Small particle size gap gradation compact-type low-noise rubber asphalt concrete

A rubberized asphalt, small particle size technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of insufficient durability of low-noise asphalt concrete, harsh service conditions, rut damage, etc. The effect of high temperature shear deformation resistance, good low temperature crack resistance, good material durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

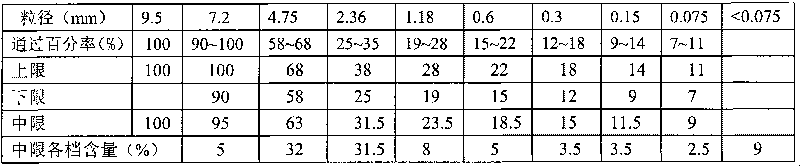

[0026] 1) According to the mineral material grading range table, select the medium-sized and small-sized crushed stones in each grade as shown in the table below.

[0027]

[0028] 2) In order to ensure that the mixture has good water stability, cement is used as a filler to replace part of the mineral powder, that is, the part <0.075 in the table, and the cement content is 8% (the weight ratio of the mineral material).

[0029] 3) The mixture uses rubber asphalt as the binder. The specification of waste tire rubber powder in rubber asphalt is about 60 mesh, which is pulverized at room temperature and has a high content of natural rubber. The content of waste tire rubber powder in rubber asphalt is about 22%. The 180°C rotational viscosity index of rubber asphalt is 3.5Pa.s.

[0030] 4) The design porosity of the mixture is 5.5%, to ensure the compactness of the mixture.

[0031] 5) The high-temperature anti-deformation ability index of the mixture is: the dynamic stabil...

Embodiment 2

[0036]2) Use slaked lime as a filler to replace part of the mineral powder, that is, the part <0.075 in the table, and the amount of slaked lime is 3% (the weight ratio of the mineral material).

[0037] All the other are identical with embodiment 1.

Embodiment 3

[0039] 2) Use cement to replace part of the mineral powder, and the cement content is 5% (the weight ratio of the mineral material).

[0040] 3) The specification of waste tire rubber powder in rubber asphalt is 40-mesh rubber powder with high content of natural rubber crushed at room temperature. The content of waste tire rubber powder in rubber asphalt is about 23%. The 180°C rotational viscosity index of rubber asphalt is 4Pa.s.

[0041] 4) The design porosity of the mixture is 5% to ensure the compactness of the mixture.

[0042] All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com