Novel assembly type seamless expansion device and construction method thereof

A technology of seamless telescopic and telescopic devices, which is applied to bridge parts, bridges, buildings, etc., to achieve the effects of strong practicability, short service life and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

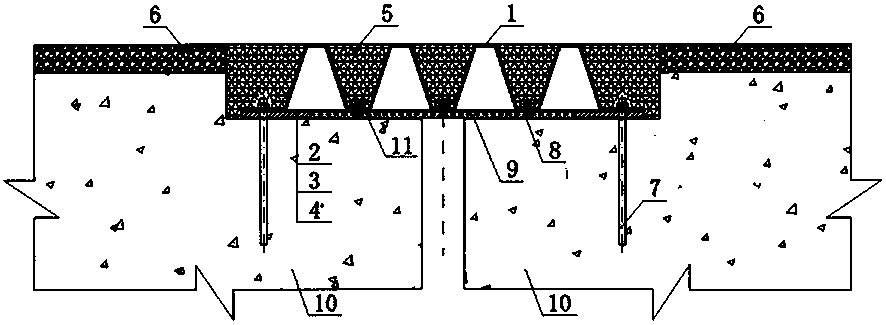

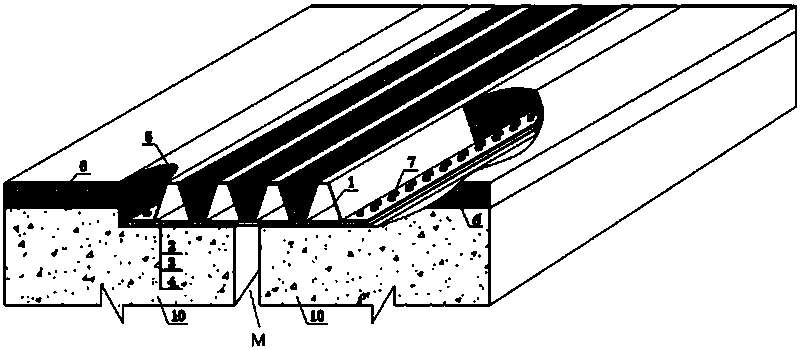

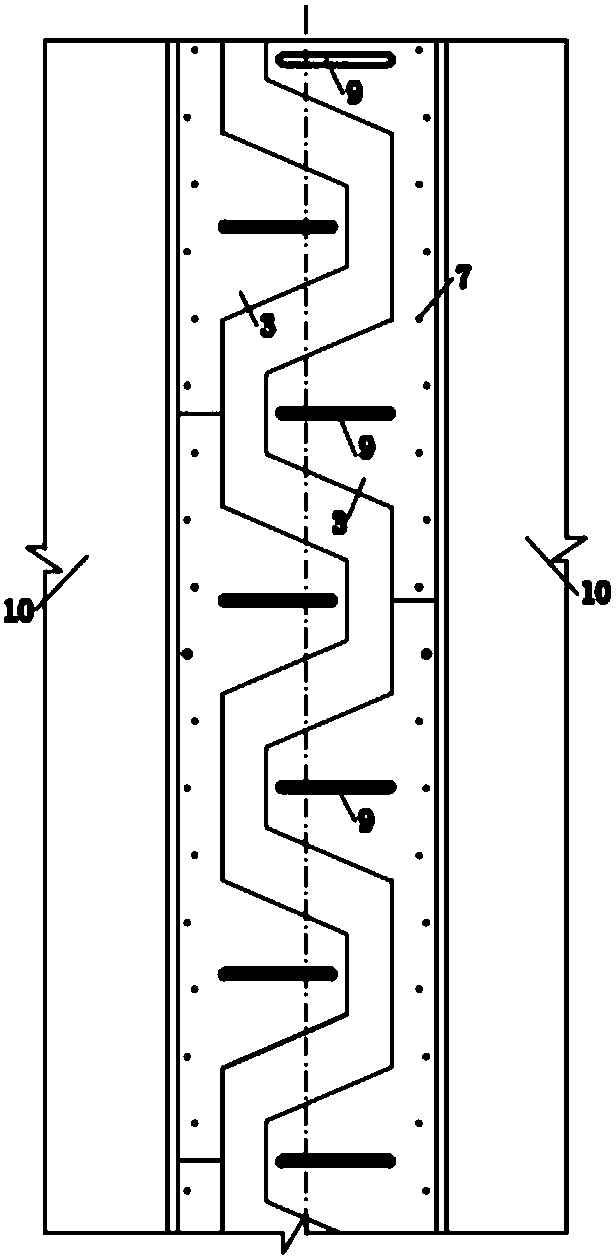

[0023] Below in conjunction with accompanying drawing, the present invention will be further described.

[0024] The new assembled seamless telescopic device of the present invention includes a main beam 10, a comb-tooth-shaped seam-spanning plate 3, a wave-shaped telescopic plate 1, a stainless steel backing plate 4, a directional hemispherical sliding groove 9 set in the comb-tooth-shaped seam-spanning plate, and a ball head Hexagon socket connection bolts 8 and cast-in-place elastic filling body 5;

[0025] An expansion joint M is arranged between the main girders 10, and a stainless steel backing plate 4 and a comb-toothed spanning plate 3 are sequentially arranged on the upper surface of the reserved notch at the end of the main girder 10, and the stainless steel backing plate 4 and the comb-toothed spanning The seam plates 3 are respectively fixed on the main beams 10 at both ends of the reserved expansion joints through embedded connecting bolts 7;

[0026] The comb-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com