Silica gel cleaning production method and sulfuric acid production method

A clean production and production method technology, applied in the direction of sulfur trioxide/sulfuric acid, silicon oxide, silicon dioxide, etc., can solve problems such as air pollution and achieve energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

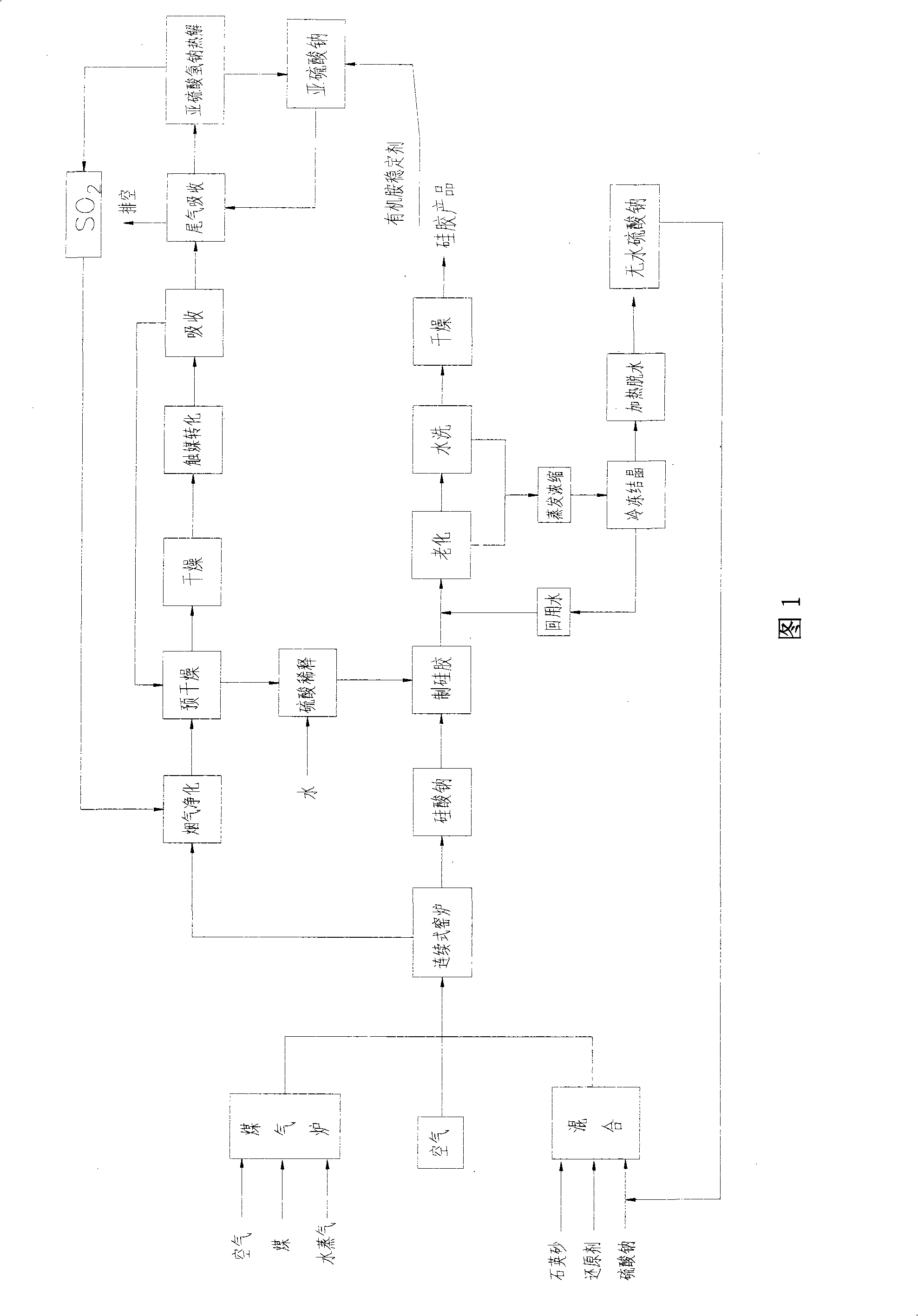

Image

Examples

Embodiment Construction

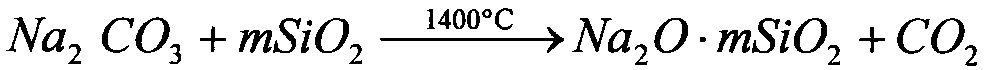

[0057] 1. Sodium silicate (Na 2 O 3.3SiO 2 ) production

[0058] The content of sodium sulfate is 99%, the average fineness is 50 mesh, the content of sodium sulfate is 98.5%, the content of silicon dioxide is 98.5%, the water content is 2.6%, the average particle size is 60 mesh, and the fixed carbon content is 72%. The average fineness Coal with a degree of 40 mesh, a calorific value of 6800 kcal / kg, and a sulfur content of 2.2% is fully mixed evenly, and the batching ratio is in accordance with the stoichiometric ratio of sodium natron with a modulus of 3.3, but the excess of sodium sulfate is 8%. The added amount of reduced coal is increased to 7% of the theoretical added amount of Yuanming powder, and it is continuously added to the horseshoe flame kiln with a heat value of 1350 kcal / Nm3 as fuel and a heating temperature of 1400 ° C. Paohuatin with a modulus of 3.3 is produced. At the same time, the total amount of flue gas (wet basis) measured is: 33653~37134Nm 3 / h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com