Energy-saving pavement crack repairing material and preparation method thereof

A technology for repairing materials and pavement cracks. It is used in building thermal insulation materials, building components, buildings, etc. It can solve problems such as air pollution and waste of energy, and achieve the effects of reducing pollution, reducing energy consumption, and good low-temperature crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

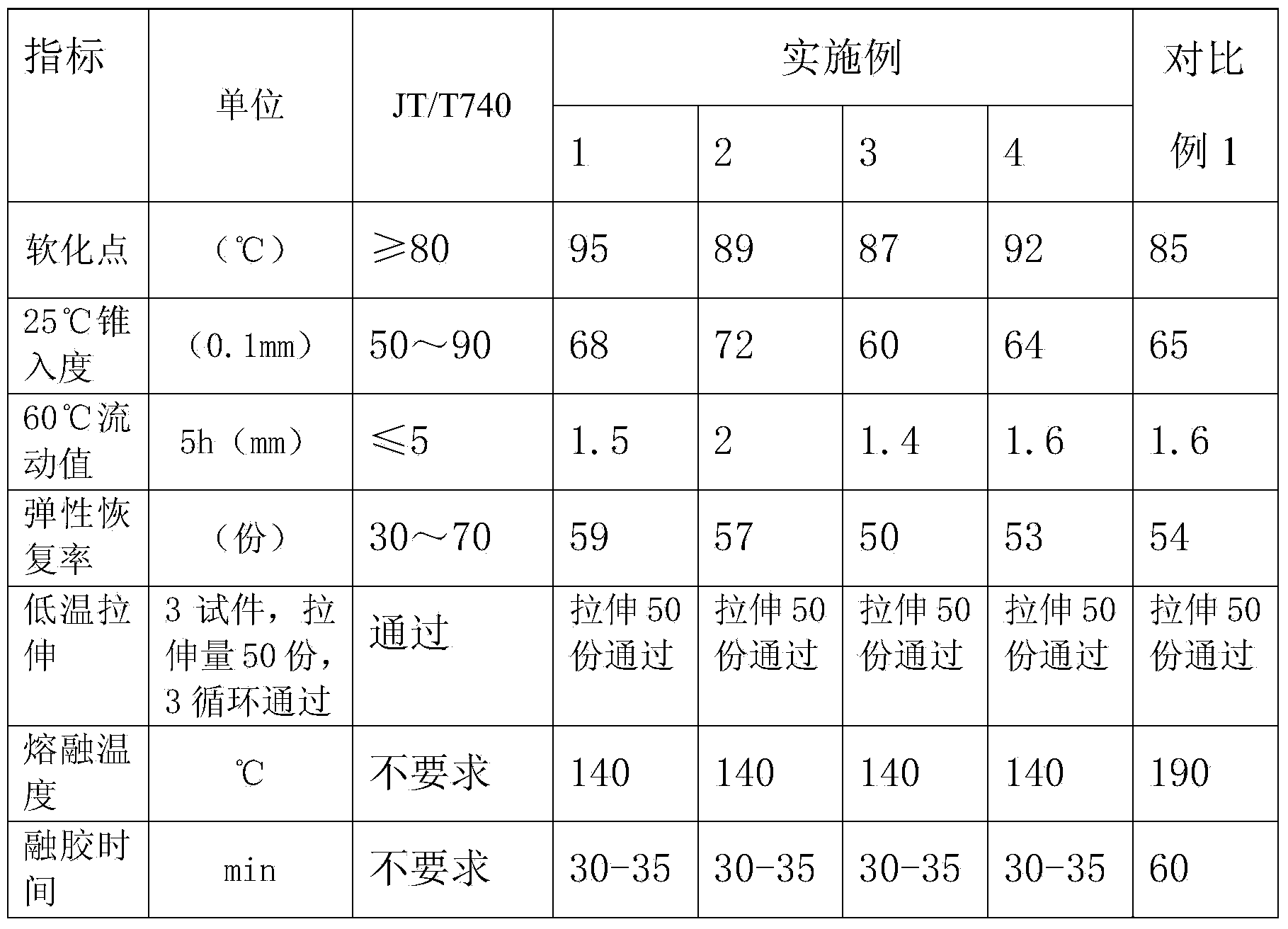

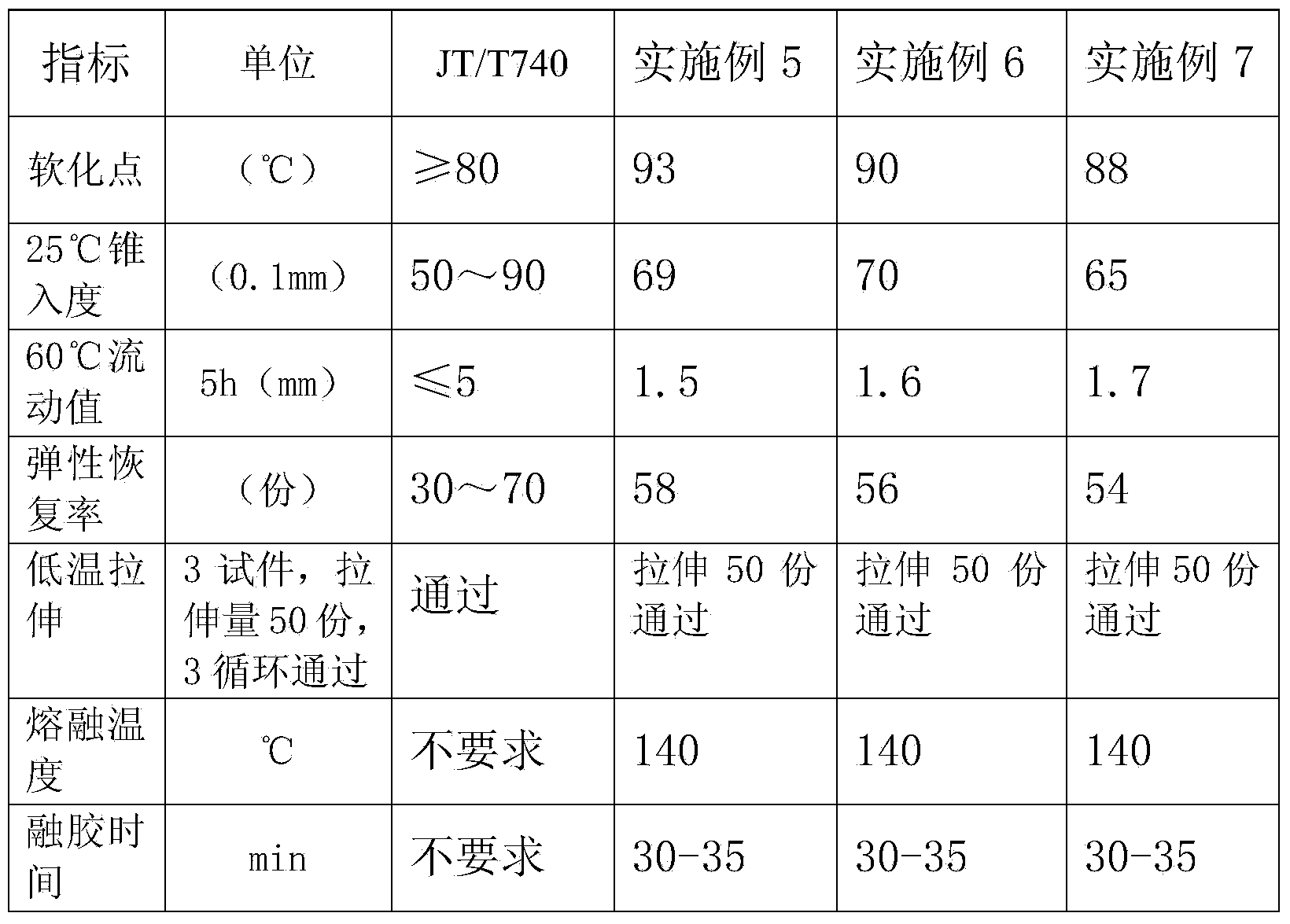

Examples

Embodiment 1

[0029] Weigh each component according to the formula quantity, 60 parts of petroleum asphalt, 5 parts of modifier, 5 parts of resin type tackifier, 12 parts of softener, 5 parts of melting temperature reducer, 1 part of plasticizer, 5 parts of viscosity regulator 5 parts, 5 parts of enhancer, 2 parts of antioxidant;

[0030] The preparation method of embodiment 1 is:

[0031] Heat petroleum-based asphalt to 180-190°C, add modifier, stir and shear at a speed of 3000 rpm for 30-40 minutes, then add softener and viscosity regulator in turn and stir at constant temperature 180-190°C for 50-70 minutes Minutes, stop heating, add resin-type tackifier when the temperature drops to 150°C, add melting temperature reducer, plasticizer, antioxidant and reinforcing agent when the temperature drops to 140°C, and stir evenly.

Embodiment 2

[0033] Weigh each component according to the formula quantity, 50 parts of petroleum asphalt, 5 parts of modifier, 7 parts of resin type tackifier, 14 parts of softener, 6 parts of melting temperature lowering agent, 1 part of plasticizer, 7 parts of reinforcing agent , 8 parts of waste rubber powder, 1 part of antioxidant; the preparation method of embodiment 2 is the same as embodiment 1.

Embodiment 3

[0035] Weigh each component according to the formula quantity, 53 parts of petroleum asphalt, 4 parts of modifier, 15 parts of resin type tackifier, 10 parts of softening agent, 5 parts of melting temperature lowering agent, 2 parts of plasticizer, 10 parts of waste rubber powder Part, 1 part of antioxidant; The preparation method of embodiment 3 is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com