Patents

Literature

134results about How to "Good low temperature crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

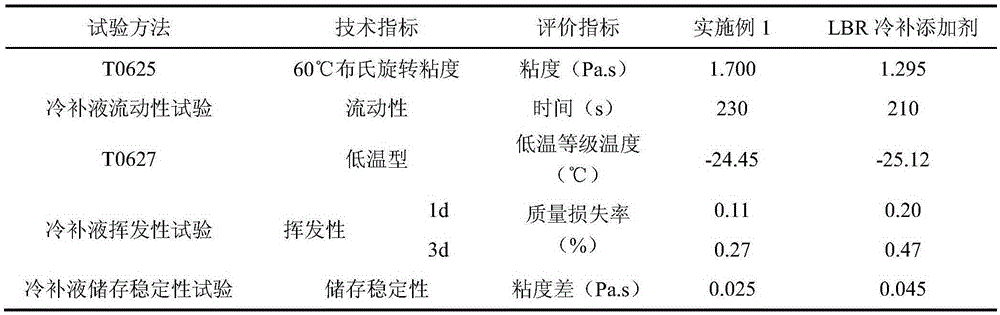

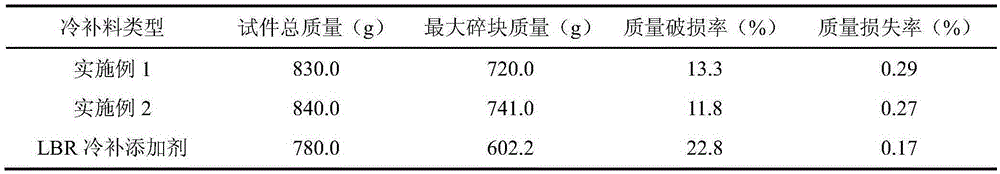

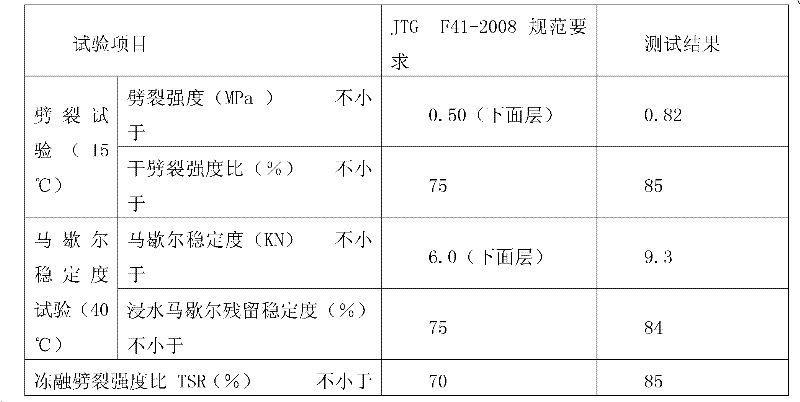

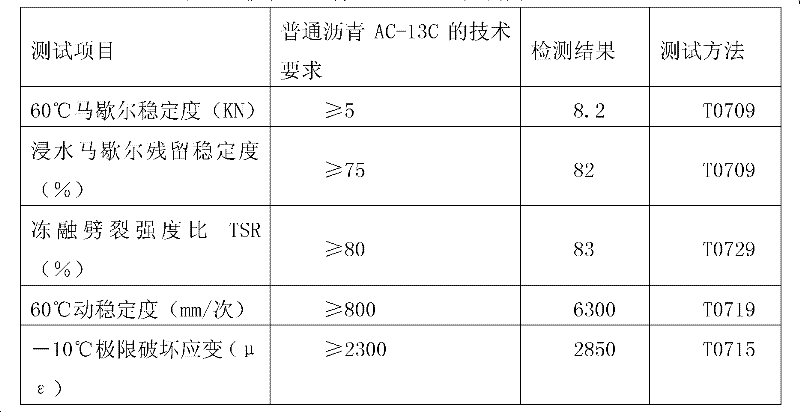

Solvent-type cold-patch asphalt liquid and preparation technology therefor

The invention relates to a solvent-type cold-patch asphalt liquid and a preparation technology therefor. The solvent-type cold-patch asphalt liquid comprises the following substances, by weight, 100 parts of petroleum asphalt, 10-15 parts of diluents, 10-15 parts of heavy oil, 10-15 parts of solvent naphtha, 1-5 parts of tackifier, 1-5 parts of strengthening agent, 0.2-0.8 part of surfactant and 0.5-0.8 part of anti-stripping agent. The above materials form performed polymers respectively and then are mixed uniformly, thus the obtained cold-patch liquid has good dispersibility, the stability of the obtained cold-patch asphalt liquid is raised, the storage stability is excellent, the employed tackifier, strengthening agent and anti-stripping agent can raise adhesion and strengthening effects of asphalt, and the surfactant can improve fluidity of asphalt substantially. The solvent-type cold-patch asphalt liquid is blended with aggregates when used to prepare cold-patch asphalt mixture for repairing pavement pits, no heating is needed during the blending process, the prepared cold-patch asphalt mixture has good initial and molding intensities and water damage resistance, and the construction workability is good.

Owner:CHANGAN UNIV +1

Asphalt cold recycling agent and preparation method thereof

ActiveCN102174267ANo pollution in the processImprove recycling ratesSolid waste managementBuilding insulationsCrack resistanceAntioxidant

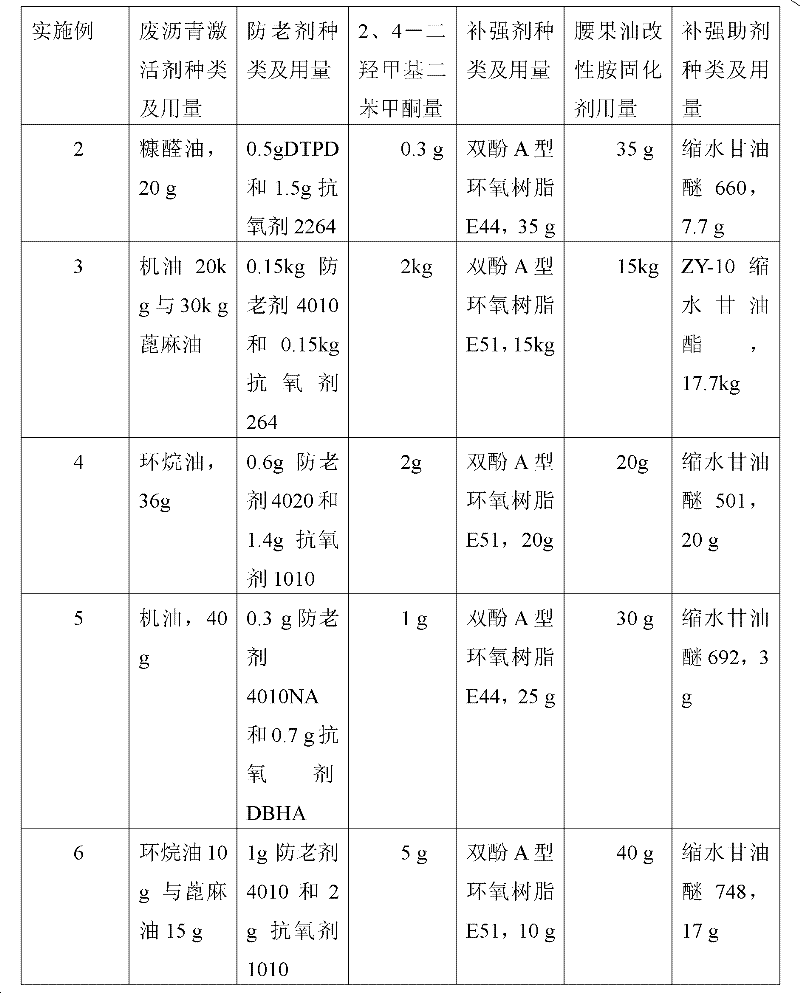

The invention relates to an asphalt cold recycling agent, which is characterized by being prepared from a waste asphalt activator, an anti-aging agent, an ultraviolet absorbent, a reinforcing agent, a reinforcing curing agent and a reinforcing auxiliary agent serving as raw materials, wherein the waste asphalt activator consists of any one or more of engine oil, castor oil, naphthenic oil, aromatic hydrocarbon oil and furfural oil; the anti-aging agent is a mixture of an antioxidant and a p-phenylenediamine anti-aging agent; the ultraviolet absorbent is 2,4-dihydroxymethyl benzophenone; the reinforcing agent is bisphenol A epoxy resin E44 or E51; the reinforcing curing agent is a cashew nut oil modified amine curing agent; and the reinforcing auxiliary agent is a glycidyl ester epoxy active diluent. An asphalt recycled mixture prepared by adding the asphalt cold recycling agent into waste asphalt has high comprehensive performance, namely high bonding strength, high-temperature performance, low-temperature crack resistance and rheological performance, the actual service life of 8 years, and high aging resistance and weather resistance.

Owner:重庆市智翔铺道技术工程有限公司

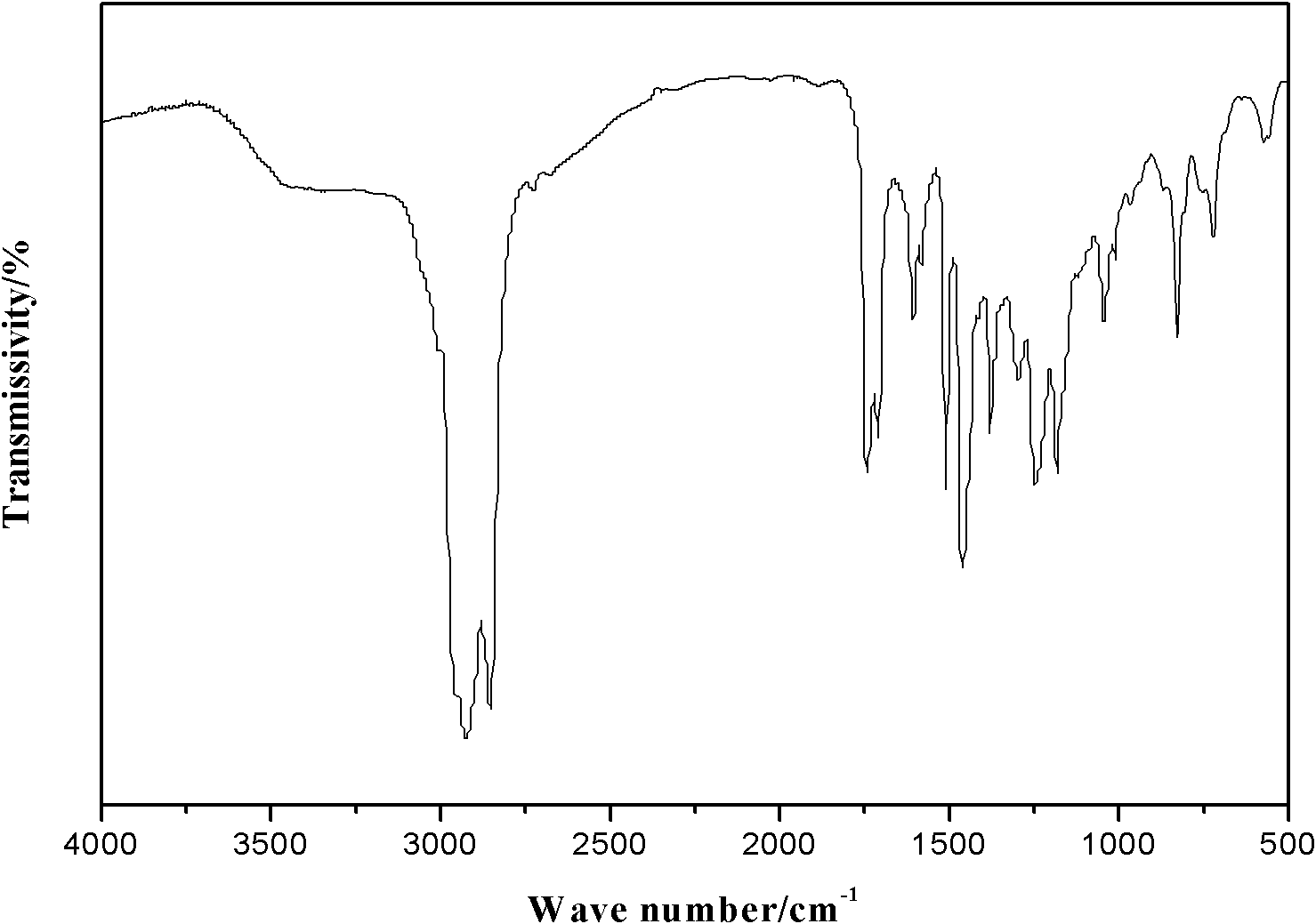

Composite emulsion modified emulsified asphalt and preparation method therefor

InactiveCN105086476AGood low temperature crack resistanceEasy to prepareBuilding insulationsPolymer chemistryCorrosion engineering

The invention introduces composite emulsion modified emulsified asphalt for building waterproof engineering and anti-corrosion engineering, and a preparation method therefor. The composite emulsion modified emulsified asphalt comprises the following components in percentage by weight: 5-75% of matrix asphalt, 5-85% of water, 0.1-5% of an emulsifier, 1-40% of a toughening agent, 1-50% of a stabilizer, 0.1-40% of a dispersant, 1-20% of fillers and 1-80% of a composite modifier. The preparation method for the composite emulsion modified emulsified asphalt is as follows: at a certain temperature, adding the dispersant, the composite modifier and water, and stirring to obtain a mixed solution; mixing the emulsifier, the toughening agent and the asphalt at a certain temperature to obtain emulsified asphalt; adding the emulsified asphalt into the mixed solution, stirring at a high speed for a period of time, and cooling; and adding the stabilizer, the fillers and the composite modifier in sequence, stirring and mixing for a period of time, and discharging. According to the preparation method, various performances of the emulsified asphalt are improved by using compounded latex and reasonable proportion; and the composite emulsion modified emulsified asphalt can be used for building waterproof engineering and anti-corrosion engineering.

Owner:重庆市化工研究院有限公司

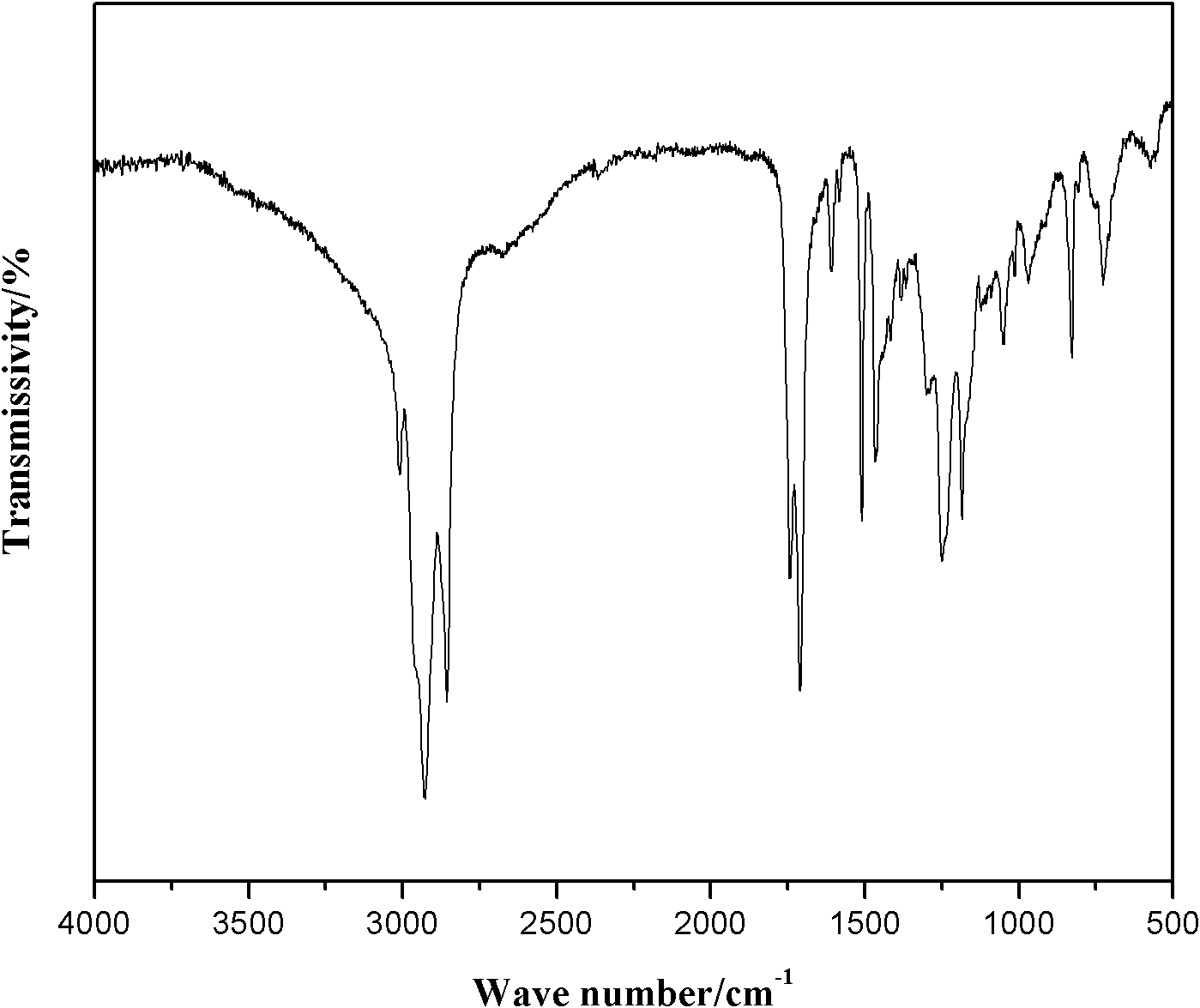

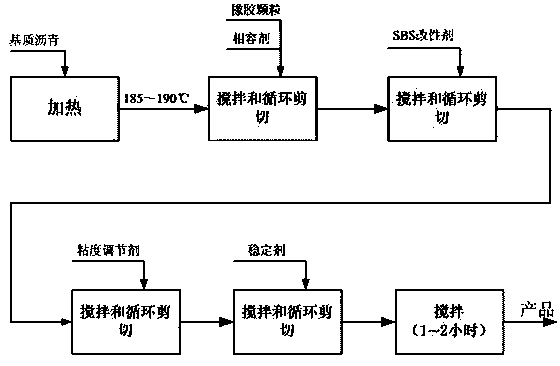

SBS-rubber powder composite modified asphalt and preparation method thereof

ActiveCN105176115AReduce waste of resourcesMaintain the balance of the ecological environmentBuilding insulationsPitch blendeWaste rubber

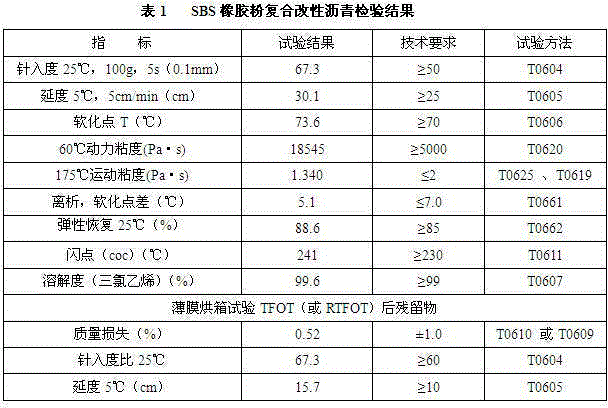

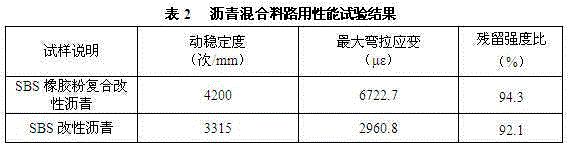

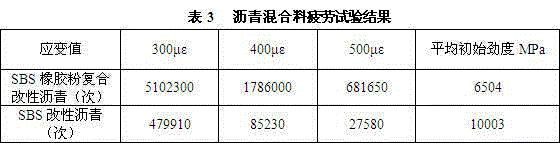

The invention belongs to the technical field of materials for asphalt pavements, and particularly relates to SBS-rubber powder composite modified asphalt and a preparation method thereof. The SBS-rubber powder composite modified asphalt is prepared from, by mass, 15-21 parts of waste rubber powder, 2-3 parts of SBS modifying agents, 0.2-0.4 part of stabilizing agents, 0.03-0.04 part of activating agents and 75-82 parts of asphalt. The preparation method of the asphalt comprises the steps that the matrix asphalt is preheated to 180 DEG C, the SBS modifying agents are added into the hot asphalt, high-speed shearing dispersion is performed for 20 min, then the activating agents, the rubber powder and the stabilizing agents are added, and high-speed shearing dispersion is performed on the temperature condition of 185 DEG C for 2 h. According to the SBS-rubber powder composite modified asphalt, a pavement paved with SBS-rubber powder composite modified asphalt mixtures has the advantages of being stable, comfort, low in noise and the like, the quality of the pavement can be obviously improved, the service life of the pavement can be prolonged, use is convenient, price is low, the properties are stable, and not only can the anti-rutting performance of the asphalt mixtures be improved, but also the obvious effects on improving the low-temperature crack resistance, water stability and fatigue resistance of the asphalt mixtures can be achieved.

Owner:辽宁省交通科学研究院有限责任公司

High-viscosity modified asphalt material and preparation method thereof

InactiveCN110041720AReduce manufacturing costOptimizing the distribution of ingredientsBuilding insulationsBituminous materialsWaste rubber

The invention discloses a high-viscosity modified asphalt material. The asphalt material is prepared from the following raw materials in parts by mass: 100 parts of matrix asphalt, 4-7 parts of a thermoplastic elastomer, 4-10 parts of waste rubber powder or an ethylene-vinyl acetate copolymer, 1-3 parts of a plasticizer, 2-4 parts of thermoplastic resin, 3-5 parts of a solubilizer, 0.2-2 parts ofa stabilizer, 0.5-1.5 parts of a chemical modifier and 0.2-0.7 part of polypropylene glycol. Through the high-viscosity modified asphalt material, the storage stability of high-viscosity modified asphalt is improved; meanwhile, high-temperature viscosity of the high-viscosity modified asphalt is reduced; when the high-viscosity modified asphalt material is applied to mixing of asphalt mixture, themixing temperature is low; the high-viscosity modified asphalt material is easy to construct, low in cost and simple in preparation method.

Owner:无锡市城市道桥科技有限公司

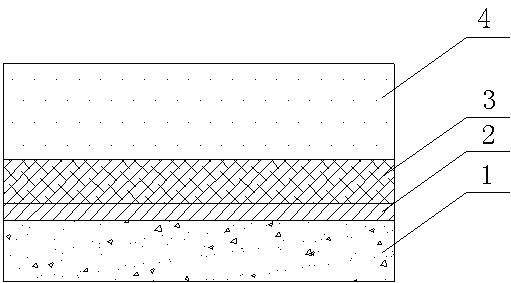

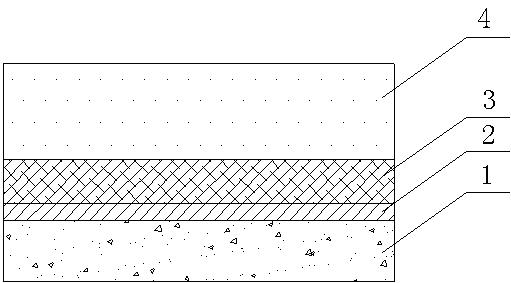

Pavement structure for cement concrete bridge deck and pavement method thereof

InactiveCN102002909AEfficient removalImprove interlayer adhesionBridge structural detailsEpoxyBridge deck

The invention relates to the technical field of traffic engineering, in particular to a pavement structure directly paved on a cement concrete bridge deck and a pavement method thereof. The pavement structure for the cement concrete bridge deck comprises a waterproof bonding layer, a stress absorption layer and a road surface layer, which are sequentially paved on the cement concrete bridge deck from bottom to top, wherein the waterproof bonding layer comprises a basalt gravel layer bonded on the cement concrete bridge deck through epoxy resin and a reactive waterproof binding agent layer coated on the basalt gravel layer. The invention also discloses a pavement method for the pavement structure. The pavement structure and the pavement method thereof enhance the bonding and shearing action between a pavement layer and a cement concrete slab, improve the using effect and service life of the pavement layer, reduce the temperature of mixing, transporting and paving, save energy and reduce environmental pollution; and the total thickness of the bridge deck pavement system is only 30 to 40 mm, so that the dead load of the bridge deck is greatly reduced, the pavement materials are saved and the construction cost is reduced.

Owner:CHONGQING JIAODA ROAD BRIDGE TECH RES

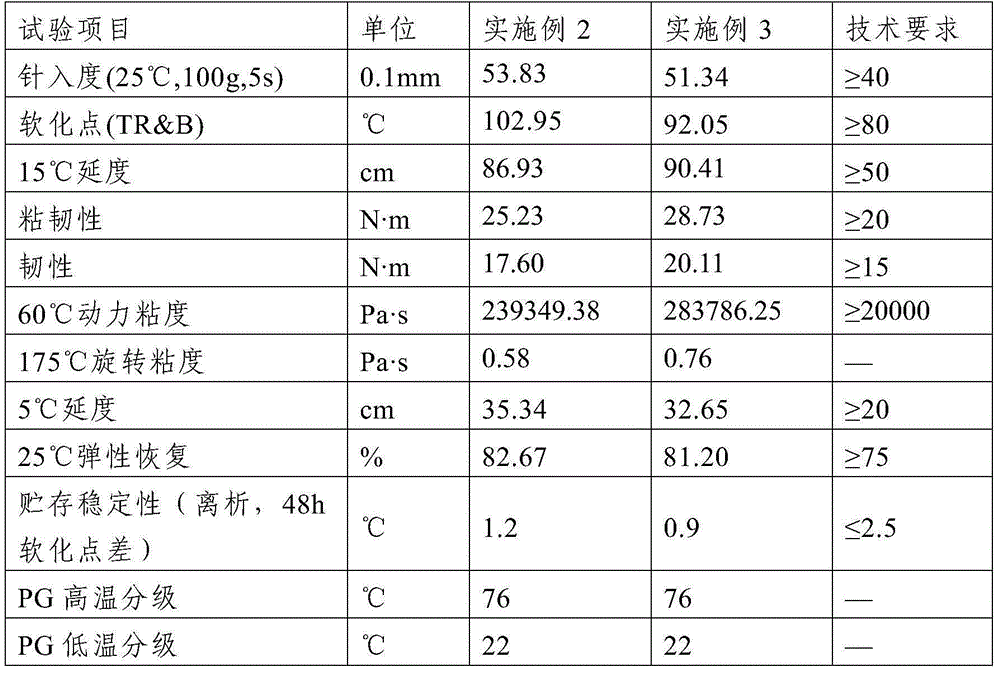

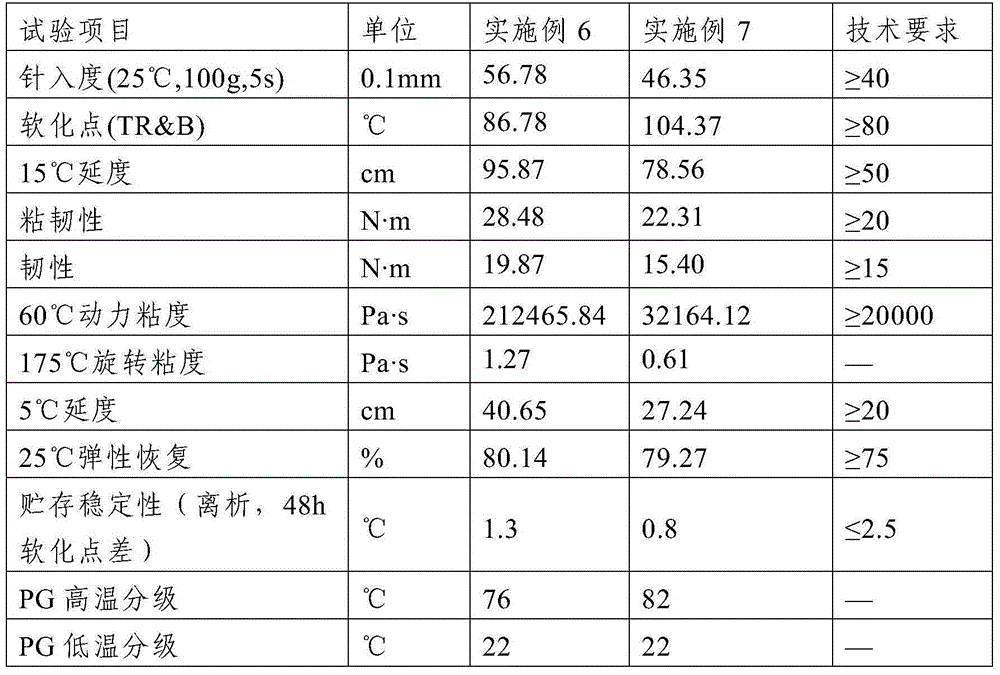

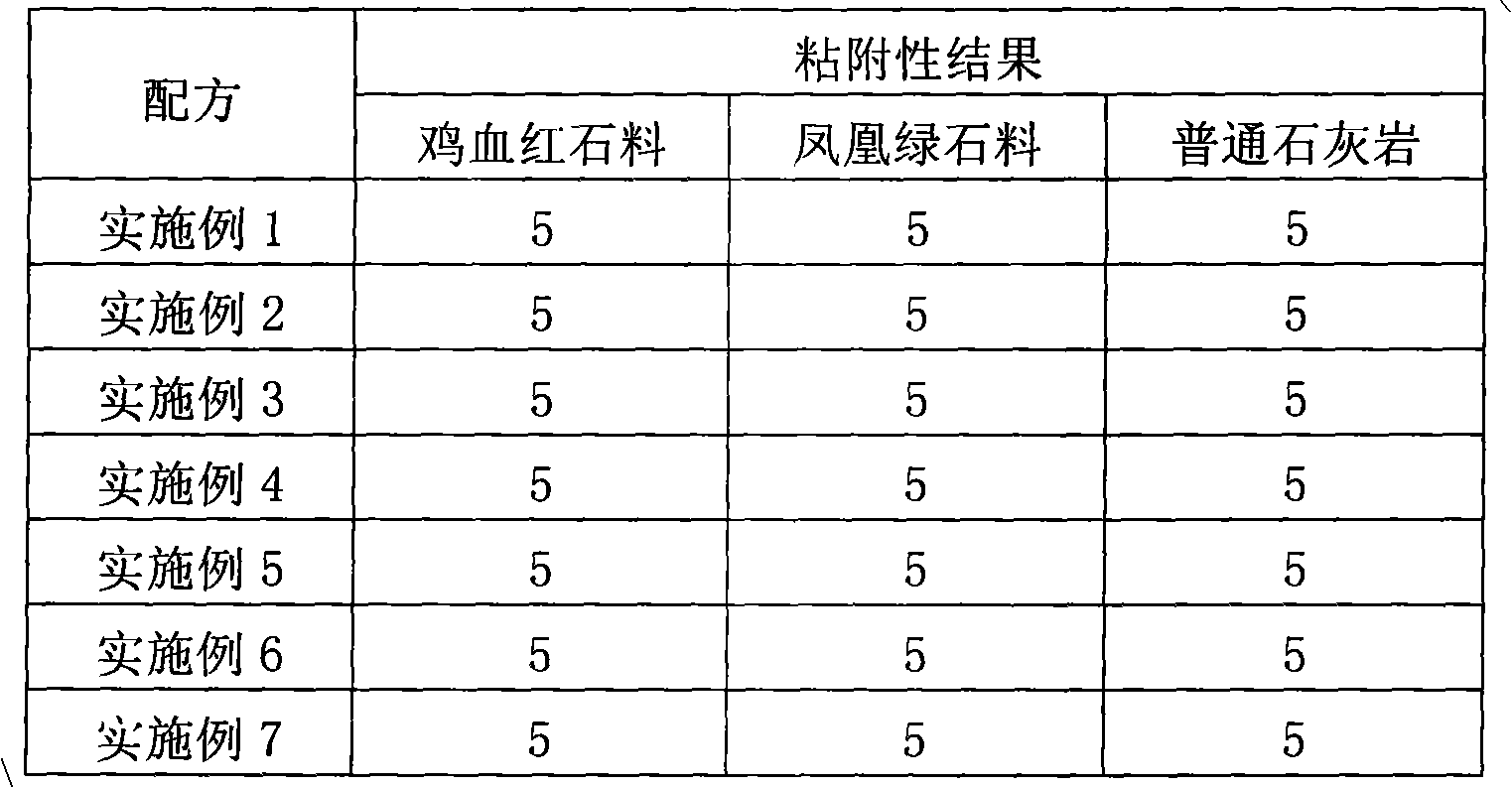

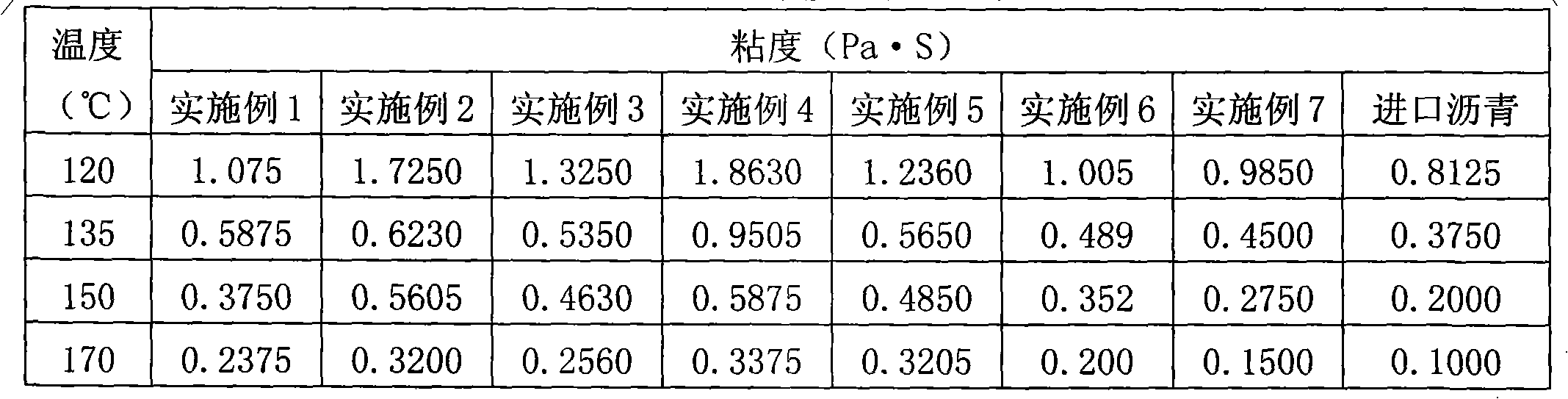

High-viscosity modified pitch and preparation method thereof

ActiveCN105111757AImprove high temperature stabilityGood low temperature crack resistanceBuilding insulationsButadiene-styrene rubberAging resistance

The invention discloses high-viscosity modified pitch which is prepared from the following raw materials in parts by weight: 100 parts of substrate asphalt, 4-9 parts of styrene copolymer, 2-5 parts of a Sasobit asphalt modifier, 0.5-3 parts of gutta-percha, 1-3 parts of butadiene styrene rubber and 0.2-1.5 parts of sulphur. Besides, the invention further discloses a method for preparing the high-viscosity modified pitch. The method comprises the following steps: 1, heating substrate asphalt, adding styrene copolymer and gutta-percha, uniformly stirring, then adding the Sasobit asphalt modifier and butadiene styrene rubber, and uniformly stirring to obtain a mixture; 2, shearing the mixture, adding sulphur, continuously shearing, and developing so as to obtain the high-viscosity modified pitch. The high-viscosity modified pitch has excellent high temperature stability, low temperature crack resistance and aging resistance, can be used for replacing expensive imported high-viscosity modified pitch under the condition of not influencing the road surface usability, and can be widely used for paving water-draining asphalt pavement.

Owner:CHANGAN UNIV

Light color cementing material and preparation method thereof

The invention relates to a light color cementing material which comprises the components mixed according to the parts by weight: 500-700 parts of base material oil, 190-450 parts of modifying agent, 45-100 parts of macromolecule copolymer, 1-10 parts of auxiliary agent and 2-6 parts of covering agent. The light color cementing material has the advantages of low cost, easy construction, good adhesion with aggregate, high temperature stability, good low temperature crack resistance and strong water damage resisting capability. After being mixed with pigments with different colors, the light color cementing material can be made into pavement materials with different colors, so as to be applicable to squares, parks, amusement parks and sidewalk road and have the function of beautifying the environment and guiding traffic; furthermore, the performance of the light color cementing material can reach the requirements of city expressway, highway and first class highway.

Owner:天津市市政工程研究院

Colored pavement cementing material and preparation method thereof

InactiveCN102558751AStrong resistance to deformation at high temperatureImprove aging resistanceIn situ pavingsBuilding insulationsPlasticizerRoad surface

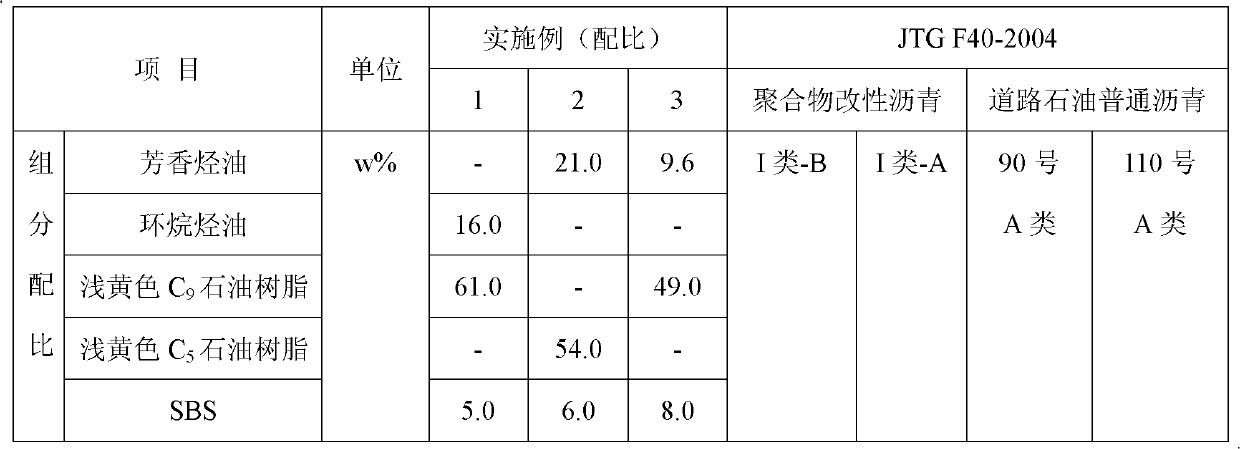

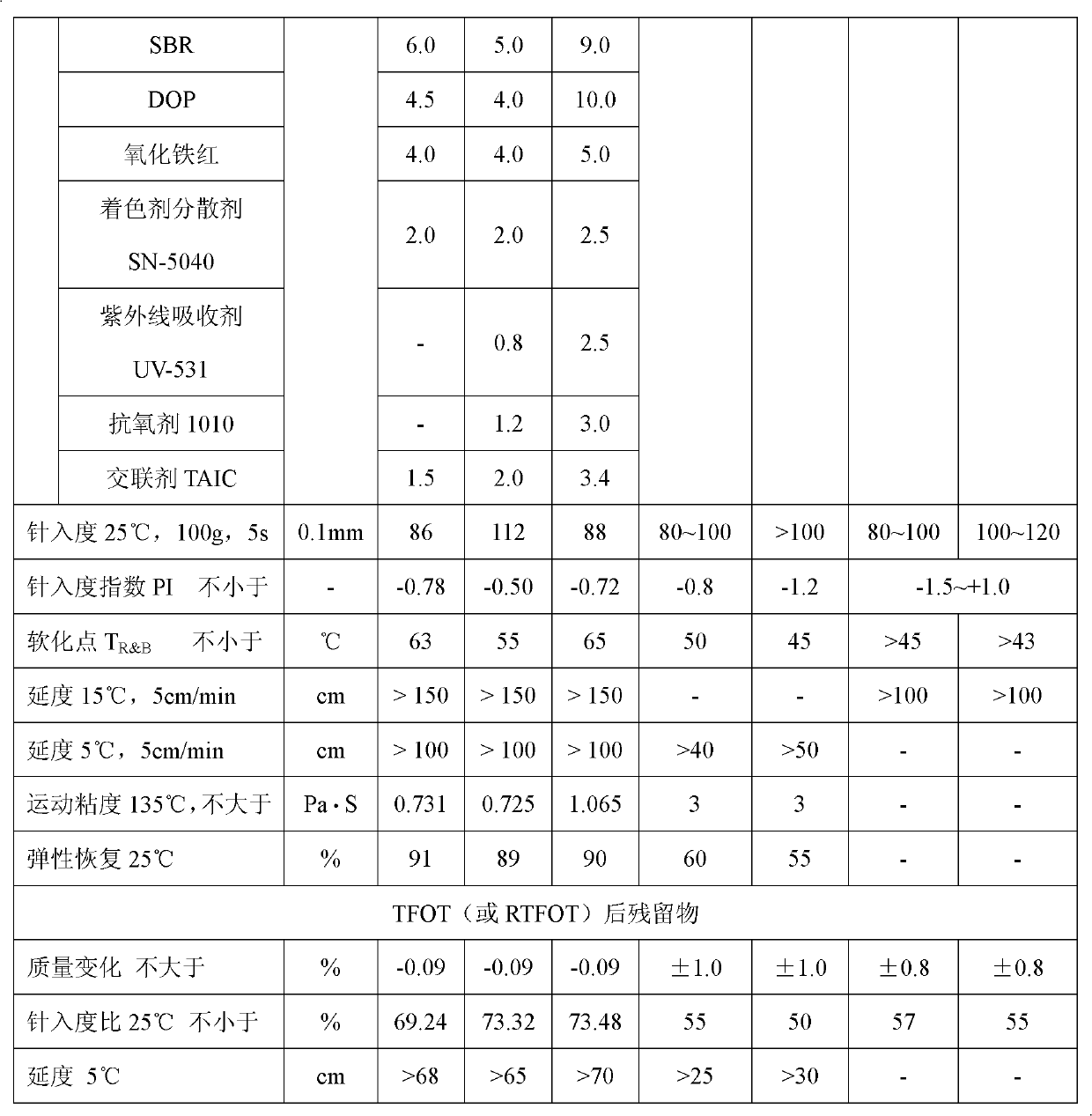

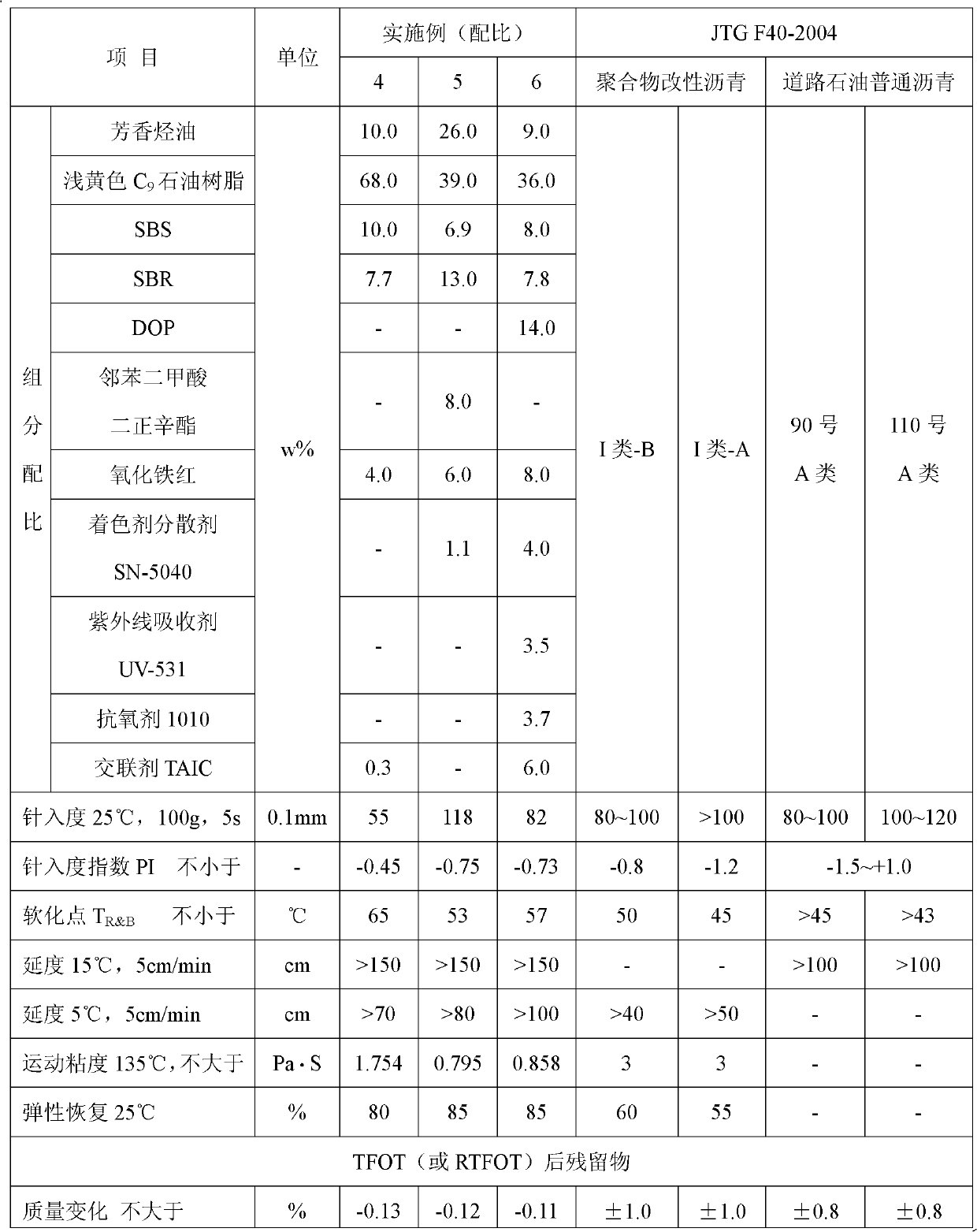

This invention discloses a colored pavement cementing material, which comprises the following components by weight: 7-27% of softener, 71% of resin tackifier, 5-13% of SBS (styrene-butadiene-styrene block copolymer), 5-15% of SBR (styrene butadiene rubber), 0-16% of plasticizer, 4-9% of coloring agent, 1-5% of colorants dispersing auxiliary, 0-4% of ultraviolet absorbent, 0-4% of antioxygen, and 0-8% of crosslinking agent. The preparation method comprises the following steps: placing the softener in a reactor, heating to a temperature of 140-150 DEG C, continuously heating, stirring and starting to add the resin tackifier, continuously stirring with a temperature of 150-180 DEG C until the resin tackifier is completely dissolved, adding the SBS to dissolve, adding the plasticizer to dissolve, and adding the SBR to dissolve, and finally adding the rest materials, stirring to sufficiently dissolve, and air cooling to get the colored pavement cementing material.

Owner:CHANGAN UNIV

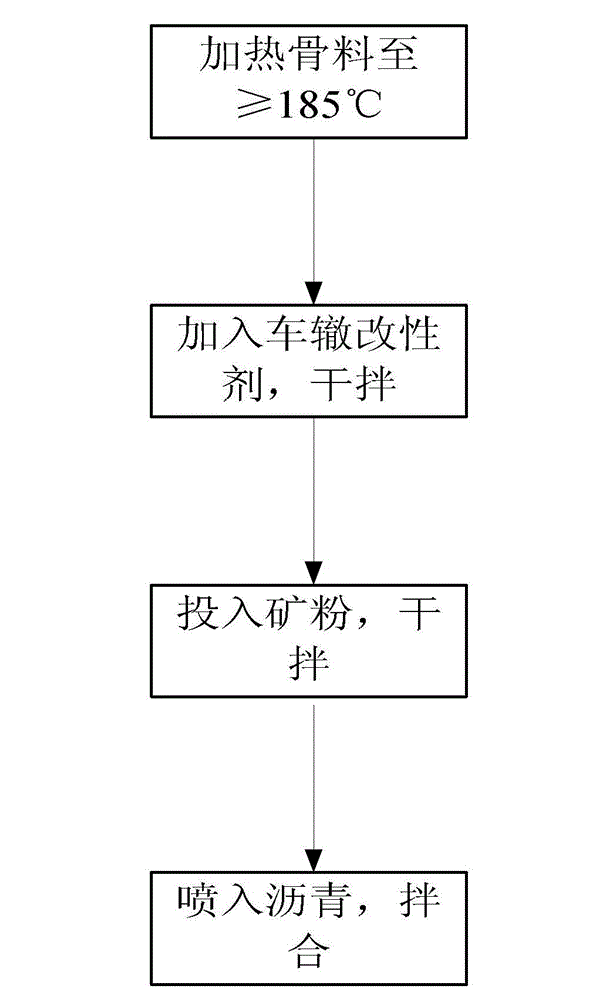

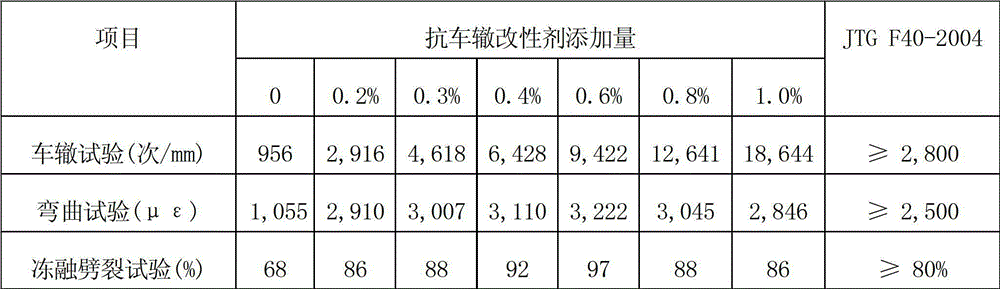

Anti-rutting modifying agent used for asphalt pavement and asphalt mixture containing anti-rutting modifying agent

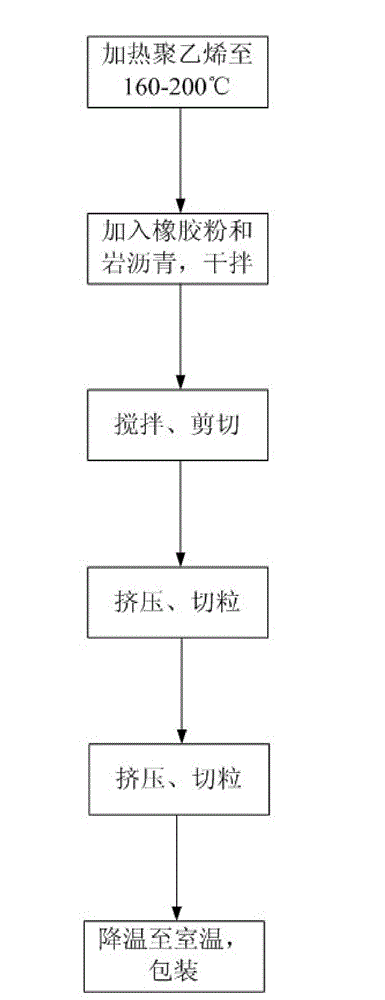

ActiveCN103059587ASolve technical problemsRealize repeated recyclingBuilding insulationsPolymer scienceEngineering

The invention relates to an anti-rutting modifying agent. The anti-rutting modifying agent comprises (a) high-density low-pressure polyethylene, (b) rubber powder and (c) rock asphalt. The anti-rutting modifying agent is good in low-temperature cracking resistance, high in bonding strength, high in water damage resistance, good in non-deformability, low in cost, simple in preparation technology, convenient to operate and convenient to add in asphalt mixture.

Owner:北京中交路通科技发展有限公司

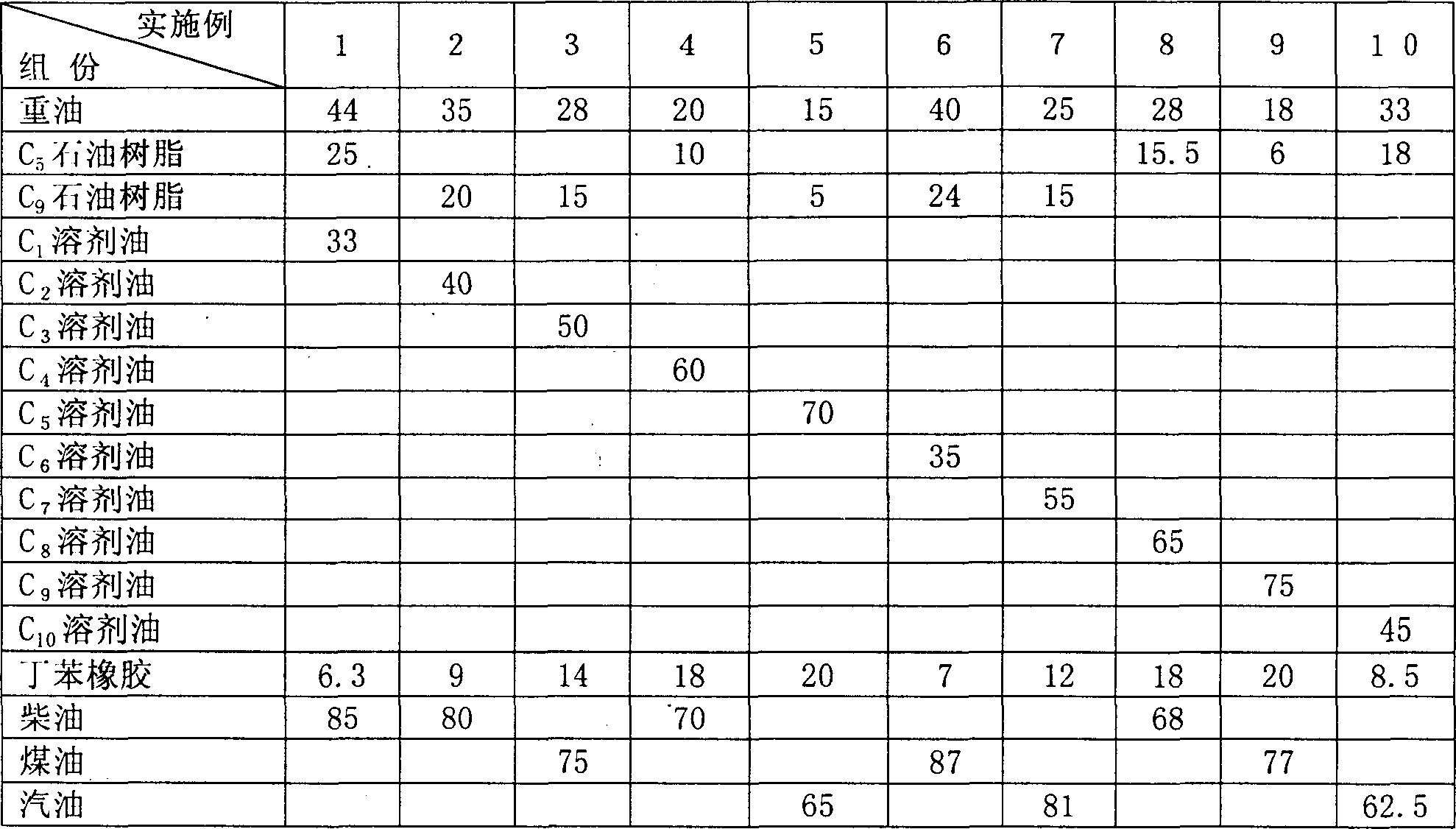

Asphalt cold repairing binding material and its production process

InactiveCN1441004AImprove featuresGood compatibilityIn situ pavingsBuilding insulationsKeroseneRoad surface

The present invention relates to a kind of asphalt road cold repairing material. It is prepared with ehavy oil, C5 or C9 petroleum resin, C1-C10 solvent oil, styrene-butadiene rubber, diesel oil or kerosene or gasoline, thermoplastic styrene-butadiene rubber, naphthenic oil, RC-10 mineral oil and road petroleum asphalt. The preparation process includes preparing prepolymer A with heavy oil and petroleum resin; preparing prepolymer B with solvent oil and styrene-butadiene rubber; preparing prepolymer C with diesel oil or kerosene or gasoline, thermoplastic styrene-butadiene rubber and naphthenic oil; preparing cold repairing asphalt additive with prepolymer A, prepolymer B, prepolymer C and RC-10 mineral oil; and adding road petroleum asphalt.

Owner:袁永长

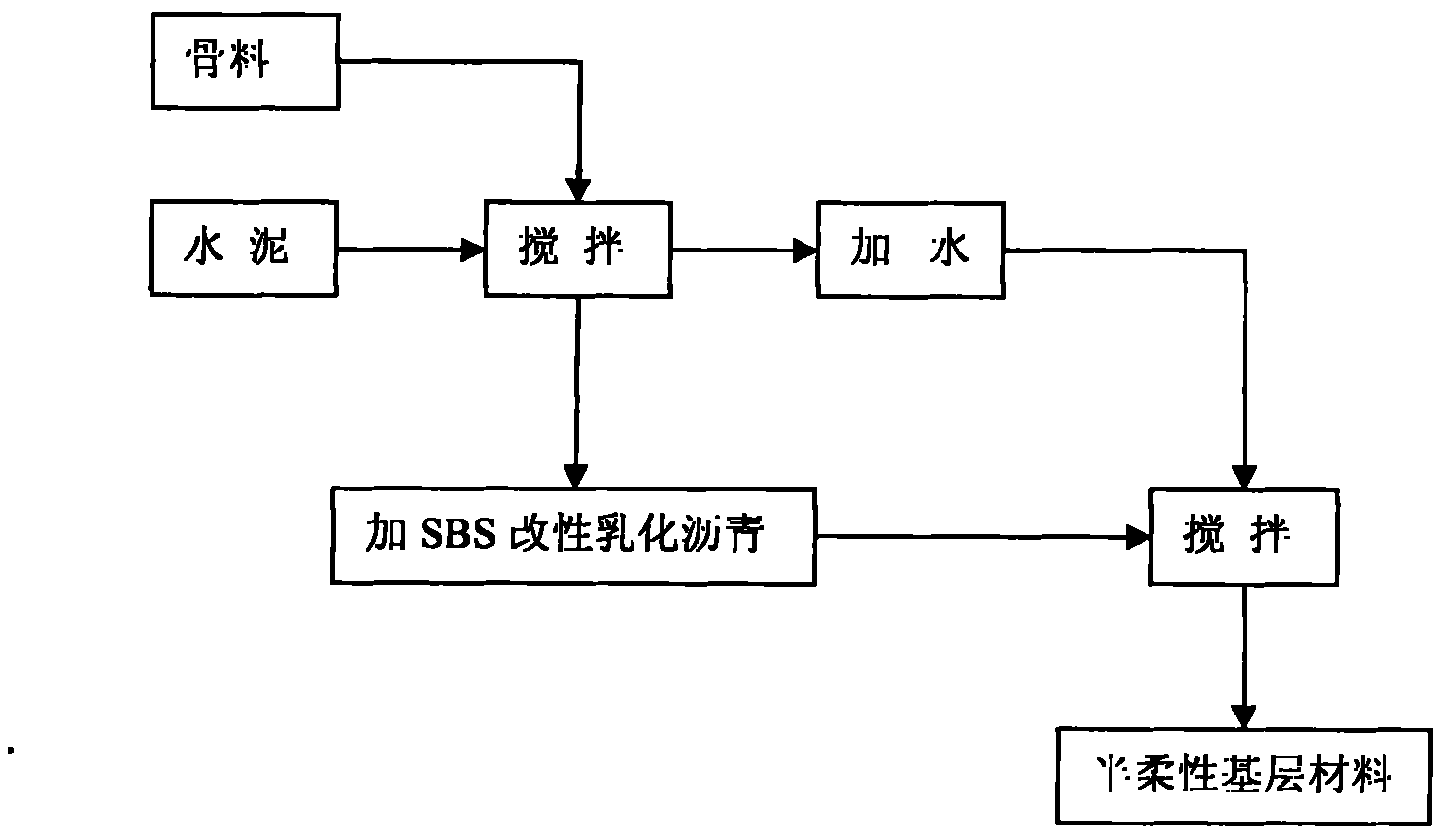

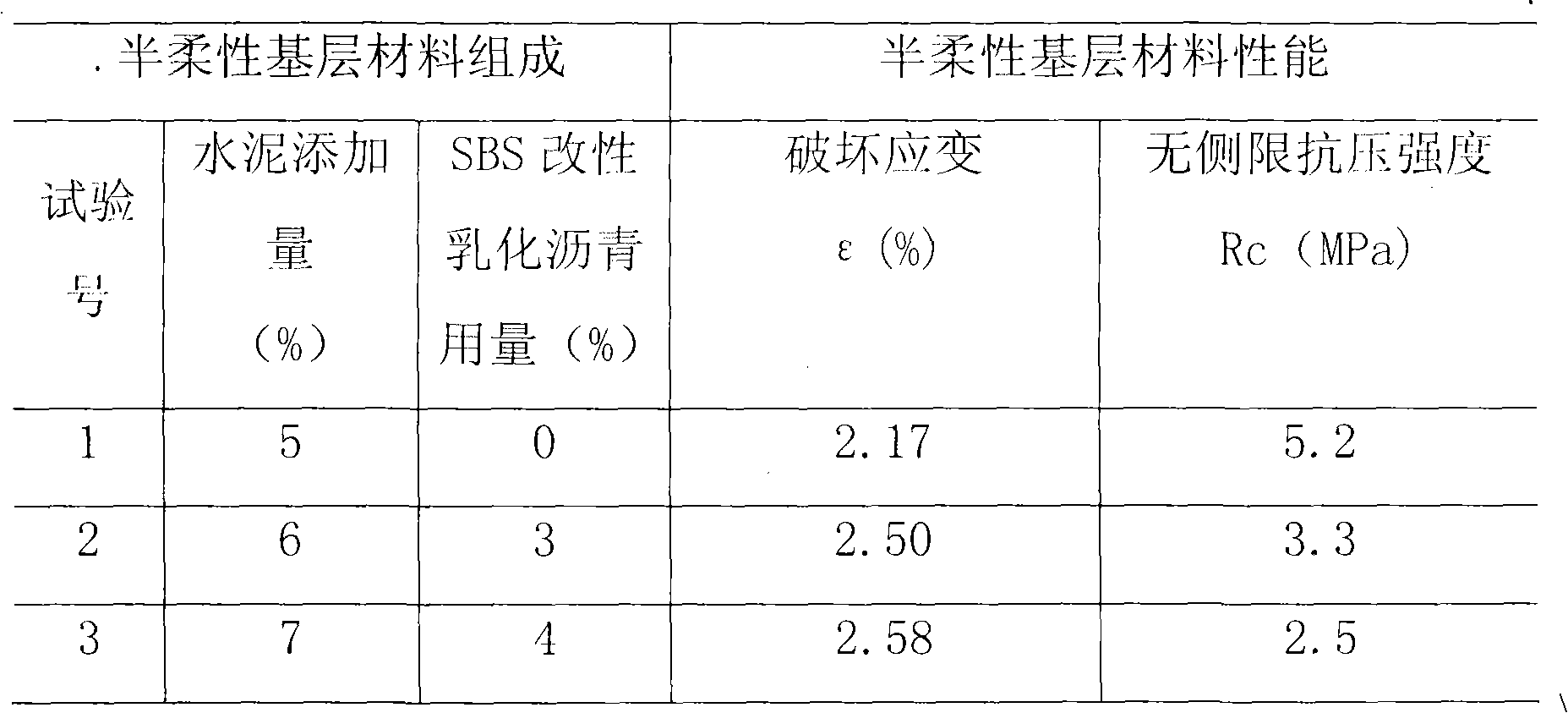

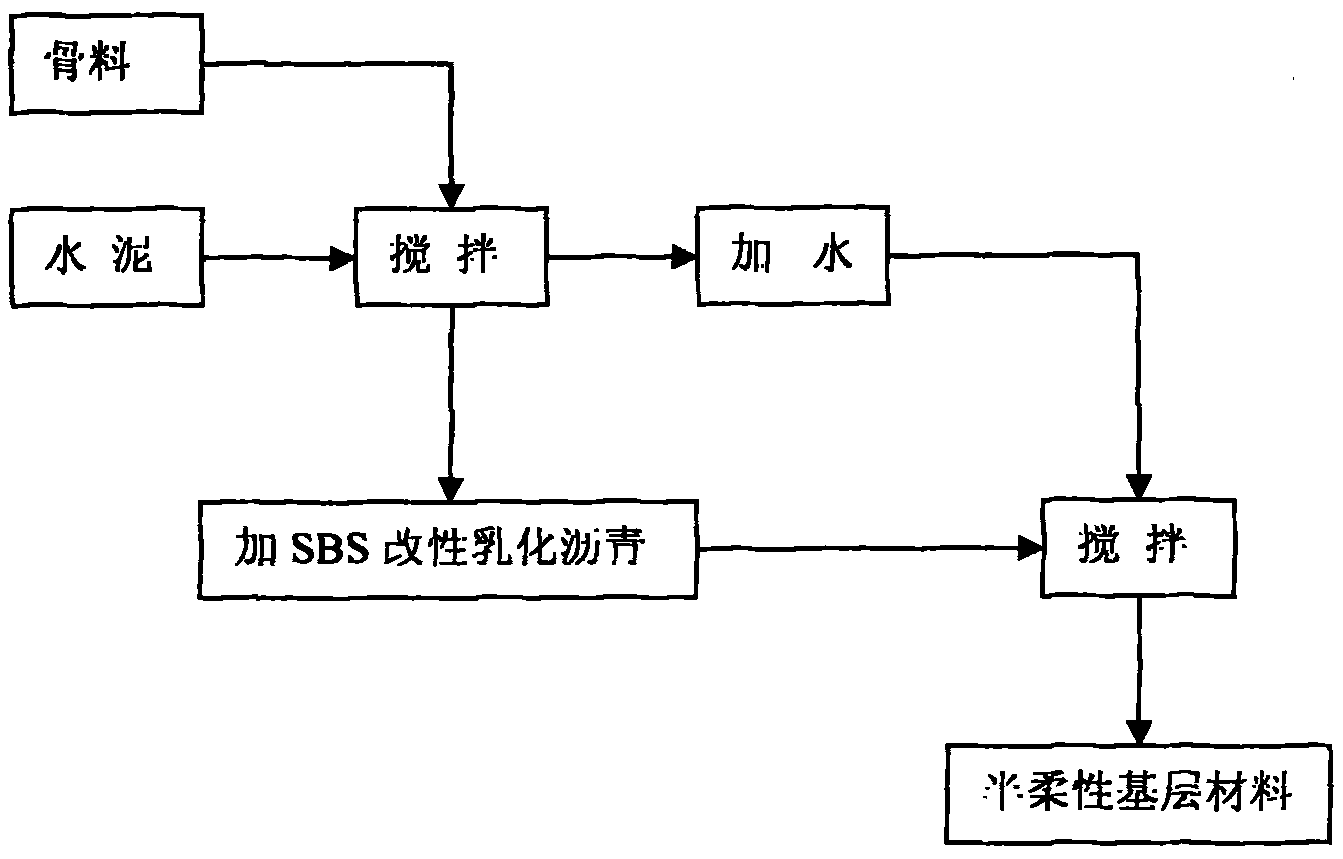

Semi-flexible base material and production method thereof

The invention provides a semi-flexible base material and a production method thereof, which belong to the technical field of modification and emulsification engineering, and comprises the following components by weight percent: 90-95% of aggregate, 3-8% of cement and 2-16% of SBS modified and emulsified asphalt. The production method comprises the following steps of: after firstly dry mixing the cement and stones uniformly, adding water and SBS modified and emulsified asphalt to stir, and after uniform mixing, obtaining the semi-flexible base material. The invention is better than rigid base material and flexible base material, compound produced by the using the semi-flexible base material has good permanent deformation resistance, improves the initial strength of semi-rigid base material and shortens the time for forming the strength, simultaneously increases the flexibility through adding emulsified asphalt, takes the advantage of asphalt and cement base stabilizing performance to make up the shortage, has appropriate rigidity, higher strength, smaller temperature sensitivity and better low temperature crack resistance, and decreases and prevents the base from cracking, and thereby preventing roads from reflection crack, playing good road use performance, and prolonging the service lives of the roads.

Owner:GUANGZHOU UNIVERSITY

Rubber powder modified emulsified asphalt waterproof coating

PendingCN103897594AImprove high temperature stabilityGood low temperature crack resistanceUnspecified rubber coatingsBuilding insulationsEmulsionPolymer science

The invention discloses a rubber powder modified emulsified asphalt waterproof coating. The rubber powder modified emulsified asphalt waterproof coating comprises emulsified asphalt and a rubber powder emulsion. Asphalt is prepared into the emulsified asphalt, swelling treatment is performed on rubber powder, the swollen rubber powder is prepared into the rubber powder emulsion, the emulsified asphalt and the rubber powder emulsion are metered, mixed and uniformly stirred, and high-speed shear modification treatment is performed by a colloidal mill to obtain the rubber powder modified emulsified asphalt waterproof coating disclosed by the invention. The waterproof coating keeps the excellent performances of rubber modified asphalt, solves the problem that the rubber modified asphalt can not be saved and used at normal temperature, overcomes the shortcomings of high energy consumption, inconvenience in construction, environmental pollution and the like of the rubber modified asphalt, and overcomes the problems of expensive price, complex manufacturing process and the like of traditional SBS (styrene-butadiene-styrene) and SBR (styrene butadiene rubber) modified emulsified asphalt. The rubber powder modified emulsified asphalt waterproof coating disclosed by the invention takes waste tire rubber powder as a modifying material so as to be in line with the national industrial policy of circular economy and low-carbon economy.

Owner:李志国

Modified asphalt for road and preparation method

InactiveCN106883626AImprove cold resistanceGood anti-crackingRoads maintainenceBuilding insulationsCelluloseEpoxy

The invention discloses modified asphalt for a road and a preparation method. The modified asphalt contains the following components: asphalt, SBS, polybutylene terephthalate, carbon powder, attapulgite clay, epoxy resin, waste rubber, polypropylene fibers, cellulose ether, nano titanium dioxide, sodium chloride, sodium silicate, filler, a compatilizer and a softener. The preparation method comprises the following steps: firstly, preparing pasty attapulgite clay; weighing asphalt and adding the same into a reaction tank; raising the temperature till the asphalt is in a dissolved flowable state; adding a polymer component, the cellulose ether, the compatilizer and the softener into the reaction tank to stir and mix to react for 2-4h; then adding the residual components into the mixture; then placing the mixture into a mixer to be mixed for 2-4h; and cooling the mixture to obtain the modified asphalt. The modified asphalt not only has the characteristics of better cold resistance, crack resistance, aging resistance and high strength, but also has a certain snow-melting and anti-freezing property, and greatly improves the using safety of an asphalt pavement.

Owner:合肥天沃能源科技有限公司

Durable rubber asphalt and preparation method thereof

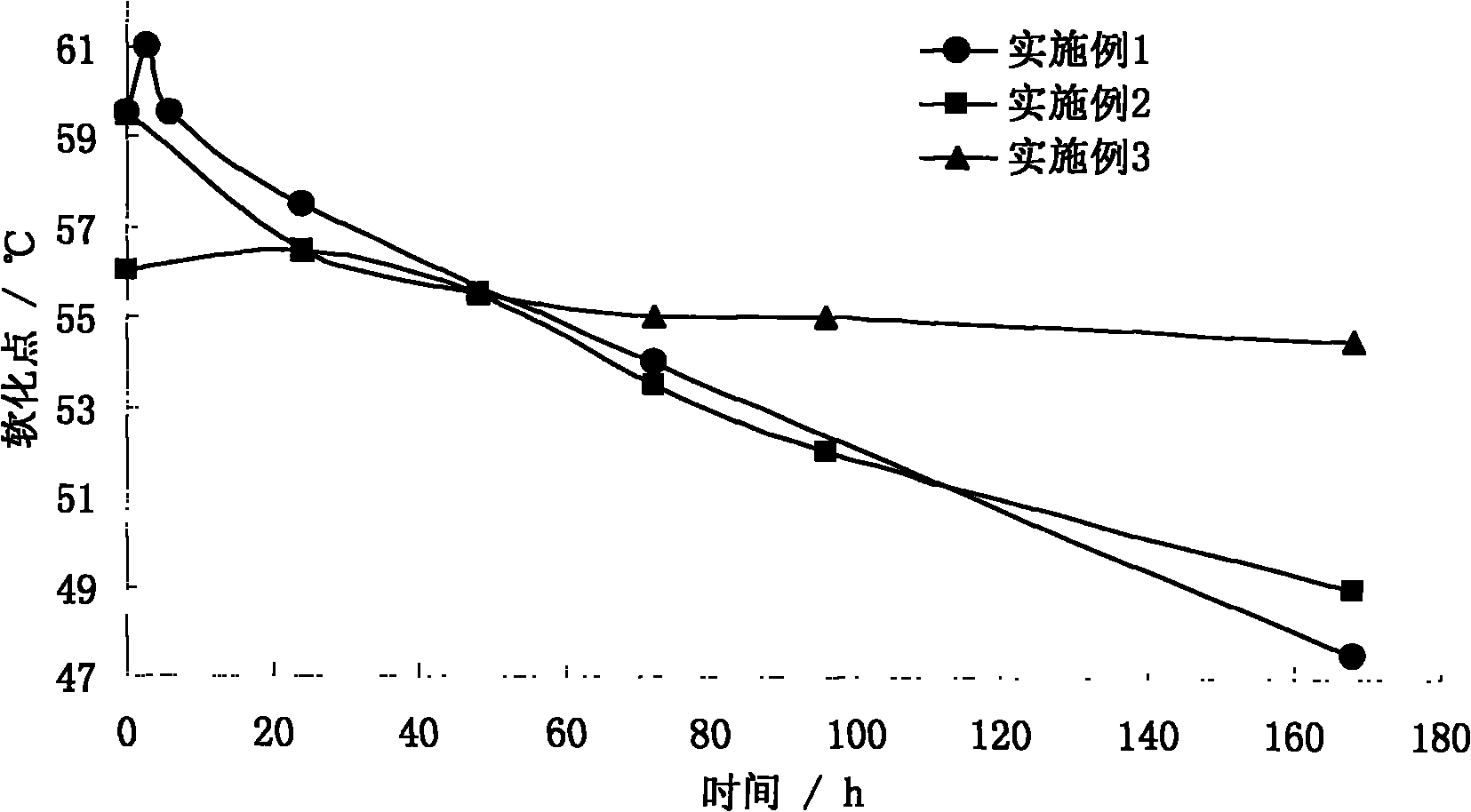

InactiveCN101870818ASolve instabilityImprove performanceBuilding insulationsHigh temperature storagePolymer science

The invention provides durable rubber asphalt, which is characterized by: comprising the raw materials of asphalt and rubber powder, wherein the amount of the asphalt is 75 to 85 percent based on the total weight of the asphalt and the rubber powder and the amount of the rubber powder is 15 to 25 percent based on the total weight of the asphalt and the rubber powder; and also comprising an activator and an anti-reversion agent, wherein the amount of the activator is 0.1 to 1 percent based on the weight of the rubber powder, and the amount of the anti-reversion agent is 0.1 to 0.5 percent based on the weight of the rubber powder. The durable rubber asphalt provided by the invention solves the instability problem of rubber powder modified asphalt stored at high temperature by using the synergistic effect of the anti-reversion agent and the activator, and has the characteristic of resisting softening point attenuation during high-temperature storage. When used in a mixed asphalt material, the durable rubber asphalt has the characteristics of low oil amount and high low-temperature anticracking performance. The durable rubber asphalt can be used in road construction and maintenance materials for making bridge surface waterproof layers, stress absorbing layers, asphalt synchronous chip sealing layers and the like.

Owner:上海道柯特沥青科技有限公司

Novel high viscosity asphalt and preparation method thereof

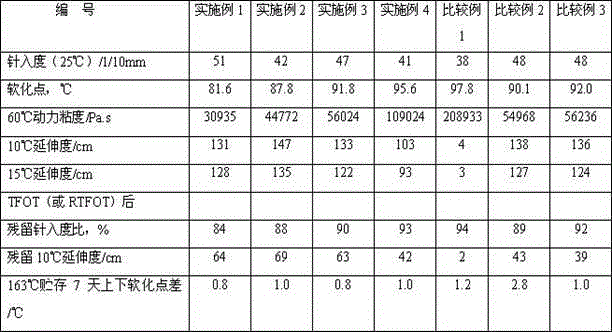

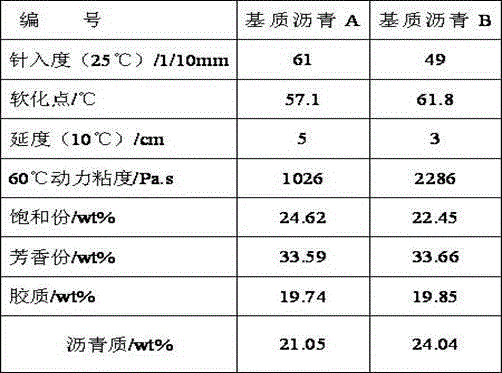

ActiveCN104559235AHigh softening pointRaise the reaction temperatureBuilding insulationsPhosphoric acidRoad surface

The invention discloses novel high viscosity asphalt and a preparation method thereof. The novel high viscosity asphalt comprises the following raw materials in parts by weight: 100 parts of base asphalt with high asphaltene content, 0.1-1.2 part of polyphosphoric acid, 2-12 parts of a ductility improver mother liquid, 1-8 parts of a dispersant, and 0.2-0.5 part of a coupling agent. The preparation method comprises the following steps: adding the polyphosphoric acid in the molten base asphalt to perform a chemical modification reaction, then adding the ductility improver mother liquid, continuing to react, and finally adding the dispersant and the coupling agent to continue to react for a period of time to prepare high viscosity asphalt, wherein the whole process is performed under a highs-speed stirring condition. The high viscosity asphalt is high in 60-degree dynamic viscosity, high in softening point, high in low-temperature ductility, stable to store, and good in adhesion to aggregates, has excellent high temperature stability, excellent low temperature anti-cracking performance, excellent anti-fatigue performance and excellent water resistance, is especially suitable for high-temperature humid areas, areas with relatively high diurnal temperature difference, and paving of heavy-duty roads and drainable pavements, effectively prevents common pavement damages such as pavement rutting, pavement upheaval, pavement fatigue cracking, pavement cold cracking and water encroachment on pavements, and prolongs the service life of the pavement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of separated plant-mixed warm-hot regenerated asphalt mixed material

InactiveCN106746926AReduce effective utilizationPromote full accessSolid waste managementPavement engineeringBituminous materials

The invention relates to an asphalt material for pavement engineering and in particular to a preparation method of a separated plant-mixed warm-hot regenerated asphalt mixed material. The preparation method comprises the following steps: (1) detecting the asphalt content of a recovered asphalt pavement material, ageing the asphalt performance and mineral aggregate gradation; (2) determining the content of the recovered asphalt pavement material, a novel aggregate, limestone mineral powder, novel asphalt and a regenerator; (3) adding the mixture into a mixing pot for prestirring; (4) adding the regenerator; (5) discharging the obtained product out of a pot and developing at 40-150 DEG C; (6) adding the heated novel aggregate into the stirring pot, adding the developed product in the step (5) and stirring; and (7) adding the novel asphalt and limestone mineral powder into the product obtained in the step (6) and stirring, and then discharging and forming. The asphalt material provided by the invention is simple in process, good in regenerating effect, high in utilization ratio of the regenerator, relatively low in cost and good in comprehensive pavement performance of the product.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Thermosetting epoxy asphalt material and preparation method thereof

The invention relates to a thermosetting epoxy asphalt material and a preparation method thereof, which are mainly used in field of buildings. The thermosetting epoxy asphalt material is characterized by being prepared from the following raw materials in part by weight: 100 parts of asphalt, 20 to 40 parts of epoxy resin, 20 to 40 parts of vulcanizer, 20 to 40 parts of curing agent, 0.3 to 1.2 parts of curing accelerator and 20 to 60 parts of oleoylchloride thermosetting epoxy asphalt compatibilizer. In the thermosetting epoxy asphalt material prepared by the method, the asphalt and the epoxy resin are uniformly mixed.

Owner:湖北永阳材料股份有限公司

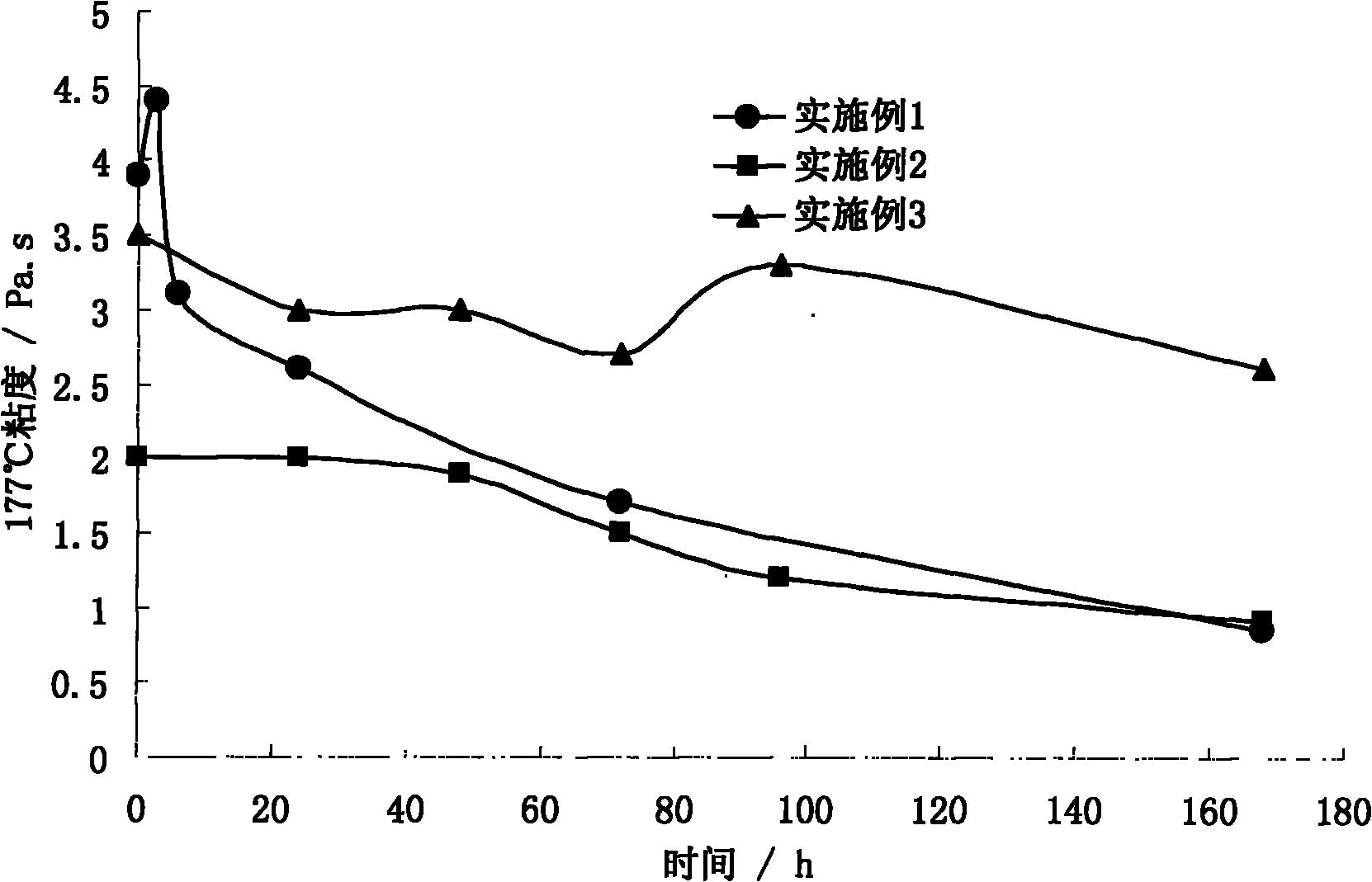

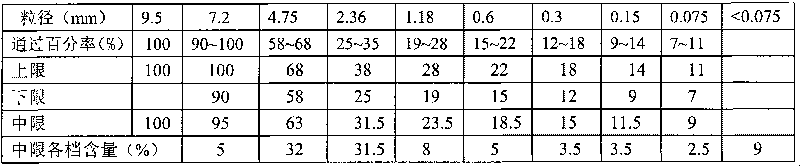

Small particle size gap gradation compact-type low-noise rubber asphalt concrete

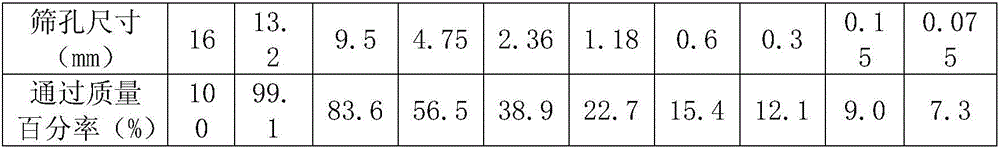

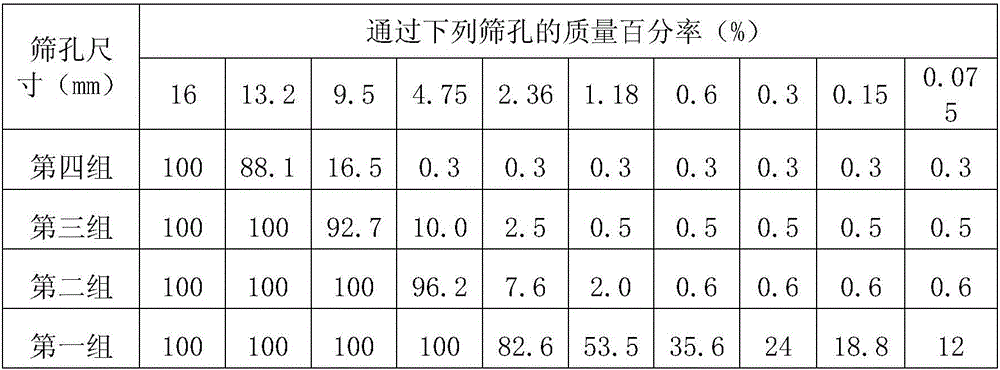

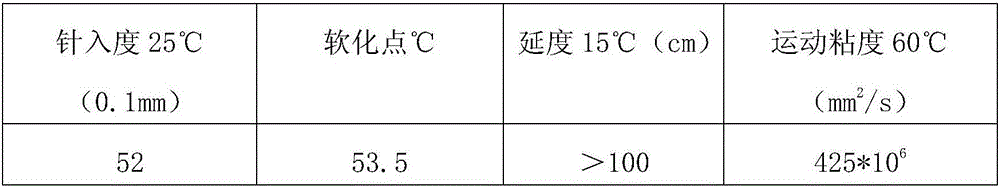

ActiveCN101746994AReduce driving noiseGood high temperature resistance to shear deformationSolid waste managementLow noisePorosity

The invention provides a small particle size gap gradation compact-type low-noise rubber asphalt concrete. The mixture has the characteristics that: 1) for the mineral aggregate gradation scope of small particle size coarse aggregate gap gradation, the maximum nominal particle size of the gradation is 7.2 mm; in order to ensure compactness, the percentage composition of padding smaller than 0.075 mm in the mixture is from 7 to 11 percent; and in order to ensure skid resistance, the percentage composition of small particle size gravels larger than 2.36mm in the mixture is from 65 to 75 percent; 2) cement or slaked lime is used to replace mineral powder; 3) rubber asphalt is used as binder material in the mixture; scrap tire crumb rubber in the rubber asphalt is crumb rubber which has the specification of 40 to 80 meshes, is pulverized in normal temperature and has higher content of natural rubber, and the addition amount of the scrap tire crumb rubber reaches 21 to 23 percent of the weight of the asphalt; and the 180 DEG C brook field viscosity index of the rubber asphalt is 2.5 to 4Pa. s; 4) the design porosity of the mixture is 5 to 6 percent. The invention not only has good road performance such as skid resistance and high temperature deformation resistance, but also has the comprehensive characteristics of good durability, wide application range and obvious reduction of noise.

Owner:交通部公路科学研究院

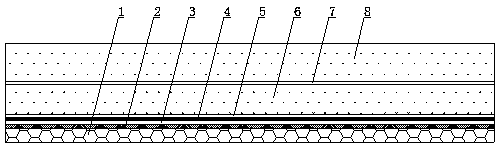

Steel box girder bridge deck pavement layer with high stability and high vibration resistance

InactiveCN104278630AHigh bonding strengthImprove bindingIn situ pavingsBridge structural detailsPolyesterEpoxy

The invention relates to a steel box girder bridge deck pavement layer with high stability and high vibration resistance. The steel box girder bridge deck pavement layer comprises a steel plate (1), wherein a waterproof bonding layer (2), a modified epoxy resin structure glue layer (3), a polyester filament and geotechnical cloth combined layer (4), a first high-viscosity modified asphalt tack coat (5), a first high-viscosity modified polyester fiber mixed stone mastic asphalt mixture layer (6), a second high-viscosity modified asphalt tack coat (7) and a second high-viscosity modified polyester fiber mixed stone mastic asphalt mixture layer (8) are arranged on the upper surface of the steel plate (1) from bottom to top. The steel box girder bridge deck pavement layer has the advantages of improving the bonding strength of an asphalt concrete pavement layer and a bridge deck slab, and improving the combining performance of the asphalt concrete pavement layer and the bridge deck slab due to high strength, good elasticity and high toughness of a geotechnical cloth; the geotechnical cloth has good traction action on the whole bridge deck slab, and finally, the purposes that the bridge deck pavement layer is prevented from shearing fracture, the asphalt pavement is prevented from translation, upheaval and other diseases in a travelling process, and the stability and vibration resistance of the bridge deck slab are effectively improved are achieved.

Owner:WUHAN UNIV

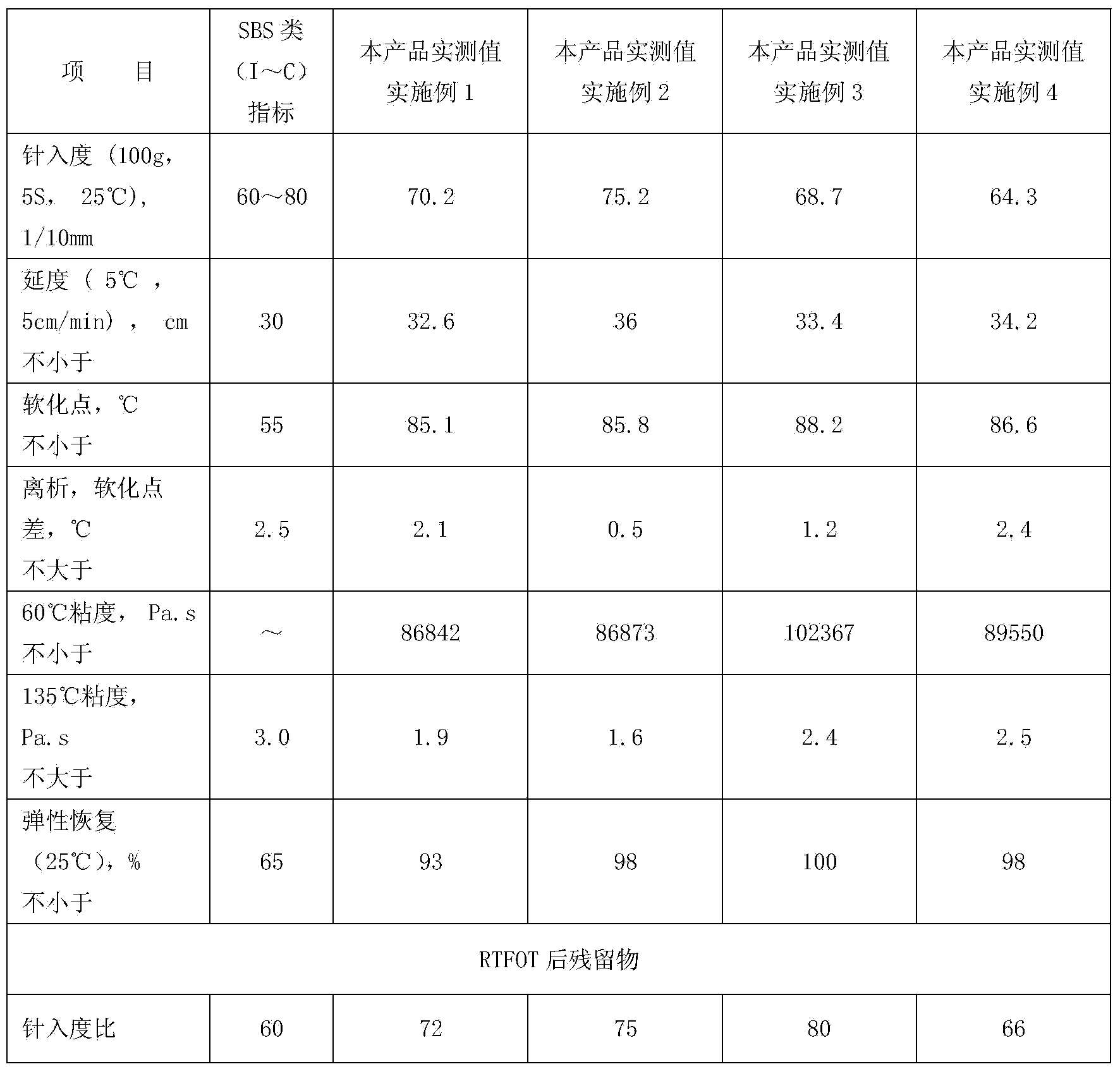

High-viscosity high-elasticity pitch and preparation method thereof

ActiveCN103849153AEasy constructionImprove workabilityBuilding insulationsViscosityMaterials science

The invention discloses high-viscosity high-elastic pitch and a preparation method thereof. The high-viscosity high-elasticity pitch prepared according to the invention has high viscosity and high elasticity as well as excellent workability, and meets the requirements of deformation resistance, fatigue resistance and long service life of large-span bridges, and with the high-viscosity high-elasticity pitch, the problem of poor workability of the existing high-viscosity high-elasticity pitch is solved; the viscosity of the pitch at 60 DEG C is larger than 80000 Pa.s, the viscosity at 135 DEG C is smaller than 3 Pa.s, the softening point reaches up to 85 DEG C above, and the cost is 20% lower than that of the common similar high-viscosity high-elasticity pitch in China at present.

Owner:CNPC JIANGSU FUEL ASPHALT

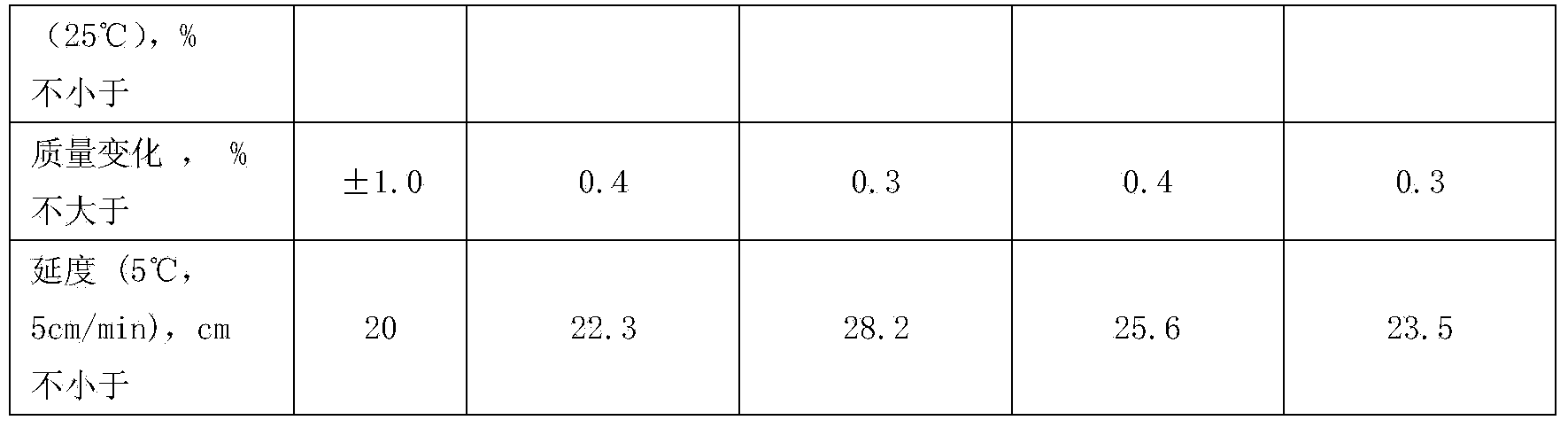

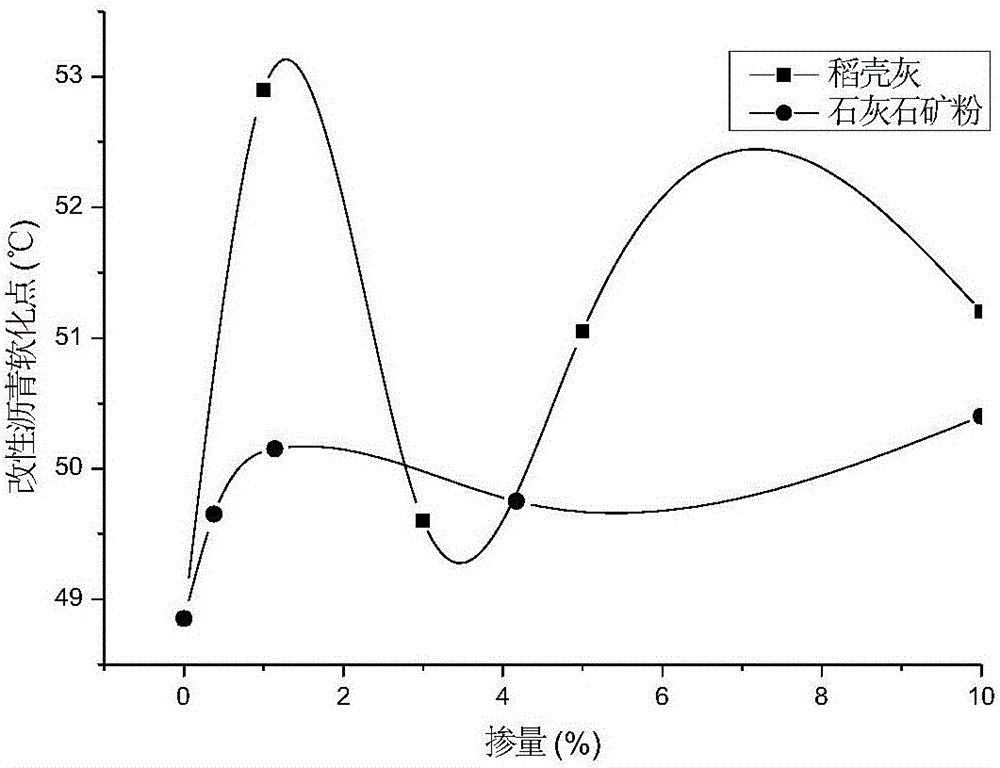

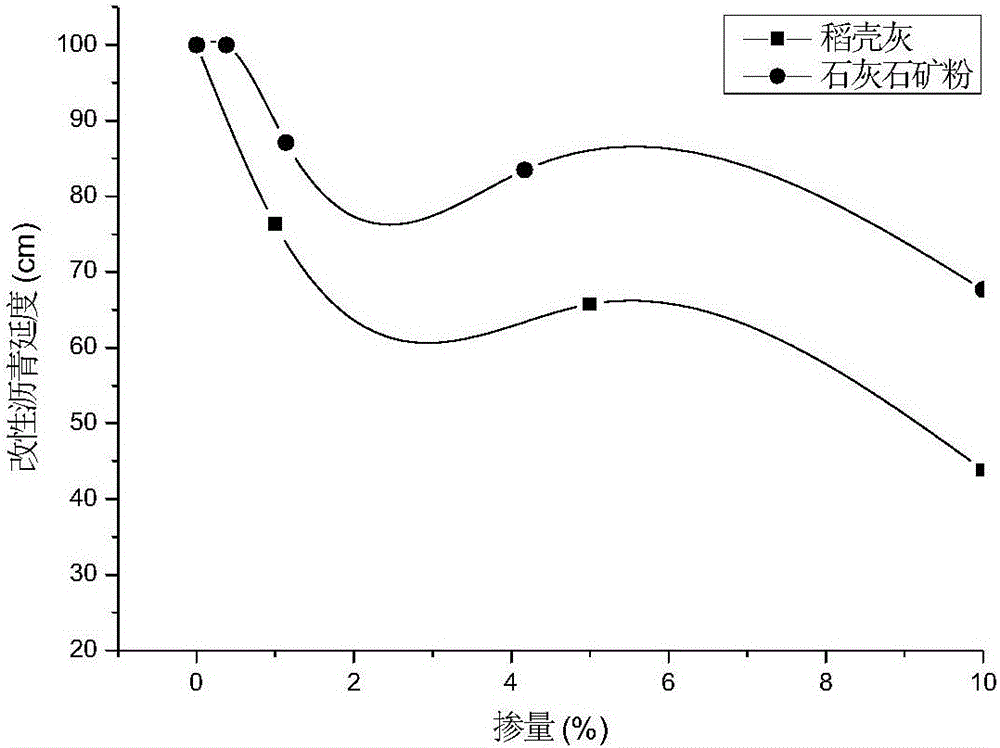

Application of rice hull ash as asphalt modifier

InactiveCN105802262AHigh viscosityHigh temperature anti-rutting performanceBuilding insulationsDiseaseCrack resistance

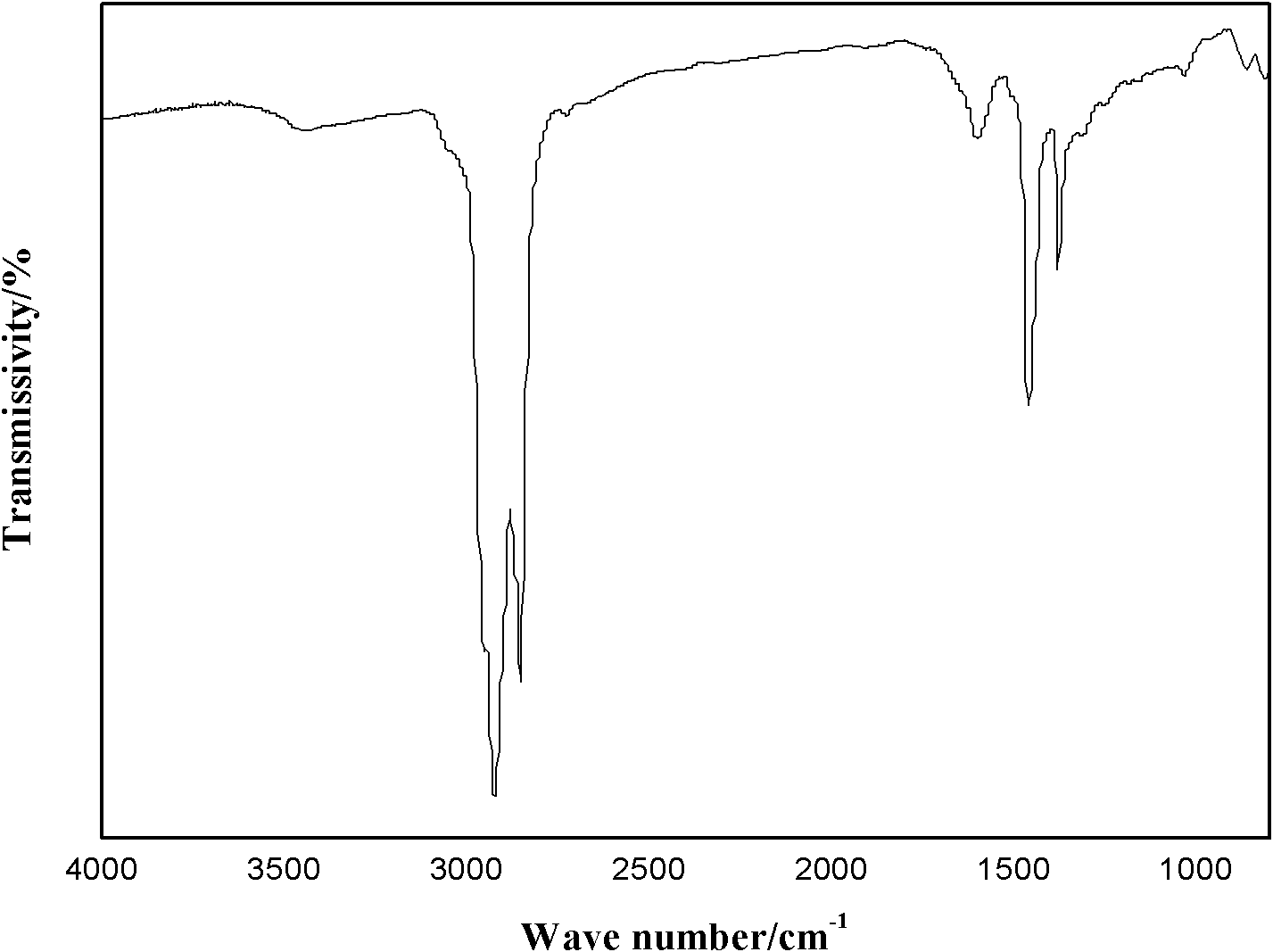

The invention relates to an application of rice hull ash as an asphalt modifier. The test of three indexes of asphalt, the Bush rotary viscosity test and the DSR (dynamic shear rheometer) test prove that the rice hull ash asphalt modifier can effectively improve high-temperature deformation resistance and durability of asphalt cement and an asphalt mixture and guarantee certain low-temperature crack resistance. Therefore, diseases of asphalt pavements in high-temperature regions are effectively reduced, the asphalt pavements can adapt to complicated and changeable environmental conditions, and driving safety and service level are guaranteed. Besides, the microwave heating test and infrared thermal imaging photographing prove that compared with limestone mineral powder filler, the rice hull ash asphalt modifier enables the modified asphalt mortar to have an obviously higher microwave heat absorption temperature-rise rate, so that the rice hull ash asphalt modifier can be applied to technical research of the field of ice and snow smelting for the asphalt pavements.

Owner:CHANGAN UNIV

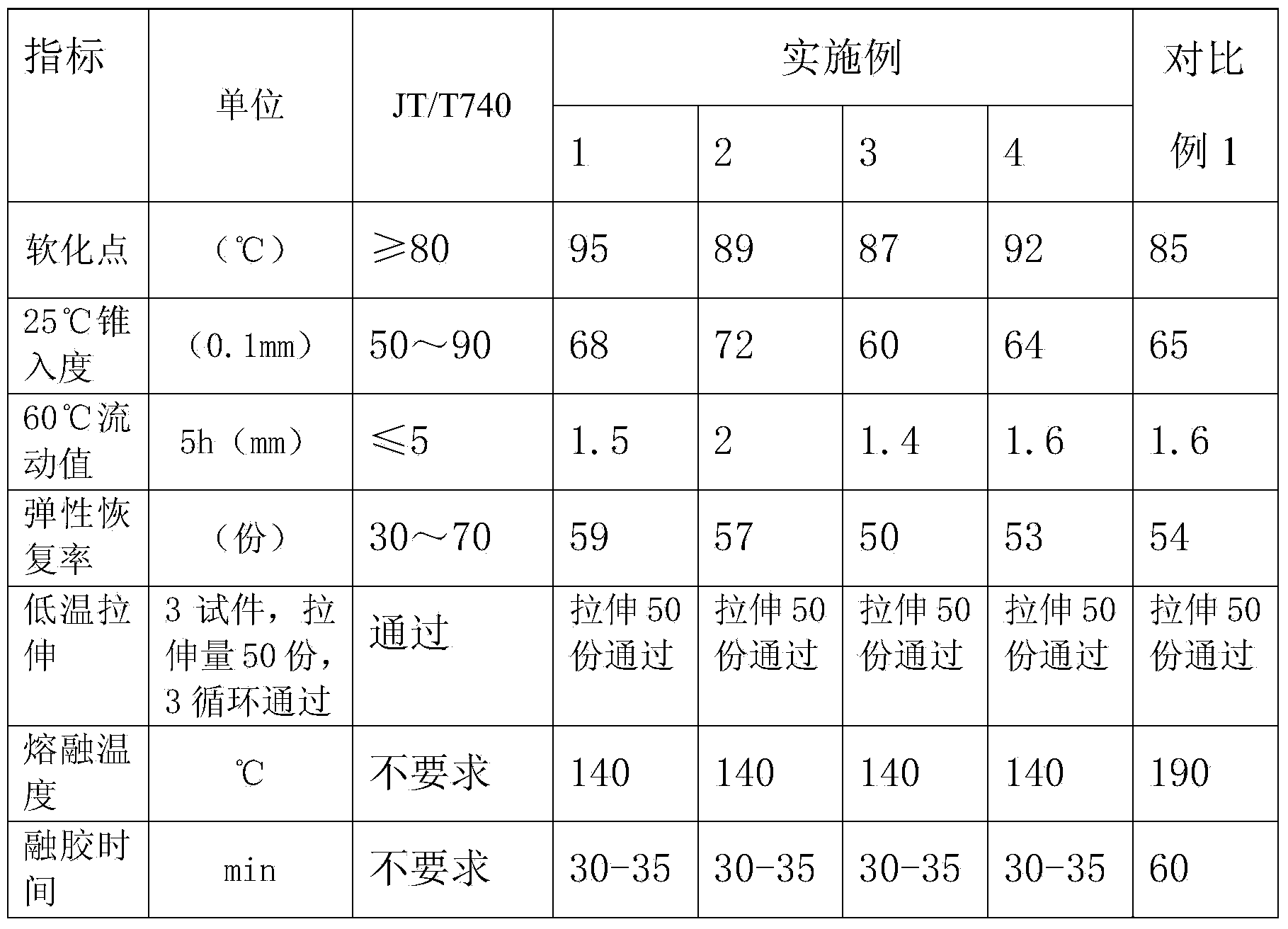

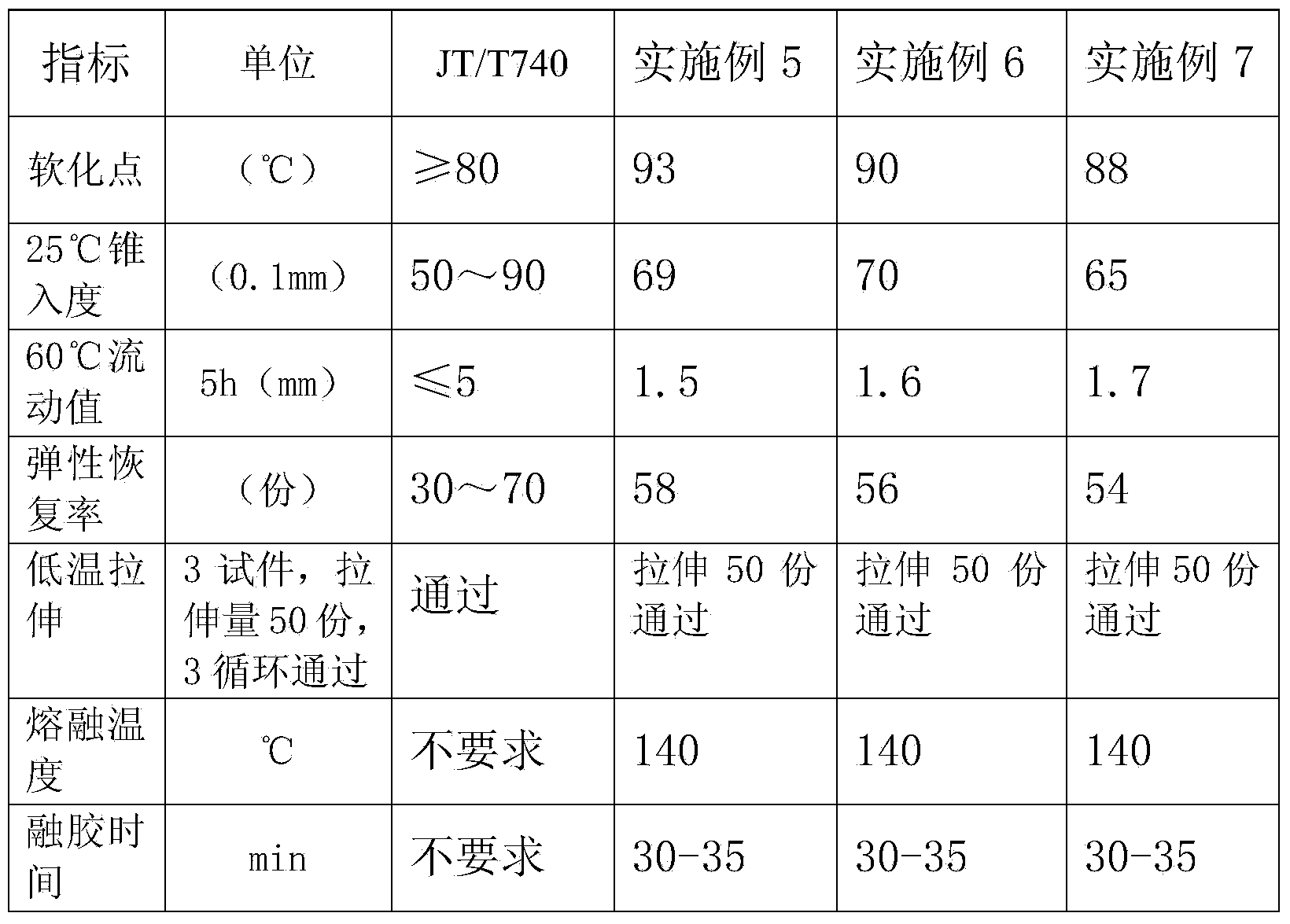

Energy-saving pavement crack repairing material and preparation method thereof

InactiveCN104046044AGood low temperature crack resistanceImprove high temperature stabilityBuilding insulationsParaffin waxPolypropylene

The invention discloses an energy-saving pavement crack repairing material and a preparation method thereof. The repairing material contains the following components by weight percent: 3% to 16% of melt temperature dropping agent; preferably, the repairing material contains 5% to 15% of melt temperature dropping agent, wherein the softening point of the melt temperature dropping agent is not lower than 110 DEG C; the melt temperature dropping agent is preferably selected from microfine wax, paraffin wax, polyethylene wax or polypropylene wax (APAO (Amorphous Poly Alpha Olefin) wax); and the softening point of the melt temperature dropping agent is preferably greater than 115 DEG C. The repairing material is good in low-temperature crack resistance, high-temperature stability, interface bonding force and aging resistance, thereby being suitable for the repairing of pouring cracks in majority of cold areas in China. According to the repairing material, the melt temperature dropping agent is adopted, so that the melt temperature is greatly decreased; the heating time is shortened; the heating construction is convenient to carry out; and the energy consumption is reduced, i.e., the pollution to the atmosphere, which is generated by the energy consumption, is reduced. The preparation method is simple and easy, and convenient for mass production.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

Joint filling glue for road maintenance and preparation method thereof

InactiveCN103805132AImprove physicsImprove mechanical propertiesNon-macromolecular adhesive additivesOil/fat/wax adhesivesPolymer sciencePolyolefin

The invention belongs to the field of asphalt pavement maintenance of roads, and specifically relates to joint filling glue for road maintenance and a preparation method thereof. The joint filling glue comprises the following components in percentage by weight: 6-8% of a modifier, 15-19% of an assistant additive and the balance of petroleum asphalt. The petroleum asphalt is any one of 70# matrix asphalt and 90# matrix asphalt. The modifier is a styrene-butadiene-styrene segmented copolymer or a mixture of the styrene-butadiene-styrene segmented copolymer and butadiene styrene rubber. The assistant additive is a mixture of more than two of cut four line oil, rubber powder, polyolefin, dibutyl phthalate, used oil and diatomite. The joint filling glue provided by the invention is reasonable in formula and better in high-temperature stability and anti-aging performance, can satisfy high-and-low temperature performances, and can be used as a road maintenance material for different climates and road conditions.

Owner:云南交投集团公路建设有限公司

Preparation method of rubber asphalt concrete

ActiveCN105801049AHigh strengthGuaranteed StrengthSolid waste managementCrack resistancePolymer science

The invention discloses a preparation method of rubber asphalt concrete. The preparation method comprises the following steps of: (I) sufficiently stirring and uniformly mixing portland cement, mineral powder fly ash, stainless steel powder and green mud at 180-190 DEG C; adding rubber asphalt; and stirring at 180-190 DEG C to obtain a mixture; (II) mixing limestone and blast furnace slag; calcining at 500-700 DEG C for 20-30 minutes; cooling; adding limestone and blast furnace slag into the mixture, and stirring at 180-190 DEG C for 4-8 minutes; adding water and high-calcium wastewater; and continuously stirring at 180-190 DEG C for 2-4 minutes to obtain a mixture; and (III) performing layered pouring of the mixture, vibrating and curing at 15-25 DEG C for 5-10day to obtain the rubber asphalt concrete. By adopting the preparation method disclosed by the invention, the compressive strength and crack resistance of the rubber asphalt concrete can be obviously enhanced.

Owner:CCCC THIRD HIGHWAY ENG

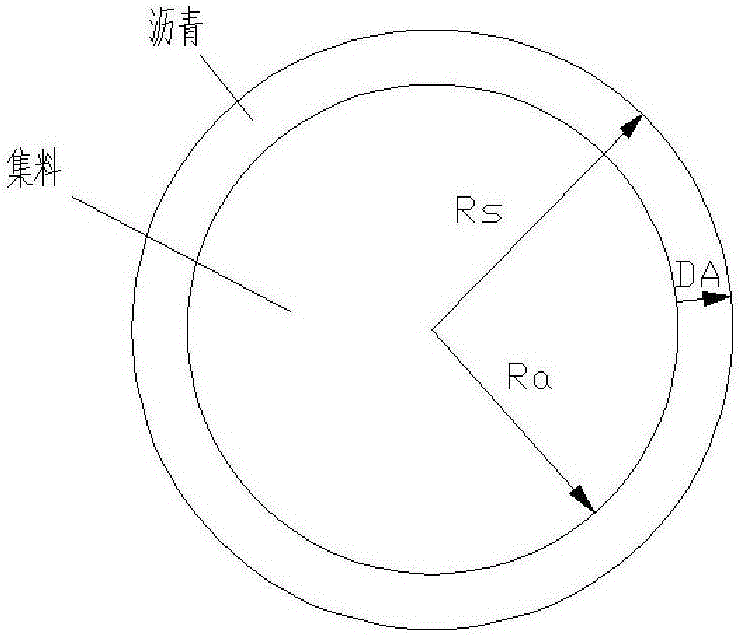

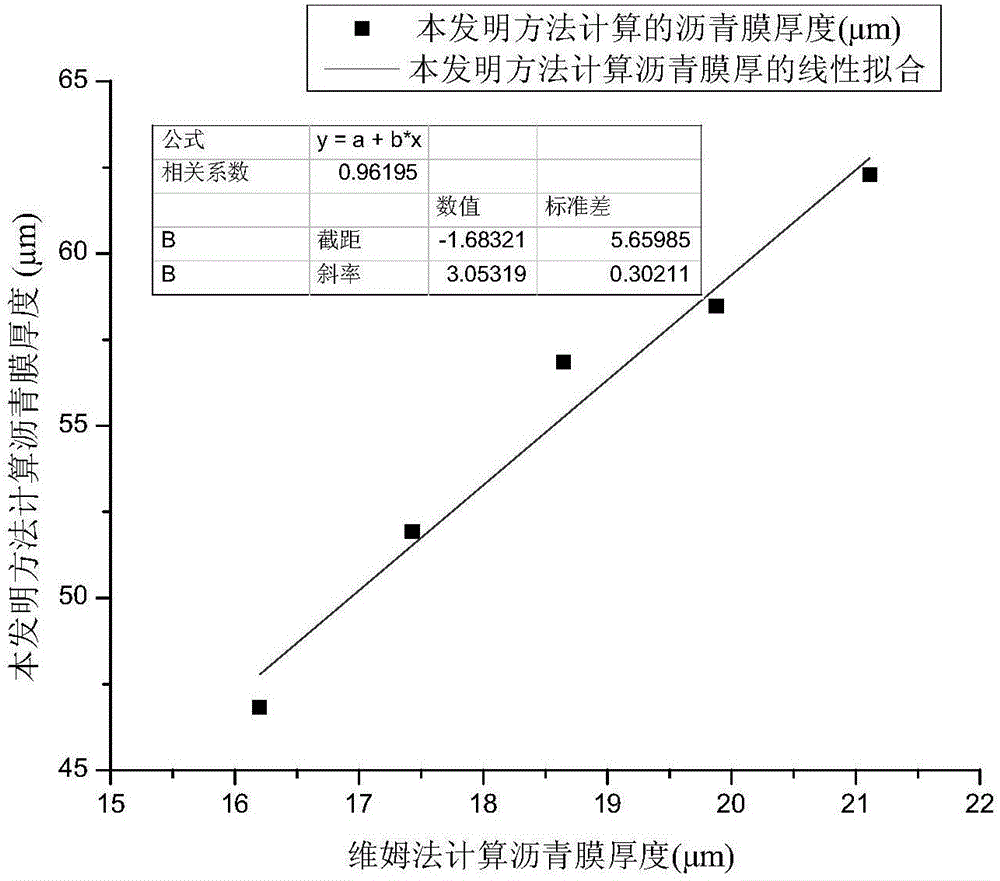

Method for calculating thickness of asphalt membrane on surface of aggregate in asphalt mixture

InactiveCN106032978AIncrease credibilityGood high temperature anti-ruttingUsing wave/particle radiation meansAsphaltPitch blende

The invention relates to a method for calculating the thickness of an asphalt membrane on the surface of aggregate in an asphalt mixture. The method comprises the steps of selecting the aggregate from an asphalt mixture sample randomly to serve as a scanning sample; scanning the scanning sample to obtain a scanning image; obtaining the total area As of the aggregate and asphalt and the area Aa of the aggregate in the scanning image, calculating the equivalent circle radium Rs corresponding to the total area As through the total area As, and calculating the equivalent circle radium Ra corresponding to the aggregate area Aa through the aggregate area Aa; obtaining the thickness of the asphalt membrane on the surface of the aggregate according to the difference between the equivalent circle radium Rs and the equivalent circle radium Ra. The thickness of the asphalt membrane on the surface of aggregate with same asphalt content and different particle sizes can be scanned and calculated, and results show that the thickness of the asphalt membrane decreases while the particle size of the aggregate increases. According to the method, data are reliable and accurate.

Owner:CHANGAN UNIV

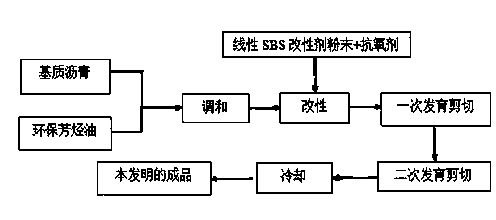

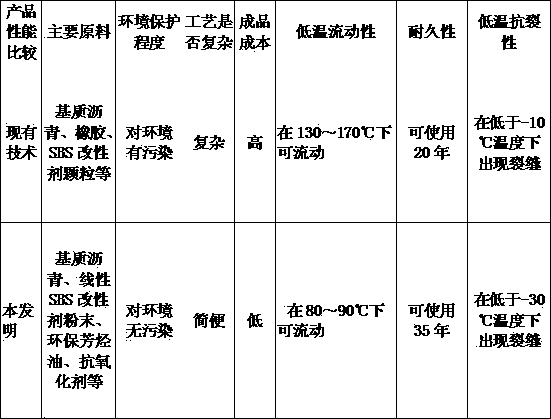

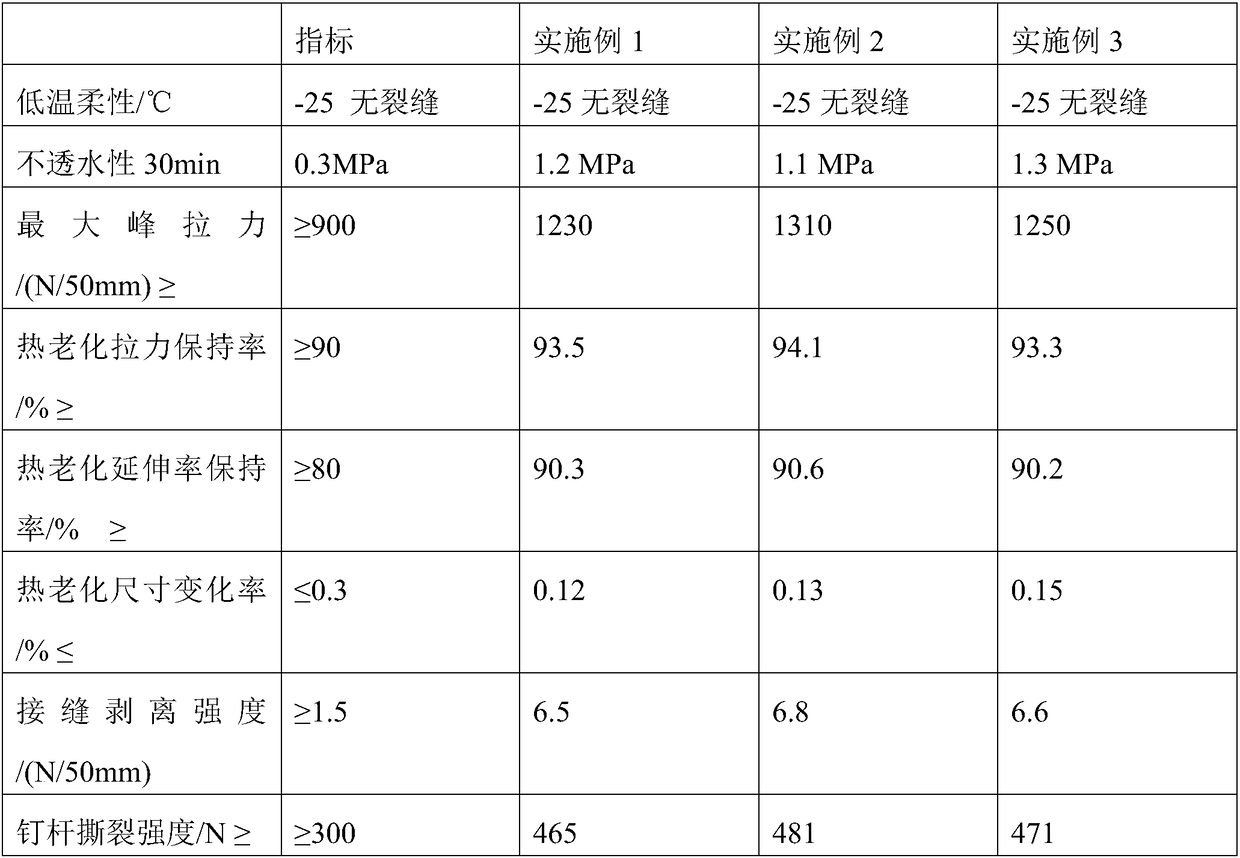

Waterproof modified asphalt for dam asphalt well and preparation method thereof

The invention relates to waterproof modified asphalt for a dam asphalt well, which is characterized by comprising the following components in percentage by mass: 55-70% of matrix asphalt, 28-40% of environment-friendly aromatic oil, 1-4.2% of linear SBS (styrene-butadiene-styrene) modifier powder and 0.8-1% of antioxidant, wherein the matrix asphalt is AH-70 asphalt or AH-100 asphalt; the environment-friendly aromatic oil is special oil GXJ-I for rubber; the linear SBS modifier powder is YH-792 or YH-791 or YH-796; and the antioxidant is KY-405 or TBY-2246. The waterproof modified asphalt provided by the invention is prepared through five steps of blending, modification, primary development shearing, secondary development shearing and cooling. The waterproof modified asphalt provided by the invention has the advantages of low-temperature fluidity and low-temperature crack resistance at 80-90 DEG C. The preparation method provided by the invention is simple and convenient, and is suitable for direct processing and production on a construction site.

Owner:HOHAI UNIV

High-ductility modified hard asphalt and preparation method thereof

InactiveCN106977965AImprove ductilityImprove high temperature stabilityBuilding insulationsPolymer scienceAlkylphenol

The invention discloses high-ductility modified hard asphalt, which is prepared from the following raw materials in parts by weight: 130 to 140 parts of petroleum asphalt, 10 to 14 parts of methyl silicone rubber powder, 18 to 22 parts of methyl vinyl silicone rubber powder, 11 to 15 parts of modified kaolin, 5 to 9 parts of barium metaborate, 12 to 15 parts of sulfated castor oil, 5 to 8 parts of trimellitic anhydride, 2 to 5 parts of alkylphenol ethoxylate, 3 to 6 parts of allyl methacrylate and 4 to 8 parts of sodium thioglycollate. The invention also discloses a preparation method of the high-ductility modified hard asphalt. The prepared modified hard asphalt has high ductility, and has good high-temperature stability and low-temperature anti-cracking performance; important market values and social values are realized.

Owner:詹澍

Acrylic resin emulsified asphalt coating

The invention discloses an acrylic resin emulsified asphalt coating which is characterized by comprising components in parts by weight as follows: 20-50 parts of an acrylic resin emulsion with the solid content of 50% and 40-70 parts of a pitch emulsified solution with the solid content of 40%, and a product is obtained. The acrylic resin emulsified asphalt coating has the advantages as follows: the weather fastness is excellent, the film coating elasticity is high, the ductility is high, the tensile strength and the durability are good, the requirements for base-layer deformation can be met, the coating has better low-temperature anti-cracking performance, the adaptability is high, and the effect is good.

Owner:吴润秀

Waste rubber composite modified asphalt waterproof material and preparation method thereof

InactiveCN108973261AImprove fusion effectEasy to integrateSynthetic resin layered productsGlass/slag layered productsPolymer modifiedBituminous waterproofing

The invention relates to a waste rubber composite modified asphalt waterproof material and a preparation method thereof. The waste rubber composite modified asphalt waterproof material sequentially comprises an upper surface isolation layer, an upper polymer modified asphalt layer, a tire basic layer, a lower polymer modified asphalt layer and a lower surface isolation layer from top to bottom, wherein the upper polymer modified asphalt layer and the lower polymer modified asphalt layer are prepared from waste rubber composite modified asphalt; the waste rubber composite modified asphalt is prepared form the following raw materials in parts by weight: 60 to 70 parts of petroleum asphalt, 10 to 20 parts of SBS (Styrene Butadiene Styrene) rubber, 5 to 10 parts of SIS (Styrene Isoprene Styrene) rubber, 10 to 20 parts of waste rubber powder, 2 to 3 parts of an asphalt modifier, 1 to 3 parts of a modified asphalt stabilizer, 0.1 to 0.3 part of graphene, 1 to 3 parts of sulfur, 0.5 to 0.8 part of petroleum sulfonate, 1 to 3 parts of succinic anhydride, 1 to 3 parts of wood vinegar, 3 to 5 parts of inorganic filler and 1 to 3 parts of metal oxide. According to the waste rubber composite modified asphalt waterproof material and the preparation method thereof, disclosed by the invention, an asphalt modification compatilizer is preferably selected, the compatibility of the waste rubber powder and the asphalt is effectively increased, and the prepared waterproof material has excellent high-temperature stability, excellent low-temperature crack resistance, aging resistance, durabilityand the like.

Owner:芜湖市颂晖商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com