Patents

Literature

103results about How to "Realize repeated recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for producing rock wool by comprehensively utilizing solid wastes

ActiveCN104692648AReduce consumptionLower melting temperatureGlass making apparatusGlass productionFiberAdhesive

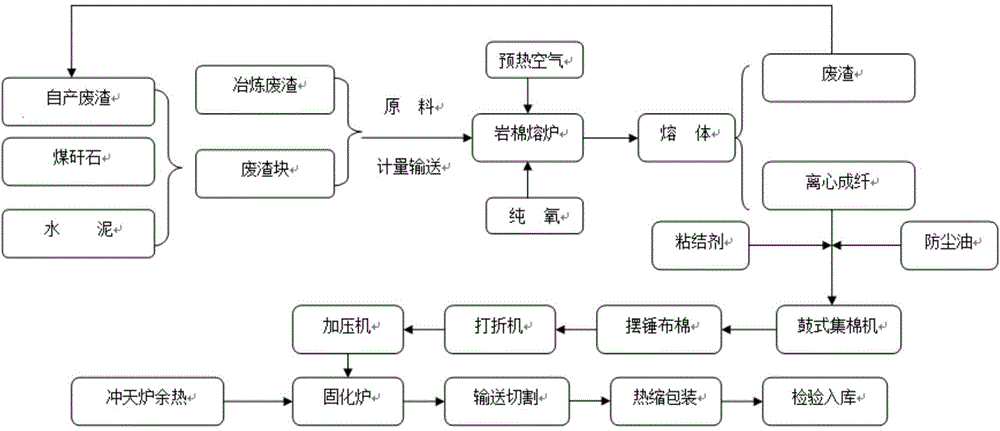

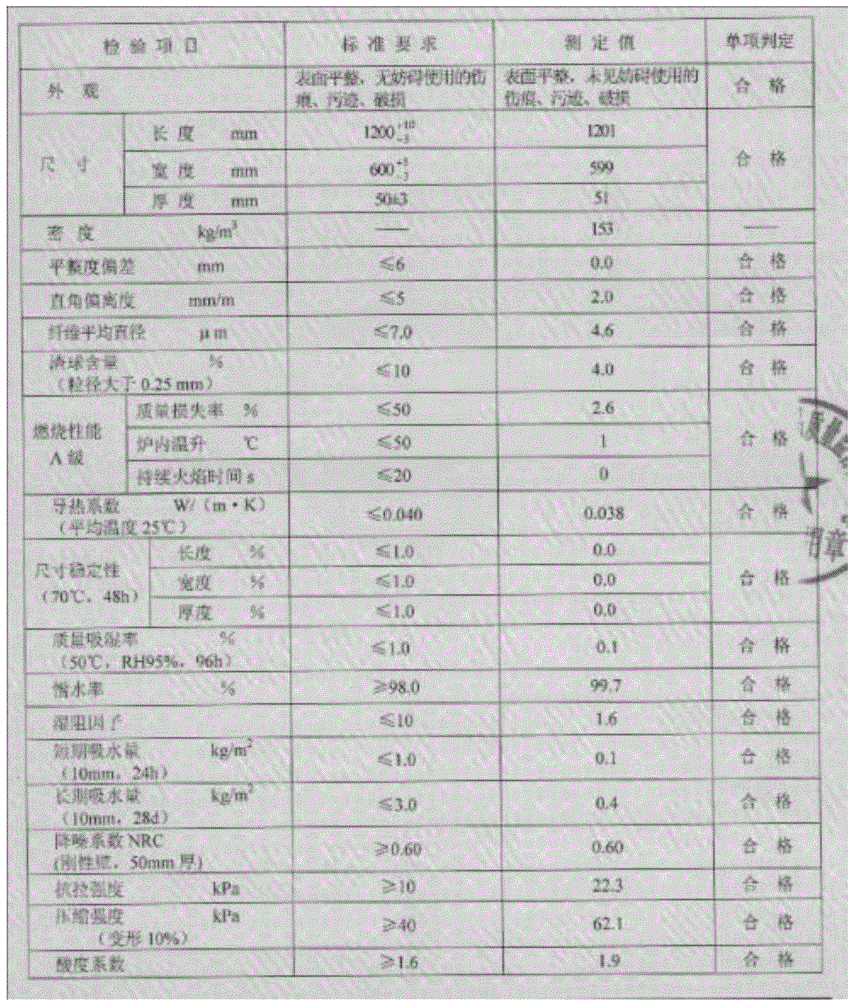

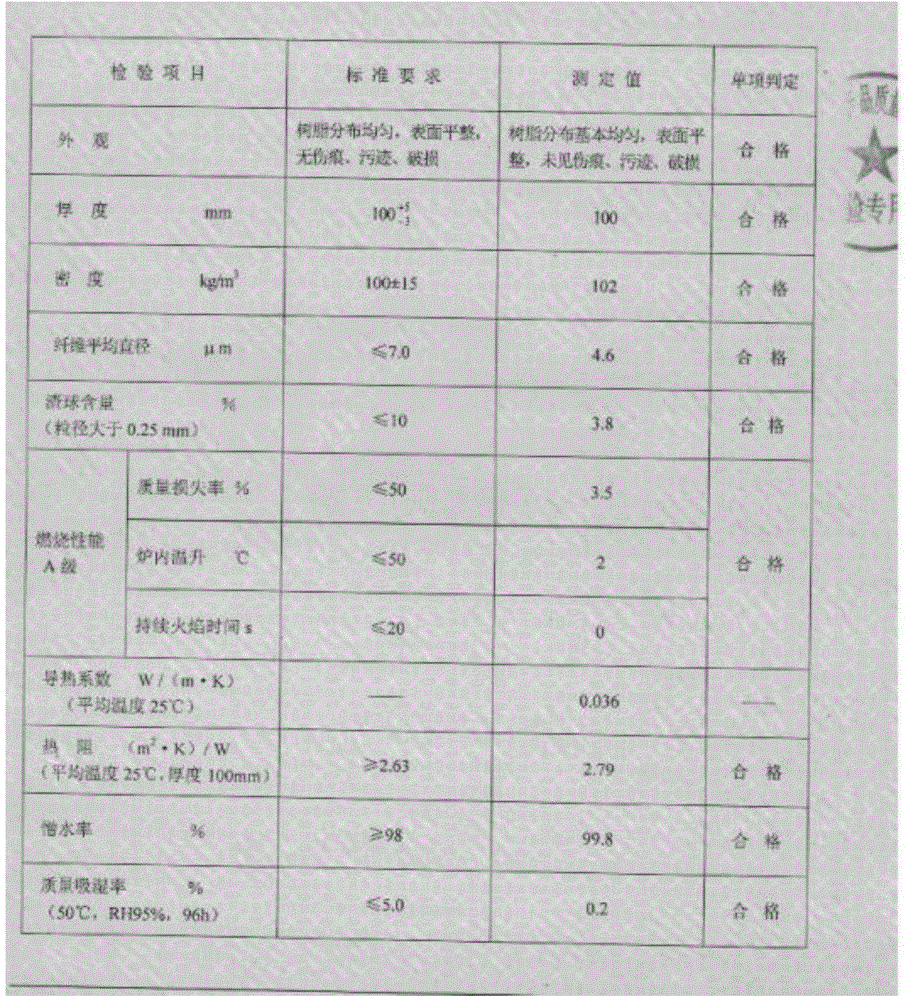

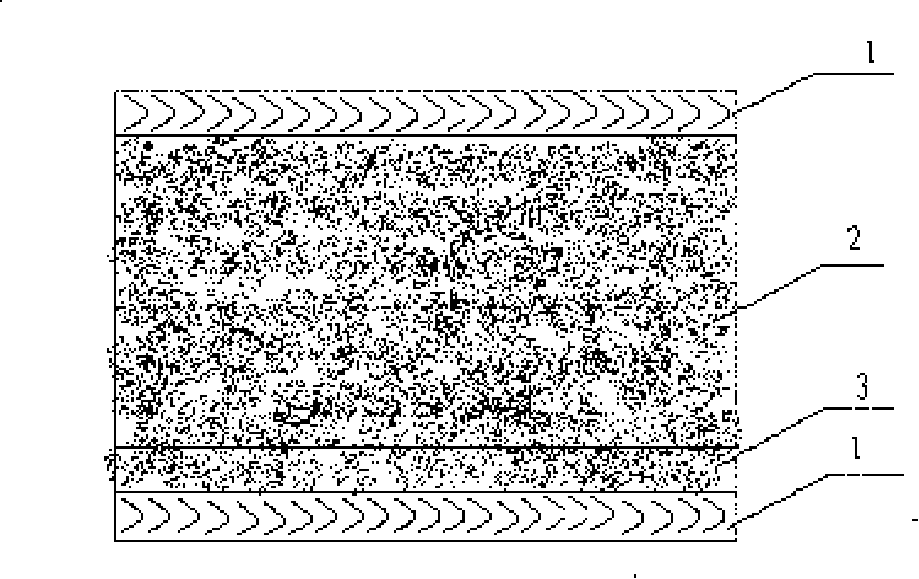

The invention discloses a method and system for producing rock wool by comprehensively utilizing solid wastes. The method comprises the following steps: a) uniformly mixing rock wool waste residue, coal gangue and cement in a mass ratio of (50-70):(20-35):(10-20) to prepare an autoclaved waste residue block; b) uniformly mixing the autoclaved waste residue block and smelting waste residue in a mass ratio of (60-80):(20-40) to obtain a mixture; c) melting the mixture at high temperature, and centrifuging at high speed for fiber formation, thereby obtaining fibers; and d) spraying an adhesive, a water repellent and a coupling agent on the fibers, and carrying out wool accumulation, solidification and cutting to obtain the rock wool plate. The method has the advantages of simple technological equipment, low energy consumption and recoverable heat source, is convenient to operate, comprehensively utilizes the solid wastes instead of the traditional basalt and dolomite to produce the rock wool product, and thoroughly solves the problem of solid wastes in the rock wool enterprise.

Owner:TAISHI ROCK WOOL

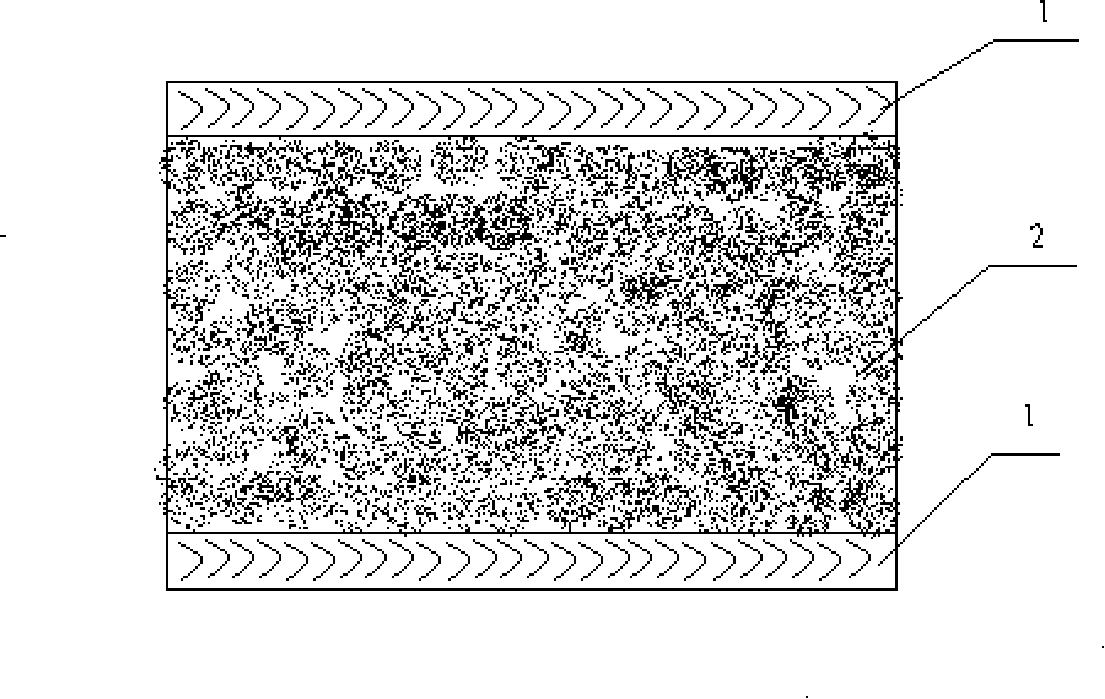

Biomass composite material wall modules and processing technology thereof

The invention provides a composite material of environmental protection wall module, which mainly consists of a plant fiber, a self-made biomass adhesive, a moisture proofing agent, a biomass perfume etc., wherein the plant fiber comprises various crop straws and smashed sawdust which is cut into a length of 1 to 8 cm; the self-made biomass adhesive comprises a modified corn starch adhesive, a tapioca starch adhesive, a soybean crude protein adhesive and a trash for sugar beet processing; the moisture proofing agent is a calcium oxide; the perfume includes lavender, camphor tree particulate and argy wormwood. The wall consists of an internal wall surface and an external wall surface wherein the internal wall surface is abrasive, which is easy to ensure surface to be finished when in interior decoration; furthermore, the perfume such as the lavender, the camphor tree particulates and the argy wormwood etc. are added, so that a fragrance generated from the perfume gives out slowly when the wall is in use, and the goal of beautifying the indoor air environment and anti mosquitoes are achieved. The external wall surface is fine sand coated to form a smooth and rigid housing which can improve the strength of the surface and be good for ventilation of outer atmosphere. The production flow comprises straw pre-treatment, cutting off, batching, adhesive spraying, burden distribution, repressing, hot pressing and modular processing. The production process meets the integral idea of sustainable development, which is characterizes in the outstanding energy saving effect, the simple technology and the low cost. The material prepared has light weight, excellent environmental protection performance and outstanding water and fire proof performance. The production material has wide source, which is characterized by the high strength, good tenacity and excellent seismic behavior.

Owner:北京格物创道科技发明有限公司

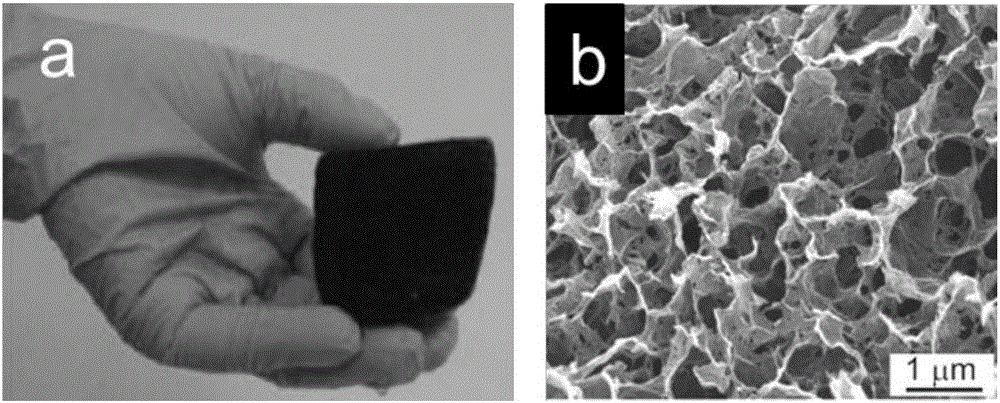

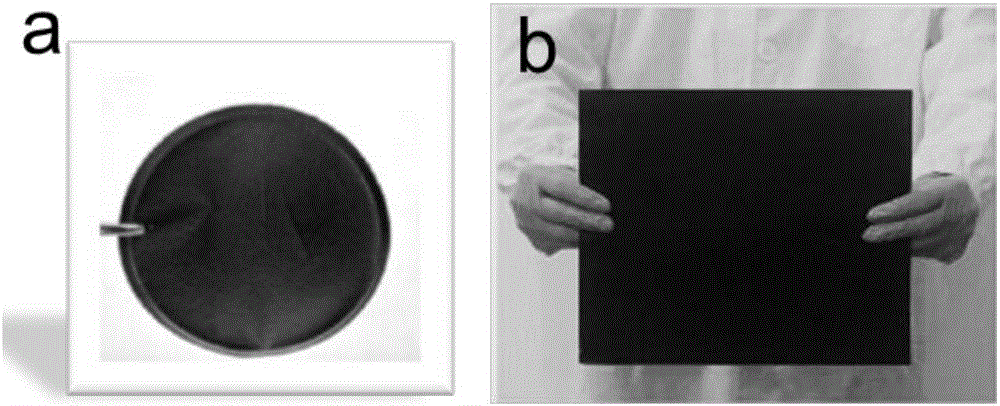

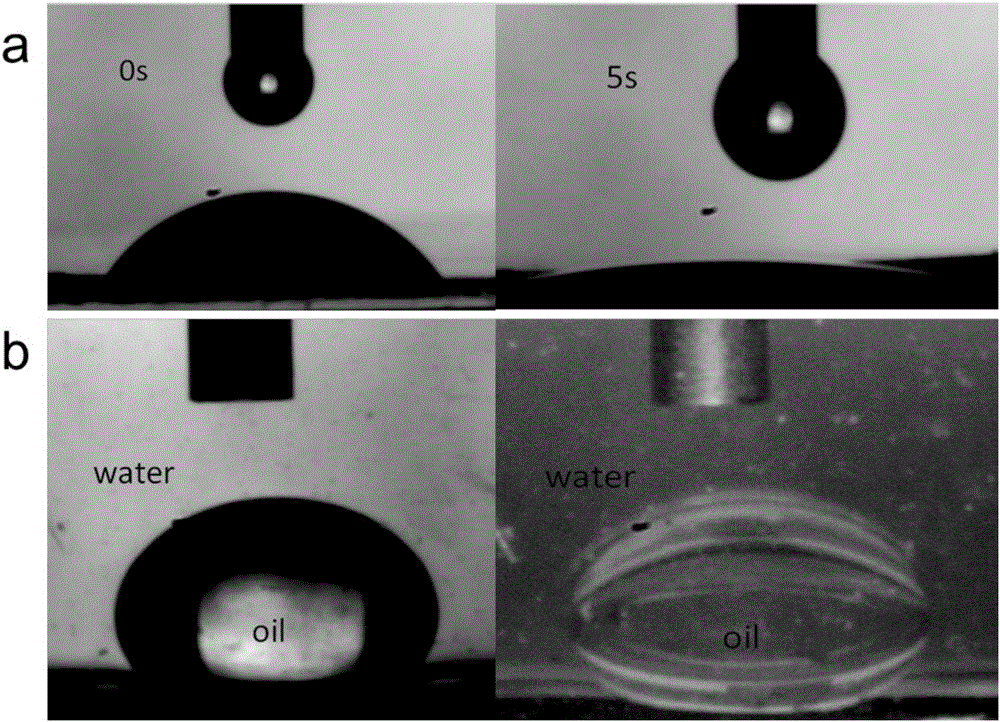

Preparation method of graphene foam-polydopamine composite membrane, product prepared with preparation method and application of product

ActiveCN106422816AImprove mechanical propertiesRealize large-scale applicationSemi-permeable membranesFatty/oily/floating substances removal devicesMaterials scienceHydrochloride

The invention discloses a preparation method of a graphene foam-polydopamine composite membrane, a product prepared with the preparation method and an application of the product. The preparation method comprises steps as follows: (1) preparation of graphene foam-polydopamine: the pH value of a graphene oxide solution is adjusted, dopamine hydrochloride is added, a precursor solution is obtained and subjected to a hydrothermal reaction, and graphene foam-polydopamine is obtained; (2) preparation of the graphene foam-polydopamine composite membrane: graphene foam-polydopamine is added to N,N-dihydroxyethylglycine and mixed with a temperature-sensitive polymer, the mixture is stirred and subjected to vacuum filtration, and the temperature-sensitive graphene foam-polydopamine composite membrane is obtained. The graphene foam-polydopamine composite membrane prepared through improvement of overall process design, reaction conditions of steps and the like of a key preparation process has good temperature sensitivity and excellent super-hydrophilic property and underwater super-lipophobicity and is very applicable to oil-water separation.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for multifunctional resin modifier for wood impregnation and application of multifunctional resin modifier

InactiveCN104070572AStrong loss resistancePromote environmental protectionWood treatment detailsPressure impregnationPhenolWeight gain

The invention belongs to a preparation method for a multifunctional resin modifier for wood impregnation and application of the multifunctional resin modifier. The low-alkali multi-element copolycondensation resin modifier which has functions of weight gaining enhancement, flame retardance and corrosion prevention is synthesized by taking phenol, formaldehyde, melamine and urea as main agents and taking boric acid and zinc borate as functional auxiliaries. By the adding of a certain amount of dipropylene glycol, the modifier can be stored stably for a long time, and repeated cyclic use is realized. The size stability, density, surface hardness, bending strength, bending-resistant elastic modulus, processing characteristic, the flame retardancy, the corrosion prevention and the abrasion resistance of plantation woods treated by the modifier are greatly improved; furthermore, the modifier is high in runoff resistance and high in environment al protection, does not have a loss effect on the toughness of the wood and cannot affect the painting decoration performance of the wood, and the application value of the plantation woods is increased.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

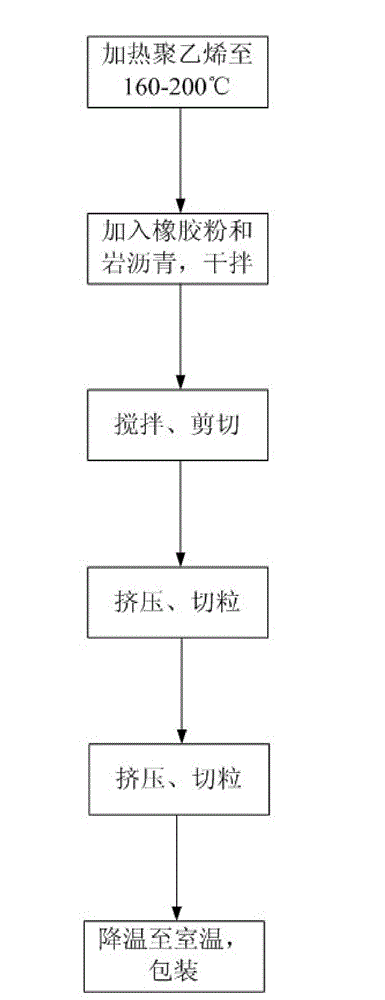

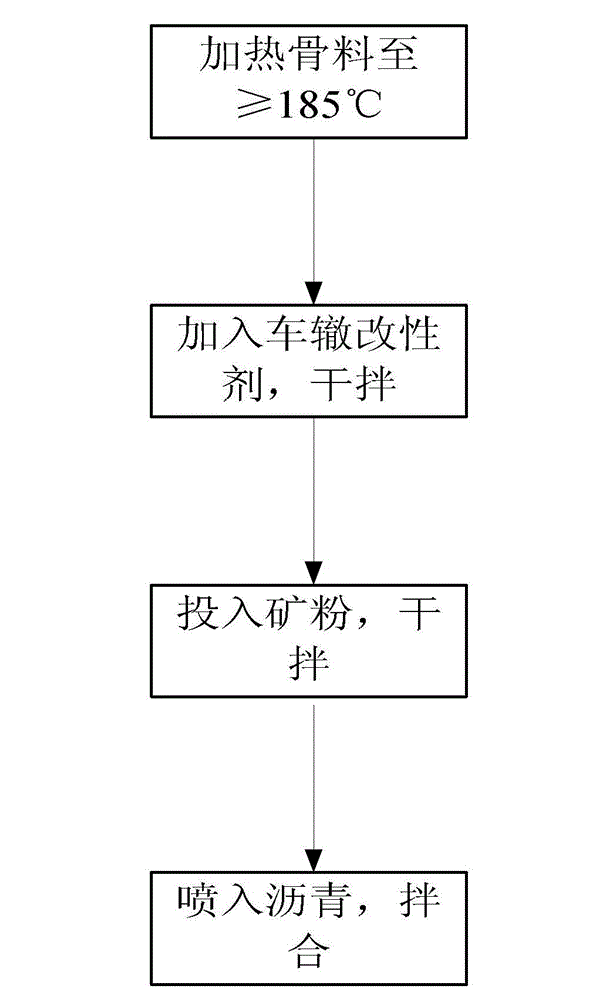

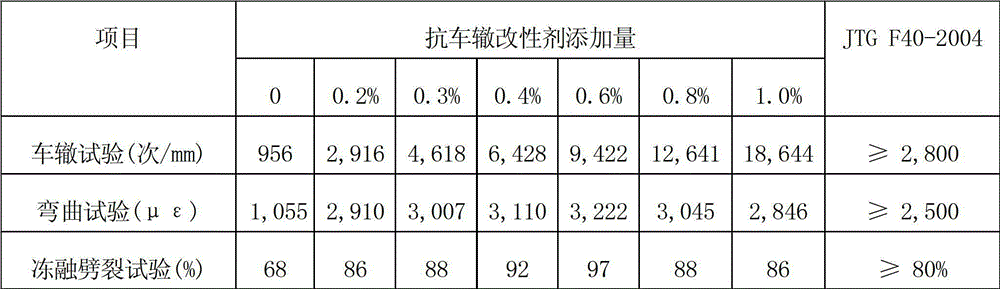

Anti-rutting modifying agent used for asphalt pavement and asphalt mixture containing anti-rutting modifying agent

ActiveCN103059587ASolve technical problemsRealize repeated recyclingBuilding insulationsPolymer scienceEngineering

The invention relates to an anti-rutting modifying agent. The anti-rutting modifying agent comprises (a) high-density low-pressure polyethylene, (b) rubber powder and (c) rock asphalt. The anti-rutting modifying agent is good in low-temperature cracking resistance, high in bonding strength, high in water damage resistance, good in non-deformability, low in cost, simple in preparation technology, convenient to operate and convenient to add in asphalt mixture.

Owner:北京中交路通科技发展有限公司

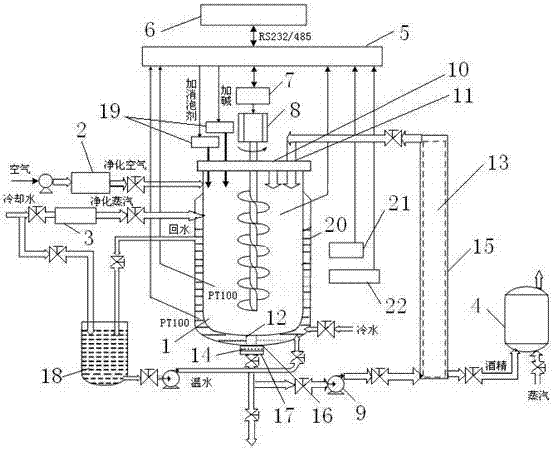

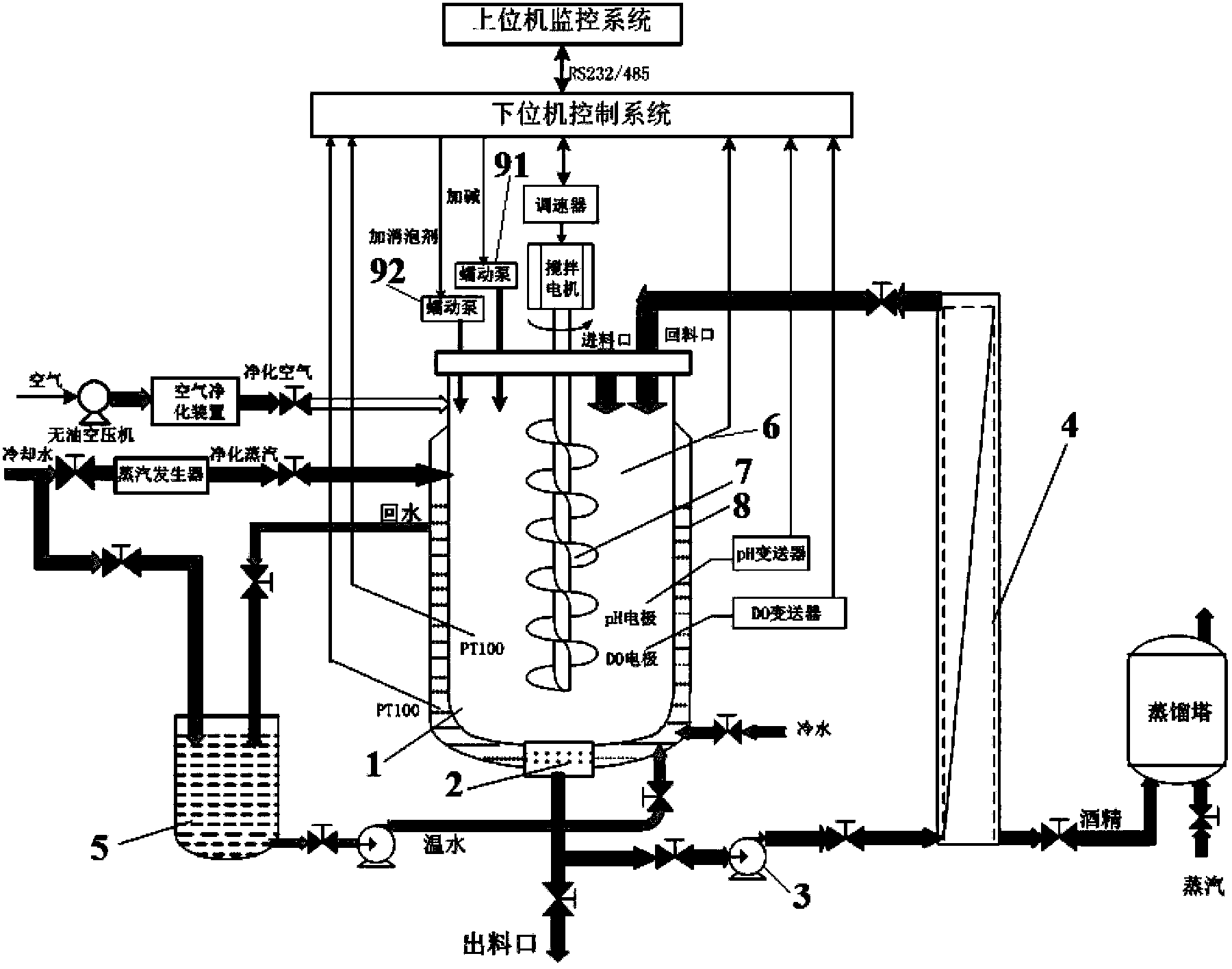

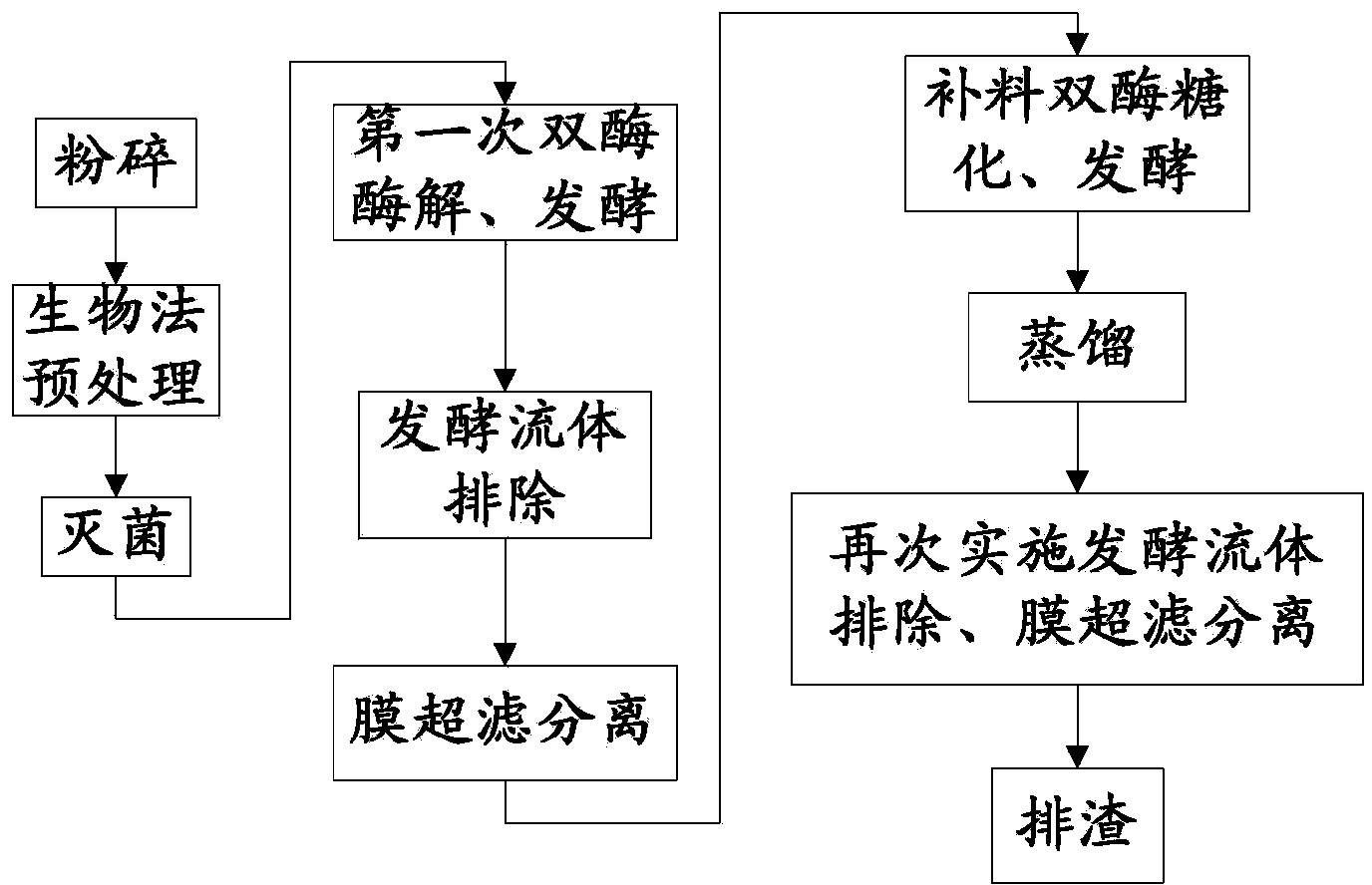

Circulating synchronous straw enzymatic hydrolysis fermentation fuel ethanol reactor and reaction method thereof

ActiveCN103243023AIncrease profitRealize repeated recyclingBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseUltrafiltration

The invention discloses a circulating synchronous straw enzymatic hydrolysis fermentation fuel ethanol reactor and a reaction method thereof. The reactor comprises a mechanical stirring fermentation tank, an air purification device, a steam generation device, a temperature control system, a distillation tower, a lower computer control system, an upper computer monitoring system, a speed regulator, a stirring motor, and a pressure pump, as well as a ceramic ultrafiltration membrane separation device, wherein the upper end of the ceramic ultrafiltration membrane separation device is connected with a return port at the upper end of the mechanical stirring fermentation tank, and the lower end of the ceramic ultrafiltration membrane separation device is connected with a fermentation residue discharge outlet at the lower end of the mechanical stirring fermentation tank through the pressure pump. The reactor integrates sterilization, enzymatic hydrolysis and fermentation, thus not only being used for production of synchronous straw enzymatic hydrolysis fermentation fuel ethanol, but also being used for production of fuel ethanol through step-by-step straw enzymatic hydrolysis and fermentation technique; the recycling of cellulose and yeast can be realized by adopting the ceramic ultrafiltration membrane separation device; and the reactor not only can be used for production of the straw enzymatic hydrolysis fermentation fuel ethanol, but also can be used for fermentation production of antibiotics, amino acids, enzymes and other biological products.

Owner:JIANGSU UNIV

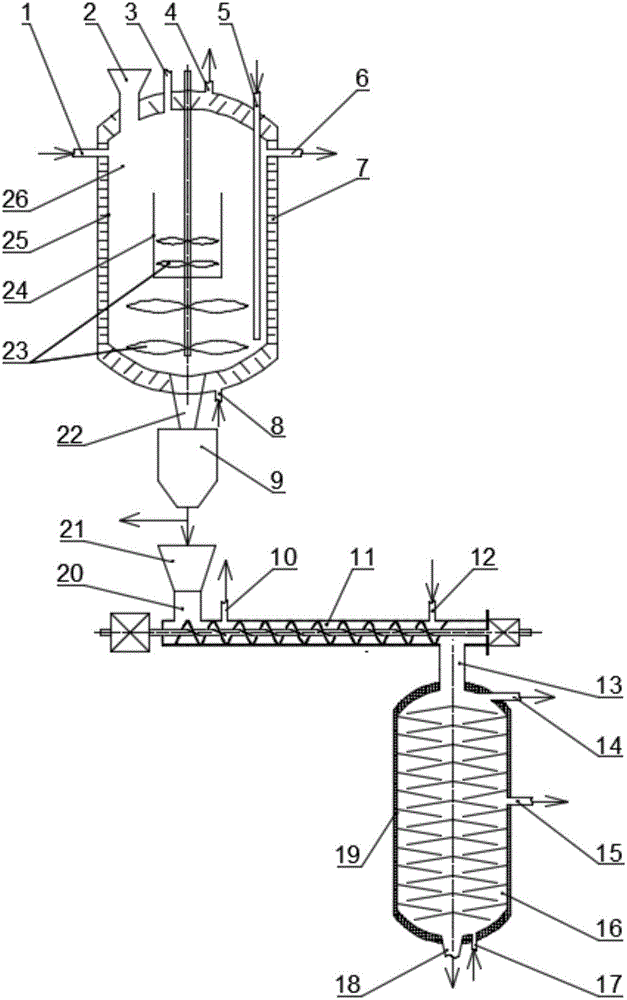

Fermentation fuel reactor and fermentation fuel production method

ActiveCN104342358AAvoid wastingLow costBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholDistillation

The invention discloses a fermentation fuel reactor and a fermentation fuel production method, relates to the technical field of microbial fermentation equipment, and solves the technical problem in the prior art that relatively high production cost of a fermentation fuel is caused because cellulase and saccharomyces cerevisiae are wasted seriously. The fermentation fuel reactor includes a fermentation tank, a filter screen, a fluid pressurization conveying device, a large and small molecule separation device and an alcohol distillation tower; the large and small molecule separation device comprises a large molecule outlet and a small molecule outlet, the large molecule outlet is communicated with a material return port of the fermentation tank, and the small molecule outlet is communicated with a raw material inlet of the alcohol distillation tower; the large and small molecule separation device enables a cellulase, xylanase and saccharomyces cerevisiae-containing filtrate in a fermentation fluid inputted by the fluid pressurization conveying device to be outputted from the large molecule outlet and allow a remaining ethanol-containing filtrate in the fermentation fluid to be outputted from the small molecule outlet. The fermentation fuel reactor and the fermentation fuel production method are used for repetitive and circular utilization of cellulase and xylanase so as to reduce the production cost of the fermentation fuel.

Owner:STATE GRID CORP OF CHINA +1

Two-stage biomass hydrothermal catalytic activation reaction device

InactiveCN106824001AEfficient catalytic decompositionEasy to openCarbon compoundsLiquid hydrocarbon mixture productionLiquid productBiological activation

The invention discloses a two-stage biomass hydrothermal catalytic activation reaction device and belongs to the field of a biomass hydrothermal technology. The device comprises a biomass high-pressure reaction kettle reactor and a vertical type activation furnace reactor which are communicated with each other through a packing auger drying bed; the biomass high-pressure reaction kettle reactor comprises a hydrothermal reaction cylinder, an additive loading tank and a biomass feeding pipe; under the condition of a carbon dioxide aqueous solution, the additive reacts with hydrogen ions in the aqueous solution to generate metal cations, so that biomass thermal decomposition is catalyzed to generate a high-quality liquid product; the biomass high-pressure reaction kettle reactor is also used for performing initial activation on hydrothermal coke; the vertical type activation furnace reactor comprises an activation reaction cylinder, a high-temperature activation gas nozzle, a round drainage plate and a ring-shaped drainage plate, and is used for preparing super activated carbon from the hydrothermal coke. The device is clever in design, can prepare supercapacitor electrode carbon and high-quality liquid products simultaneously by utilizing two-stage biomass hydrothermal catalytic activation reaction, and is high in energy utilization rate and high in production efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

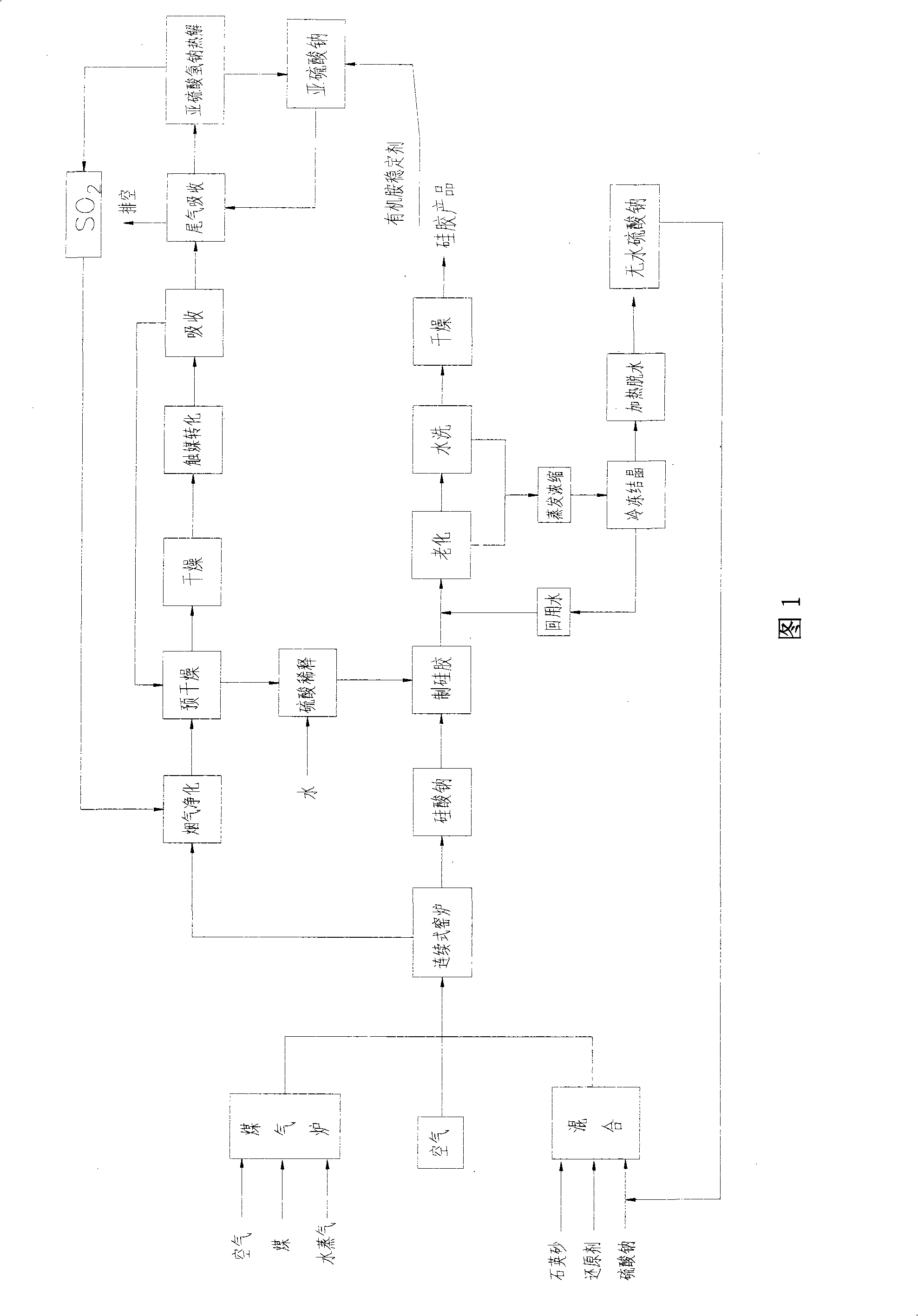

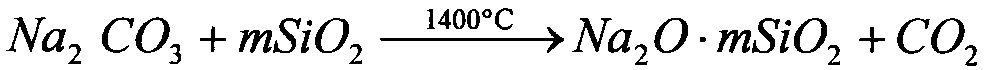

Silica gel cleaning production method and sulfuric acid production method

InactiveCN101327931ASave energyRealize repeated recyclingSilicaSulfur-trioxide/sulfuric-acidHigh concentrationPersulfate

The invention relates to a cleaning production method of a silica gel and a production method of a sulfuric acid belonging to the preparation technology field of the silica gel and sulfuric acid, wherein the silica gel production method employs sulfuric acid to react with alkali metal silicate, the alkali metal silicate is prepared by kraft process and the material sulfuric acid is completely or partially from sulfur compounds in the recovered flue gas during the production of another material alkali metal silicate. The production method of the invention achieves the repeated recycle of the sulfur element and the alkali metal element, improves the resource utilization rate and solves the environmental protection problem. The sulfuric acid production method of the invention is to recover the sulfur compounds in the flue gas during the production of the alkali metal silicate and to produce sulfuric acid by the unsteady conversion technology, which overcomes the problems of higher concentration of sulfur dioxide and little fluctuation required in the acid-making technology and achieves the autothermal equilibrium of the conversion with little investion and low energy consumption.

Owner:QINGDAO MAKALL GROUP CO LTD

Loaded organic sulfoacid solid catalyst and preparation method thereof

InactiveCN102600895AIncrease acidityIncrease the number ofOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic sulfonic acidOrganic solvent

The invention belongs to the technical field of catalysis, in particular relates to a solid acid catalyst loaded with organic sulfoacid groups by an immersion method and a preparation method of the solid acid catalyst. The method for preparing the catalyst provided by the invention comprises the following steps: (1) throwing an activated carrier into an immersion solution prepared from styrene, an initiator and an organic solvent to immerse and load; (2) in the presence of protective gas, allowing styrene to conduct a polymerization reaction to obtain a load precursor loaded with polystyrene monomolecular film on the surface; and (3) mixing and sulfonating the load precursor and a sulfonating agent, and the like. The loaded organic sulfoacid solid catalyst utilizes the polymerization reaction of styrene for ensuring that the active groups of the catalyst partially form the structure of polystyrene, and after the sulfonating reaction, a plurality of sulfo group structures can be formed in each active group, so that the acid content of the whole catalyst is greatly improved; and the degree of polymerization of polystyrene in the catalyst can reach 2-100, and the quantity of the loaded sulfoacid groups is greatly increased.

Owner:山东华阳油业有限公司 +1

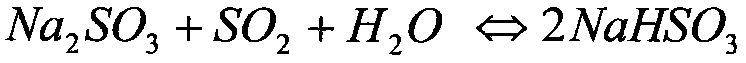

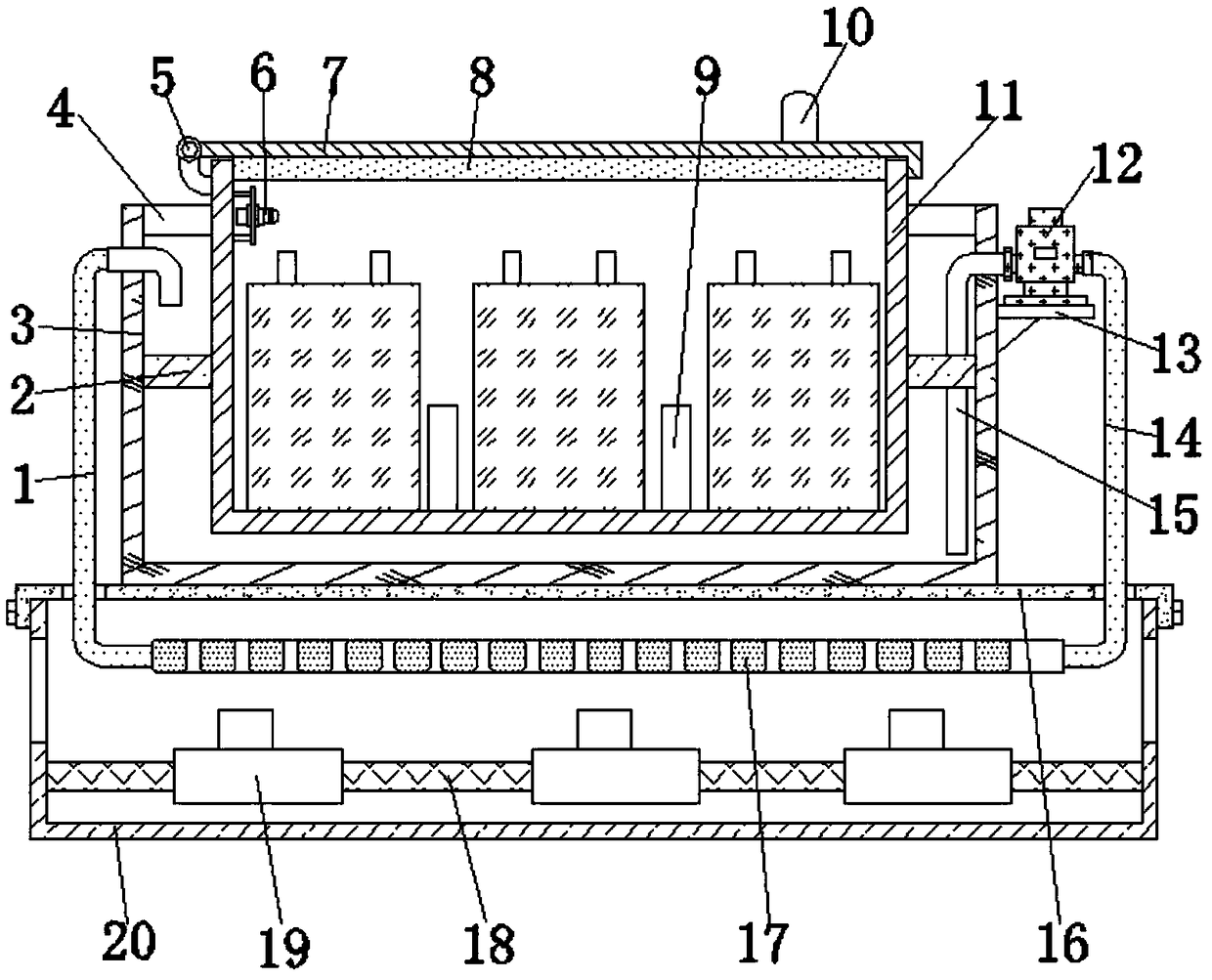

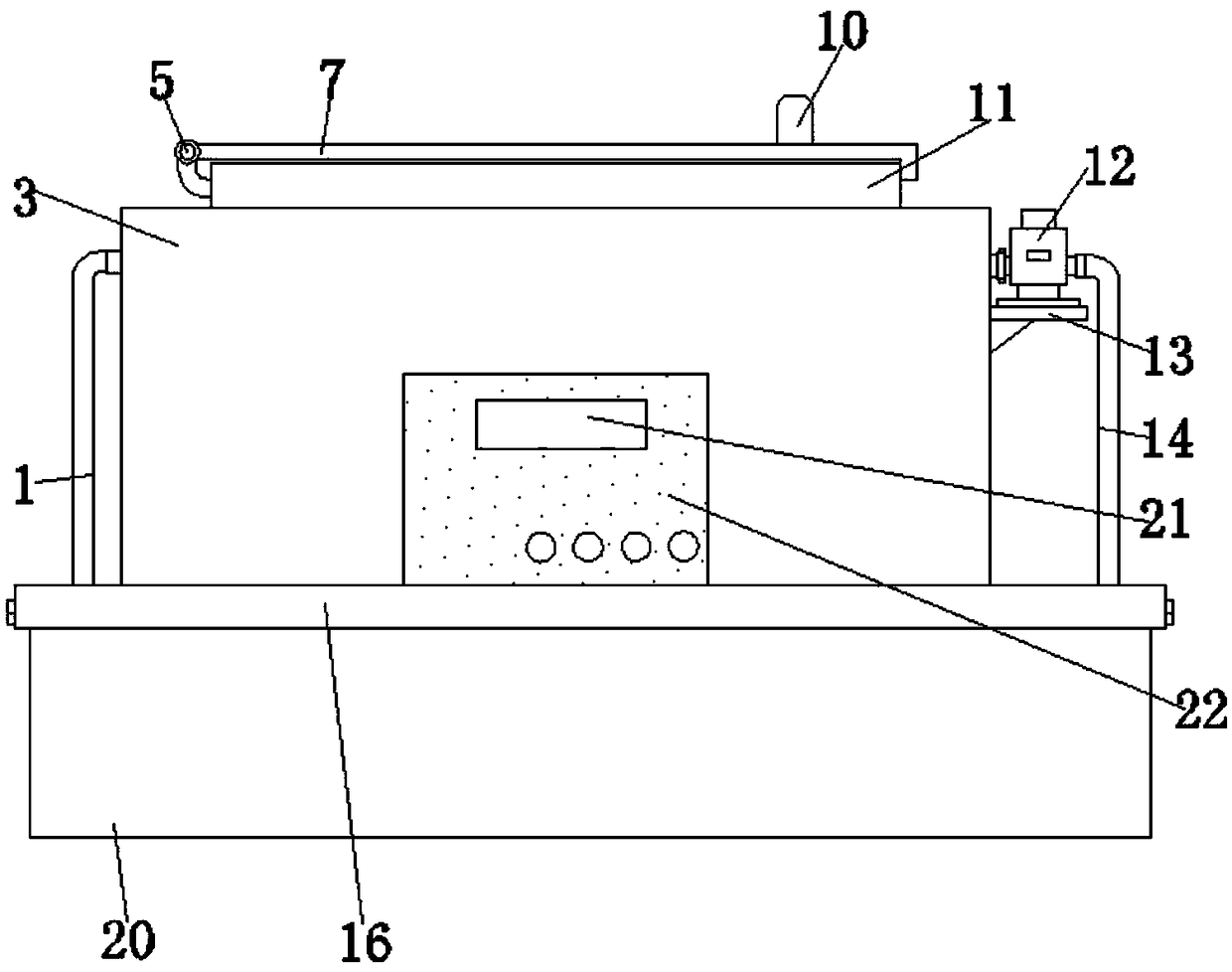

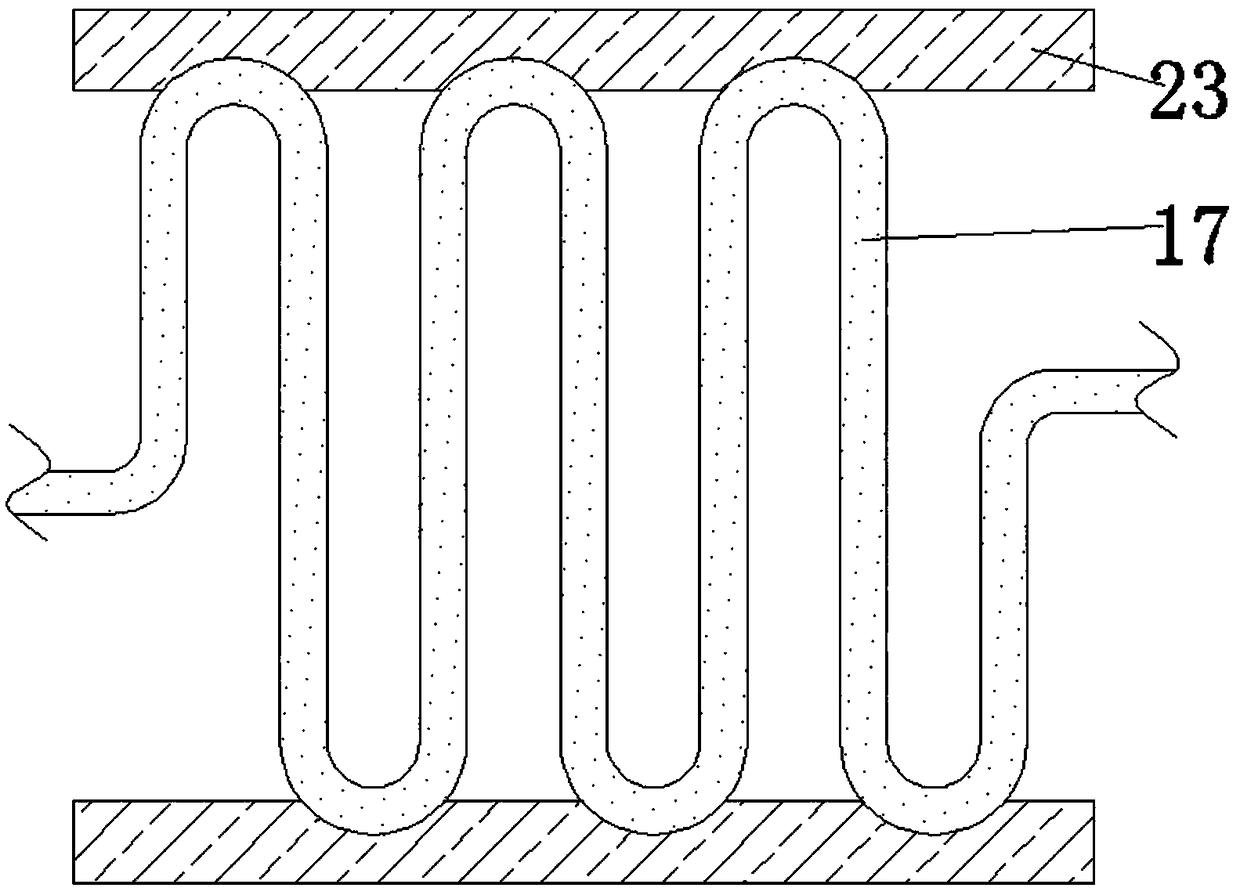

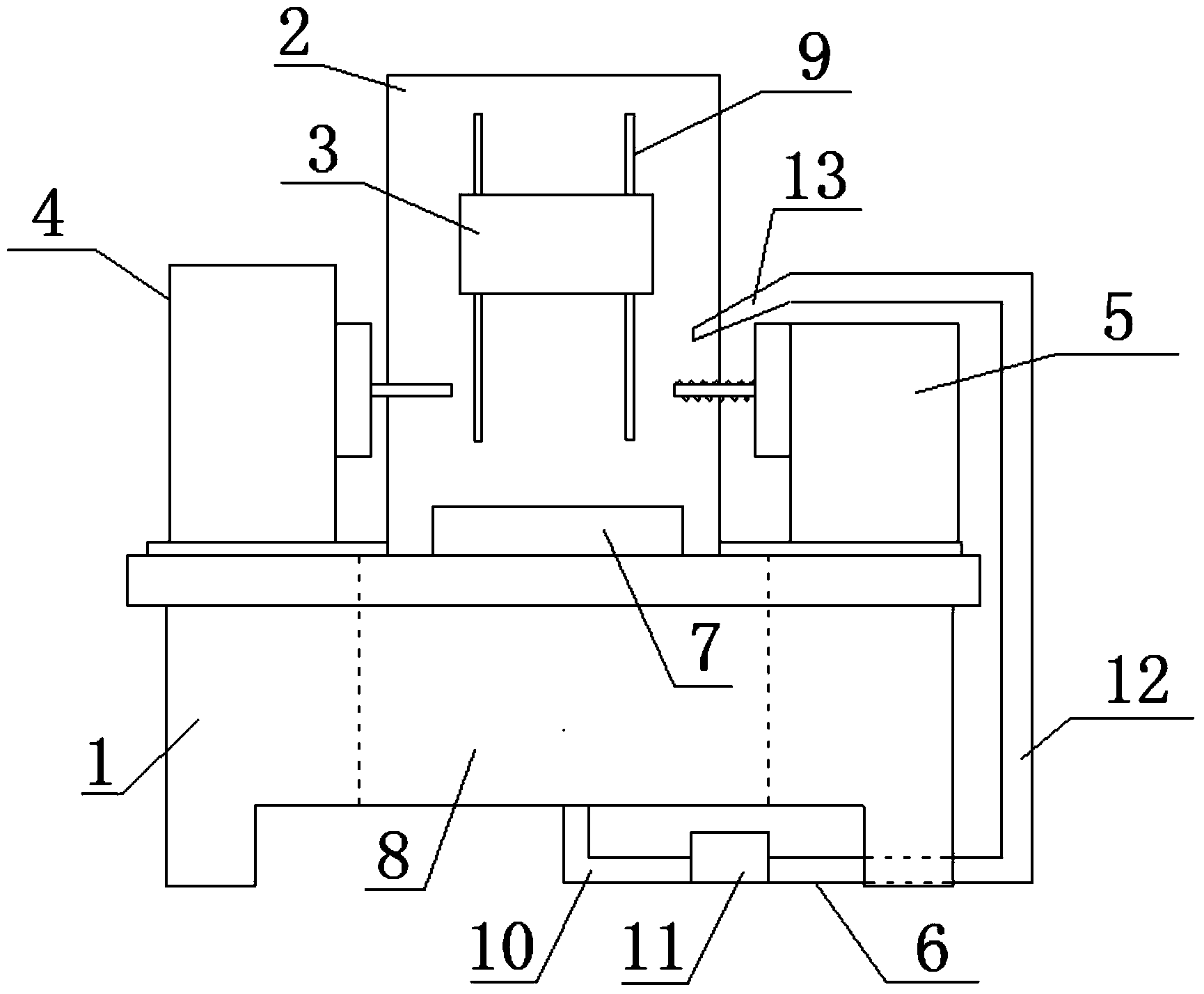

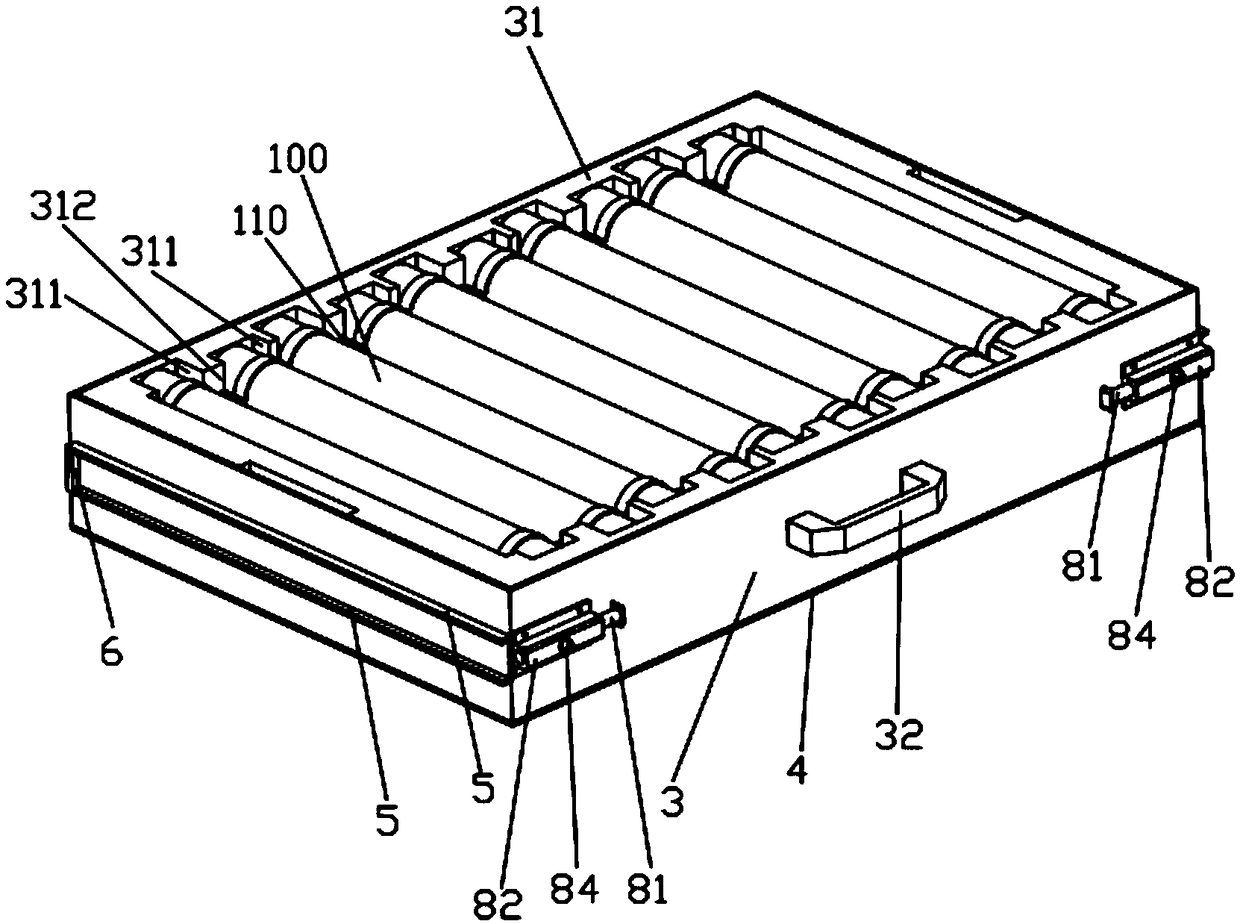

Battery pack with circular water cooling and radiating function

InactiveCN108717985AAchieve installationAchieve coolingSecondary cellsCell component detailsElectricityNew energy

The invention discloses a battery pack with a circular water cooling and radiating function. The battery pack comprises a cooling box; a box cover is fixed to the outer wall, close to the top, of thecooling box through bolts; the outer walls of both sides of the cooling box are configured with rectangular holes; mounting plates are welded to the inner walls of both sides of the cooling box, and the mounting plates are located below the rectangular holes; equidistantly distributed mounting holes are configured on the top outer walls of the mounting plates, and the inner walls of the mounting holes are welded with refrigerators; the inner walls of both sides of the cooling box are welded with strip-shaped plates; the two opposite side outer walls of the two strip-shaped plates are welded with return pipes placed in the same horizontal direction; and the return pipes are of a serpentine curved structure. The battery pack with the circular water cooling and radiating function provided bythe invention is compact in structure, practical and novel, and is used for the battery pack for battery installation for new energy vehicles; and a theft battery pack has the circular water cooling and radiating function, so that the influence of over-high temperature on the electricity storage capacity of a battery is avoided, and the service life of the battery is prolonged.

Owner:十堰派生工贸有限公司

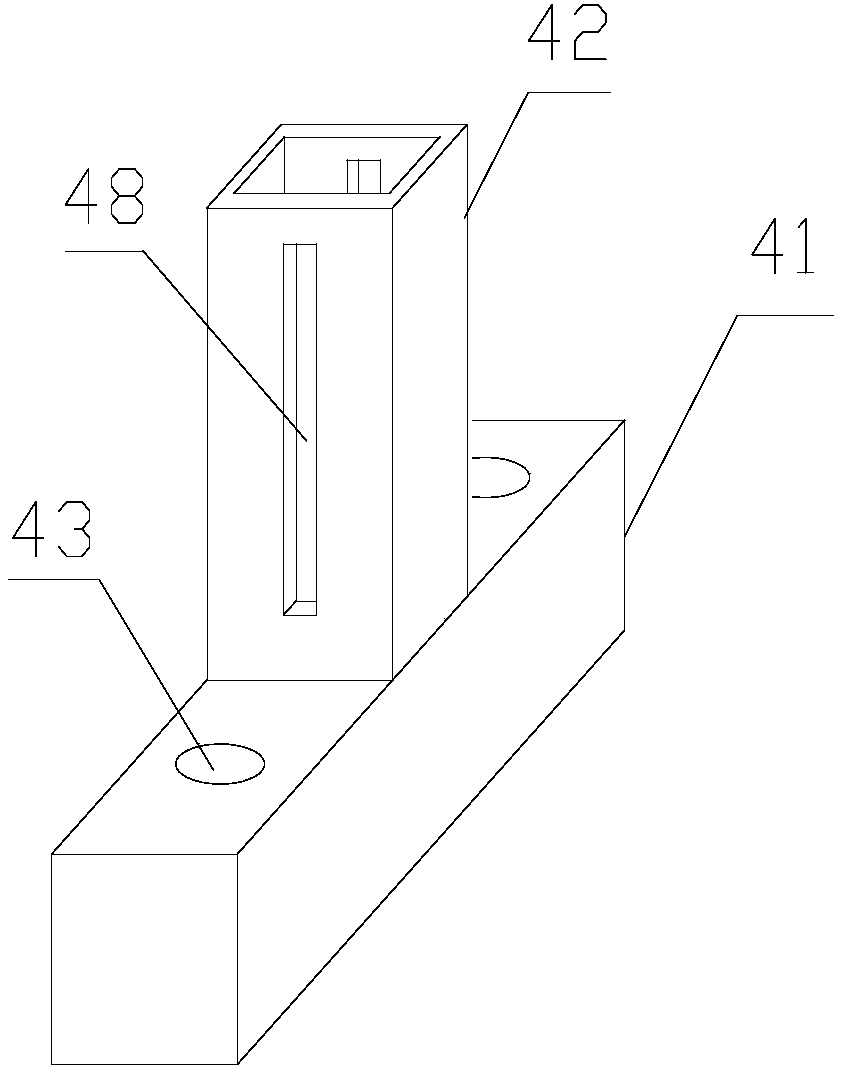

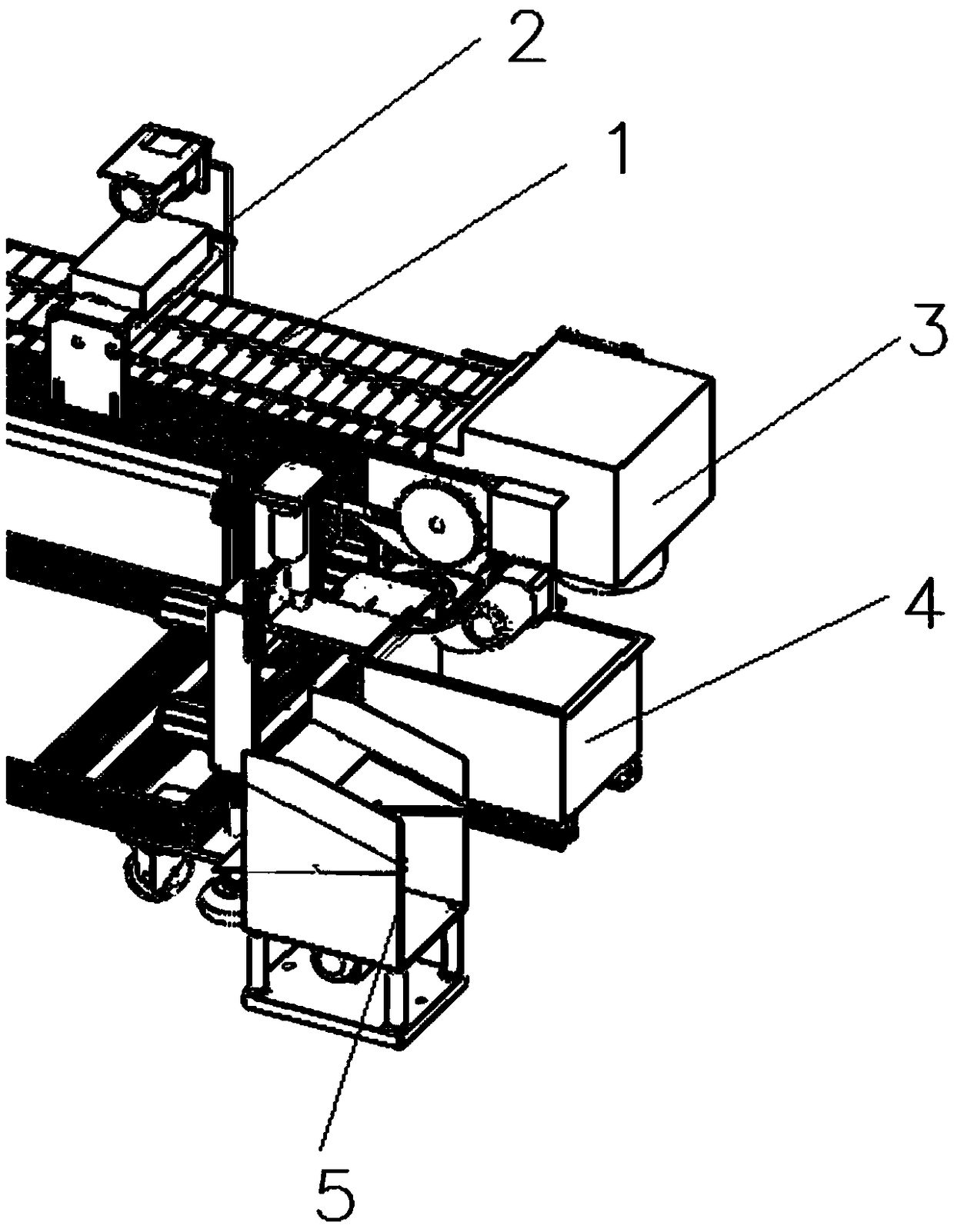

Thread machining tool capable of recovering liquid waste

InactiveCN104162804AReduce labor intensityRealize repeated recyclingOther manufacturing equipments/toolsMaintainance and safety accessoriesLiquid wasteReciprocating motion

The invention relates to a thread machining tool capable of recovering liquid waste. The thread machining tool comprises a work table, a stand column, an ejector device, a drilling machine, an internal thread machining device and a liquid waste circulating device, wherein the ejector device is arranged on the side face of the stand column and can vertically move in a reciprocating mode. The stand column is fixedly arranged on the surface of the work table. The drilling machine and the internal thread machining device are arranged on the two sides of the stand column respectively and can be located on the surface of the work table in a horizontal moving mode. One end of the liquid waste circulating device is connected to the lower end of the work table. The other end of the liquid waste circulating device is arranged above the internal thread machining device. Compared with the prior art, drilling and tapping can be carried out at the same time, the liquid waste can be recovered, the production efficiency is improved, the machining precision is promoted, and the labor intensity of operators is relieved.

Owner:梁淑慧

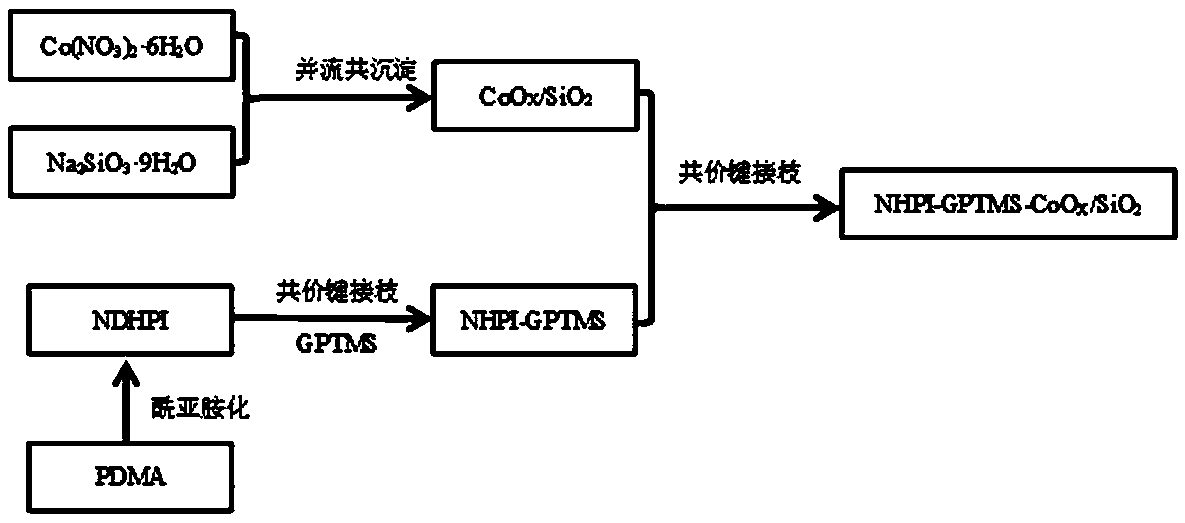

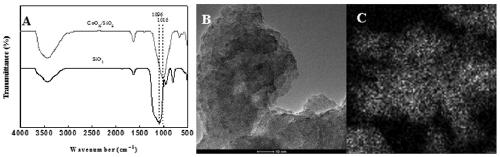

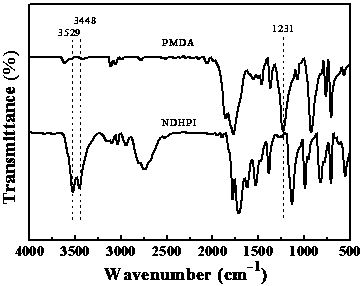

NHPI-GPTMS-CoOX/SiO2 heterogeneous catalyst, applications and recovery method thereof

InactiveCN110193381AReduce consumptionRealize repeated recyclingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRecovery methodToluene oxidation

The invention relates to a NHPI-GPTMS-CoOX / SiO2 heterogeneous catalyst, applications and a recovery method thereof, and belongs to the technical field of heterogeneous catalysts, wherein Co<2+>-containing CoOX / SiO2 is prepared by using a co-precipitation method, and then NHPI is immobilized on the CoOX / SiO2 through a covalent bond grafting method to prepare the NHPI-GPTMS-CoOX / SiO2 catalyst. According to the present invention, the cobalt in the NHPI-GPTMS-CoOX / SiO2 has good dispersibility, and forms the Si-O-Co bond with the carrier SiO2, the cobalt content is basically unchanged during the catalyst preparation and the catalytic toluene oxidation reaction, and the leaching phenomenon is not observed; the NHPI is grafted with the silane coupling agent KH-560 (GPTMS) through the C-O-N bond,and the GPTMS is bonded to the carrier through the Si-O-Si bond; when the catalyst is recycled, the graft bond of the NHPI does not break, such that the significant loss of the NHPI cannot be generated; and in the selective oxidation of toluene with hexafluoroisopropanol as solvent, the catalyst has good catalytic activity, good selectivity and good stability.

Owner:YANGZHOU UNIV

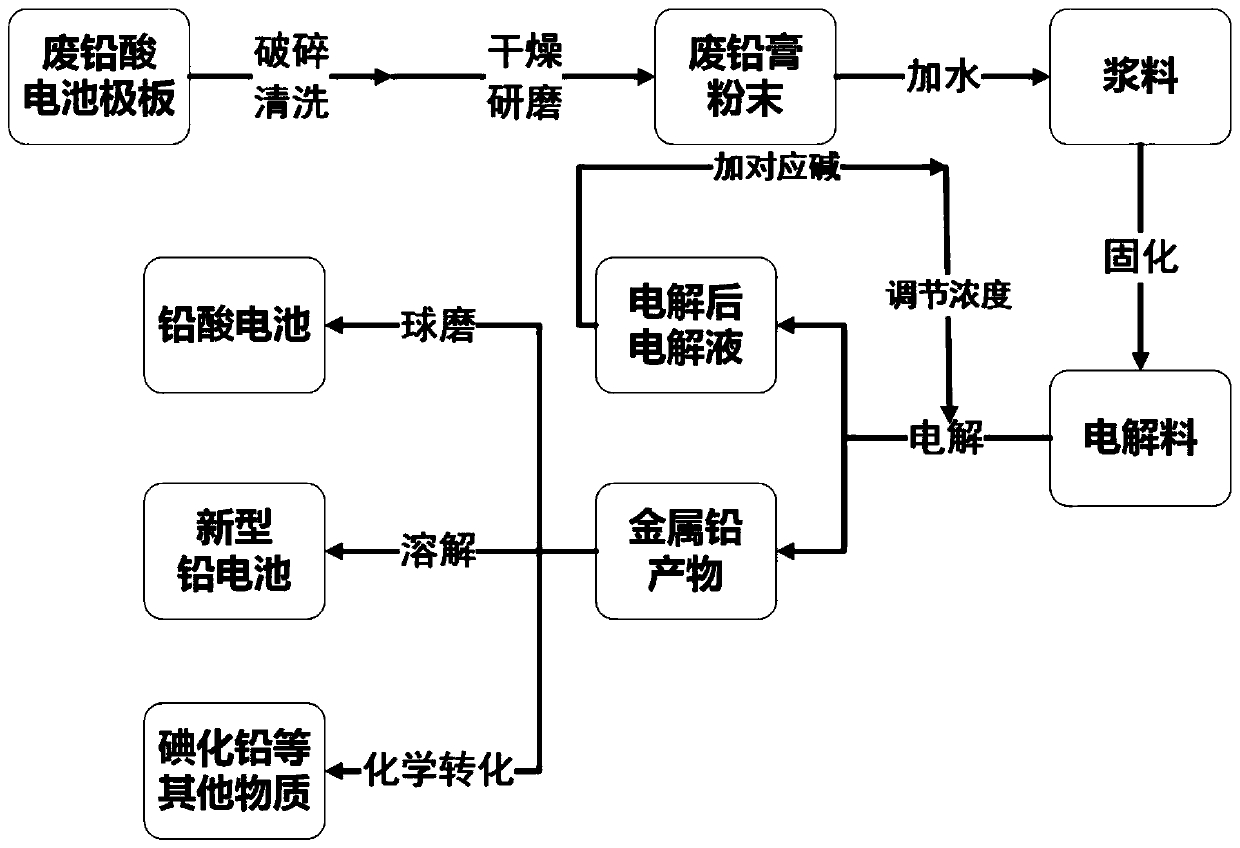

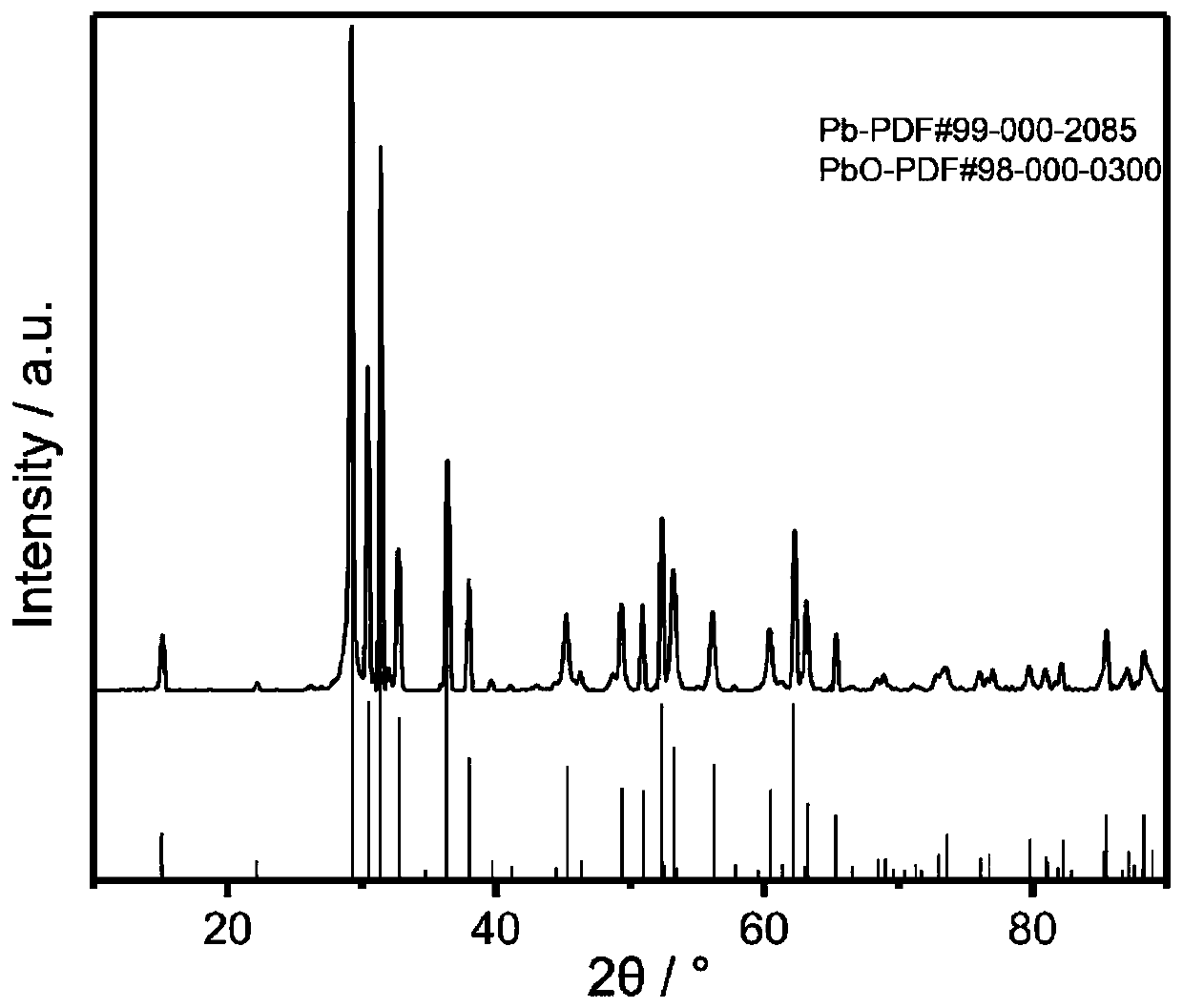

Recycling process of waste battery lead

ActiveCN105925807ARealize repeated recyclingHigh purityPhotography auxillary processesWater/sewage treatment bu osmosis/dialysisElectrolysisLEAD TETROXIDE

The invention relates to the technical field of battery recycling equipment, in particular to a recycling process of waste battery lead. The recycling process is completed according to the following steps that a lead storage battery is mechanically cut off and broken and then is washed and screened at the same time by a rotary screen washing machine through an alkaline solution, plastic, waste electrolytes and lead bullion are screened out, and the waste electrolytes are conveyed to an ultrafiltration membrane processing system to be processed; lead carbonate is subjected to electromagnetic induction heating, sufficient oxygen is led in, the electromagnetic induction frequency ranges from 8 KHz to 60 KHz, the control temperature ranges from 330 DEG C to 460 DEG C, heat preservation is performed for 5 h to 6 h, and completely-oxidized lead tetroxide will be obtained; and in the electrolysis period, an electromagnetic induction magnetic field is applied at the bottom of an electrolytic tank, the magnetic induction intensity is 800 mT, and national standard number 1 lead is obtained. The recycling process has the beneficial effects that refining of the lead is achieved through a method that electrolysis is used in cooperation with electromagnetism, the purity of the lead is greatly improved, and repeated recycling of precious metal is also achieved; and the recycling process is simple, machining is easy, the recycling process is suitable for large-scale recycling, and therefore the recycling cost is reduced.

Owner:GUANGDONG NEW ENVIRONMENTAL PROTECTION TECH CO LTD +1

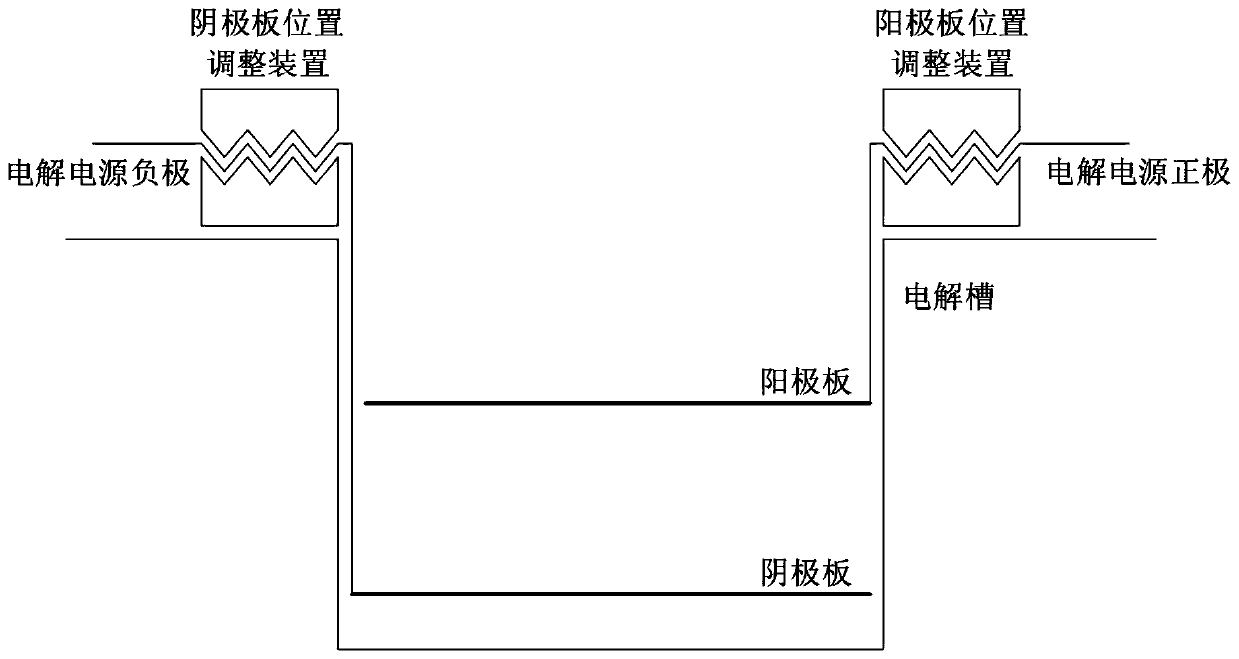

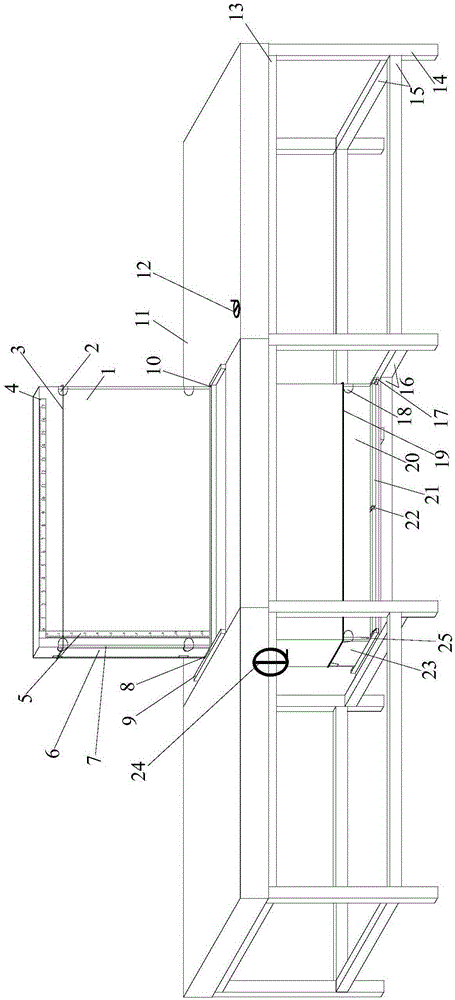

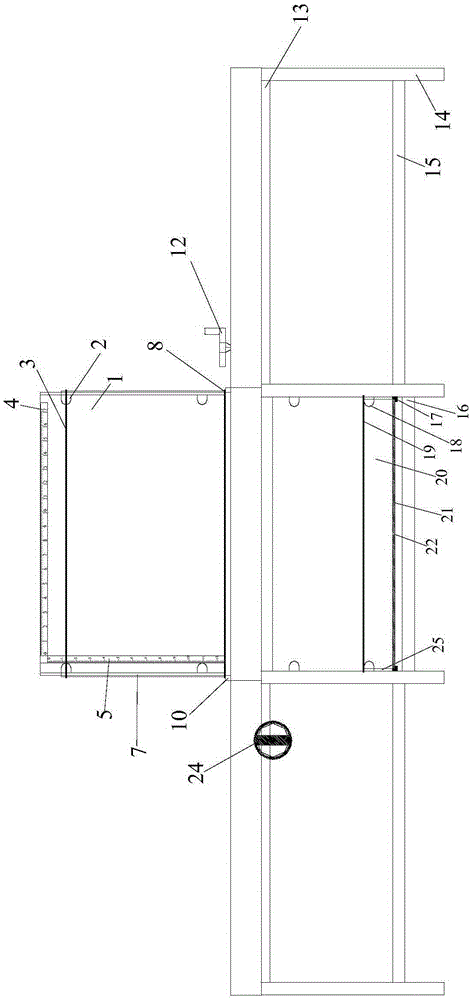

Method for recovering lead from waste lead paste by solid phase electrolysis method

ActiveCN111455404AReduce consumptionSimple processPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentLead dioxide

The invention discloses a method for recovering lead from waste lead paste by a solid phase electrolysis method, and belongs to the technical field of lead resource recovery. The method for recoveringthe lead from the waste lead paste by the solid phase electrolysis method comprises the steps that the waste lead paste is first made into a paste waste lead paste electrolytic material and a cathodeplate is coated with the waste lead paste electrolytic material; electrolyte is added to an electrolytic cell; the cathode plate coated with the electrolytic material is inserted into the electrolyte, and an anode is inserted into the electrolyte; the anode is an electrode with oxygen evolution electrocatalysis; the cathode plate and the anode are connected with a negative electrode and a positive electrode of a direct current power supply separately to make electrolysis in the electrolytic cell; and water at the anode loses electrons and precipitates oxygen, the electrolytic material on thecathode plate obtains the electrons and is reduced in situ to a lead single substance and attached to the cathode plate, that is, the lead is recovered from the waste lead paste. The method for recovering the lead from the waste lead paste by the solid phase electrolysis method directly electrolyzes the waste lead paste after simple pulping, lead sulfate, lead dioxide and lead oxide in the waste lead paste obtain the electrons and form in situ the lead simple substance, a large number of pretreatment processes are saved, the consumption of reagents is reduced, the process is simple, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

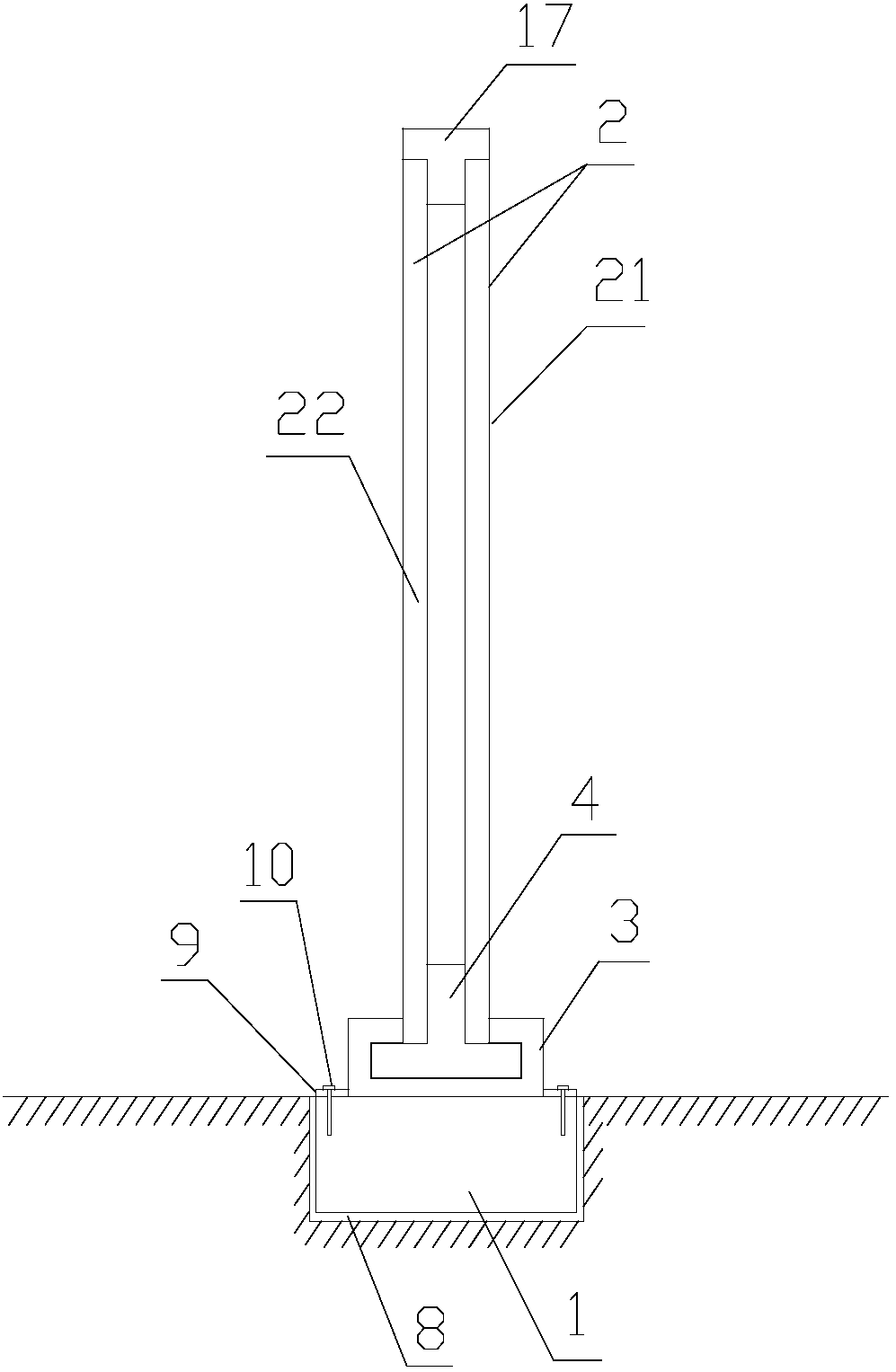

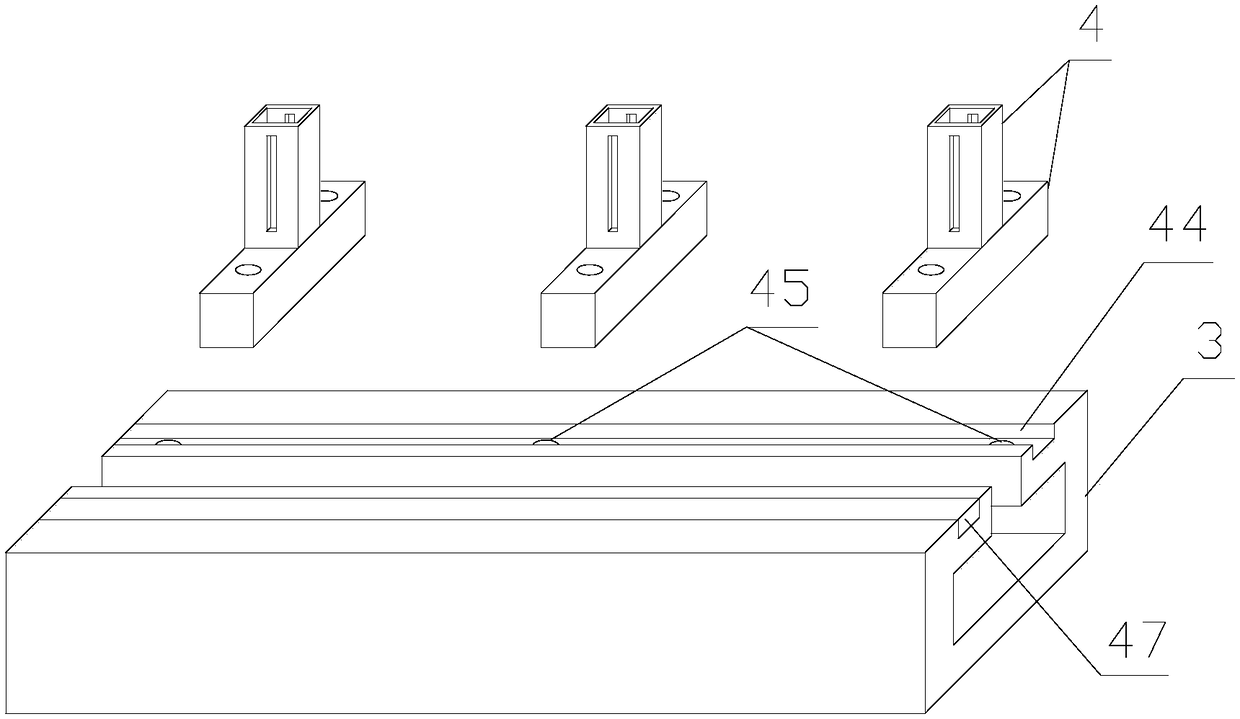

Similar material simulation test device and method

InactiveCN105259332ASimple structureNovel and reasonable designEarth material testingTest materialTest platform

The invention relates to a similar material simulation test device and method. The similar material simulation test device comprises a test platform, a transparent test device located on the test platform, a horizontal rotating handle located on the test platform and connected with a recovery power device, a vertical rotating handle located on the front side of the test platform and connected with an adjusting device for adjusting a coal discharge window, a cross beam used for supporting and fixing the test platform, stand columns used for supporting the cross beam, a stable bottom beam, and a transparent glass recovery device fixed to a supporting bottom beam. The similar material simulation test method includes the steps that firstly, similar simulation materials are laid; secondly, the coal discharging window is adjusted; thirdly, coal seam mining is simulated; fourthly, phenomenon observation is performed; fifthly test material are recycled.

Owner:XIAN UNIV OF SCI & TECH

A kind of resin type silicate wood modifier and preparation method of modified material thereof

ActiveCN104044193BImproves loss resistanceGood dimensional stabilityWood impregnation detailsTougheningPollution

The invention belongs to a resin type silicate wood modifier and a preparation method of a modified material of the modifier. According to the preparation method, the resin type silicate wood modifier is prepared by taking melamine, formaldehyde, urea and soluble sodium silicate as main raw materials as well as respectively taking polyvinyl alcohol and diethylene glycol as a toughening agent and a stabilizer; the resin type silicate wood modifier can be stably stored for a long time and can be repeatedly recycled. The modifier has the advantages that the dimensional stability, the density, the surface hardness, the anti-bending strength, the anti-bending elastic modulus, the impact toughness and the wear resistance of artificial forest wood processed by virtue of the modifier are substantially improved, the modifier has the advantages that the flame retardance and environment-friendly effect are achieved, no pollution is caused to a human body and the environment, the leachability resistance of the modifier in the processed wood is improved, and the application value of the artificial forest wood is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

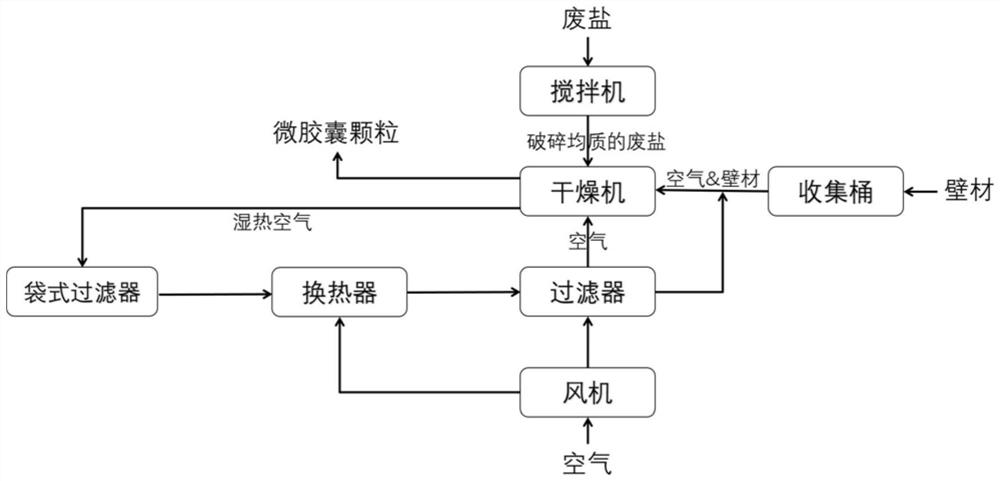

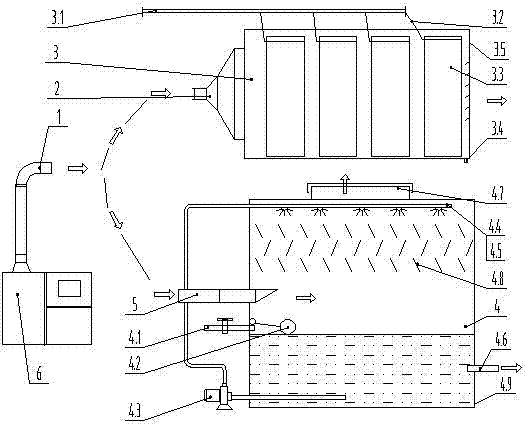

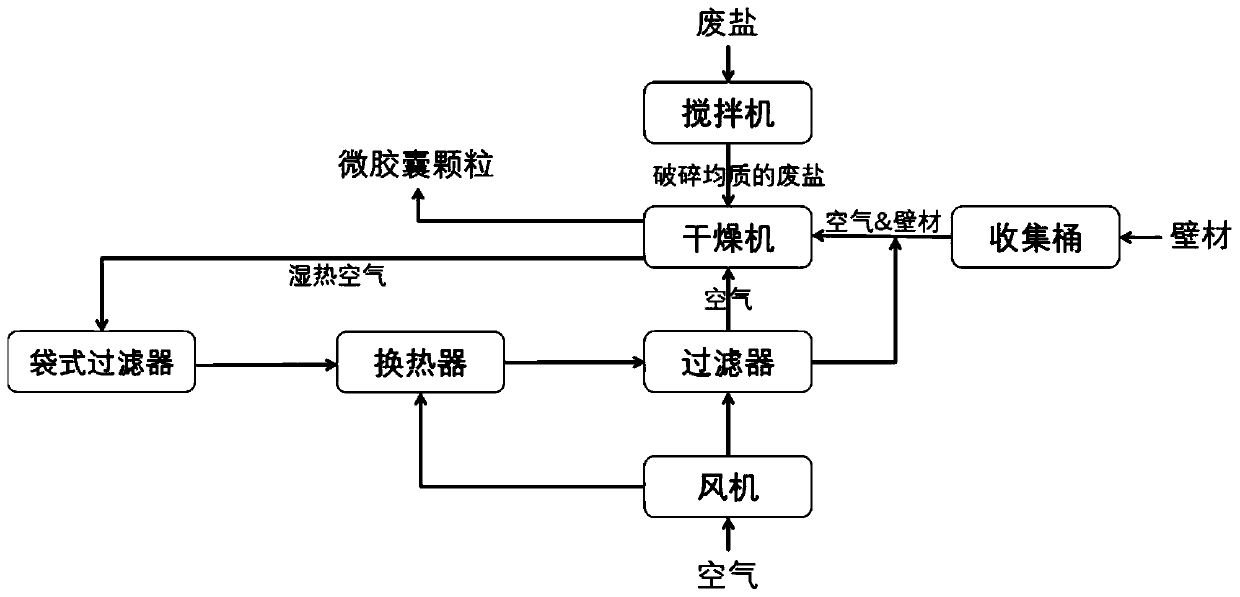

Treatment method of industrial waste salt

ActiveCN110216125BRealize repeated recyclingNo pollutionSolid waste disposalTransportation and packagingProcess engineeringEnvironmental engineering

The invention discloses a treatment method for industrial waste salt, which comprises the steps of: crushing and homogenizing the waste salt and sending it into a dryer; using a fan to pass air into a heat exchanger for heating, and filtering the heated air Feed in from the bottom of the dryer to float the waste salt at the bottom of the dryer, and the air forms an air-lift circulation flow inside the dryer; spray mist wall material into the dryer forming microcapsule particles by coating waste salt; collecting the microcapsule particles. The invention realizes non-selective and harmless treatment of industrial waste salt by adopting the method of wrapping industrial waste salt with wall material to form microcapsules.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

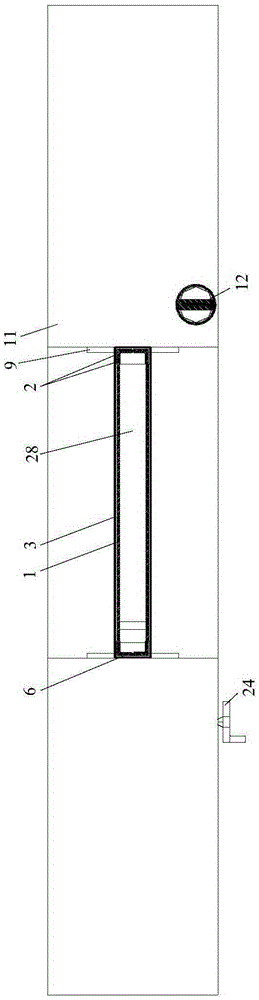

Auxiliary equipment for building construction and with dust-proof and environment-friendly function

The invention discloses auxiliary equipment for building construction and with a dust-proof and environment-friendly function. The auxiliary equipment for building construction and with the dust-proofand environment-friendly function comprises a base and enclosing baffles. The base is fixed in the ground. The bottom ends of the enclosing baffles are fixed on the base, and C-shaped channel steel is laid on the base in the extension direction. The enclosing baffles comprise first baffles and second baffles, and the first baffles and the second baffles have the same structure and size. The surfaces of the first baffles and second baffles are arranged in parallel, and gaps exist between the first baffles and the second baffles. The bottom ends of the first baffles and the second baffles are detachably fixed to the C-shaped channel steel through connecting pieces. The adjacent two enclosing baffles are connected by connecting columns, and the axial bottom ends of the connecting columns aredetachably fixed to the C-shaped channel steel through connecting pieces. Clamping grooves are formed in the side walls of column bodies of the connecting columns, so that the radial cross sections of the column bodies are in of a cross-shaped structure, and the sides of the first baffles and second baffles of the adjacent enclosing baffles are embedded in the clamping grooves. Mist spraying mechanisms are further arranged on the connecting columns. The auxiliary equipment for building construction meets the comprehensive requirements of safety, stability, flexible and convenient installationand disassembly, environmental protection and economy.

Owner:四川尧顺建设集团有限公司

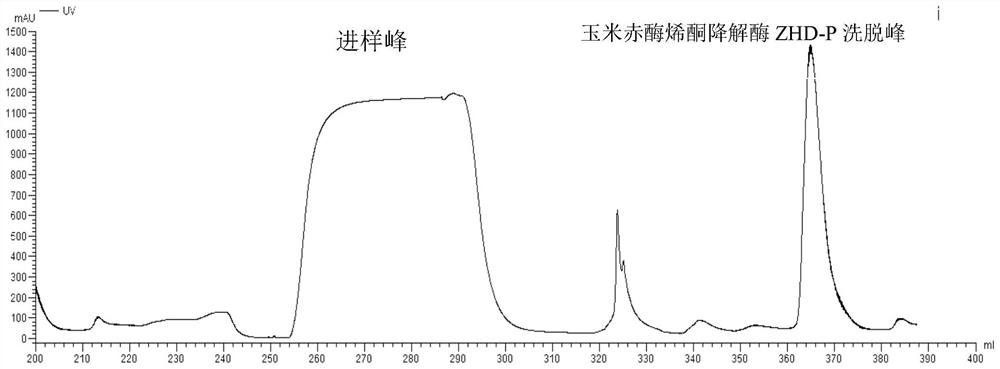

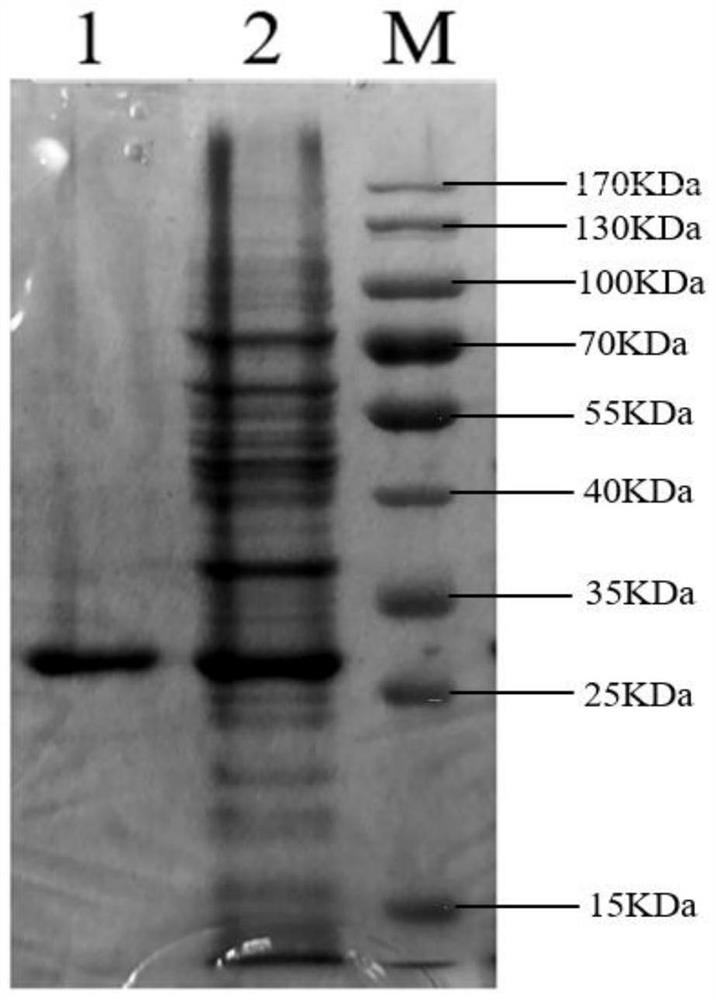

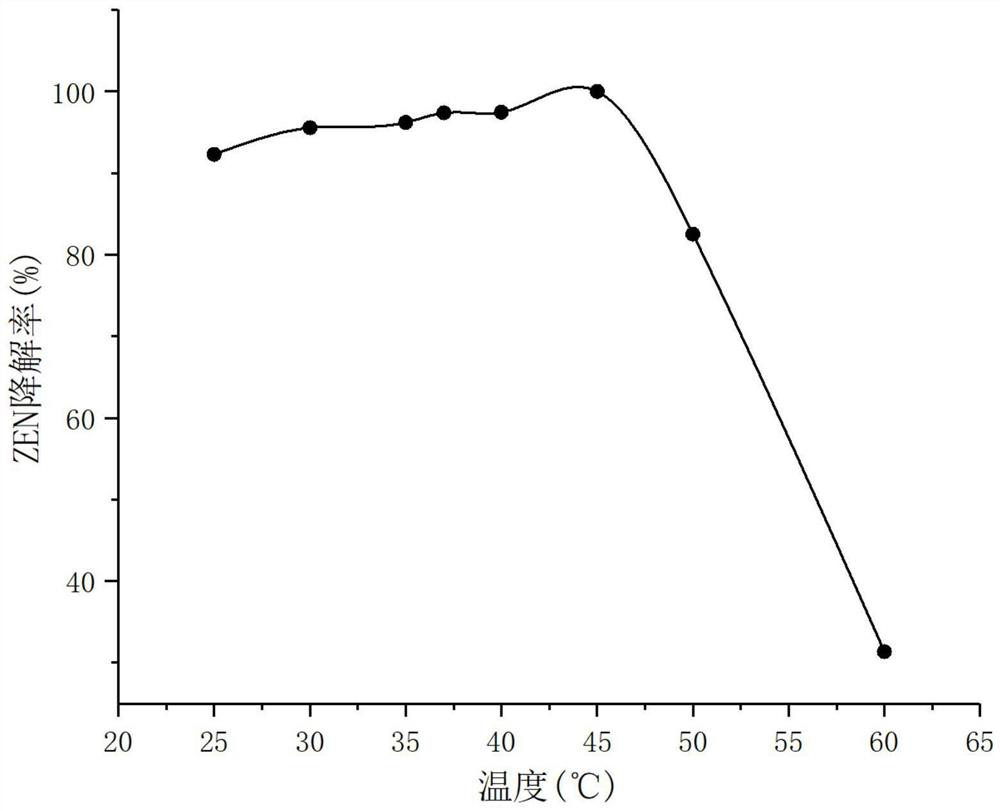

Optimized zearalenone degrading enzyme ZHD-P encoding gene, recombinant thallus, surface display system and application

PendingCN112430611AEfficient degradationRealize repeated recyclingBacteriaHydrolasesBiotechnologyHeterologous

The invention discloses an optimized zearalenone degrading enzyme ZHD-P encoding gene, a recombinant thallus, a surface display system and application. The nucleotide sequence of the zearalenone degrading enzyme encoding gene is as shown in SEQ ID NO. 1. The coding gene can realize heterologous high-efficiency expression in escherichia coli. The recombinant zearalenone degrading enzyme has the advantages of being high in enzyme activity, wide in temperature and pH application range, good in tolerance and the like, zearalenone (ZEN) can be efficiently degraded, and the recombinant zearalenone degrading enzyme has good industrial application prospects. Zearalenone degrading enzyme ZHD-P is displayed on the surface of escherichia coli BL21 cells in a positioned mode, detection of whole-cell enzyme activity shows that display expression of zearalenone degrading enzyme ZHD-P on the surfaces of the cells is successfully achieved, and the whole-cell catalyst which does not need to be purified, can be repeatedly used and is low in cost is obtained. The method is used for biodegradation of zearalenone, and has a good industrial application prospect.

Owner:SOUTH CHINA UNIV OF TECH

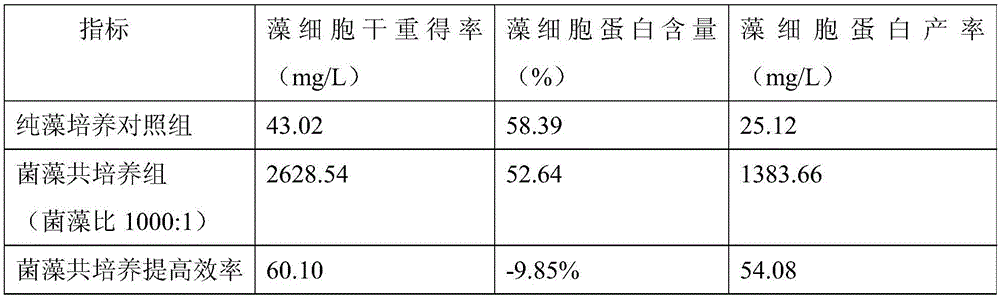

Method for increasing yield of chlorella through two-round bacterium adding co-culture and method for preparing biological feed

InactiveCN105695356AIncrease productionIncrease growth rateBacteriaUnicellular algaeSewageMicrobiology

The invention discloses a method for increasing the yield of chlorella through two-round bacterium adding co-culture and a method for preparing biological feed. The method for increasing the yield of the chlorella through two-round bacillus-alga adding co-culture comprises the steps that 1, rice endophytic bacteria added at the first time and the chlorella are subjected to first-round bacterium-chlorella co-culture under illumination, and a first-round bacterium-chlorella co-culture solution is obtained after culture is finished; 2, rice endophytic bacteria added at the second time are replenished into the first-round bacterium-chlorella co-culture solution, second-round bacterium-chlorella co-culture is carried out under illumination, and a second-round bacterium-chlorella co-culture solution is obtained after culture is finished; 3, the second-round bacterium-chlorella co-culture solution is subjected to cell separation, and chlorella cell sediment and a supernatant bacterium solution containing the rice endophytic bacteria are obtained. According to the method, the chlorella pyrenoidosa living cell sediment can serve as a biological matrix for degradation of azo dyes in water and other sewage purifying treatment after being washed and resuspended, dried chlorella cells can be obtained after the chlorella pyrenoidosa living cell sediment is dried, and the dried chlorella cells serve as raw materials for preparing the feed and extracting grease, protein, pigments, growth factors and other related biologics.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

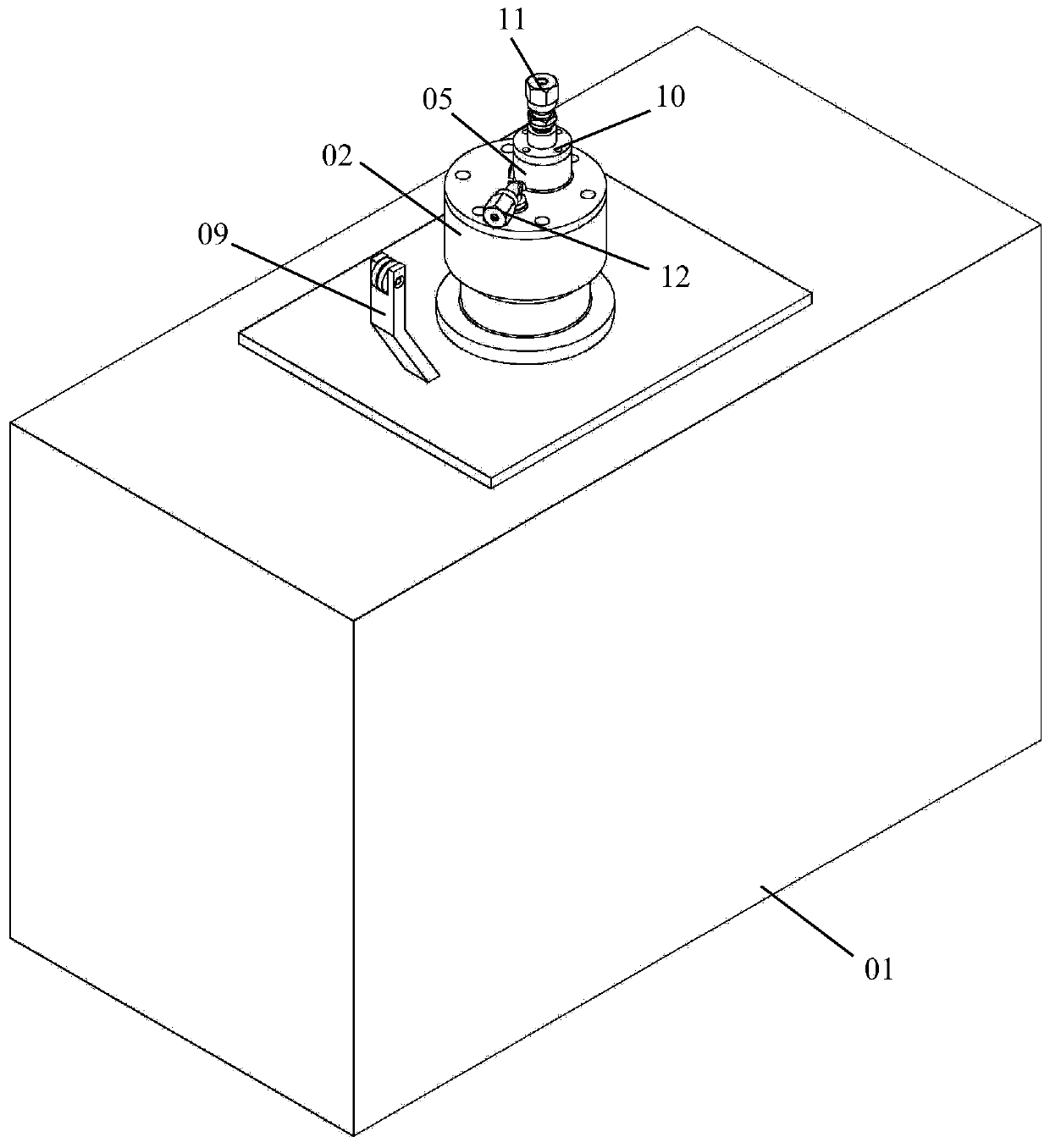

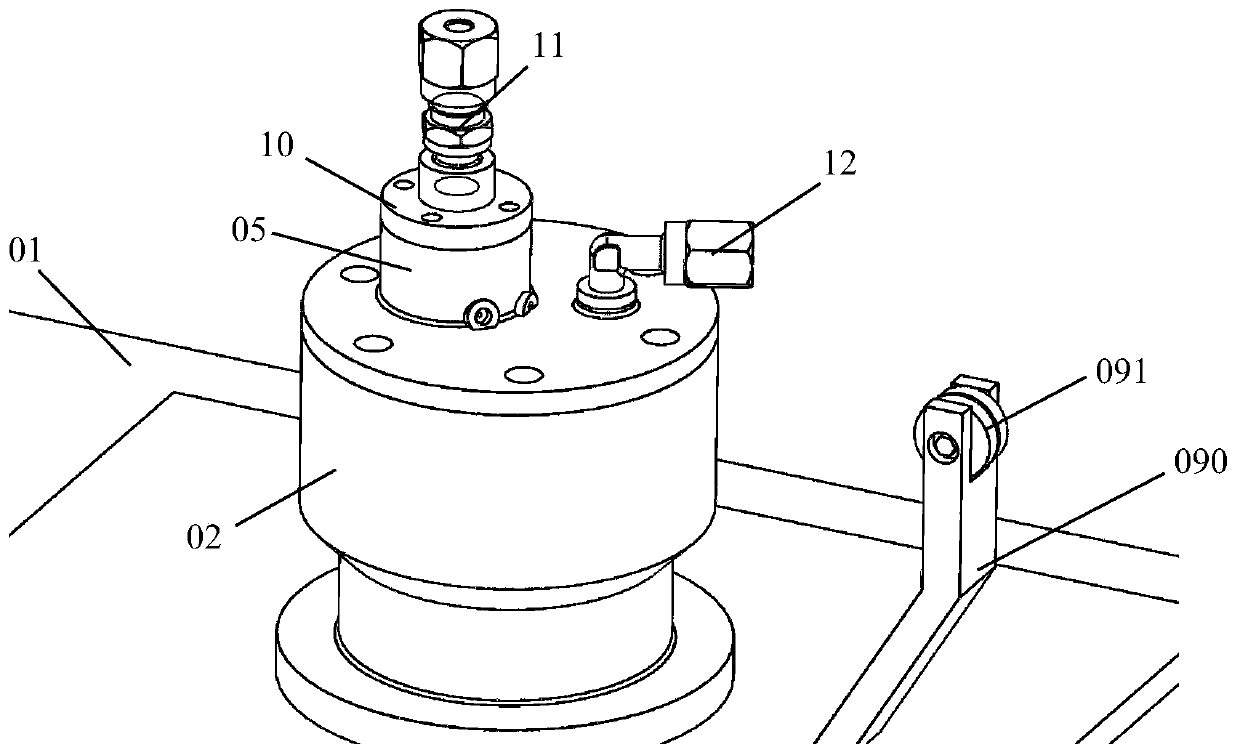

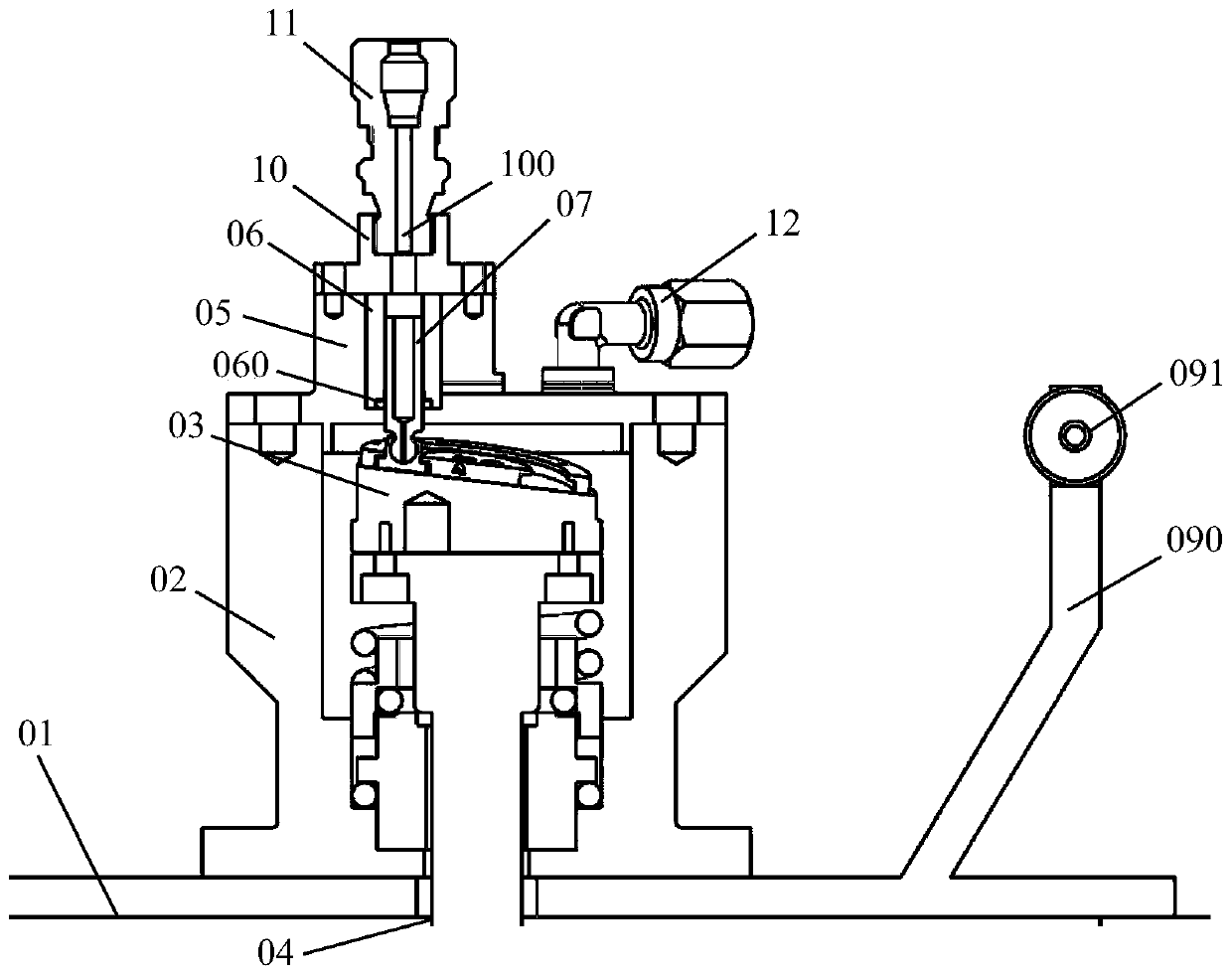

Plunger pump motion abrasion and leakage measuring testbed capable of exerting centrifugal force

ActiveCN110425124AOvercome the defect of lack of consideration of centrifugal forceImprove the simulation effectMachine part testingDetection of fluid at leakage pointEngineeringCentrifugal force

The invention discloses a plunger pump motion abrasion and leakage measuring testbed capable of exerting centrifugal force. The testbed is characterized in that a main cavity body is fixed to the topsurface of a testbed body, a rotating part is rotationally connected in a cavity of the main cavity body, a driving part is arranged in the testbed body and is used for driving the rotating part to rotate, a plunger cavity body is fixedly arranged at the top of the main cavity body in a sealing manner, a lining is sleeved in a cavity of the plunger cavity body, a layer of resin fills the space between the inner wall of the plunger cavity body and the side wall of the lining, a stepped groove is formed in the lower portion of the inner wall of the lining, a sealing ring is arranged in the stepped groove in a sleeved mode, an oil pumping hole communicating with the stepped groove is formed in the side walls of the lining and the plunger cavity body, a plunger is movably connected into the lining, the bottom of the plunger is connected with the rotating part, the plunger moves up and down under the driving of the rotating part in a reciprocating mode, a screw penetrates through the side wall of the plunger cavity body and is fixedly connected with the side wall of the lining, and the screw is connected with a force applying component. According to the testbed, the defect that a traditional testbed lacks centrifugal force consideration during the leakage amount and the plunger abrasion testing is overcome, the simulation effect is good, and the test precision is high.

Owner:BEIHANG UNIV

Method for preparing formic acid, methanol and methane by using metal hydro-thermal to reduce CO2

InactiveCN101265148BRealize resourcesReduce operating energy consumptionHydrocarbon from carbon oxidesOrganic compound preparationReaction temperaturePollution

The invention discloses a method of reducing CO2 to prepare methanoic acid, methanol and methane under hydrothermal conditions by using metal, and relates to the method of transforming pure CO2 gas or CO2 in waste gas into industrial material that is the methanoic acid, the methanol and the methane. The pure CO2 or CO2 in waste gas, water as well as reducer, and a catalyst are put in a hydrothermal reactor; the CO2 is performed through hydrothermal reduction to obtain the methanoic acid, the methanol and the methane under the conditions that the addition quantity of the reducer is 1 to 25 times (by molar ratio) the content of the CO2 which is put in the reaction equipment, the addition quantity of the catalyst is 0 to 10 times (by molar ratio) the quantity of the reducer, the reaction temperature ranges from 200 DEG C to 245 DEG C, the reaction pressure ranges from 5MPa to 25MPa, the pH value ranges from 8 to 14, and the reaction time ranges from 10 minutes to 12 hours. A gaseous phase products that is the methane can be collected through gas-liquid separation, and the methanoic acid and the methanol mixed solution is separated and purified at the same time. The method efficiently transforms the CO2 into organic matters with high additional value in a low consumption way, the CO2 is changed into resource, the technology is simple without the secondary pollution, and worthful economic and social benefits are realized.

Owner:TONGJI UNIV

Waste heat utilization device for air compressor

InactiveCN103615373ARealize repeated recyclingImprove the humidification effectPositive displacement pump componentsDirect contact heat exchangersWater tanksHeating energy

The invention discloses a waste heat utilization device for an air compressor. The waste heat utilization device comprises the air compressor, a humidifier and a heating water tank. A waste hot air outlet of the air compressor, a hot air inlet of the humidifier and a hot air inlet of the heating water tank are respectively formed in the air compressor, the humidifier and the heating water tank; the waste hot air outlet of the air compressor is respectively communicated with the hot air inlet of the humidifier and the hot air inlet of the heating water tank. The waste heat utilization device has the advantages that waste heat of the air compressor is smartly combined with the humidifier and the heating water tank, so that abandoned heat energy can be effectively utilized, energy sources can be recycled, energy can be saved, environments can be protected, and the heat of the air compressor can be sufficiently dissipated.

Owner:JIANGSU TAIDA TEXTILE

Treatment method of industrial waste salt

ActiveCN110216125ARealize repeated recyclingNo pollutionSolid waste disposalTransportation and packagingEnvironmental engineeringToxic industrial waste

The invention discloses a treatment method of industrial waste salt. The treatment method comprises the following steps of crushing and homogenizing the waste salt and then feeding the waste salt intoa dryer; introducing air into a heat exchanger for heating by using a fan, filtering heated air and then feeding the filtered heated air from the bottom of the dryer to enable the waste salt positioned at the bottom of the dryer to float, and forming a gas lifting circulating flow in the dryer by the air; spraying a mist-shaped wall material into the dryer so as to wrap the waste salt to form microcapsule particles; and collecting the microcapsule particles. The treatment method realizes non-selective harmless treatment of the industrial waste salt by wrapping the industrial waste salt by thewall material to form microcapsules.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

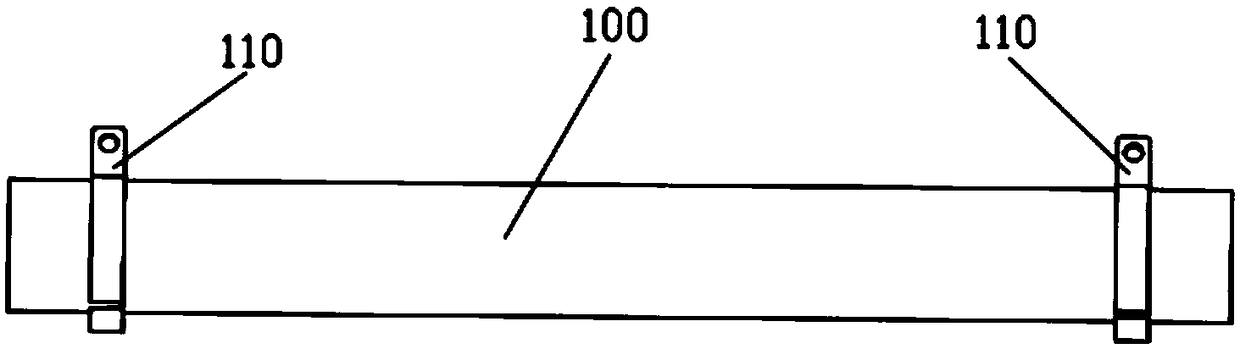

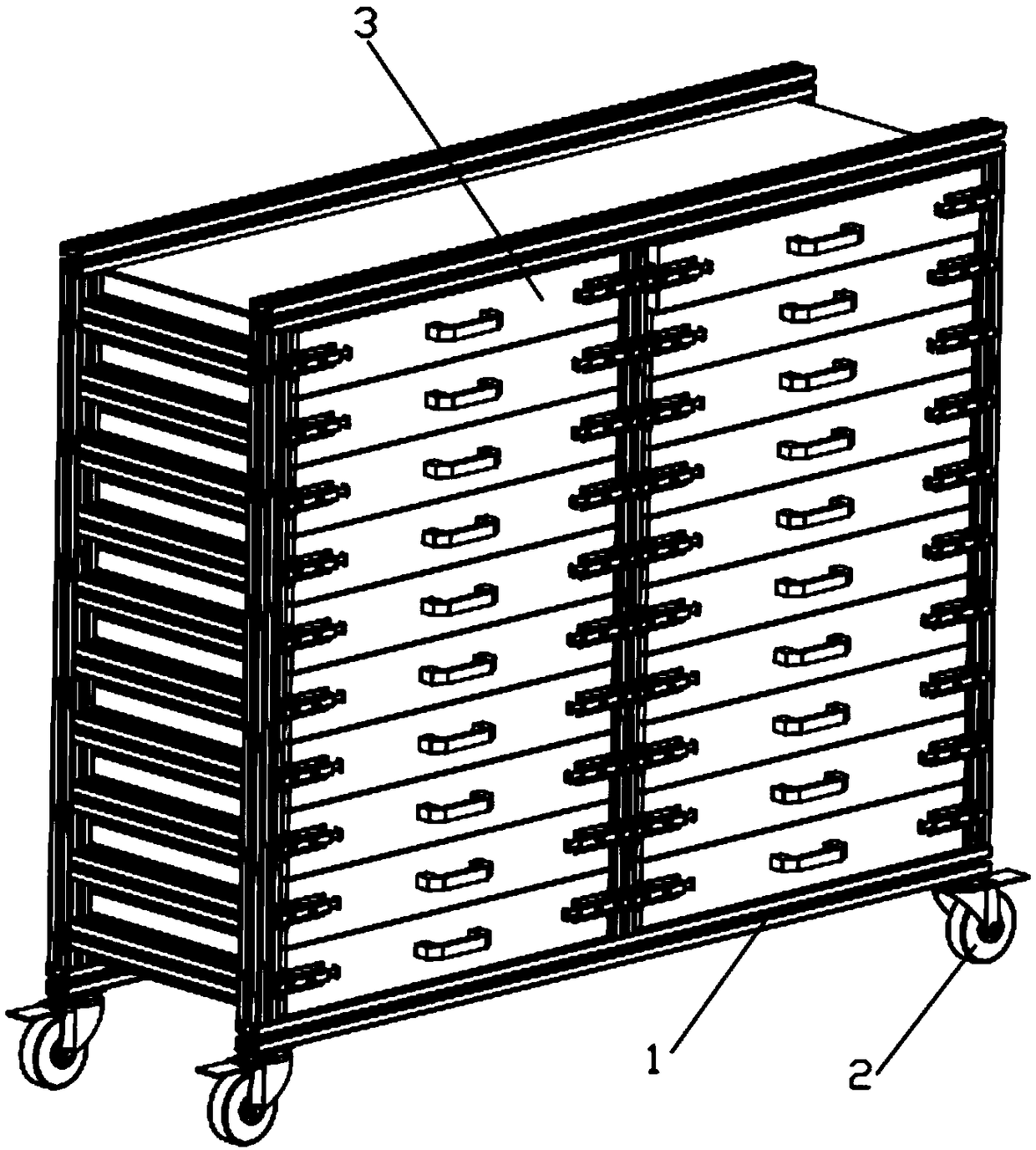

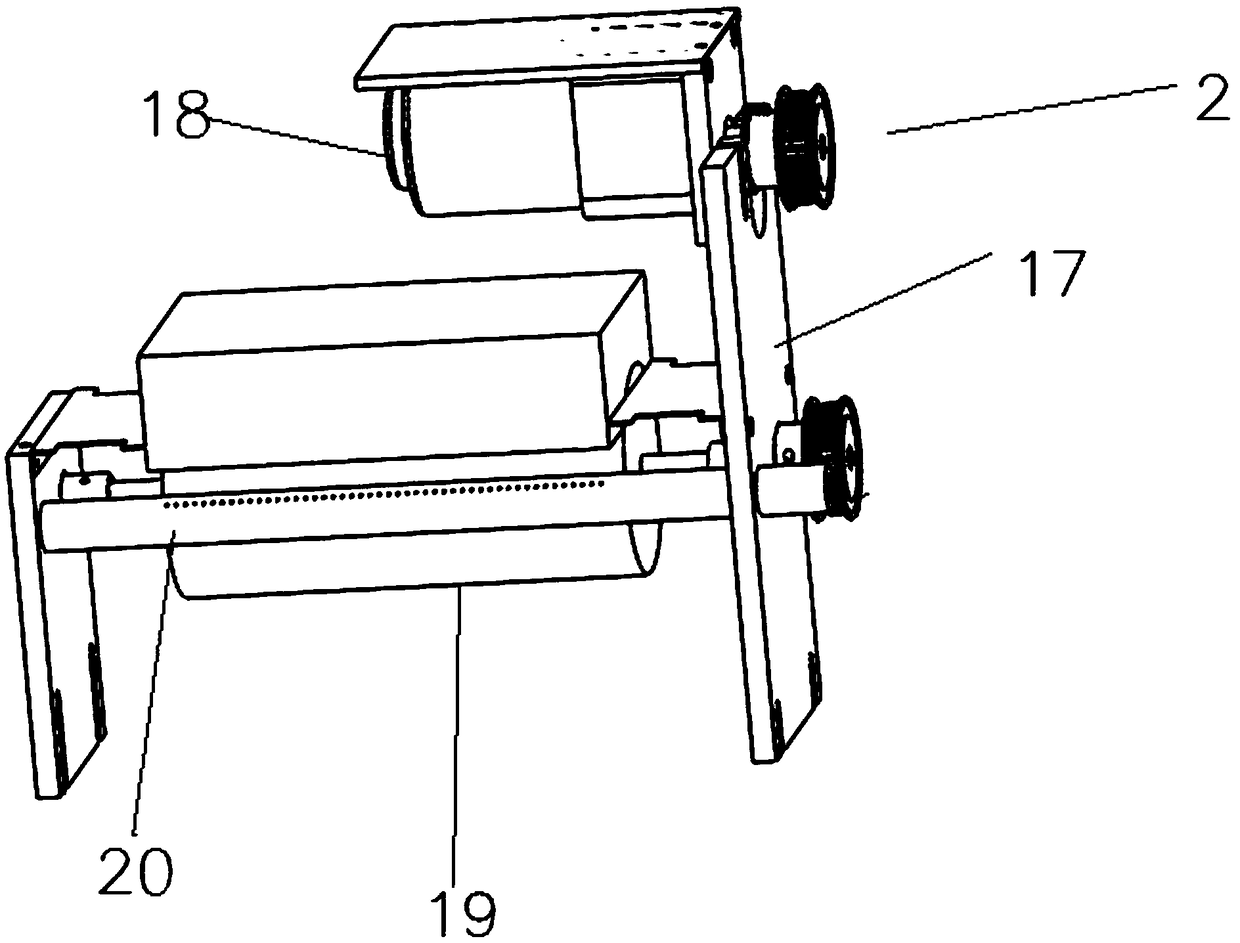

Transfer vehicle for resistors without brackets

PendingCN109455213AEasy accessRealize repeated recyclingSupporting partsHand carts with multiple axesElectrical resistance and conductanceResistor

The invention discloses a transfer vehicle for resistors without brackets. The transfer vehicle is characterized in that the resistors are in a long-strip shape, clamps are arranged at the portions, close to the two ends, of each resistor respectively, drawers arranged on the vehicles, protection pads are arranged in the drawers, and accommodating grooves are formed in the protection pads; the shape and size of the accommodating grooves are matched with those of the resistors, and when the resistors need to be transferred to the next working procedure, the resistors are placed in the drawers and then transferred to the next working procedure through the transfer vehicle; after the resistors are taken out, the transfer vehicle is moved back again to transfer the resistors again, repeated recycling is achieved, the environment is better protected, and the cost is also lower; the resistors are put in the drawer, and are convenient to take and place, and the time can be saved; meanwhile, the transfer vehicle can transfer more resistors at a time, and the efficiency can also be improved.

Owner:HUNAN FUDE ELECTRICAL +2

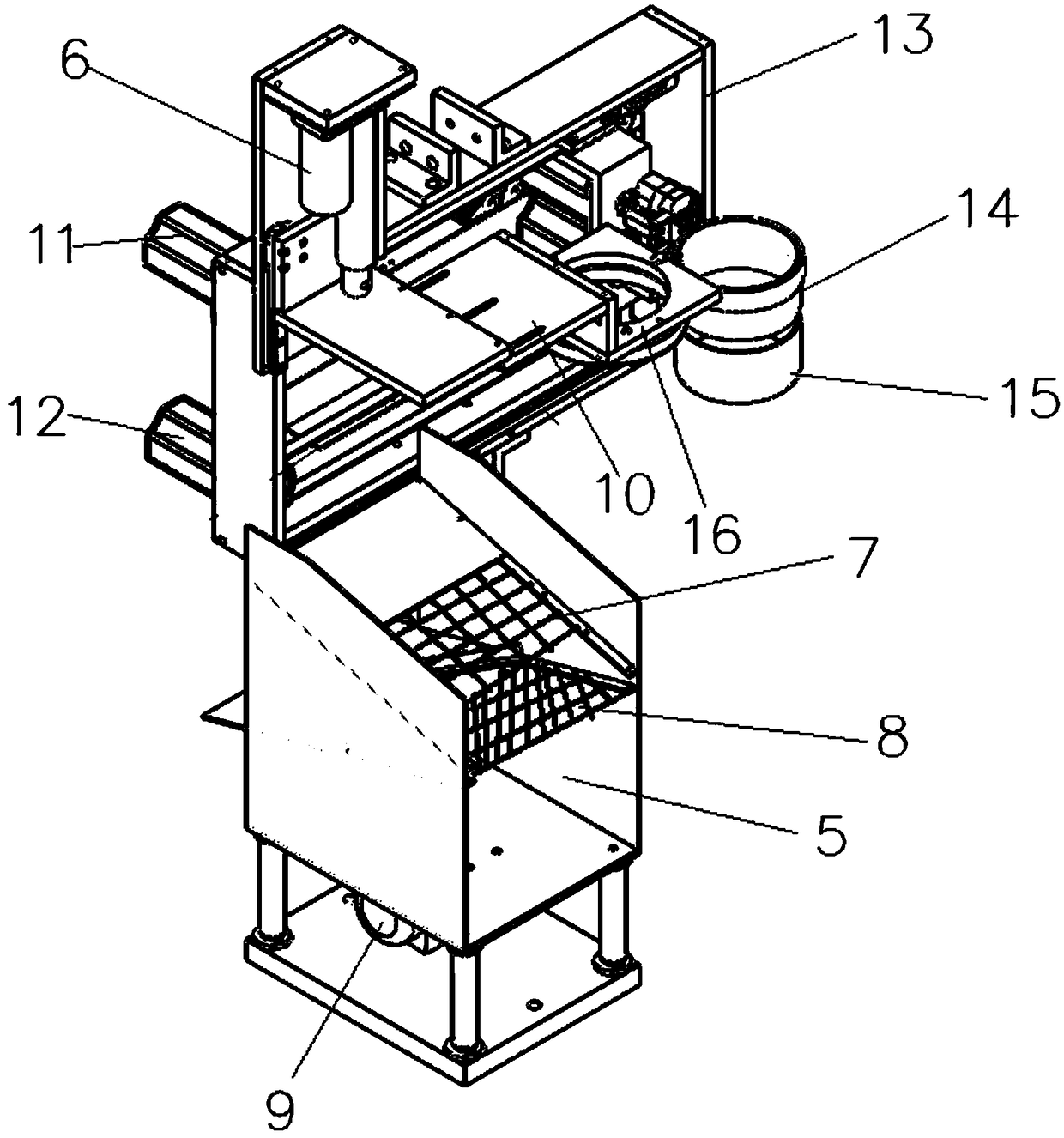

Automatic production device for aphidiidae products

ActiveCN109221022AAvoid harmNot easy to gather into groupsAnimal husbandryPulp and paper industryImpurity

The invention discloses an automatic production device for aphidiidae products. The device comprises a stripping device, and the stripping device comprises a conveying belt and a washing device on theconveying belt. A separation assembly comprises drainage pieces, an air-drying piece and a collection piece, wherein after collecting a mixture of pupae and water obtained by the stripping device, the drainage pieces move to the air-drying piece, the air-drying piece can press on the drainage pieces for air drying, after the air drying piece exits from a pressing mode, and the drainage pieces move to the collection piece again and do turnover movement, so that the air-dried pupae and impurities are poured into the collection piece. By means of the device, the pupae can be stripped from leaves, the pupa mixture is effectively separated, automatic pipelining operation is achieved in the overall process, manpower is saved, and the pupa separation efficiency is high.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

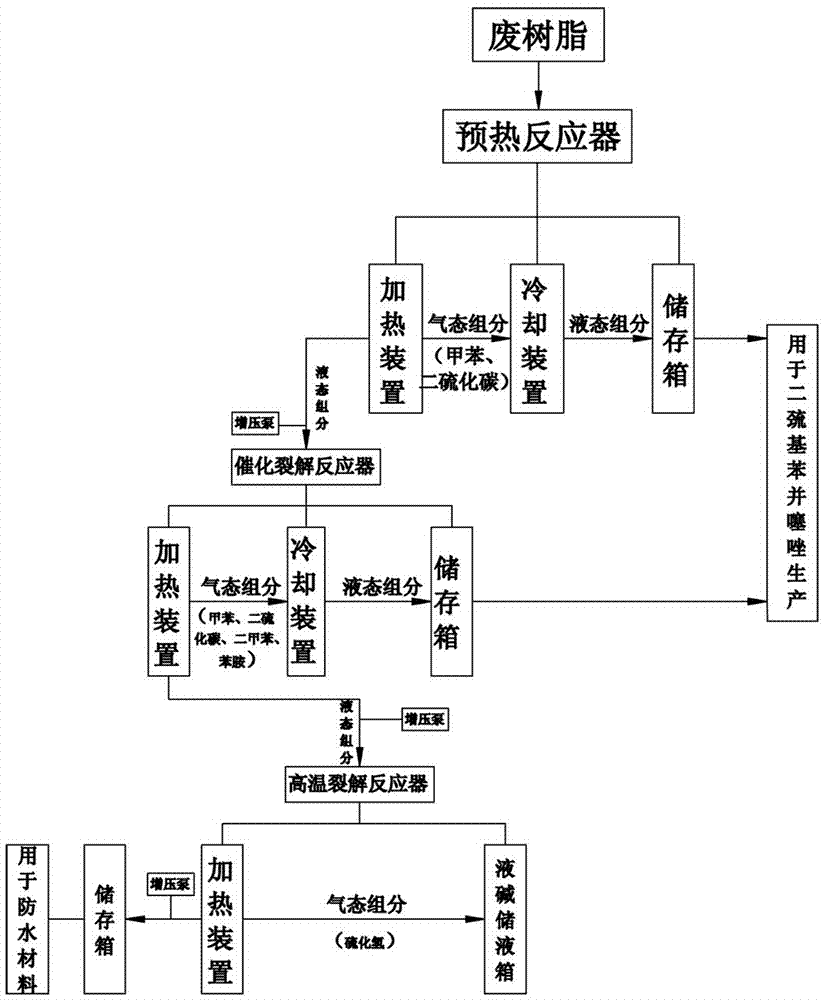

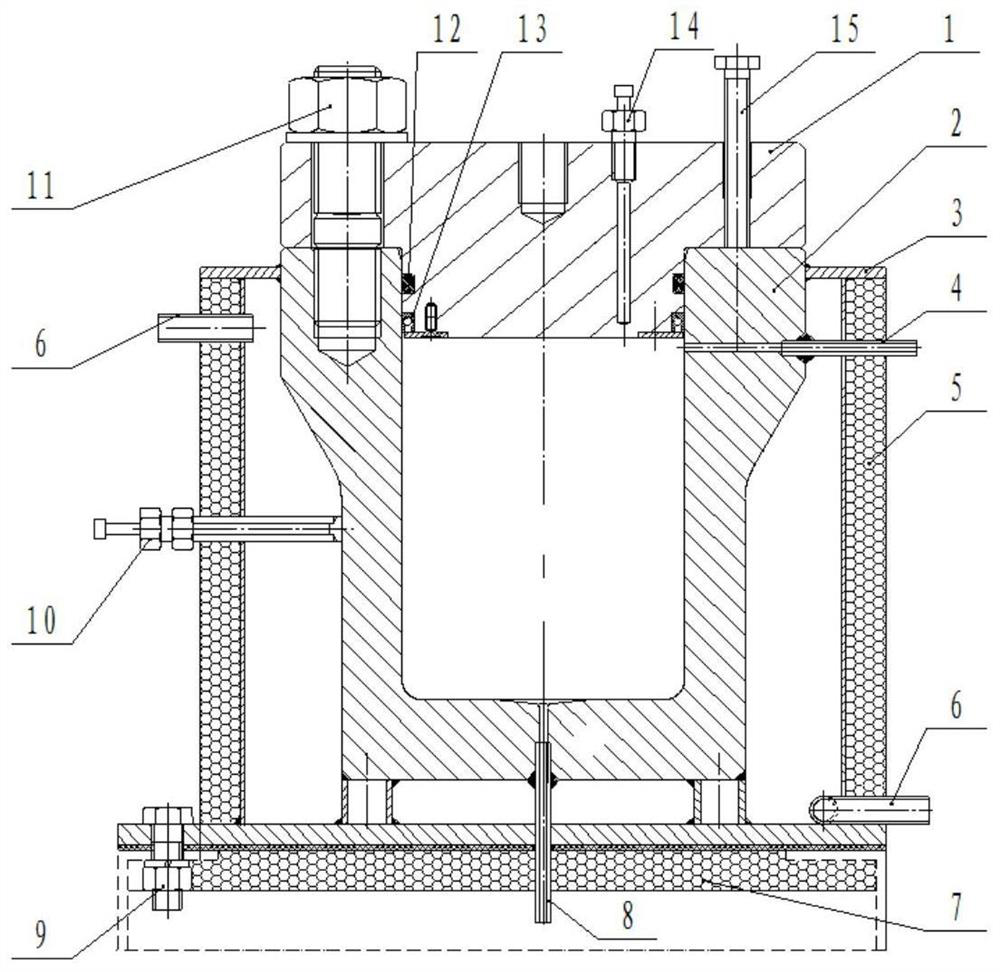

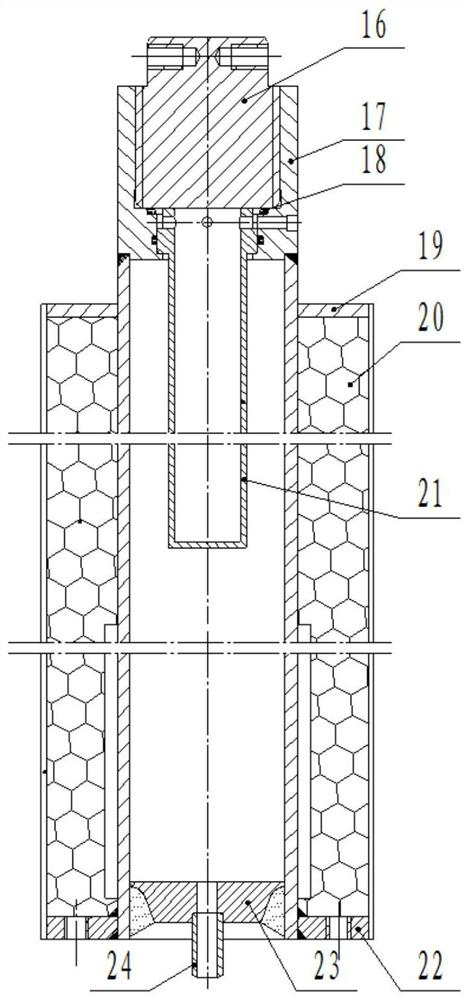

Harmless waste resin treating technology

InactiveCN107286910ARealize repeated recyclingAvoid long-term storage problemsOrganic chemistryOther chemical processesLiquid wasteChemical reaction

The invention discloses a harmless waste resin treating technology which comprises the following steps: performing preheating treatment on waste resin generated in a 2-mercaptobenzothiazole production process to obtain liquid waste resin for standby application; performing low-temperature catalytic cracking treatment on the standby liquid waste resin, keeping a temperature as 70 to 200 DEG C, keeping a pressure as -1 to 0MPa and performing catalytic cracking for 10 to 20 hours; performing high-temperature cracking treatment, keeping a temperature as 200 to 450 DEG C, keeping a pressure as -1 to 0MPa and keeping cracking time as 20 to 40 hours; performing separation and collection treatment: treating separated gas-state cracking distillate by liquid caustic soda and generating sodium hydrosulfide by chemical reaction; introducing heterocyclic compound of cracked residual component into a storage tank having water, taking out after being cooled and cured and packaging. The harmless waste resin treating technology disclosed by the invention achieves resource reutilization, greatly reduces production cost, saves resources and enhances product competitiveness.

Owner:可名芸

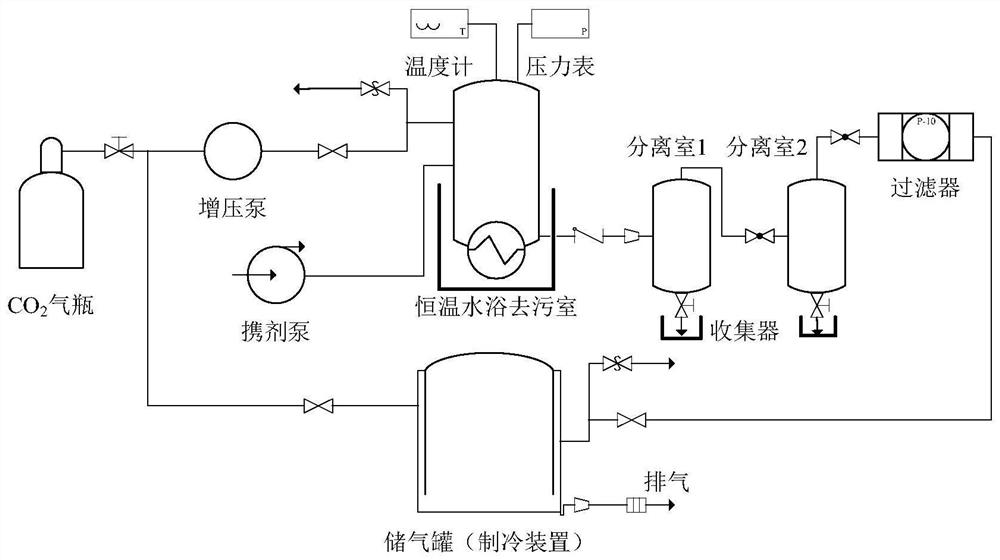

Radioactive pollution supercritical carbon dioxide chemical decontamination method and decontamination device thereof

PendingCN112974412ARealize repeated recyclingRealize the collectionCleaning processes and apparatusControl systemRadioactive contamination

The invention discloses a radioactive pollution supercritical carbon dioxide chemical decontamination method and a decontamination device thereof. The decontamination device comprises a gas storage tank, a booster pump, a mixer, a preheater, a decontamination chamber, a separation chamber, a filter, a detergent carrying pump, a detergent container, a refrigerating device, a constant-temperature heating device, a waste collector, a metering pump, a valve, a pipeline, an instrument, a safety device and a control system. According to the radioactive pollution supercritical carbon dioxide chemical decontamination method, the characteristics of diffusivity and dissolving capacity of supercritical carbon dioxide fluid are utilized, the supercritical carbon dioxide fluid is adopted as a solvent to dissolve a chemical detergent, and the decontamination device can be used for decontamination of the inner cavity surface, micro pores and high-precision surfaces of equipment or components and has the advantages of being good in accessibility, small in damage, capable of recycling decontamination media, little in secondary pollution and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

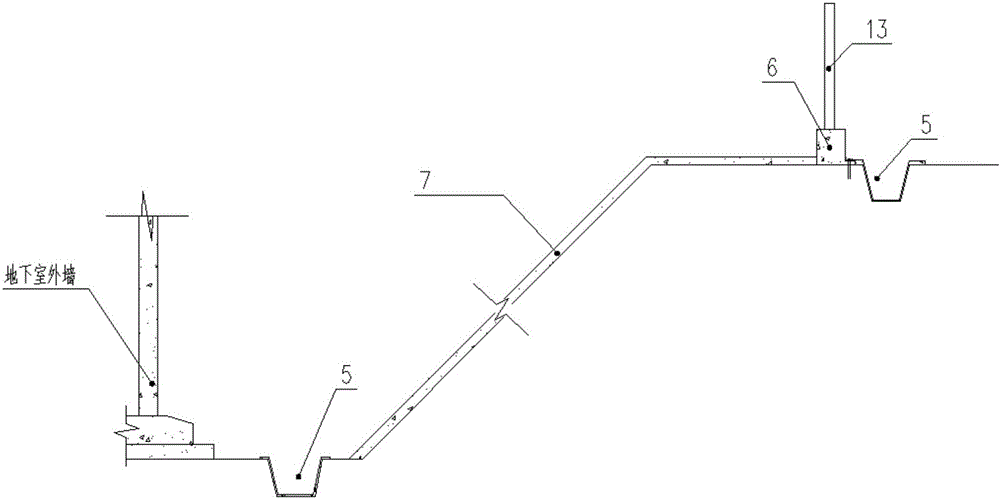

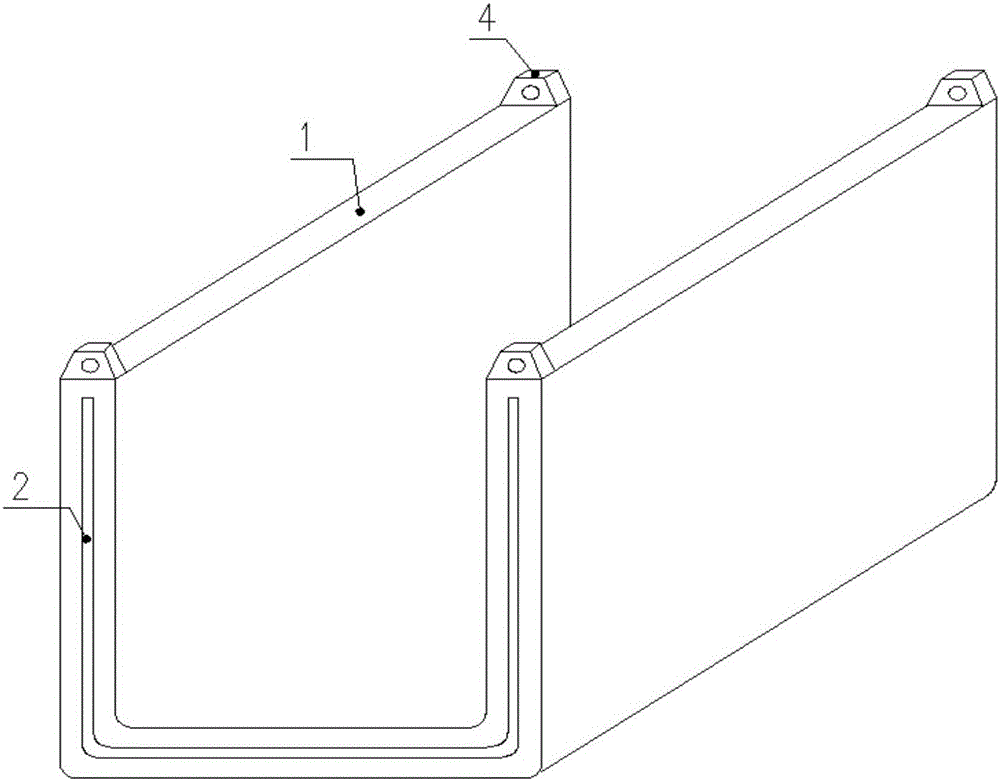

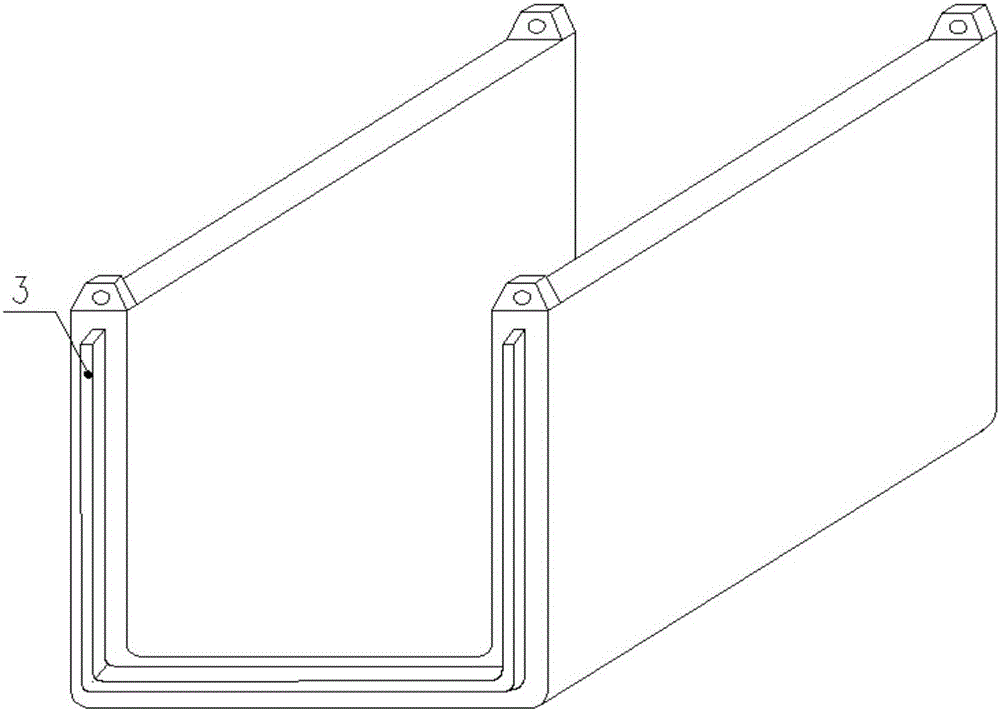

Construction method for mountable recyclable foundation pit drainage and protection system

ActiveCN105839656ASimplify construction stepsSave manufacturing cost and time costExcavationsRetaining wallUtilization rate

The invention discloses a construction method for a mountable recyclable foundation pit drainage and protection system. The construction method comprises the following specific steps that a concrete pavement is laid on the slope surface of a foundation pit, and a concrete slope protection coping is laid at the top of the foundation pit; after the side, away from the foundation pit, of the slope protection coping is tamped through plain soil and flattened, a prefabricated water retaining device is arranged; a foundation trench is excavated in the side, away from the foundation pit, of a water retaining wall, and the size of the foundation trench is adapted to that of a prefabricated drainage device; the drainage device is arranged in the foundation trench; and after construction is completed, a drainage tank and the water retaining wall are sequentially dismantled, so that recycling and reutilization are achieved. According to the construction method for the mountable recyclable foundation pit drainage and protection system, the drainage tank is in a U shape or an inverted trapezoidal shape, manufacturing and draining are convenient, and the drainage amount is large, so that rapid draining of water is facilitated; and effective drainage of underground engineering can be achieved due to the fact that the construction method for the whole drainage and protection system is simple in structure, convenient to construct and high in repeatable recycling utilization rate of all the parts.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com