Optimized zearalenone degrading enzyme ZHD-P encoding gene, recombinant thallus, surface display system and application

A technology of zearalenone and surface display carrier, applied in the field of genetic engineering, can solve the problems of less than 15%, no literature extraction and purification and enzymatic properties, difficult to remove strains in the later stage, etc., and achieves the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062]Example 1. Construction of recombinant expression vector

[0063]1. Artificial synthesis of gene sequence

[0064]The optimized nucleotide sequence shown in SEQ ID NO. 1 was entrusted to Nanjing GenScript Biotechnology Co., Ltd. to artificially synthesize the gene according to conventional techniques in the field, insert the gene into the plasmid vector pUC57, and store it for later use.

[0065]2. Amplification of gene sequence and linearization of expression vector

[0066]Use primer zhd-pF (as shown in SEQ ID NO.3, Primer means primer, the same below) and primer zhd-pR (as shown in SEQ ID NO.4) to amplify the nucleus shown in SEQ ID NO.1 Nucleotide sequence, and named it zhd-pDNA fragment.

[0067]The plasmid pET22b(+) was digested with NdeI and XhoI, and the digested products were recovered by agarose electrophoresis, and the linearized expression vector pET22b(+) was obtained.

[0068]3. Construction of recombinant expression vector

[0069]Using NEBuilder HiFi DNA Assembly Cloning Kit, conne...

Embodiment 2

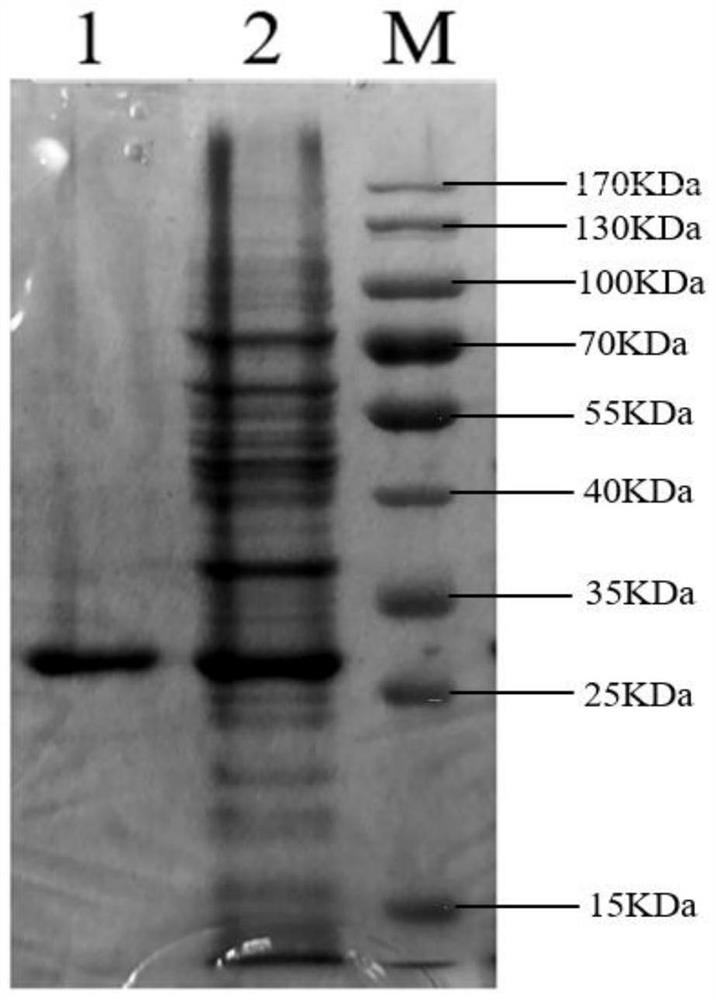

[0073]Example 2. Expression and purification of target protein

[0074]1. IPTG induced expression of recombinant bacteria

[0075]The positive recombinant bacteria BL21 / pET22b(+)-zhd-p prepared in step 4 of the above example 1 was inoculated into 10mL LB liquid medium (containing 100mg / L Amp), cultured at 37°C for 8-10h, then 1mL was transferred Receive 100mL LB liquid medium (containing 100mg / L Amp). Incubate at 37°C, 200 rpm, for 2 hours, measure OD600, and when OD600 exceeds 0.7A (no more than 0.8A), add isopropyl-β-D-thiogalactopyranoside (IPTG) to a final concentration of 1mmol / L, Incubate at 22°C, 200 rpm, for 16-22 hours. The control bacteria prepared in step 4 of Example 1 were cultured using the same procedure.

[0076]2. Preparation of crude enzyme solution

[0077]After the induction is over, put the fermentation broth in two 100mL centrifuge tubes, centrifuge at 4℃, 8000rpm for 5min, pour out the supernatant, add 20mL TE buffer, resuspend the bacteria, 4℃, 8000rpm, centrifuge 5min, ...

Embodiment 3

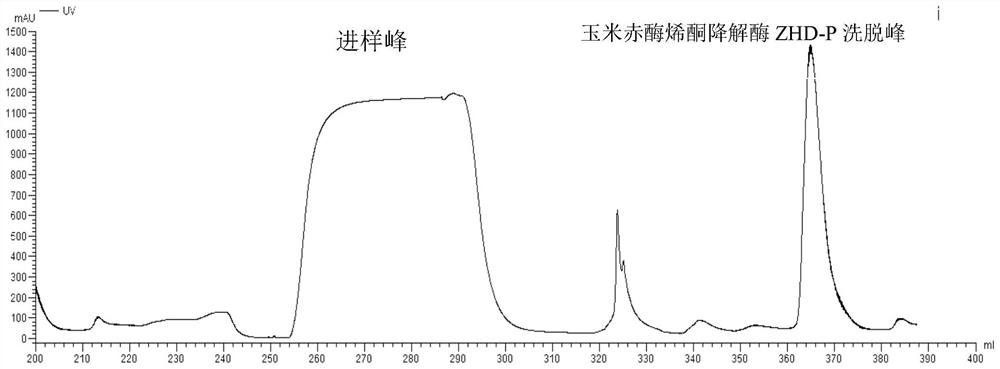

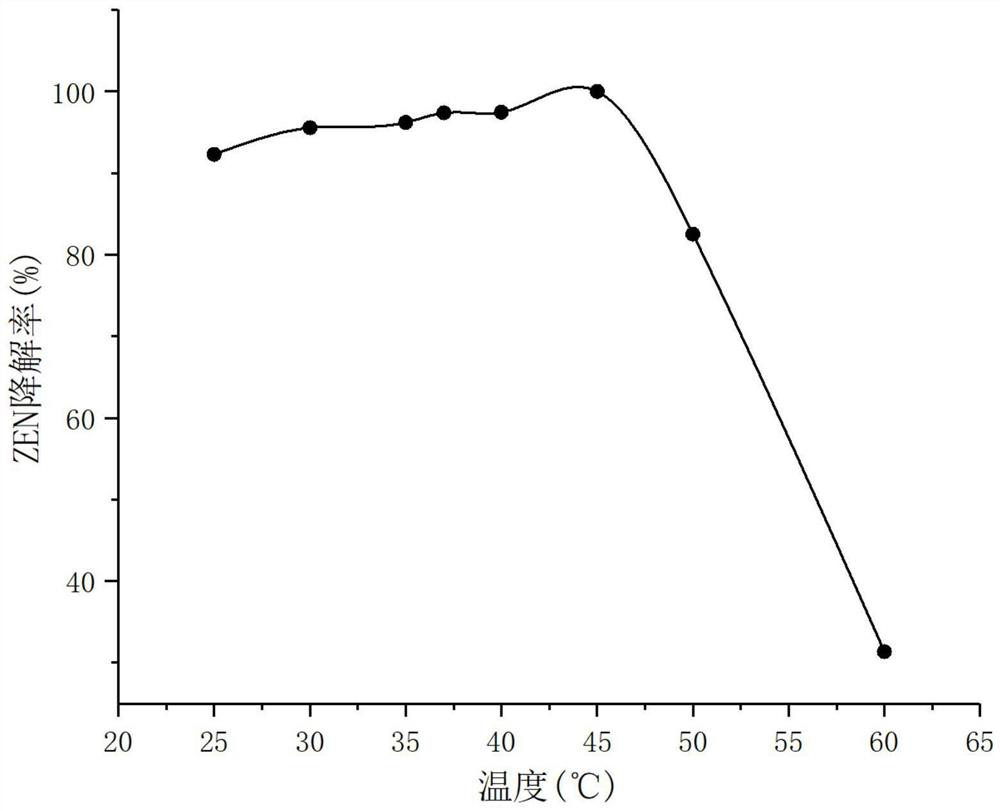

[0088]Example 3. Test for degradation of zearalenone by recombinant zearalenone degrading enzyme ZHD-P

[0089]The protein concentration of the recombinant zearalenone ZHD-P pure enzyme solution in step 4 of Example 2 was determined to be 1.3891 mg / mL. The recombinant zearalenone degrading enzyme ZHD-P pure enzyme solution in step 4 of Example 2 was diluted 4 times with Buffer A solution (0.5M Nacl, 20Mm Tris, adjusted to pH 8.0 with HCl solution). The protein concentration of the enzyme solution was 0.3473 mg / mL. The diluted enzyme solution is tested for enzyme activity. The diluted enzyme solution is recorded as the diluted enzyme solution.

[0090]Using zearalenone as the substrate, the degradation rate of the substrate by the zearalenone degrading enzyme ZHD-P was determined. The determination method is: 5μL of diluted enzyme solution, 5.0μL of 1.0mg / ml ZEN and 240.0μL of 50mmol / L Tris-HCl (pH 7.5). After mixing, react for 30min at 45℃, and then add 250μL of methanol to stop. reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com