Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

A technology for design of asphalt mixture and mix ratio, which is applied in the direction of material inspection products, sustainable waste treatment, solid waste management, etc., can solve the problems of heavy workload and the inability to consider the relationship between the amount of asphalt and the gradation of mineral materials, etc., to achieve The effect of good road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

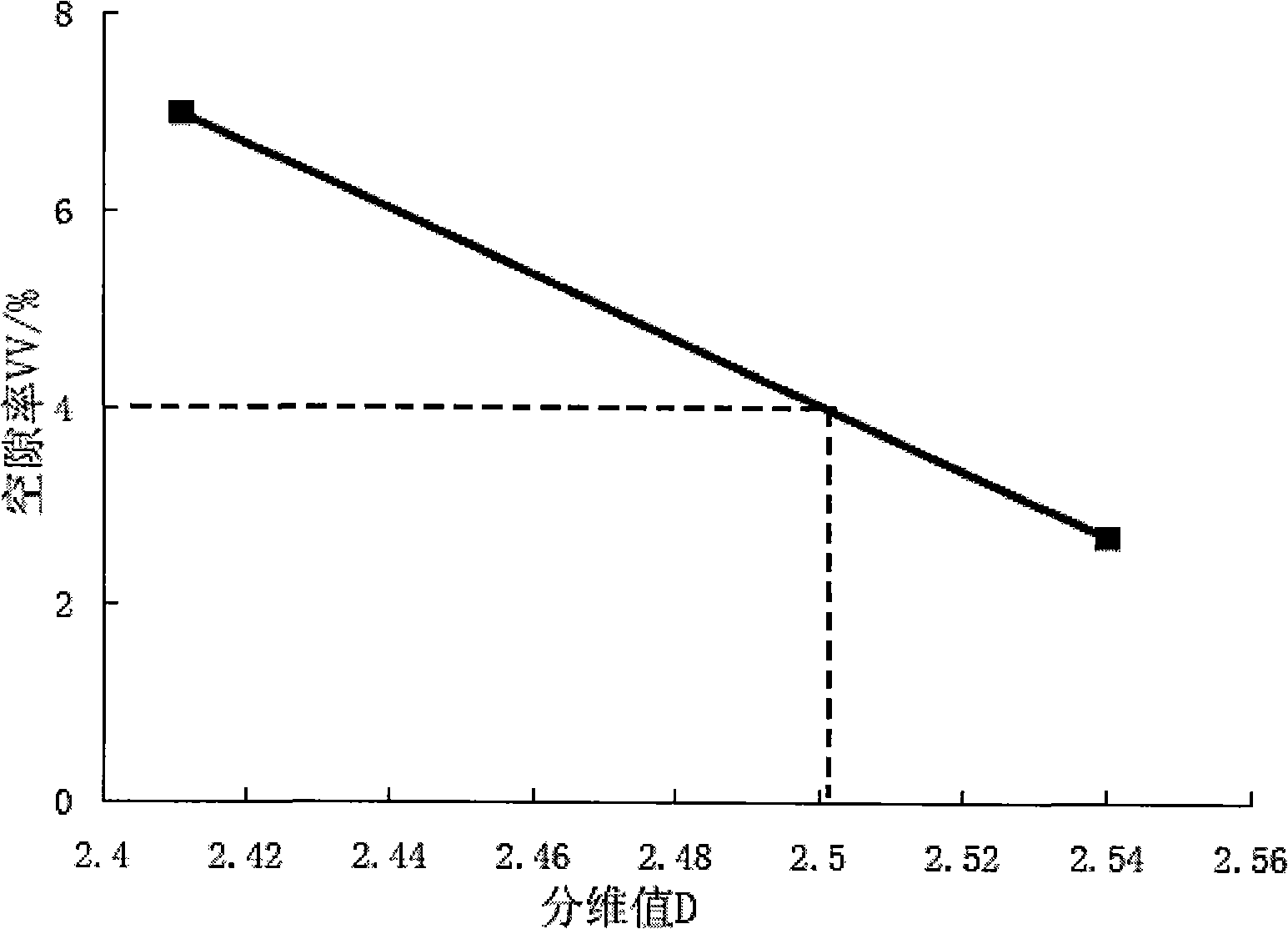

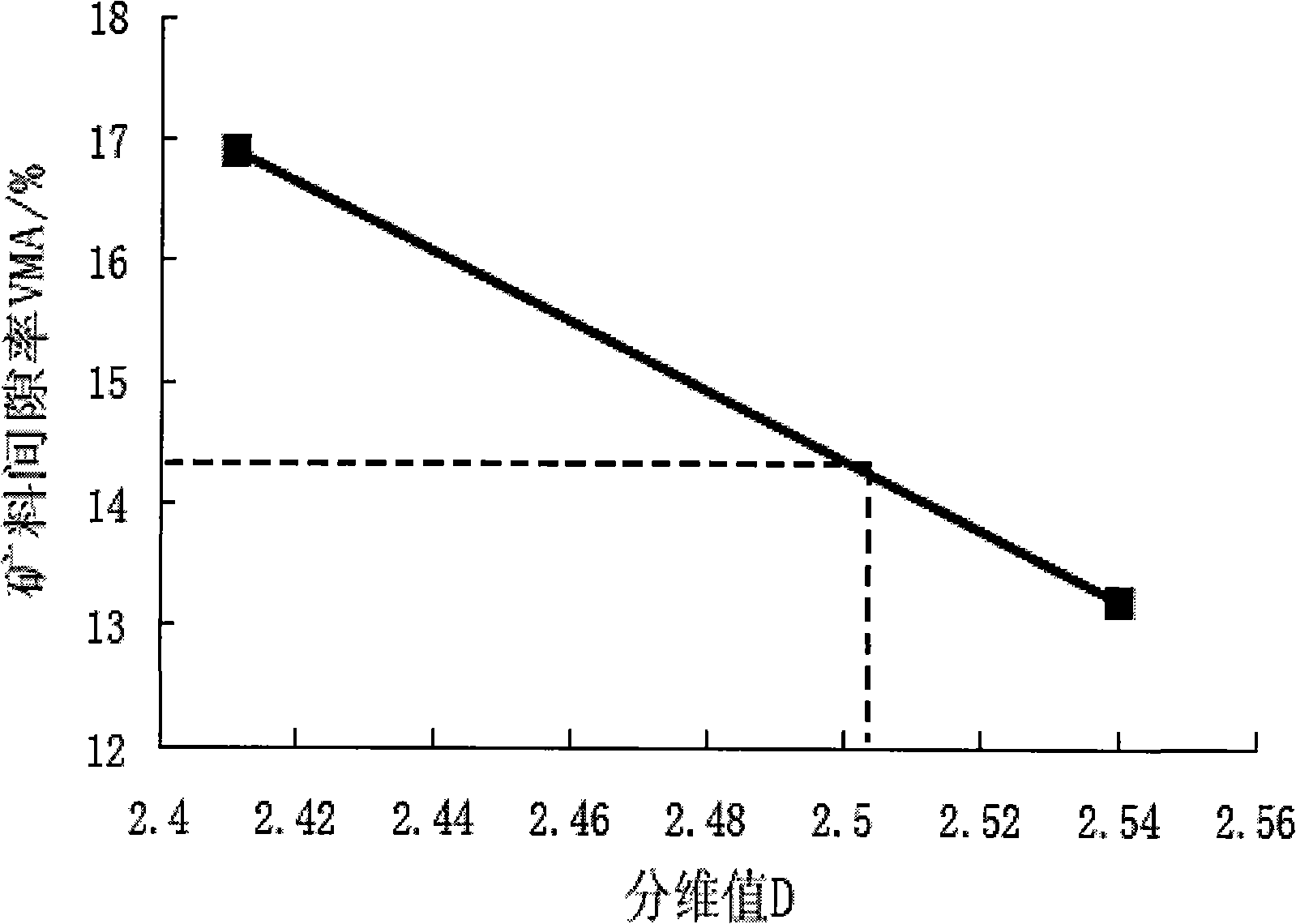

[0045] Since the design process of different gradation types is similar, the following will only take AC-16 as an example to briefly illustrate the asphalt mixture design process based on fractal theory.

[0046]1. Establish the mathematical models of mineral particle size distribution and mineral mass distribution respectively:

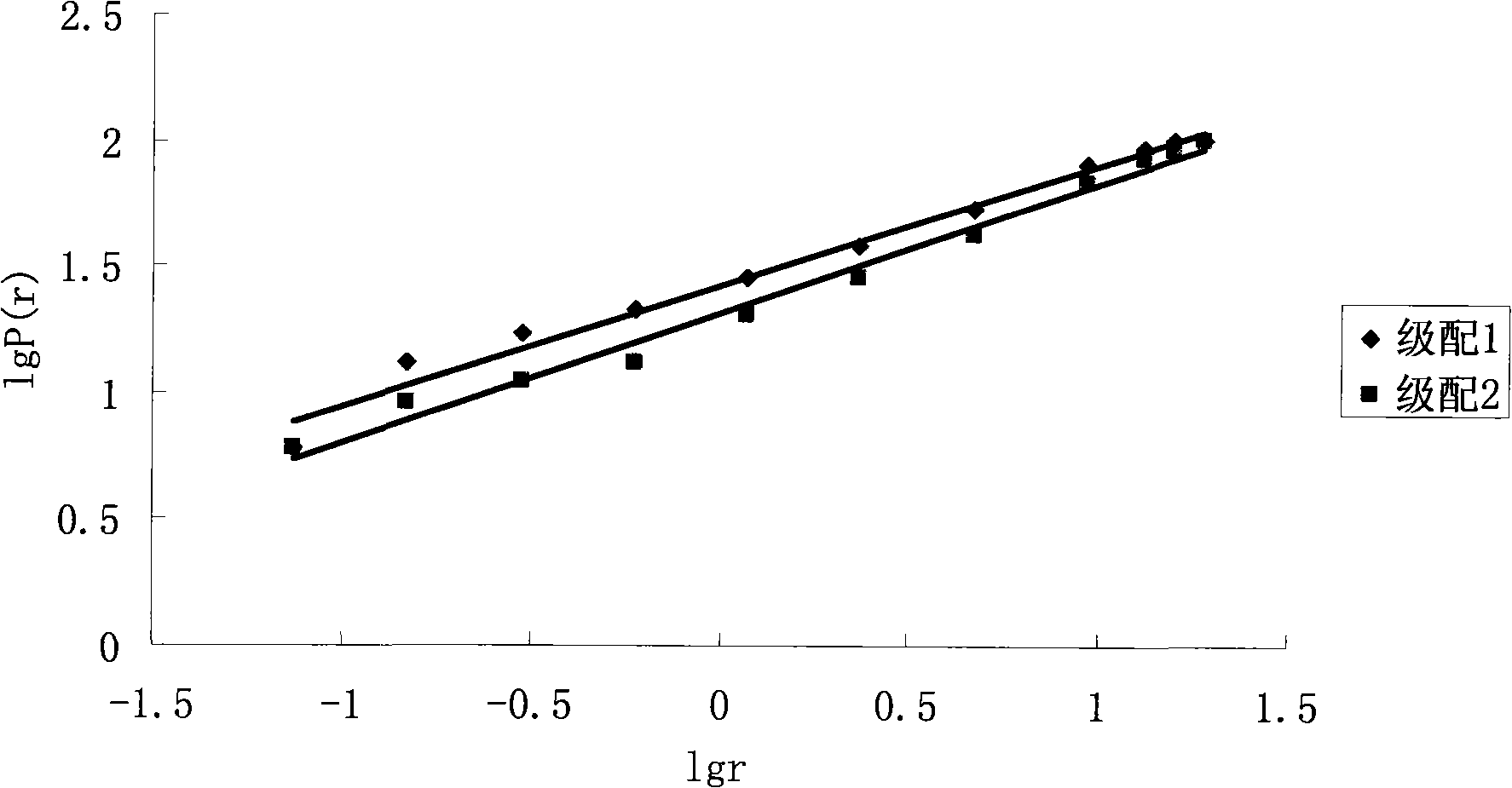

[0047] 1.1 Mathematical model of mineral particle size distribution:

[0048] Suppose the particle size of the mineral material is r, the number of particles with a particle size not greater than r is N(r), and the number of mineral material particles with a particle size greater than r is N′(r), N 0 is the total number of mineral particles. According to fractal theory there are

[0049] N(r)+N'(r)=N 0 (1)

[0050] N(r)=Cr -D (2)

[0051] In the formula: C is a constant; D is the particle size fractal dimension value.

[0052] Thus, the particle size distribution function can be defined as

[0053] F ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com