A process for suppressing deformation of green ceramics during the processing of multilayer ceramic circuits

A multi-layer ceramic and circuit processing technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of reducing the effective utilization rate of green ceramics, reducing production efficiency, and increasing costs, and is conducive to the whole process of automatic production. , High-level alignment accuracy, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The following are the method steps for suppressing the deformation of green ceramics in the process of multi-layer ceramic circuit processing, please refer to Figure 1-4 :

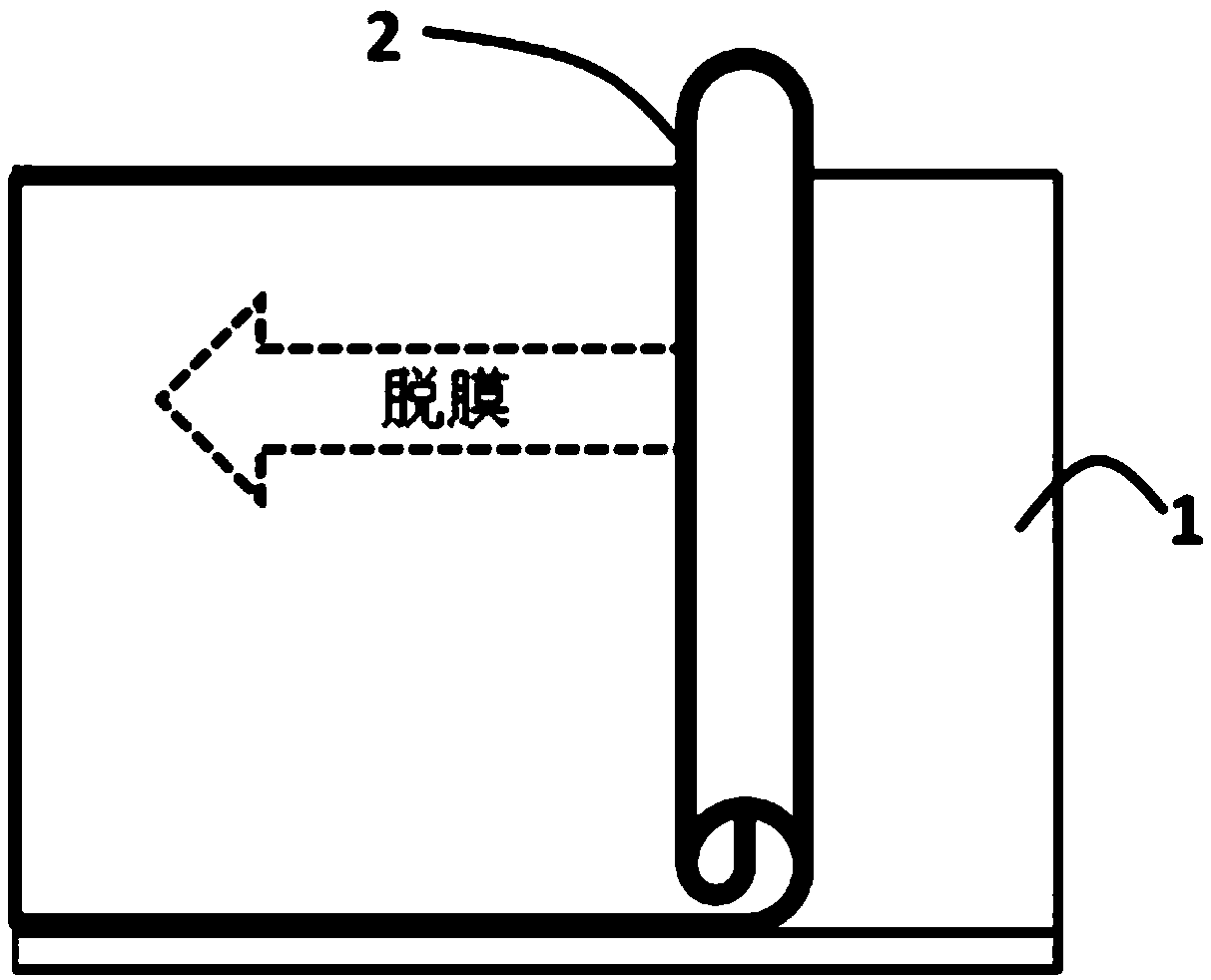

[0023] 1) After the green porcelain is cut to the standard process size, tear off the Mylar film 2 of the green porcelain from the green porcelain 1, such as figure 1 shown.

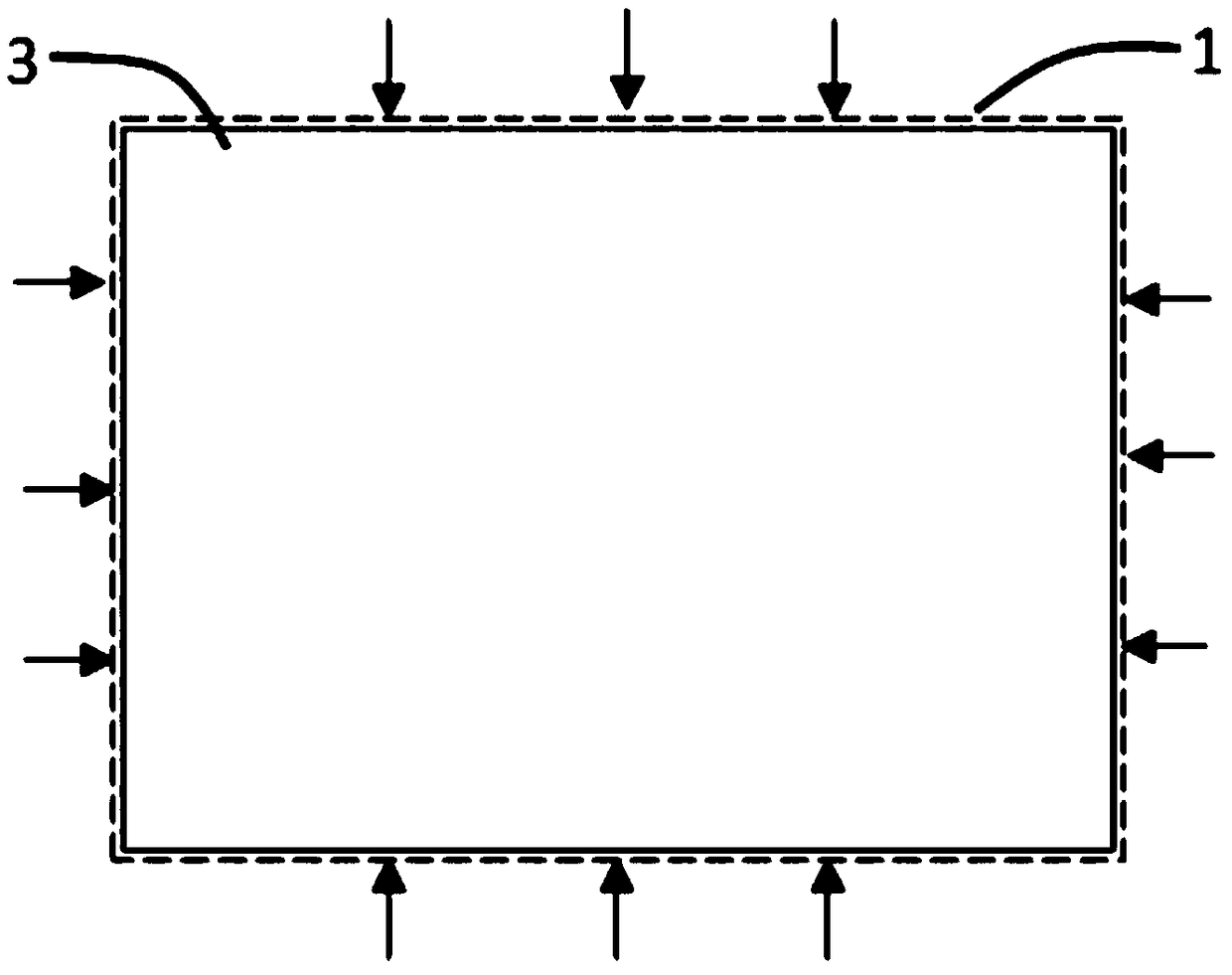

[0024] 2) Dry the green porcelain 1 without film at a temperature of 60°C for 30 minutes to obtain the green porcelain 3 deformed in place, such as figure 2 shown.

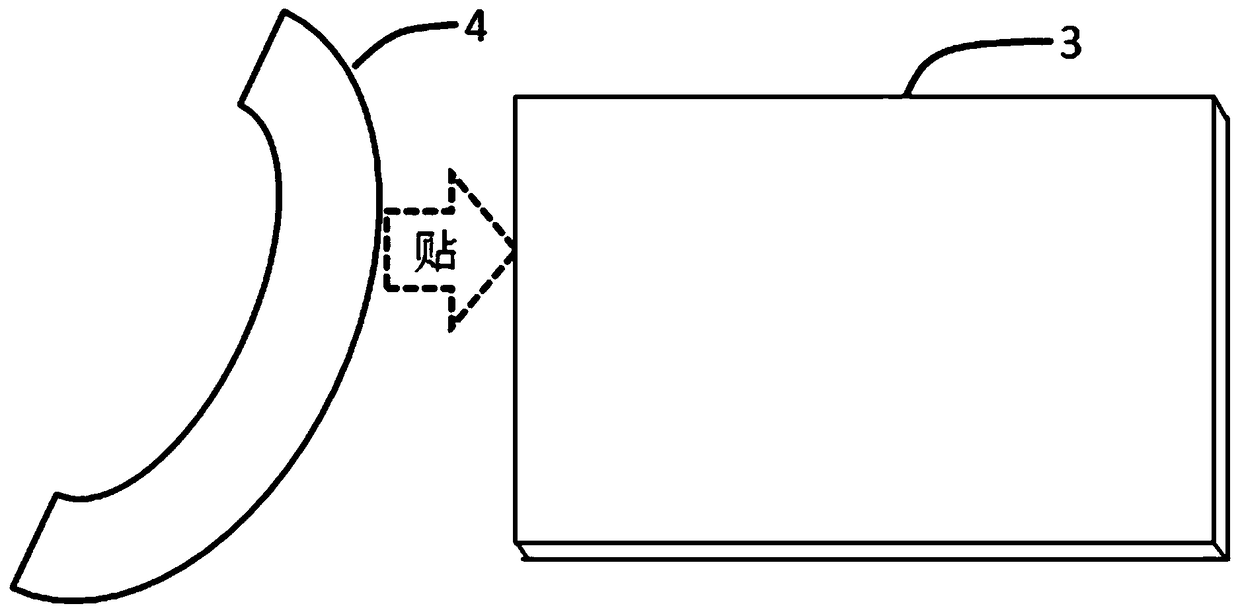

[0025] 3) Paste the organic diaphragm 4 coated with 1 μm low-viscosity coating on one side on the deformed green porcelain 3, such as image 3 shown. The thickness of the organic membrane 4 is 50 μm.

[0026] 4) The green porcelain after the second filming is as Figure 4 As shown, the green ceramics 3 and the organic film 4 are well bonded, and the green ceramics can be kept low in deformation during the processing of the multi-layer co-fired ceramic circ...

Embodiment 2

[0030] The following are the method steps for suppressing the deformation of green ceramics in the process of multi-layer ceramic circuit processing, please refer to Figure 1-4 :

[0031] 1) After the green porcelain is cut to the standard process size, tear off the Mylar film 2 of the green porcelain from the green porcelain 1, such as figure 1 shown.

[0032] 2) For green porcelain 1 without film, place it naturally for 8 hours in a 100,000-level purification environment to obtain green porcelain 3 deformed in place, such as figure 2 shown.

[0033] 3) Paste the organic diaphragm 4 coated with 2.5μm low-viscosity coating on one side on the deformed green porcelain 3, such as image 3 shown. The thickness of the organic membrane 4 is 75 μm.

[0034] 4) The green porcelain after the second filming is as Figure 4 As shown, the green ceramics 3 and the organic film 4 are well bonded, and the green ceramics can be kept low in deformation during the processing of the mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com