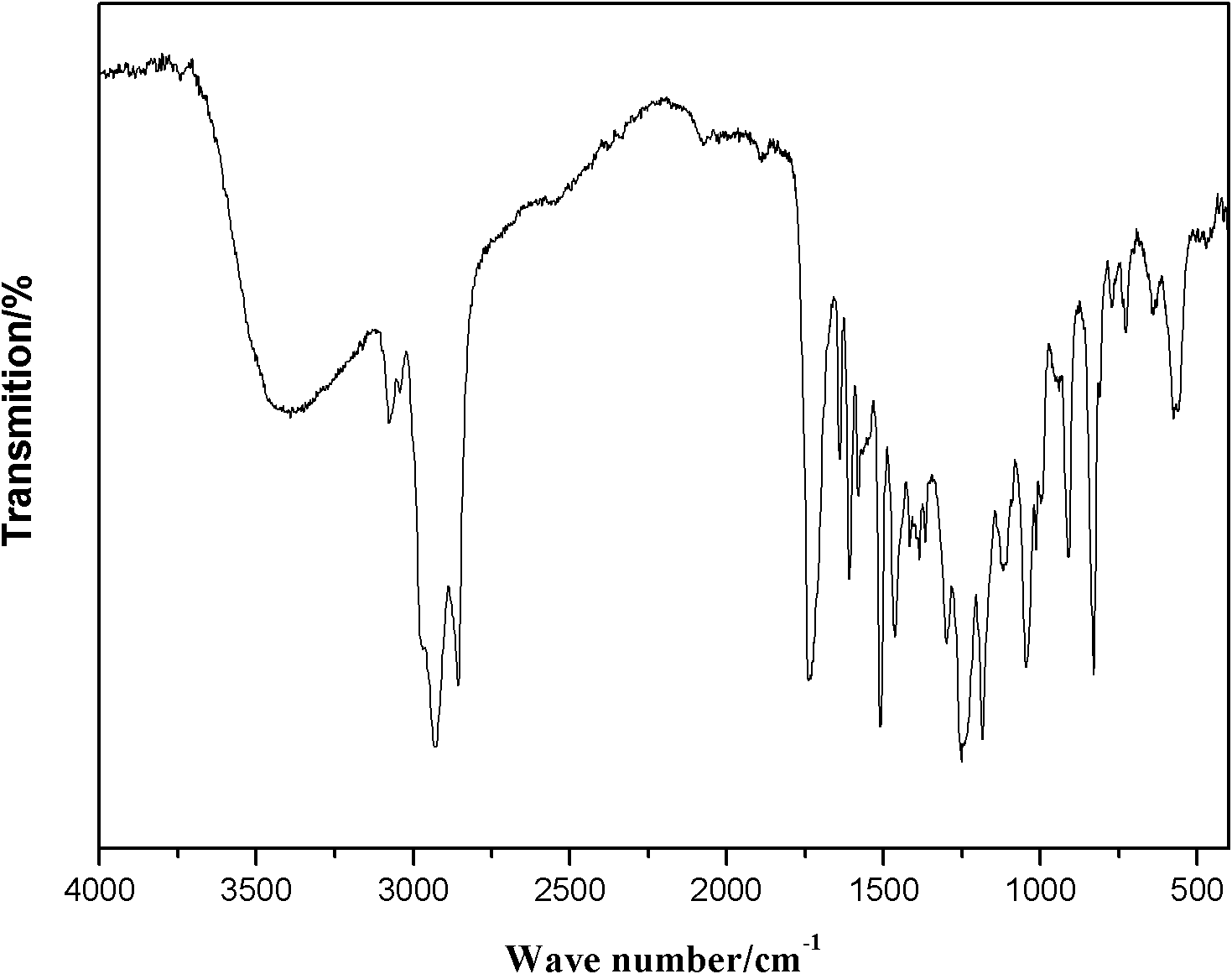

[0040] The preparation method of modified epoxy resin thermosetting epoxy asphalt compatibilizer comprises the steps of: dissolving 80 parts by weight of epoxy resin E-51 in 187 parts by weight of chloroform, adding 100 parts by weight of oleic acid , drop 0.01-0.1 parts (1-2 drops) of tin tetrachloride (this is a Lewis acid catalyst) and react at 40°C for 1 hour to obtain a modified epoxy resin thermosetting epoxy asphalt compatibilizer.

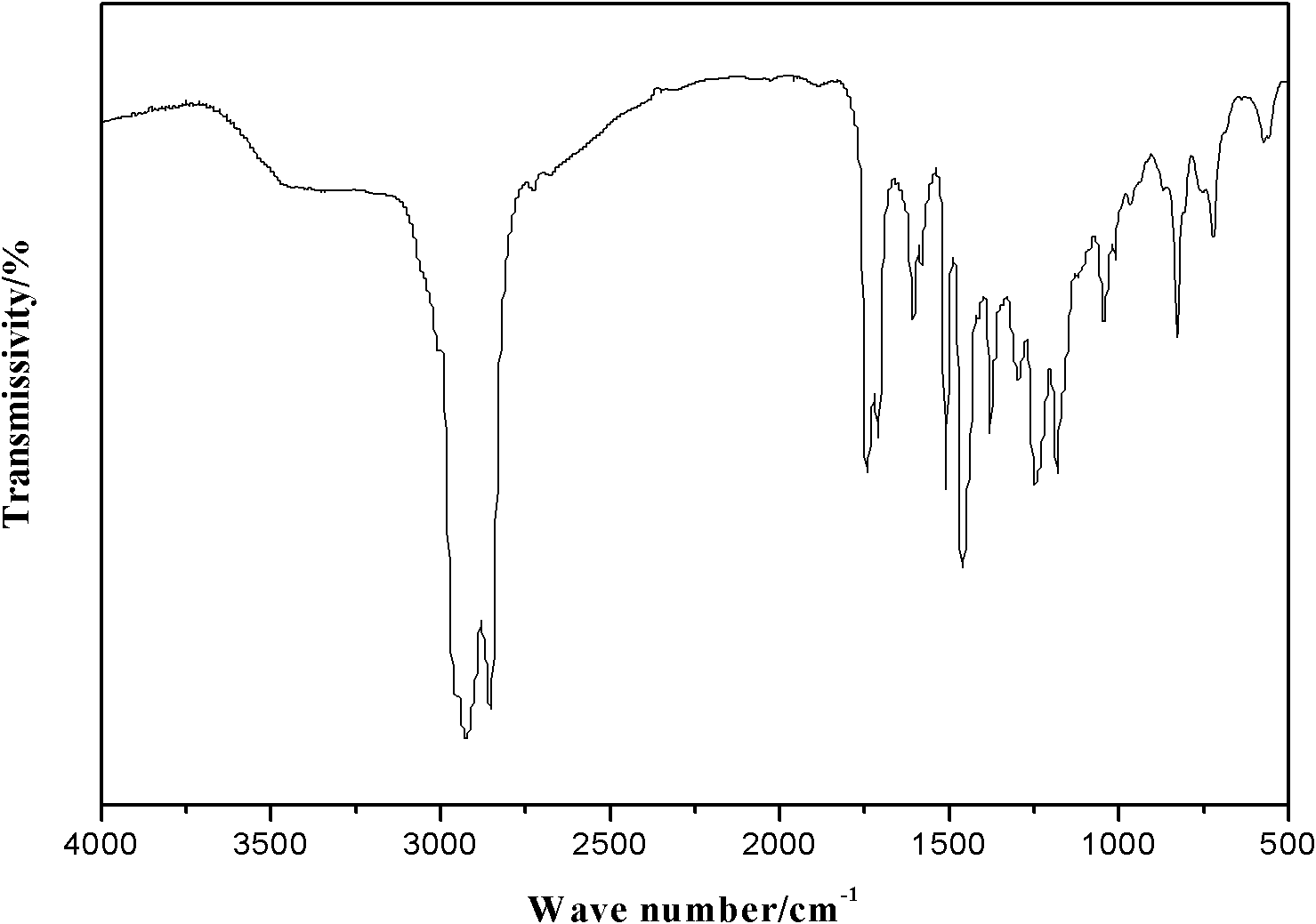

[0041] The application of modified epoxy resin thermosetting epoxy asphalt compatibilizer (for preparing thermosetting epoxy asphalt material): the preparation method of modified thermosetting epoxy asphalt material, it comprises the steps: 100 grams of Shell No. 70 asphalt, 35 Gram epoxy resin E-44, 40 grams of compatibilizer (modified epoxy resin thermosetting epoxy asphalt compatibilizer), 40 grams of vulcanizing agent (tetramethylthiuram disulfide), 20 grams of methyltetrahydrophthalic anhydride Mix with 0.7 g of 2,4,6-tris(dimethylamin...

Embodiment 2

[0046] The preparation method of modified epoxy resin thermosetting epoxy asphalt compatibilizer comprises the steps of: dissolving 80 parts of weight of epoxy resin E-44 in 187 parts of weight of chloroform, adding 100 parts of weight of oleic acid , drop 0.01-0.1 parts (1-2 drops) of tin tetrachloride (this is a Lewis acid catalyst) and react at 45°C for 1 hour to obtain a modified epoxy resin thermosetting epoxy asphalt compatibilizer.

[0047] Application of modified epoxy resin thermosetting epoxy asphalt compatibilizer (for preparing thermosetting epoxy asphalt material): the preparation method of modified thermosetting epoxy asphalt material, it comprises the steps: 100 grams of petroleum asphalt (Qilu brand AH -90 heavy traffic road asphalt), 20 grams of epoxy resin E-51, 20 grams of compatibilizer (modified epoxy resin thermosetting epoxy asphalt compatibilizer), 20 grams of vulcanizing agent (tetramethylthiuram disulfide ), 20 grams of phthalic anhydride and 0.3 gram...

Embodiment 3

[0050] The preparation method of modified epoxy resin thermosetting epoxy asphalt compatibilizer comprises the steps of: dissolving 80 parts by weight of epoxy resin E-42 in 187 parts by weight of chloroform, adding 100 parts by weight of oleic acid , drop 0.01-0.1 parts (1-2 drops) of tin tetrachloride (this is a Lewis acid catalyst) and react at 40°C for 1.5 hours to obtain a modified epoxy resin thermosetting epoxy asphalt compatibilizer.

[0051] Application of modified epoxy resin thermosetting epoxy asphalt compatibilizer (for preparing thermosetting epoxy asphalt material): the preparation method of modified thermosetting epoxy asphalt material, it comprises the steps: 100 grams of SBS modified asphalt, 20 Gram epoxy resin E-42, 20 grams of compatibilizer (modified epoxy resin thermosetting epoxy asphalt compatibilizer), 20 grams of vulcanizing agent (tetramethylthiuram disulfide), 20 grams of methyl hexahydrophthalic anhydride , 0.3 g of 2,4,6-tris(dimethylaminomethyl)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com