Preparation method of separated plant-mixed warm-hot regenerated asphalt mixed material

A technology for reclaiming asphalt and mixtures, applied in the field of asphalt materials, can solve the problems of graying materials, varying degrees of coating, and poor uniformity of mixtures, etc., and achieve the effects of increasing the development process, improving the regeneration effect, and changing the mixing sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

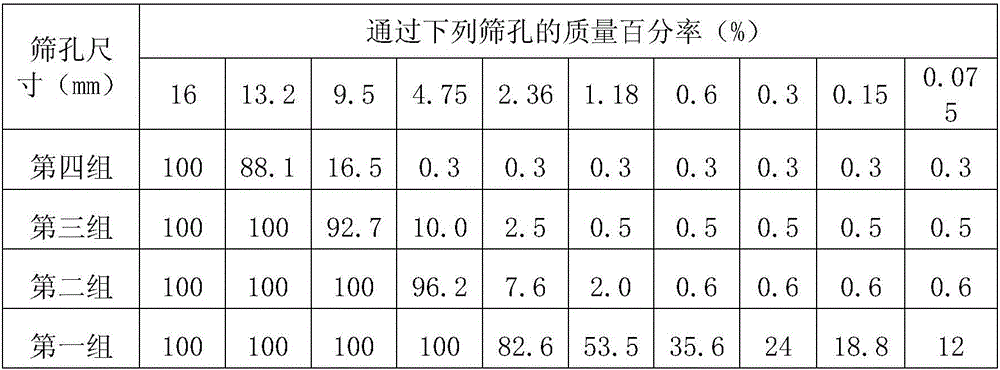

[0028] The embodiment of indoor test: the old broken asphalt pavement (RAP) used in the test is the material of the same source and the same particle size specification. At first, the RAP is sampled in the mixing plant, and then according to the "Highway Engineering Asphalt and Asphalt Mixture Test Regulations" (JTG The method of T 0735 in E20-2011) carries out asphalt content test, and the asphalt ratio that test records this RAP is 4.51%, and the old ore in the RAP that test is obtained is sieved, and sieving test result is shown in Table 1; Adopt " The method T 0726 in Highway Engineering Asphalt and Asphalt Mixture Test Regulations (JTG E20-2011) conducts extraction test on RAP, recovers the old asphalt after the extraction test, and conducts performance test. The test results are shown in Table 2.

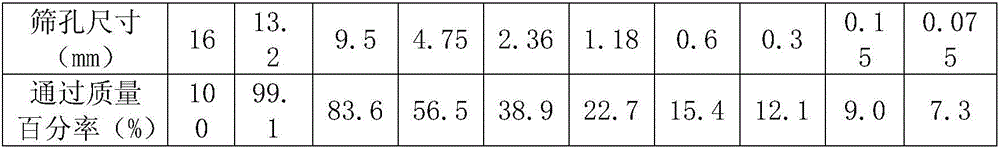

[0029] Table 1 Results of old ore grading test in RAP

[0030]

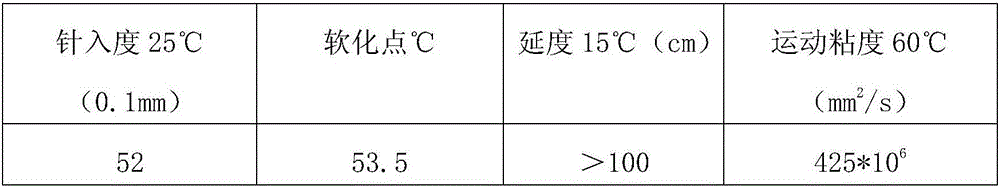

[0031] Table 2 Test results of old asphalt performance indicators in RAP

[0032] Penetration 25°...

Embodiment 2

[0071] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is:

[0072] (1), in this embodiment, the new asphalt adopts AH-130 road petroleum asphalt, and the amount of new asphalt accounts for 2.74% of the mass percentage of the separated factory-mixed warm-heated recycled asphalt mixture; the regeneration agent is selected from Jiangsu Tiannuo Road Material Technology Co., Ltd. The produced TNZS-50 regenerant has a kinematic viscosity of 50mm at 60°C 2 / s, the amount of regenerated agent accounted for 0.16% of the mass percentage of the separated factory-mixed warm recycled asphalt mixture.

[0073] (2) The heating temperature of RAP is 70°C, the heating temperature of new aggregate is 90°C, and the heating temperature of regenerant is 40°C.

[0074] (3) Divide the cooked RAP and regenerant mixture into 7 equal samples (W0, W1, W2, W3, W4, W5, W6), store them in a dedicated growth chamber at 40°C, grow W0 for 0.5h, W1 developed for 1 h...

Embodiment 3

[0091] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is:

[0092] (1) In this embodiment, the new asphalt adopts AH-70 road petroleum asphalt, and the amount of new asphalt accounts for 2.65% of the mass percentage of the separated plant-mixed warm-heat recycled asphalt mixture; the regeneration agent is selected from Jiangsu Tiannuo Road Material Technology Co., Ltd. The produced TNZS-110001 regenerant has a kinematic viscosity of 11520mm at 60°C 2 / s, the amount of regenerant in the mass percentage of warm recycled asphalt mixture is 0.25%.

[0093] (2) The heating temperature of RAP is 120°C, the heating temperature of new aggregate is 170°C, and the heating temperature of regenerant is 80°C.

[0094] (3) Divide the cooked RAP and regenerant mixture into 7 equal samples (X0, X1, X2, X3, X4, X5, X6) and store them in a dedicated growth chamber at 130°C. X0 is grown for 0.5h, X1 developed for 1 hour, X2 developed for 2 hours, X3 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com