High-viscosity modified pitch and preparation method thereof

A modified asphalt, high-viscosity technology, applied in building components, building insulation materials, construction, etc., can solve the problems of unverified reliability, unstable product performance, and poor engineering practicability, and achieve low production cost and cost-effectiveness High and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

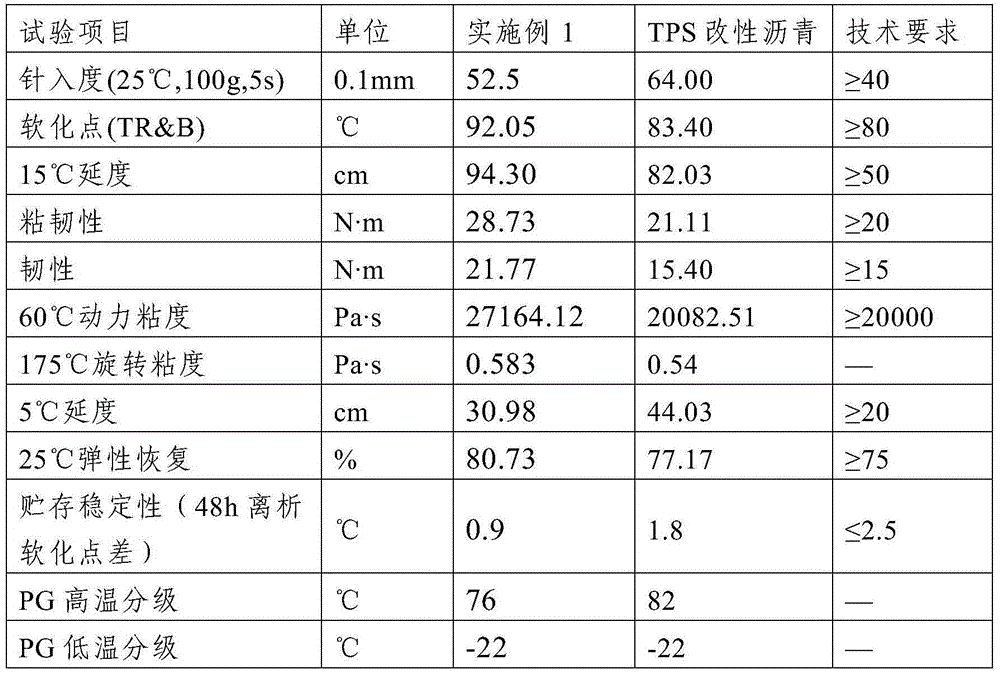

Embodiment 1

[0021] The high-viscosity modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of base asphalt, 6 parts of styrene copolymer, 3 parts of Sasobit asphalt modifier, 1 part of Eucommia gum, 2 parts of styrene-butadiene rubber, and 0.4 parts of sulfur parts; the styrene copolymer is preferably a star-shaped styrene-butadiene-styrene block copolymer.

[0022] The method for preparing high-viscosity modified asphalt in this embodiment comprises the following steps:

[0023] Step 1. After heating the base asphalt to 150°C, add styrene copolymer and Eucommia gum and stir evenly, then add Sasobit asphalt modifier and styrene-butadiene rubber and stir evenly to obtain a mixture; the base asphalt is preferably SK-90# asphalt ;

[0024] Step 2: Cut the mixture described in Step 1 at a temperature of 175°C for 60 minutes, then add sulfur to continue shearing for 30 minutes, and then develop it at a temperature of 175°C for 4 hours to obta...

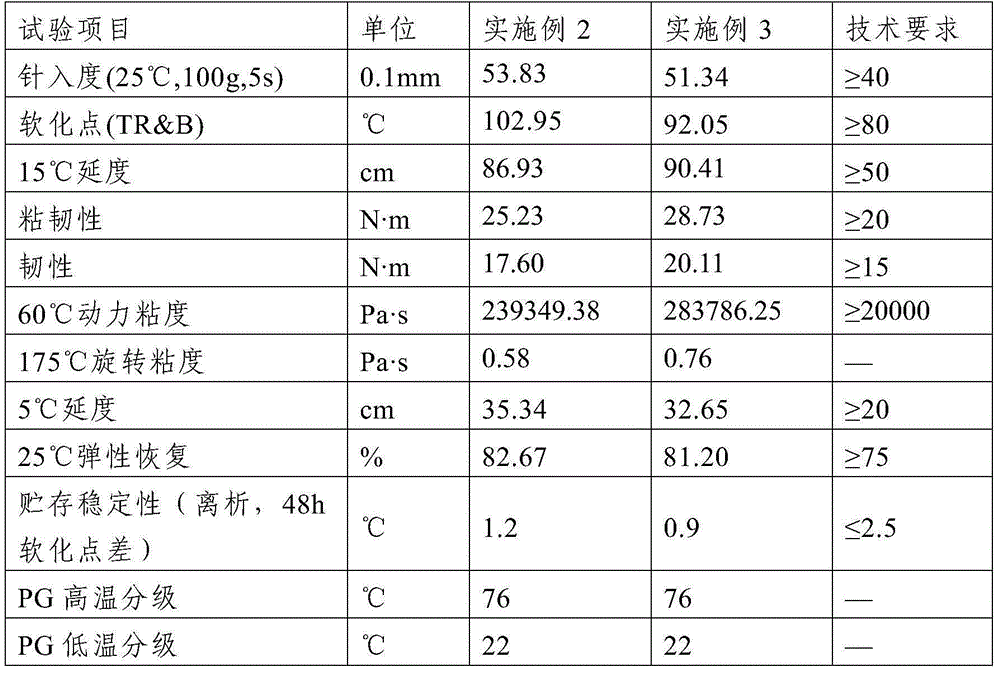

Embodiment 2

[0030] The high-viscosity modified asphalt in this embodiment is made from the following raw materials in parts by weight: 100 parts of base asphalt, 7 parts of styrene copolymer, 3 parts of Sasobit asphalt modifier, 1 part of Eucommia gum, 2 parts of styrene-butadiene rubber, and 0.4 parts of sulfur parts; the styrene copolymer is preferably a star-shaped styrene-butadiene-styrene block copolymer.

[0031] The method for preparing high-viscosity modified asphalt in this embodiment comprises the following steps:

[0032] Step 1. Heat the base asphalt to 160°C, add styrene copolymer and Eucommia gum and stir evenly, then add Sasobit asphalt modifier and styrene-butadiene rubber and stir evenly to obtain a mixture; the base asphalt is preferably SK-90# asphalt ;

[0033] Step 2: Cut the mixture described in Step 1 for 45 minutes at a temperature of 185°C, then add sulfur and continue to cut for 15 minutes, and then develop it for 1 hour at a temperature of 185°C to obtain high-...

Embodiment 3

[0035] The high-viscosity modified asphalt in this embodiment is made from the following raw materials in parts by weight: 100 parts of base asphalt, 5 parts of styrene copolymer, 4 parts of Sasobit asphalt modifier, 2 parts of Eucommia gum, 3 parts of styrene-butadiene rubber, and 0.8 parts of sulfur parts; the styrene copolymer is preferably a star-shaped styrene-butadiene-styrene block copolymer.

[0036] The method for preparing high-viscosity modified asphalt in this embodiment comprises the following steps:

[0037] Step 1. Heat the base asphalt to 155°C, add styrene copolymer and Eucommia gum and stir evenly, then add Sasobit asphalt modifier and styrene-butadiene rubber and stir evenly to obtain a mixture; the base asphalt is preferably SK-90# asphalt ;

[0038] Step 2: Cut the mixture described in step 1 at a temperature of 180°C for 55 minutes, then add sulfur to continue shearing for 25 minutes, and develop it at a temperature of 180°C for 2.5 hours after shearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com