Self-cementing leaking stoppage agent and leaking stoppage method

A loss-stopping agent and cementing technology, applied in chemical instruments and methods, earth-moving drilling and production, wellbore/well components, etc., can solve the problems of repeated leakage, poor temperature resistance, loose structure, etc. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Acrylamide monomer 25%, N,N'-methylenebisacrylamide 0.1%, sodium carbonate 0.5%, bentonite 24.3%, polyacrylamide 5%, polyacrylamide-acrylate gel particles with a particle size of 4mm 5%, particle diameter is 35% of fine calcium carbonate of 500 mesh, length is 5% of polypropylene fiber of 12mm, ammonium persulfate 0.1%.

Embodiment 2

[0034] Acrylamide monomer 30%, N,N'-methylenebisacrylamide 0.3%, sodium carbonate 0.3%, bentonite 22.2%, polyacrylamide potassium salt 4%, polyacrylamide-acrylic acid gel with a particle size of 3mm 5% of particles, 30% of calcium carbonate with a particle diameter of 400 meshes, 8% of polyacrylonitrile fibers with a length of 9mm, and 0.2% of ammonium persulfate.

Embodiment 3

[0036] 35% acrylamide monomer, 0.5% dimethyl diallyl ammonium chloride, 0.2% sodium carbonate, 21.0% bentonite, 2% polyacrylamide, 3% polyacrylamide gel particles with a particle size of 2mm, granules The diameter is 30% of calcium carbonate of 300 meshes, the length is 8% of polyurethane fiber of 6mm, and 0.3% of potassium persulfate.

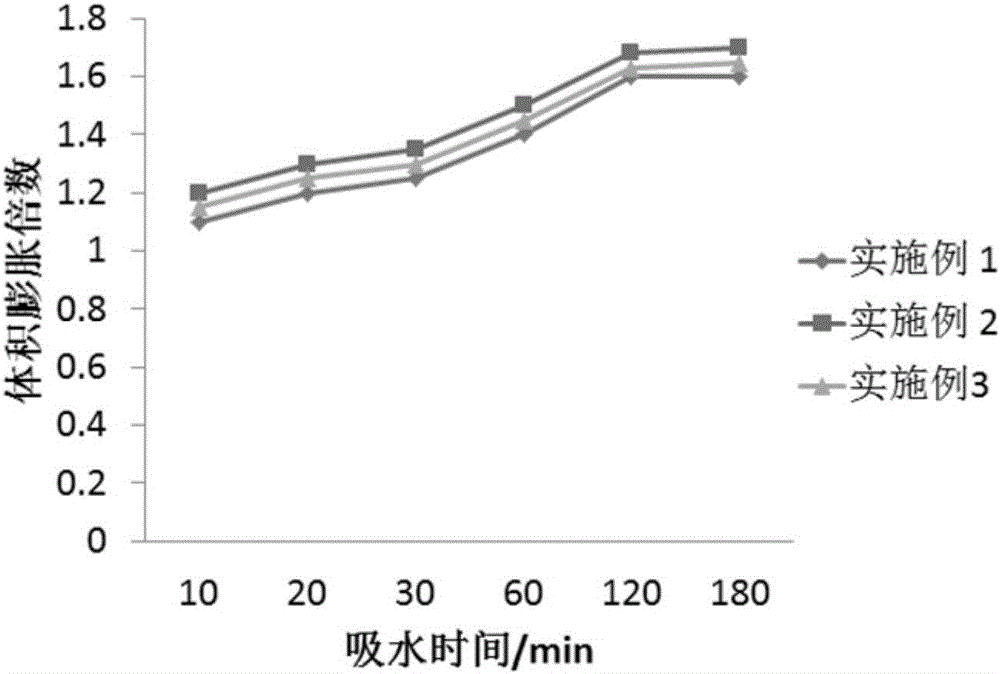

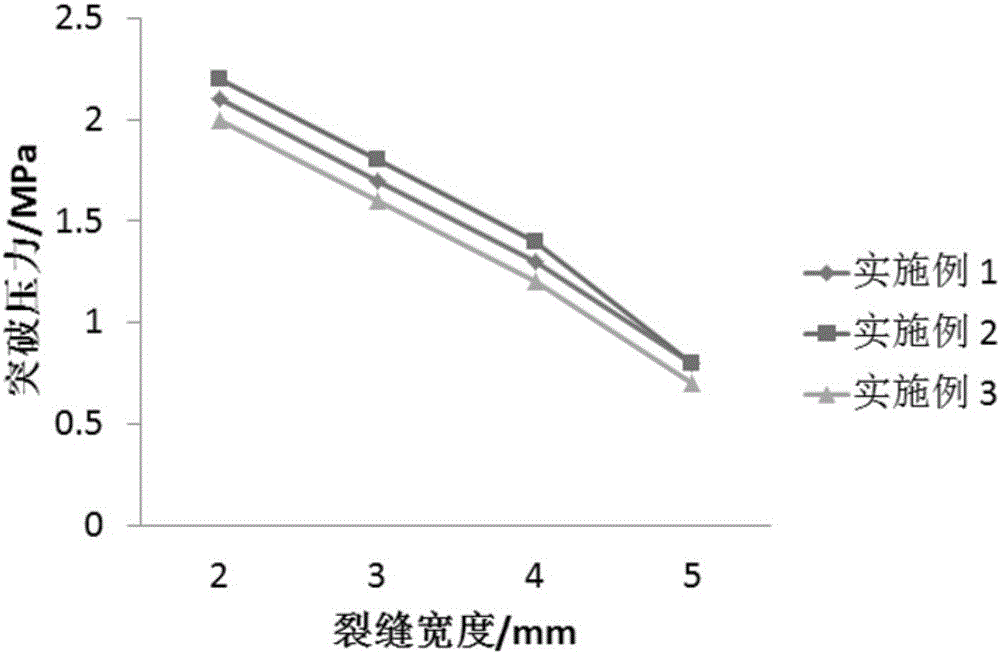

[0037] The above examples are all prepared by a mixer. After mixing the plugging materials, add 20 parts (weight) of self-cementing plugging agent for every 100 parts (weight) of water, stir evenly, and put them into a closed container or a plugging mold After being placed in an incubator at 80°C for a few hours, a rubber plug or plugging mold is formed for performance evaluation, see figure 1 and 2 .

[0038] performance evaluation

[0039] 1. Water absorption and expansion performance of rubber stopper

[0040] The experiment of water expansion ratio of rubber stopper adopts the method of direct measurement of volume change. The test met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com