Solvent-type cold-patch asphalt liquid and preparation technology therefor

A cold-filling asphalt and solvent-based technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor strength, poor viscosity and fluidity of cold-filling asphalt mixture, etc., to improve the reinforcement effect and construction. Good workability and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation technique of the present invention comprises the following steps:

[0028] (1) In parts by weight, heat 100 parts of petroleum asphalt to a molten state, then add 10 to 15 parts of diluent therein, and mix uniformly to make prepolymer A;

[0029] (2) Warm up 10-15 parts of heavy oil to 75-85°C in a reactor, add 1-5 parts of tackifier, mix well to make prepolymer B;

[0030] (3) Heat 10-15 parts of solvent oil to 45-55°C, add 1-5 parts of reinforcing agent, 0.2-0.8 parts of surfactant and 0.5-0.8 parts of anti-stripping agent in sequence, and mix evenly to make a pre- Polymer C;

[0031] (4) Mix prepolymer A, prepolymer B and prepolymer C evenly to make a solvent-based cold patch asphalt liquid.

[0032] The above mixtures are all stirred and mixed by using a high-speed shearing machine, and the rotating speed is 1500~3000r / min, and the step (1), step (2) and step (4) are all stirred for 10min. In the step (3), due to the addition of the additive Too much,...

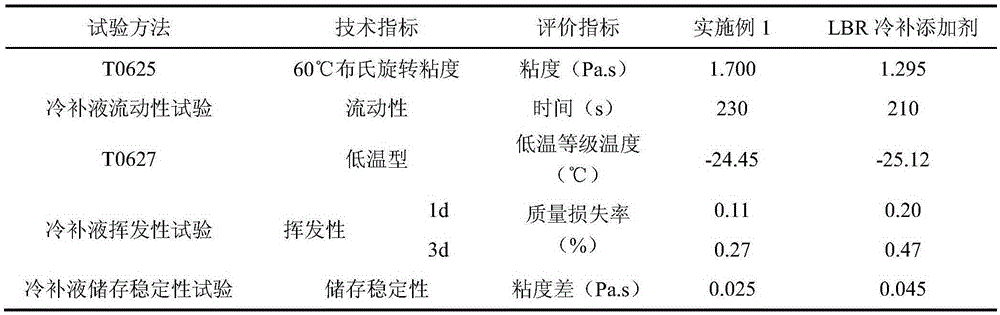

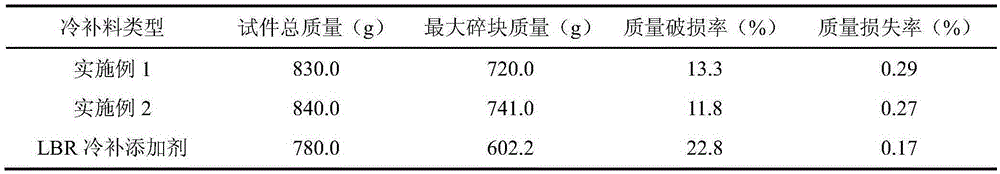

Embodiment 1

[0036] (1) Preparation of prepolymer A according to the stated parts by weight, heating 100 parts of 70# petroleum asphalt to a molten state, then adding 10 parts of 10# diesel oil to it, and using a rotating speed of 2000r / min to cut the asphalt Dilution time is about 10min to make prepolymer A;

[0037] (2) Preparation of prepolymer B According to the stated parts by weight, heat 10 parts of heavy oil to 80°C in a reactor, add 1 part of coumarone resin, and stir evenly to make prepolymer B. The shearing time is about 10min;

[0038] (3) prepare prepolymer C according to the weight part, with 10 parts of C 1 Aromatic solvent oil is heated to 50°C in a reaction kettle, and 1 part of lignocellulose, 0.2 part of fatty alcohol polyoxyethylene ether and 0.5 part of PA-1 anti-stripping agent are added in sequence in order, and uniformly stirred to prepare For prepolymer C, the shearing time is about 15 minutes;

[0039] (4) Preparation of solvent-based cold asphalt liquid The mi...

Embodiment 2

[0045] (1) Preparation of prepolymer A According to the stated weight parts, heat 100 parts of 90# petroleum asphalt to a molten state, then add 10 parts of 0# diesel oil to it, and use a rotating speed of 2000r / min to cut the asphalt Dilution time is about 10min to make prepolymer A;

[0046] (2) Preparation of prepolymer B According to the stated weight parts, heat 10 parts of heavy oil to 80°C in the reactor, add 1 part of C 5 Aromatic petroleum resin, stir evenly to make prepolymer B, and the shearing time is about 10 minutes;

[0047] (3) prepare prepolymer C according to the weight part, with 13 parts of C 2 Aromatic solvent oil is heated up to 50°C in the reaction kettle, and 3 parts of wollastonite powder, 0.5 part of octadecyltrimethylammonium chloride and 0.5 part of AMR-II type anti-stripping agent are added in sequence, Stir evenly to make prepolymer C, and the shearing time is about 15 minutes;

[0048] (4) Preparation of solvent-based cold asphalt liquid The mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com