Waterproof modified asphalt for dam asphalt well and preparation method thereof

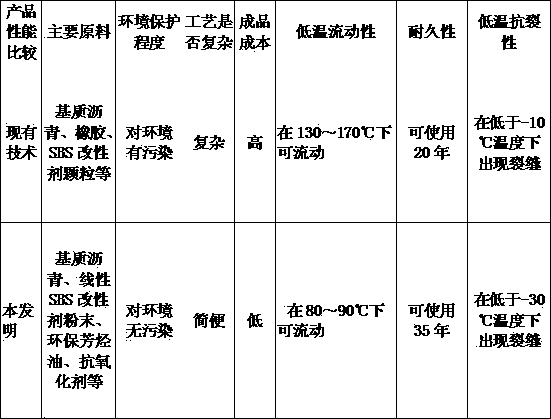

A technology of modified asphalt and asphalt well, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of high softening point of modified asphalt, complex asphalt preparation process, and low durability of asphalt, and achieve good low temperature crack resistance performance and high temperature performance, the preparation method is simple and fast, and the effect of good flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

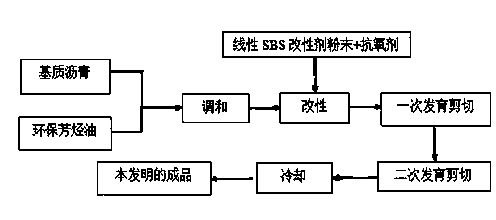

Method used

Image

Examples

Embodiment 1

[0031] A waterproof modified asphalt for dam asphalt wells proposed by the present invention is prepared according to the required weight. The raw materials include (by mass percentage): 55% matrix asphalt, 40% environmentally friendly aromatic oil, 4.2% linear SBS modifier powder and 0.8% antioxidant, the specific implementation steps are as follows:

[0032] Step 1, blending: first heat the base asphalt with a mass percentage of 55% to a molten state at 120°C, then add an environmentally friendly aromatic oil with a mass percentage of 40%, and stir it with a mixer to make it fully mixed; wherein, the base asphalt is AH-70 asphalt; environmentally friendly aromatic oil is special oil for GXJ-I rubber;

[0033] Step 2, modification: after heating the mixture obtained in step 1 to 150°C, add 4.2% by mass of linear SBS modifier powder and 0.8% by mass of antioxidant to form asphalt colloid; among them, linear SBS The modifier is YH-792, and the particle size of its powder is 10...

Embodiment 2

[0039] A waterproof modified asphalt for dam asphalt wells proposed by the present invention is prepared according to the required weight. The raw materials include (by mass percentage): 70% base asphalt, 28% environmentally friendly aromatic oil, 1% linear SBS modifier powder mixed with 1% antioxidant. The specific implementation steps are as follows:

[0040] Step 1, blending: first heat the base asphalt with a mass percentage of 70% to a molten state at 145°C, then add an environmentally friendly aromatic oil with a mass percentage of 28%, and stir it with a mixer to make it fully mixed; wherein, the base asphalt is AH-100 asphalt; environmentally friendly aromatic oil is GXJ-Ⅰ special oil for rubber;

[0041] Step 2, modification: after heating the mixture obtained in step 1 to 180°C, add 1% by mass linear SBS modifier powder and 1% by mass antioxidant to form asphalt colloid; among them, linear SBS The modifier is YH-791, and the particle size of its powder is 100-200 mes...

Embodiment 3

[0047] A waterproof modified asphalt for dam asphalt wells proposed by the present invention is prepared according to the required weight. The raw materials include (by mass percentage): 63% matrix asphalt, 34% environmentally friendly aromatic oil, 2.1% linear SBS modifier powder mixed with 0.9% antioxidant. The specific implementation steps are as follows:

[0048] Step 1, blending: first heat the base asphalt with a mass percentage of 63% to a molten state at 135°C, then add an environmentally friendly aromatic oil with a mass percentage of 34%, and stir it with a mixer to make it fully mixed; wherein, the base asphalt is AH-70 asphalt; environmentally friendly aromatic oil is special oil for GXJ-I rubber;

[0049] Step 2, modification: After heating the mixture obtained in Step 1 to 170°C, add linear SBS modifier powder with a mass percentage of 2.1% and an antioxidant with a mass percentage of 0.9% to form an asphalt colloid, wherein, The linear SBS modifier is YH-796, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com