Sulphur-modified asphalt mixed materials formulation and its construction process

A technology of asphalt mixture and modified asphalt, which is applied in building insulation materials, building components, buildings, etc., to achieve the effects of improved water damage resistance, strong adhesion, and enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

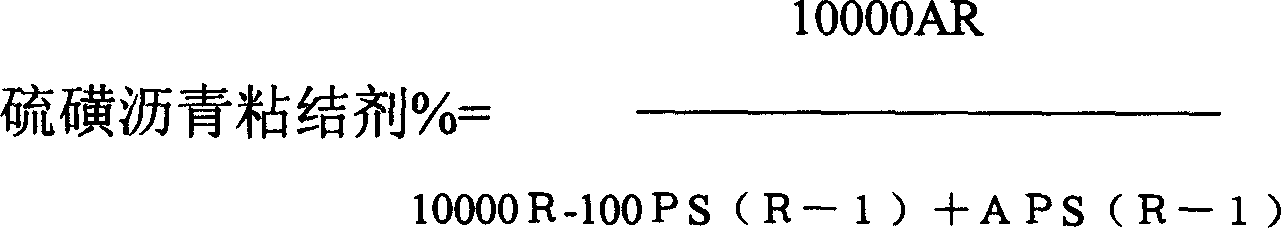

Image

Examples

Embodiment 1

[0040] Modified pellets / asphalt = 50 / 50 obtains a very hard "full rigid" mixture, which replaces about 40% of asphalt by volume. This surface layer has excellent anti-rutting performance, but its flexibility is very low, so it can only be used when the roadbed is very good and the pavement structure is very rigid. This kind of mixture hardens earlier and must be operated quickly, and the final pressing temperature should not be lower than 110°C. The desired compacted density is rapidly achieved at elevated temperatures. In addition, the smog emitted by the mixture of this proportion is also relatively large.

Embodiment 2

[0042] Modified pellets / bitumen = 40 / 60 resulted in a "semi-rigid" mix that replaced about 30% of the bitumen. The stability of this mixture is higher than that of conventional asphalt mixture, so the pavement has high anti-rutting performance, while maintaining sufficient flexibility and good fatigue resistance. The mixing temperature is controlled at about 140°C, and paving and compaction can be carried out according to conventional techniques. It can be applied to the needs of general roads and is widely used.

Embodiment 3

[0044] Mix / asphalt = 30 / 70 gives a "flexible" mix that replaces about 20% of the asphalt. The performance of this mixture is basically similar to that of conventional asphalt mixture, but its stability is slightly better, and all the processes are the same as conventional ones.

[0045] What kind of ratio to use should be selected according to the functional needs of the road and the strength and stiffness of the road surface design.

[0046] Selection of asphalt mixture

[0047] Sulfur can be compatible with all asphalts, but the effects are different. Different asphalts and different ratios can obtain different properties of the mixture. Using softer asphalt, the effect is more obvious. In Tianjin area, AH90 asphalt is used at a ratio of 40 / 60, and the effect achieved is similar to that of SBS modified asphalt. If using softer asphalt, in order to achieve the above effect, it is necessary to increase the proportion of modified particles. Therefore, the appropriate ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com