Patents

Literature

58 results about "Kraft process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

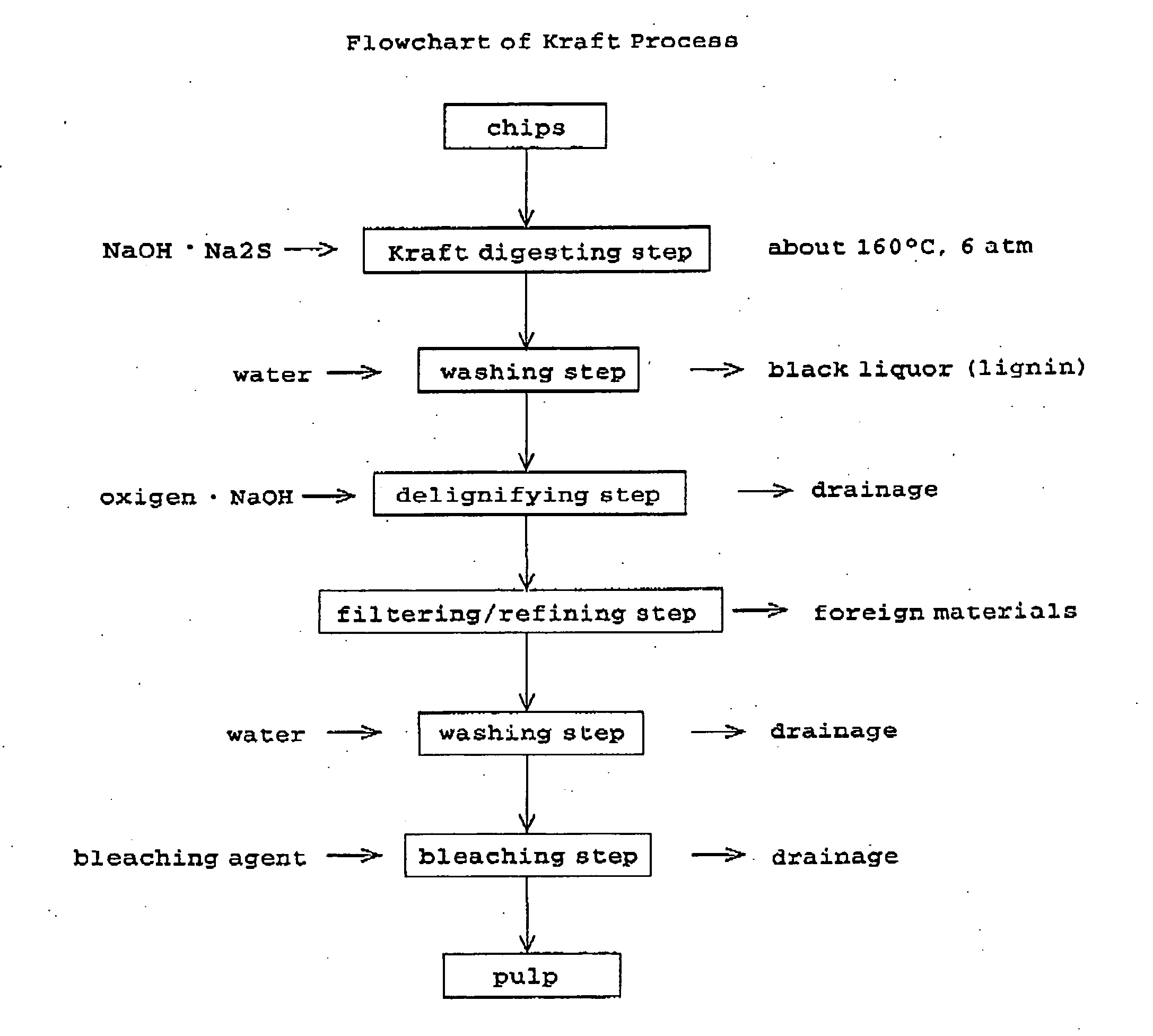

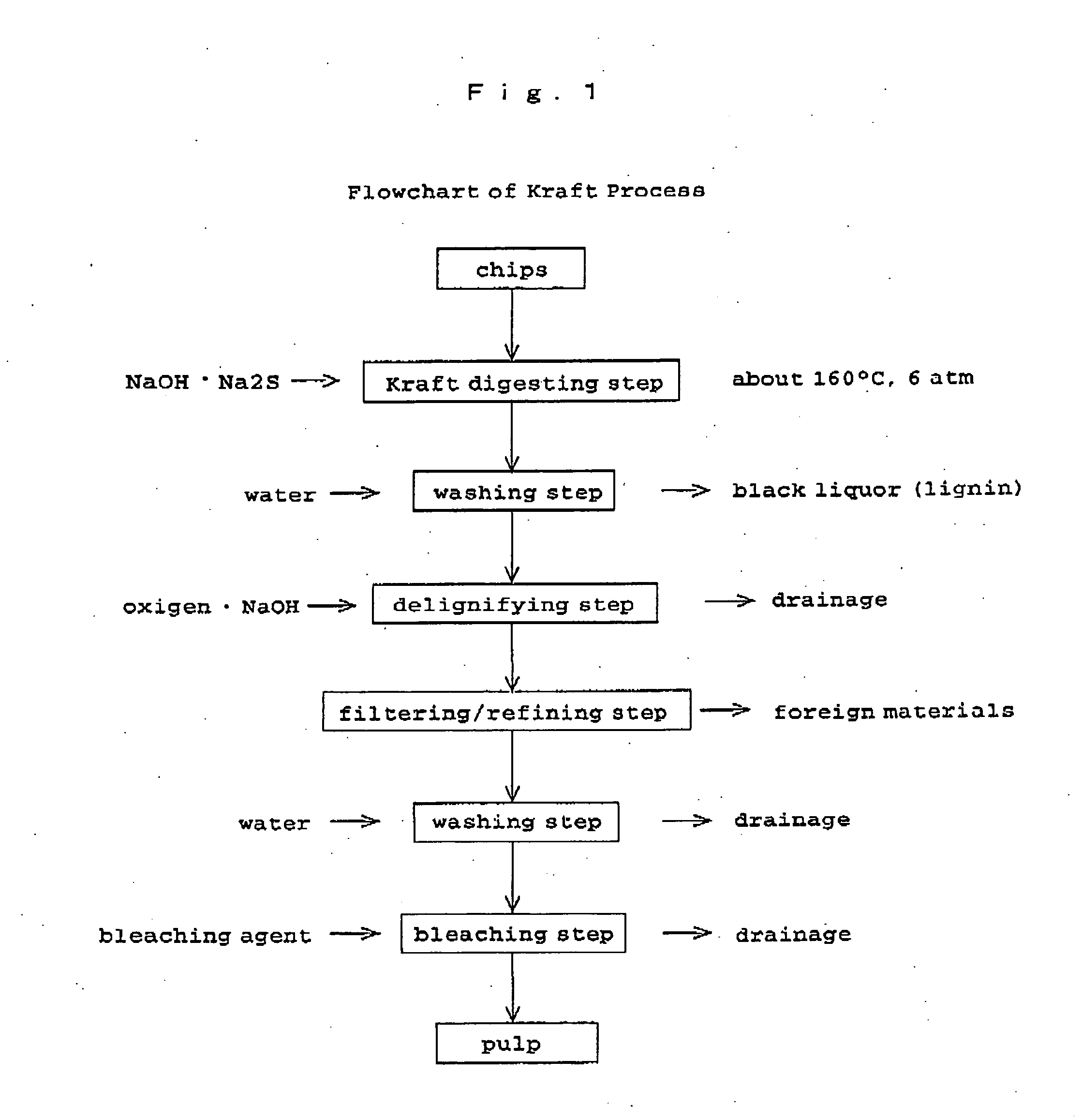

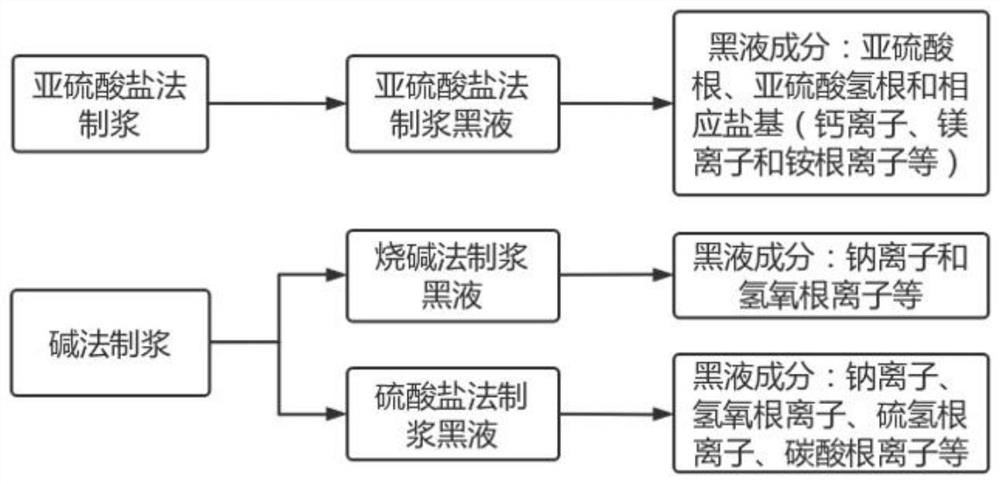

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibers, the main component of paper. The kraft process entails treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na₂S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes.

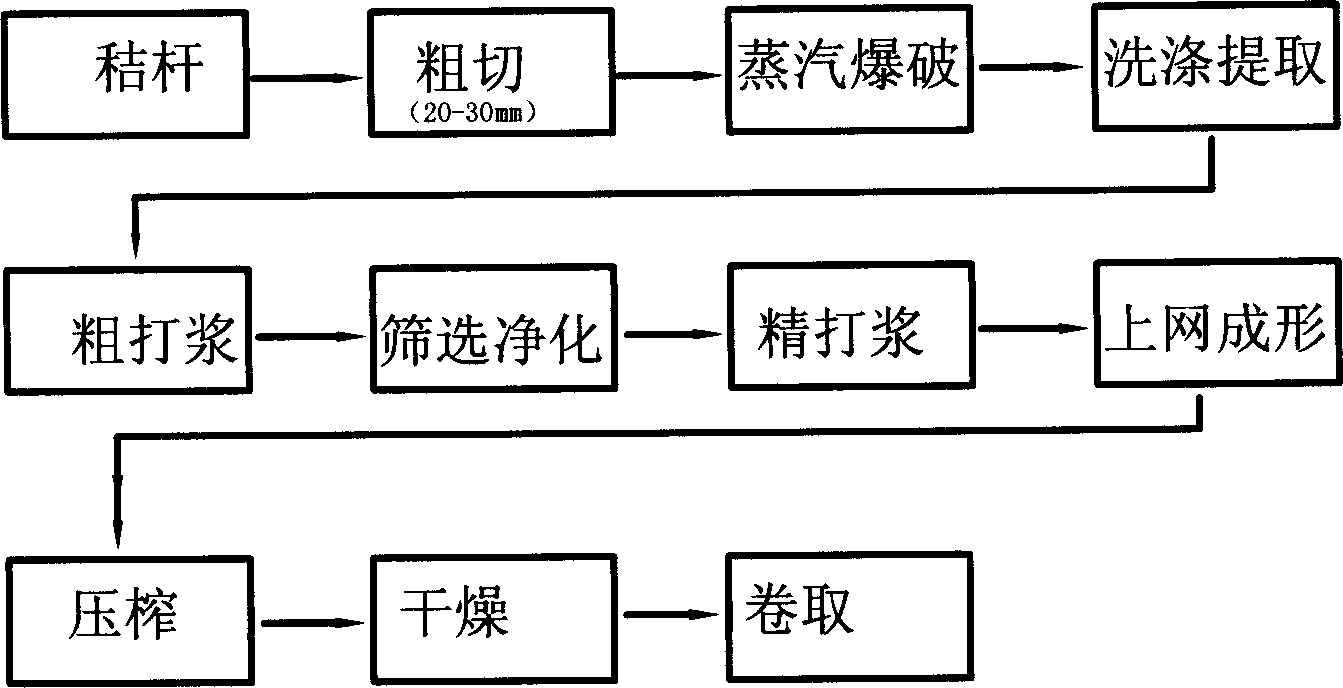

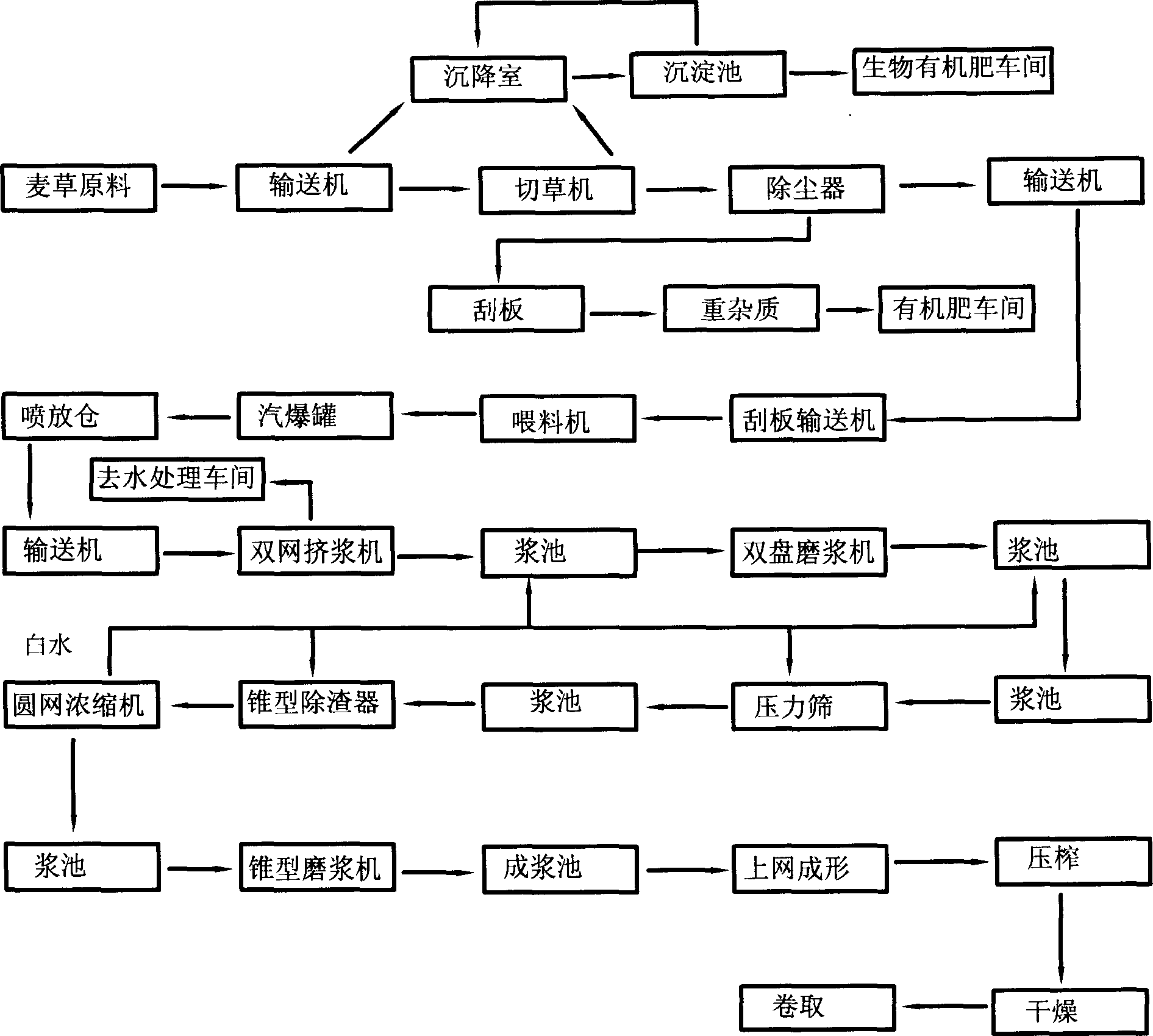

Corrugated paper produced by steam blasting straw to pulp and its production method

The invention relates to light weight high fatigue resistance semi-chemical corrugated paper produced by steam blasting stalk Kraft process and its manufacturing method. The method includes the following steps: using stalk as the raw material; do steam blasting after coarse cutting; adding its 0.5-2% bone dry weight into caustic soda; filling in steam blasting pot; vapor phase boiling temperature is 145-180 deg.C; pressure is 0.9-2.0MPa; treatment is time 12-18 min; gaining steam blasting stalk; washing and extracting; coarse beating; sieving; purifying; fine beating; gaining steam blasting ryegrass pulp; mixing the pulp and the existing natural color long fiber with 50-70% and 30-50% of their absolute dry percentages; facing wire and forming; pressing; drying; balling up to gain finished products. The invention has the advantages of low energy consumption, low pollution, and high yield. And it is good for environmental protection. The produced semi-chemical corrugated paper has the features of light weight, high fatigue resistance, and flat appearance.

Owner:山东丰源中科生态科技有限公司

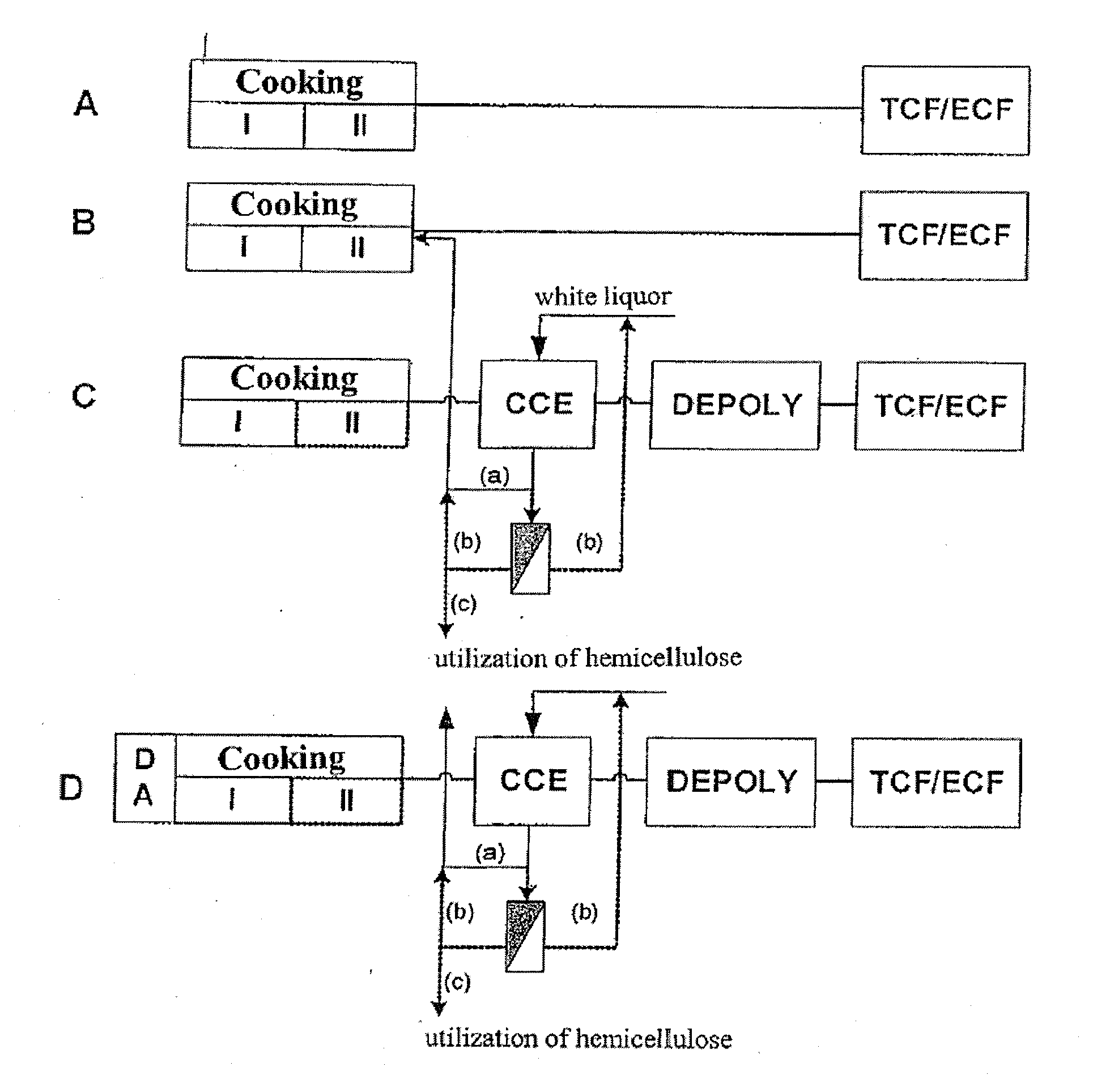

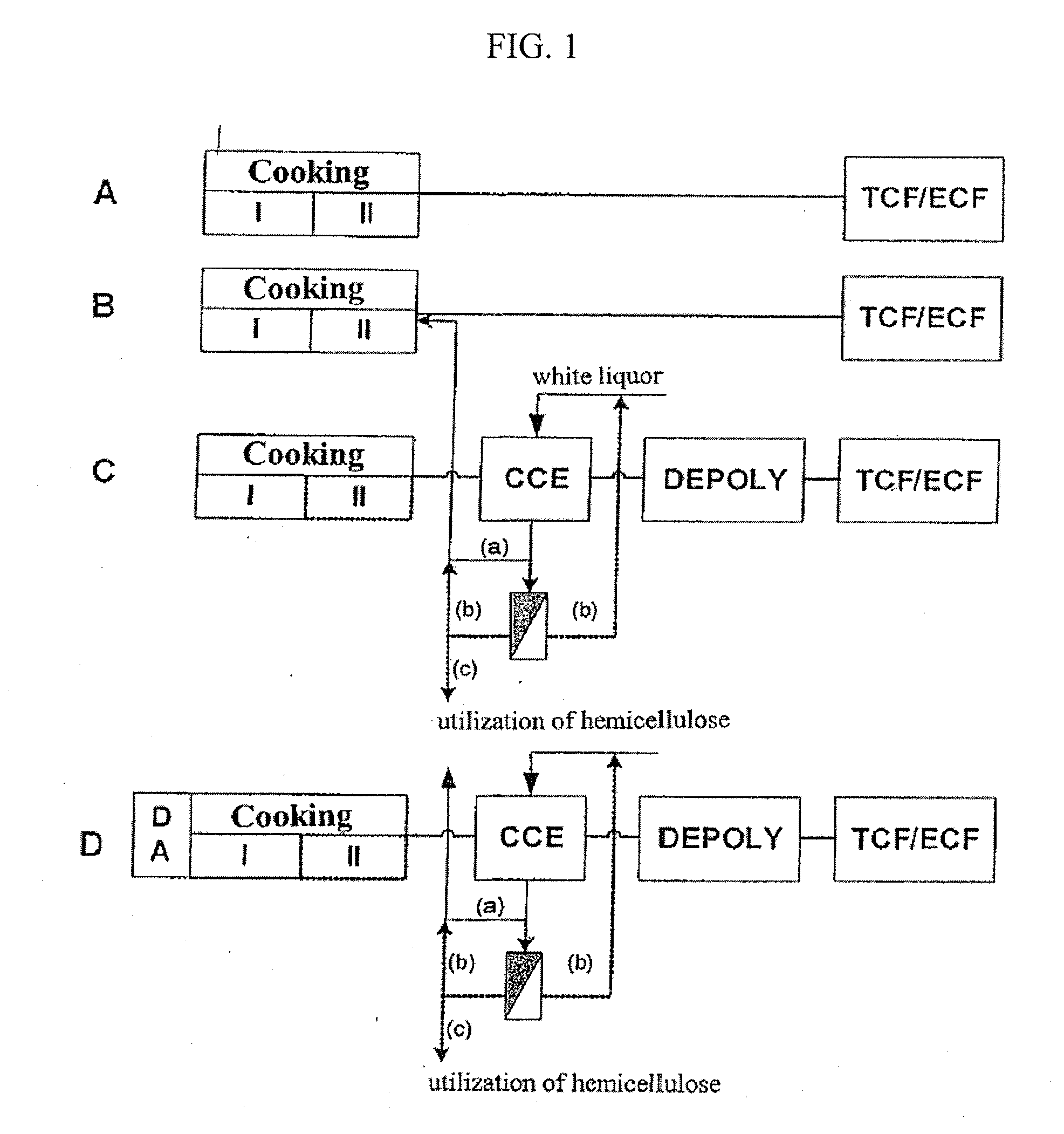

Process For Producing A Pulp

ActiveUS20090312536A1Easy to solvePretreatment with water/steamNon-fibrous pulp additionKraft processPulp and paper industry

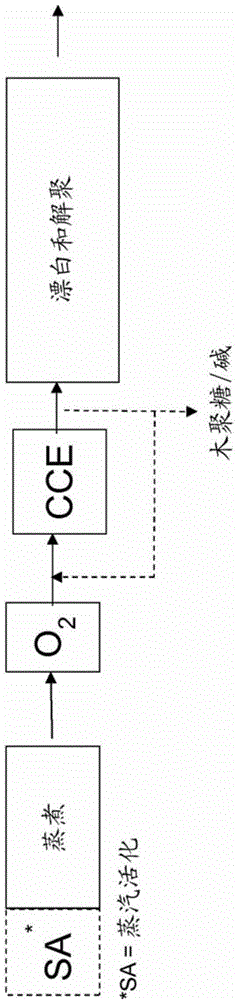

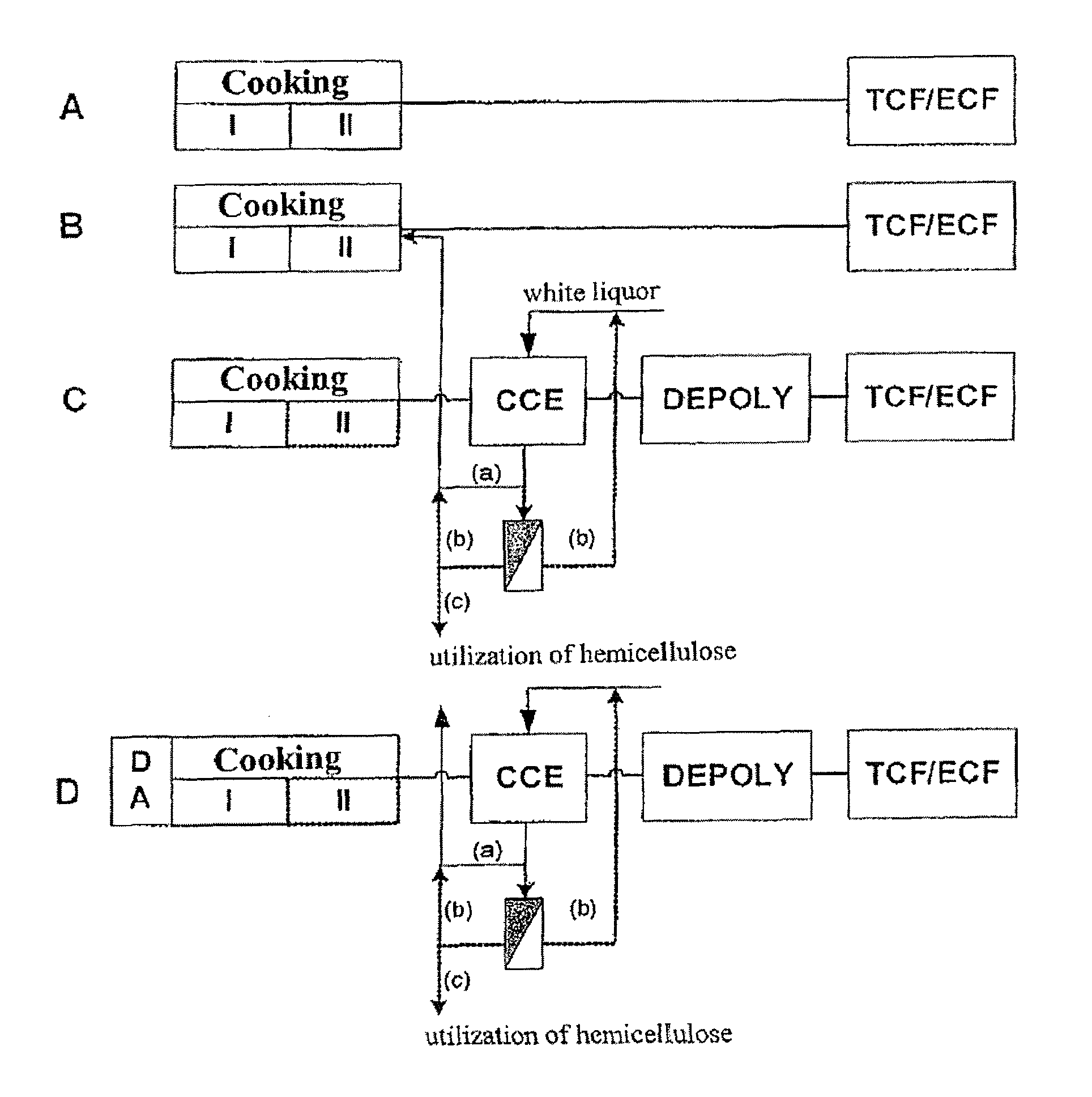

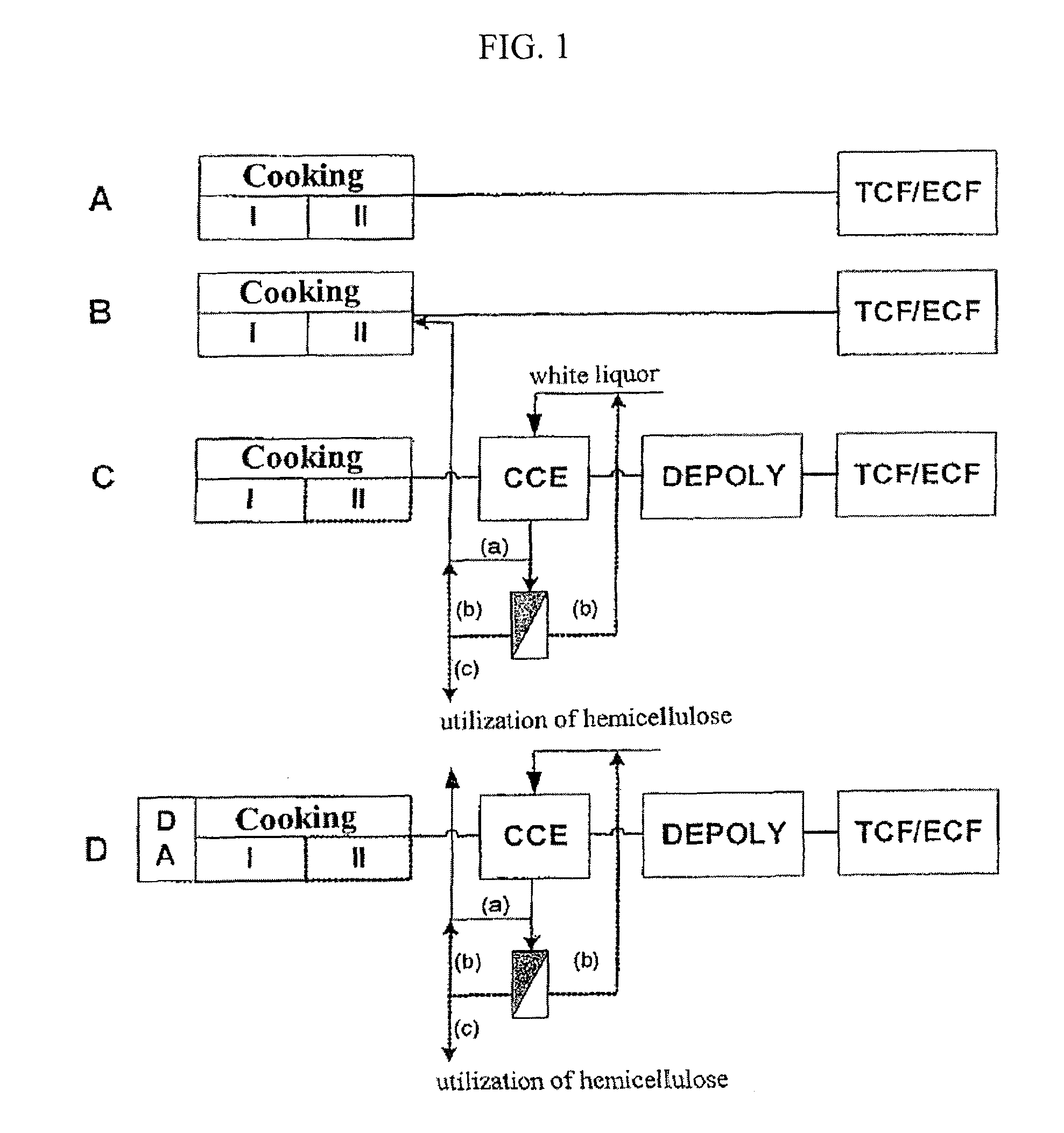

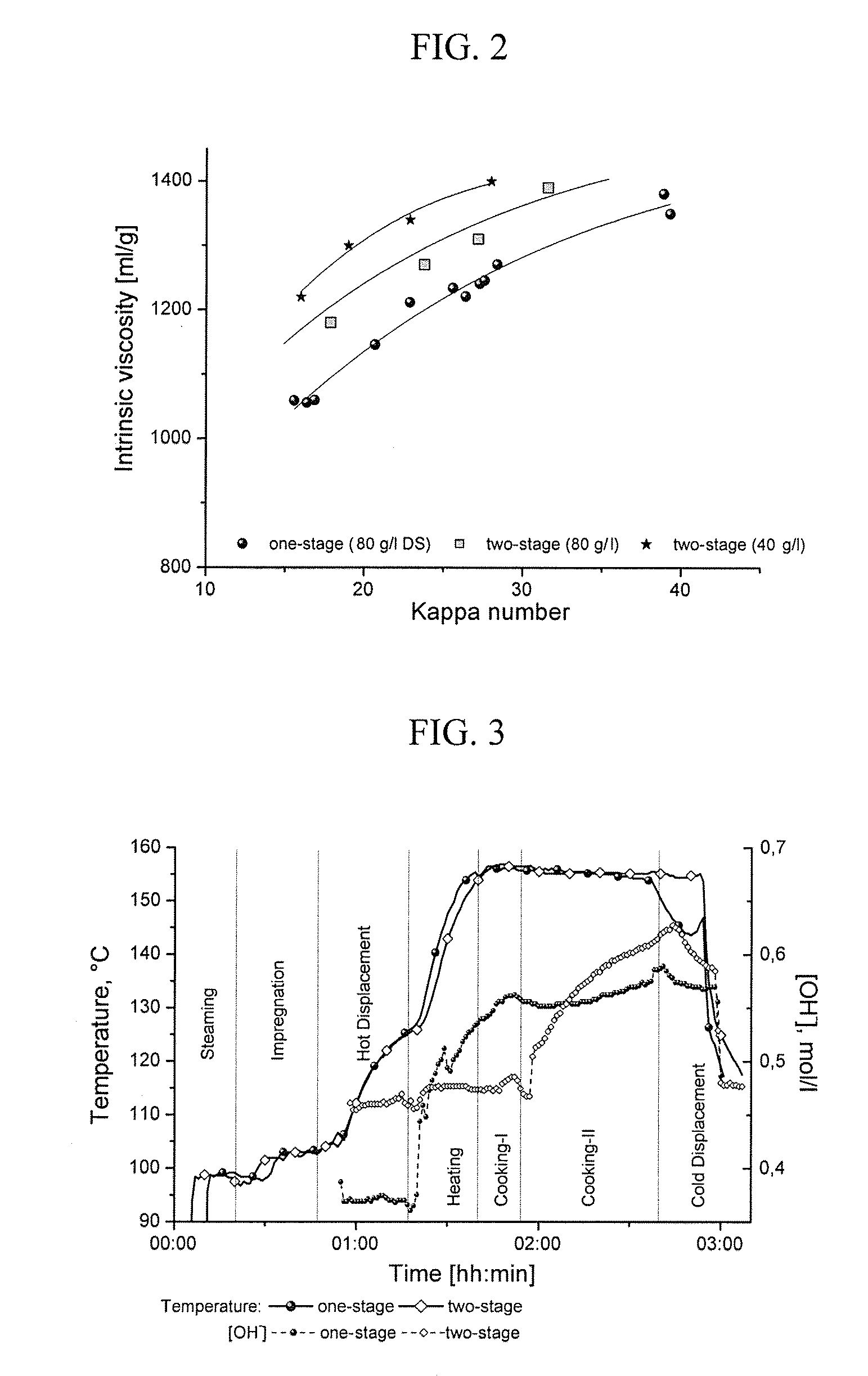

The invention relates to a process for producing a dissolving pulp from a cellulosic starting material using the kraft process, comprising the step of cooking the starting material with a cooking liquor. The process according to the invention characterized in that the starting material is exposed to a steam treatment prior to cooking and that the pulp obtained by cooking is subjected to cold caustic extraction (CCE) in the course of further processing.

Owner:LENZING AG

Naturally degradative cotton linter plastic film and manufacture process thereof

InactiveCN101629398AEfficient use ofUnable to penetrateWater-repelling agents additionPaper/cardboardFiberParaffin wax

The invention relates to a naturally degradative short linter plastic film and a manufacture process thereof, belonging to the field of plastic films. The manufacture process comprises the following steps: dedusting short linters, ramie short fibers and silk leftover bits; uniformly mixing according to a proportion; cutting short; placing in a cooking boiler; adding NaOH, anthraquinone and water; increasing temperature; keeping pressure; boiling; preparing pulp by a sulphate pulping method; filtering pulp liquid; cleanly flushing filtered substances; adding water to prepare the pulp liquid; beating the pulp liquid at a beating degree of 50 DEG SR; adding daiamid epoxy chloropropane resin and cellulose to uniformly scatter in a pulp scattering machine; diluting with water; forming handsheets in a water circulating handsheet former; airing the handsheets at a room temperature; steeping the handsheets in a whiteruss steeping tank; immediately fishing out and smoothening the handsheets with a brush; enabling the prepared handsheets, i.e. paper-based semi-finished products of non-weaving cloth, to keep still at the room temperature; steeping the semi-finished products in a sizing liquid steeping tank; immediately fishing out and smoothening the semi-finished products; placing the semi-finished products in an oven to prebake so that sizing liquid is fully permeated and stuck to the semi-finished products; and raising the temperature and baking for molding treatment to obtain the naturally degradative short linter plastic film.

Owner:JIANGNAN UNIV +1

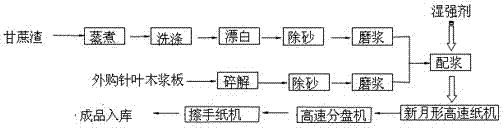

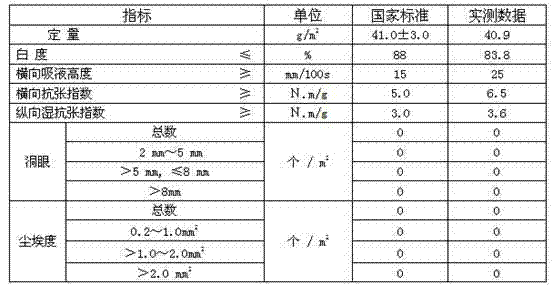

Method and equipment for producing paper hand towel from bagasse pulp

ActiveCN103757973AImprove uniformityGood dry and wet strengthPulp beating/refining methodsPaper-making machinesKraft processPapermaking

The invention relates to a method for papermaking, and particularly relates to a method and equipment for producing a paper hand towel form bagasse pulp as a main raw material. According to the method, firstly, 80%-90% of bagasse pulp and 10%-20% of softwood pulp are taken as raw materials, wherein the bagasse pulp is boiled by a sulfate process, washed and then bleached so as to obtain bleached bagasse pulp, and the softwood pulp adopts market pulp; secondly, an aquapulper, a high concentration grit separator and a double disc refiner are used; thirdly, a proper wet strength agent is adopted; fourthly, a crescent high speed toilet paper machine is adopted; fifthly, a low beating degree is adopted; sixthly, in the whole process from pulp preparation to paper rolling, automatic operation control with a DCS (distributed control system) is adopted, paper sheet quantification and moisture are monitored on line and regulated automatically by a QCS (quality control system); seventhly, a point-to-point embossing manner is adopted; eighthly, a high-speed rewinding and splitting machine is used. The produced paper hand towel has tensile strength and proper air permeability, and reaches high standards in strength, wet strength, water absorption, air permeability, flexibility and the like.

Owner:广西广业贵糖糖业集团有限公司

Straw cutting-free method for preparing straw pulp by spherical digester alkali digestion

InactiveCN102400404AImprove the environmentImprove qualityPulping with inorganic basesNon-woody plant/crop pulpAnthraquinonesBlack liquor

The invention provides a straw cutting-free method for preparing straw pulp by spherical digester alkali digestion. The method comprises the following steps of: washing a straw raw material; adding a hot alkali solution, adding water, mixing uniformly, and heating; performing digestion by adopting a conventional sulfate method or a caustic soda anthraquinone method; stopping the digestion when the lignin discharged from the straw raw material by the digestion reaches 75 to 90 percent, discharging a black liquor I, and thus obtaining straw pulp; and adding the hot alkali solution into the straw pulp, performing digestion and conventional washing and thus obtaining unbleached pulp, wherein the thin black liquor discharged during washing is a black liquor II, the black liquor II and water are added into the new straw raw material together, and the unbleached pulp is continuously obtained by repeating. The straw cutting process is eliminated in the method, so that the flow for preparing the pulp by using the straw is simplified; and on the premise of ensuring the digestion effect, the concentration of the solid matter of the black liquor can be improved to over 13 percent, the stock loss of the raw material is reduced by about 5 percent, the single-pot digestion capacity is improved by 10 to 15 percent, and the yield and the viscosity of the formed pulp are raised with different degrees.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Process for biological treating collosol material by pulping paper making technology

InactiveCN1786342AReduce the amount addedImprove retentionNon-fibrous pulp additionPaper/cardboardFiberKraft process

The invention relates to collosol material biological treatment method in Kraft process paper technology. It belongs to Kraft process paper technique field. It includes the following steps: adding pectase into bleached mechanics pulp, crushed news paper deink pulp, or off-machine water; the use level of pectase is 20-160g / ton pulp or 1.0-40g / ton off-machine water; treatment temperature is 40-80 centigrade degree; treatment time is 1h-8h; pH value is 7.0-11.0. The invention can greatly reduce mechanics pulp and waste paper pulp DCS charge demand to reduce cation polymer adding quality or cancel, increase fiber fines keeping rate and DCS adsorption, reduce production cost and gooey, and increase paper unit working capability.

Owner:QILU UNIV OF TECH

Kraft pulping process of camphorwood

ActiveCN110438834AQuality improvementMeet production needsPulping with inorganic basesChemical/chemomechanical pulpPaper productionSlurry

The invention discloses a kraft pulping process of camphorwood. The kraft pulping process comprises the following preparation steps that 100% camphorwood pieces are taken out for peeling, chipping andscreening operations, sent into a cooking pot for cooking operation, put into a scrubber for washing operation, sent into a pressure screen for screening operation, carried out bleaching operation byusing hydrogen peroxide, and sent into a slurry tower for storage operation. According to the kraft pulping process of the camphorwood, the purpose is that the camphorwood pieces after stewed camphorand camphor oil can be reused, process flow and process parameters can be made according to the material characteristics of camphorwood, the pulping cost is low, the pulp quality is good, and needs of high-grade paper production can be fully met.

Owner:YUEYANG FOREST & PAPER CO LTD

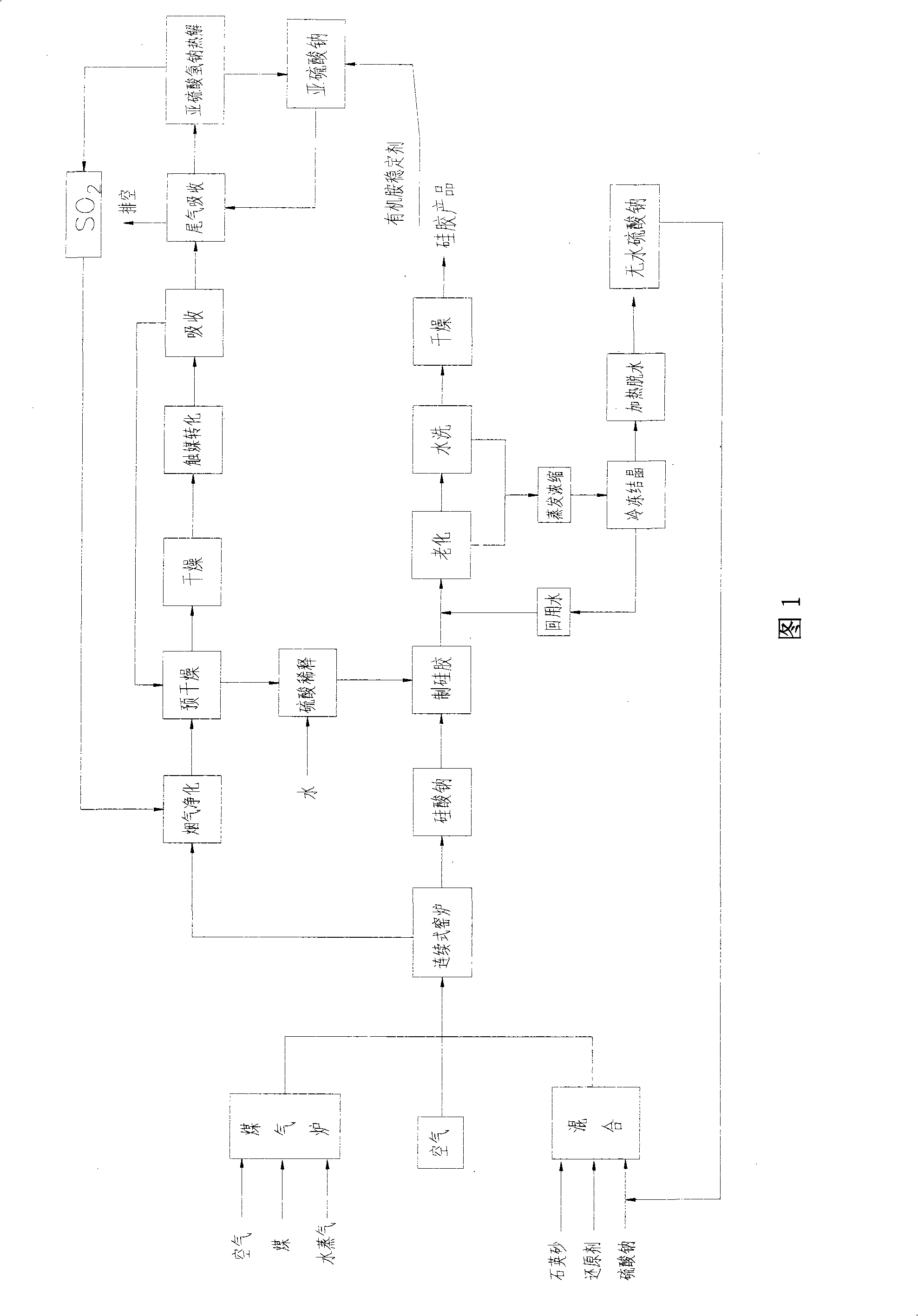

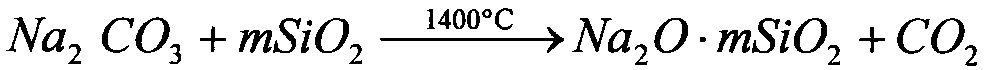

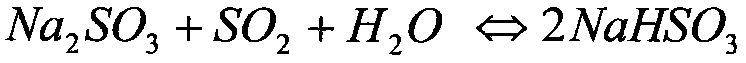

Silica gel cleaning production method and sulfuric acid production method

InactiveCN101327931ASave energyRealize repeated recyclingSilicaSulfur-trioxide/sulfuric-acidHigh concentrationPersulfate

The invention relates to a cleaning production method of a silica gel and a production method of a sulfuric acid belonging to the preparation technology field of the silica gel and sulfuric acid, wherein the silica gel production method employs sulfuric acid to react with alkali metal silicate, the alkali metal silicate is prepared by kraft process and the material sulfuric acid is completely or partially from sulfur compounds in the recovered flue gas during the production of another material alkali metal silicate. The production method of the invention achieves the repeated recycle of the sulfur element and the alkali metal element, improves the resource utilization rate and solves the environmental protection problem. The sulfuric acid production method of the invention is to recover the sulfur compounds in the flue gas during the production of the alkali metal silicate and to produce sulfuric acid by the unsteady conversion technology, which overcomes the problems of higher concentration of sulfur dioxide and little fluctuation required in the acid-making technology and achieves the autothermal equilibrium of the conversion with little investion and low energy consumption.

Owner:QINGDAO MAKALL GROUP CO LTD

High-purity sulfate pulp, as well as production method and application thereof

ActiveCN102619126AHigh pulping yieldEmission reductionPulp bleachingPulping with inorganic basesSolubilityOxygen

The invention relates to high-purity sulfate pulp, as well as a production method and an application thereof. The high-purity sulfate pulp is prepared by stewing wood fiber raw material through a sulfate process for pulping, performing oxygen delignification and bleaching with DOEOPD1P, wherein the content of alpha cellulose in the pulp is not lower than 88% by weight; the content of pentosan is 4.5-6.5% by weight; the alkali solubility S18 of the pulp is 6.0-8.5% by weight; a DCM (dichloromethane) extract of the pulp is 0.1-0.30% by weight; the ash content is not higher than 0.15% by weight; the iron content is not higher than 20mg / kg; the SiO2 content is not higher than 50mg / kg; the inherent viscosity is 450-550dl / g; and the whiteness is not lower than 87% ISO, and the pulp is used for being mixed into dissolving pulp for producing viscose fiber.

Owner:湖南骏泰新材料科技有限责任公司

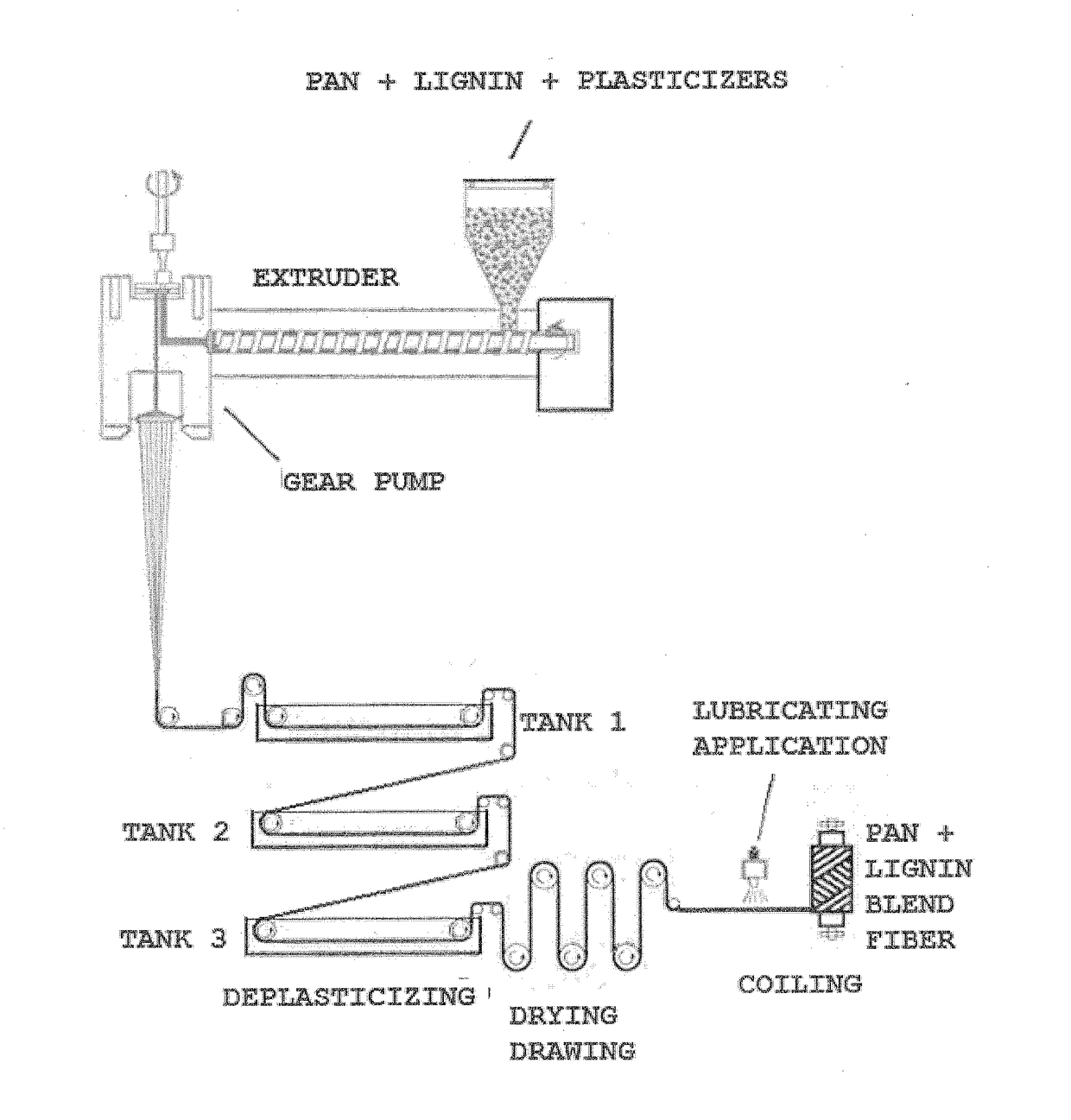

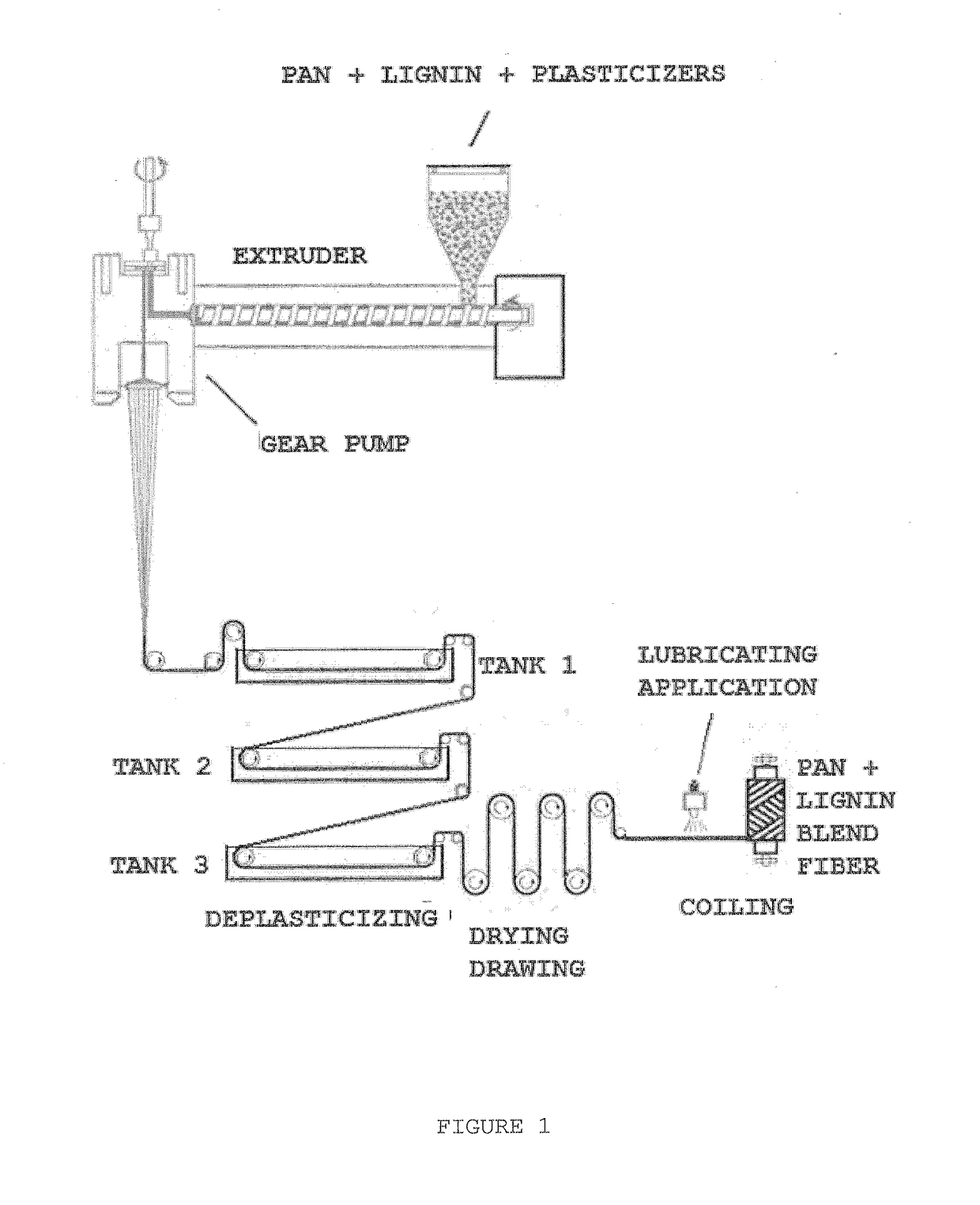

Composition of polyacrylonitrile/lignin blend and use thereof in melt spinning carbon fibre precursors

InactiveUS20180282535A1High productNo toxicityCarbon preparation/purificationMonocomponent synthetic polymer artificial filamentBiodieselCarbon fibers

Described is a method of producing fibers by melting process in spinning extruders by using a composition containing polyacrylonitrile (PAN), lignin and plasticizers with high boiling point and dipolar moment, such as glycerine and glycerol carbonate. The use of thermal stabilizers also derived from halogenated glycerol, known as halodridines, and additives derived from the esterification of glycerin with fatty and phosphoric acids are also described. By removing the plasticizers and the soluble additives in polar solvents, such as water and alcohols, shortly after the spinning step, it is possible to produce fibers from PAN / lignin blend with characteristics similar to those produced by traditional wet spinning process, widely used in the production of carbon fiber. The lignin used may be that obtained by the Kraft Process. The glycerin used as a plasticizer can be derived from the production of biodiesel, which does not need to be purified by distillation process.

Owner:LAB QUIMICOS E METROLOGICOS QUIMLAB LTDA

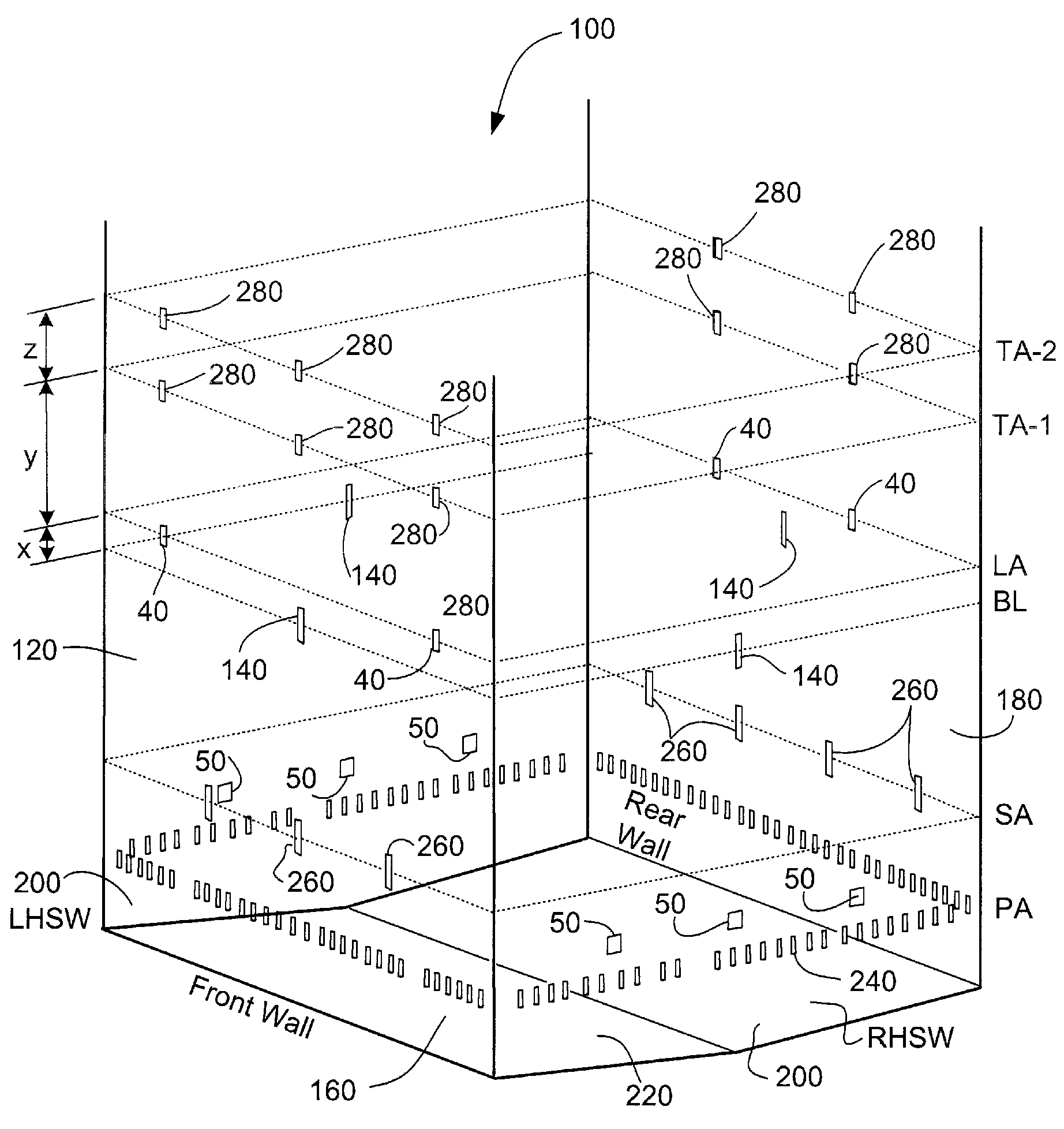

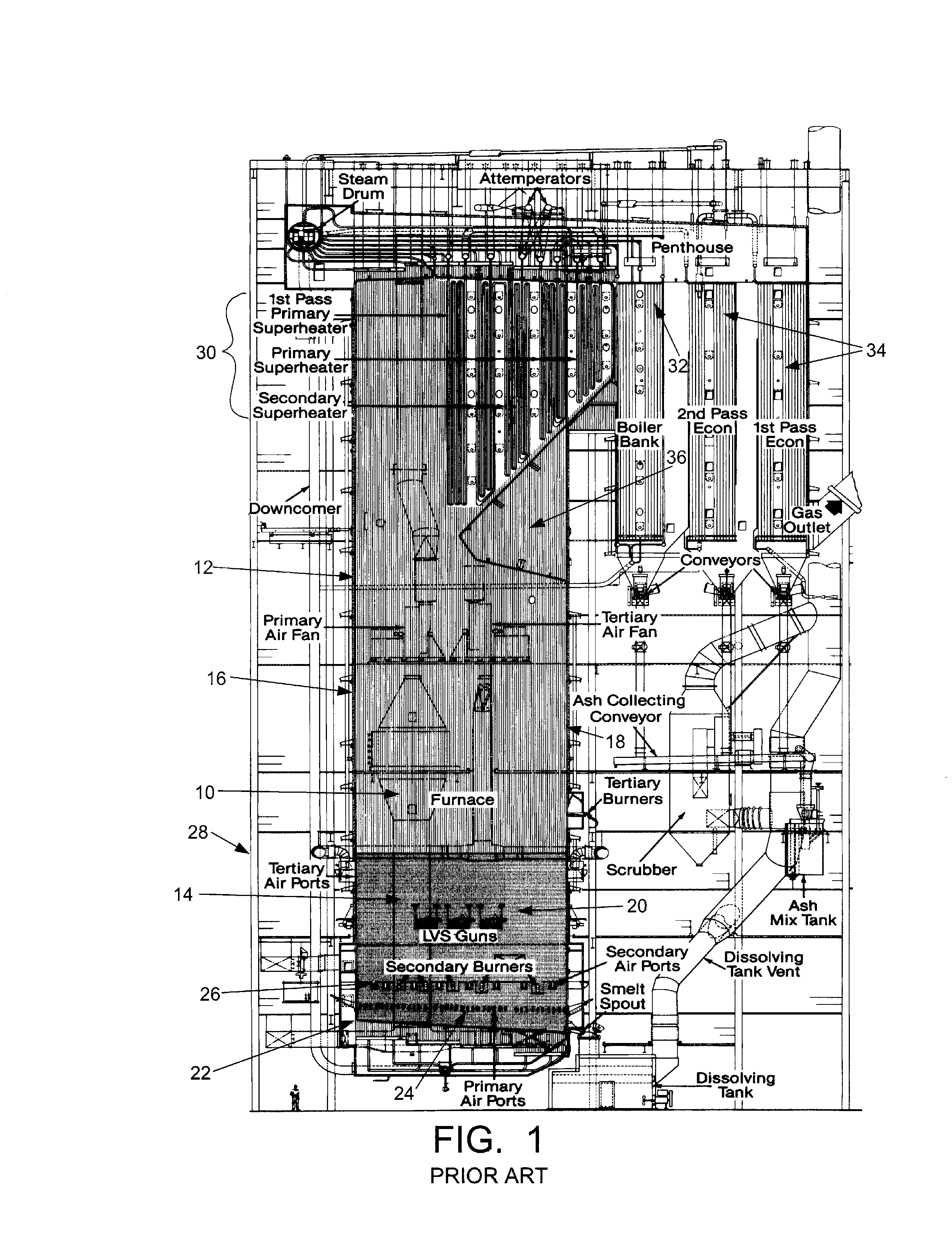

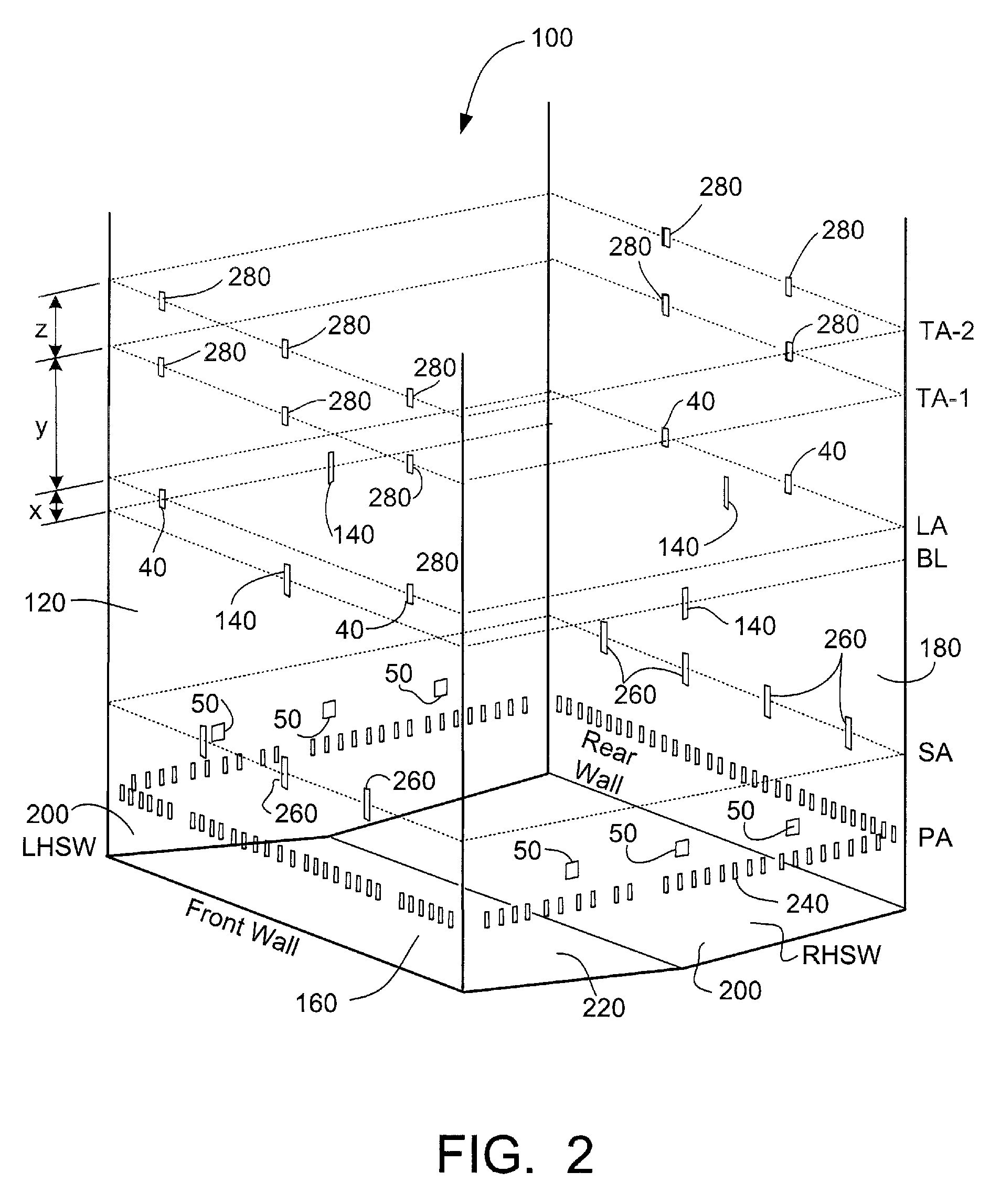

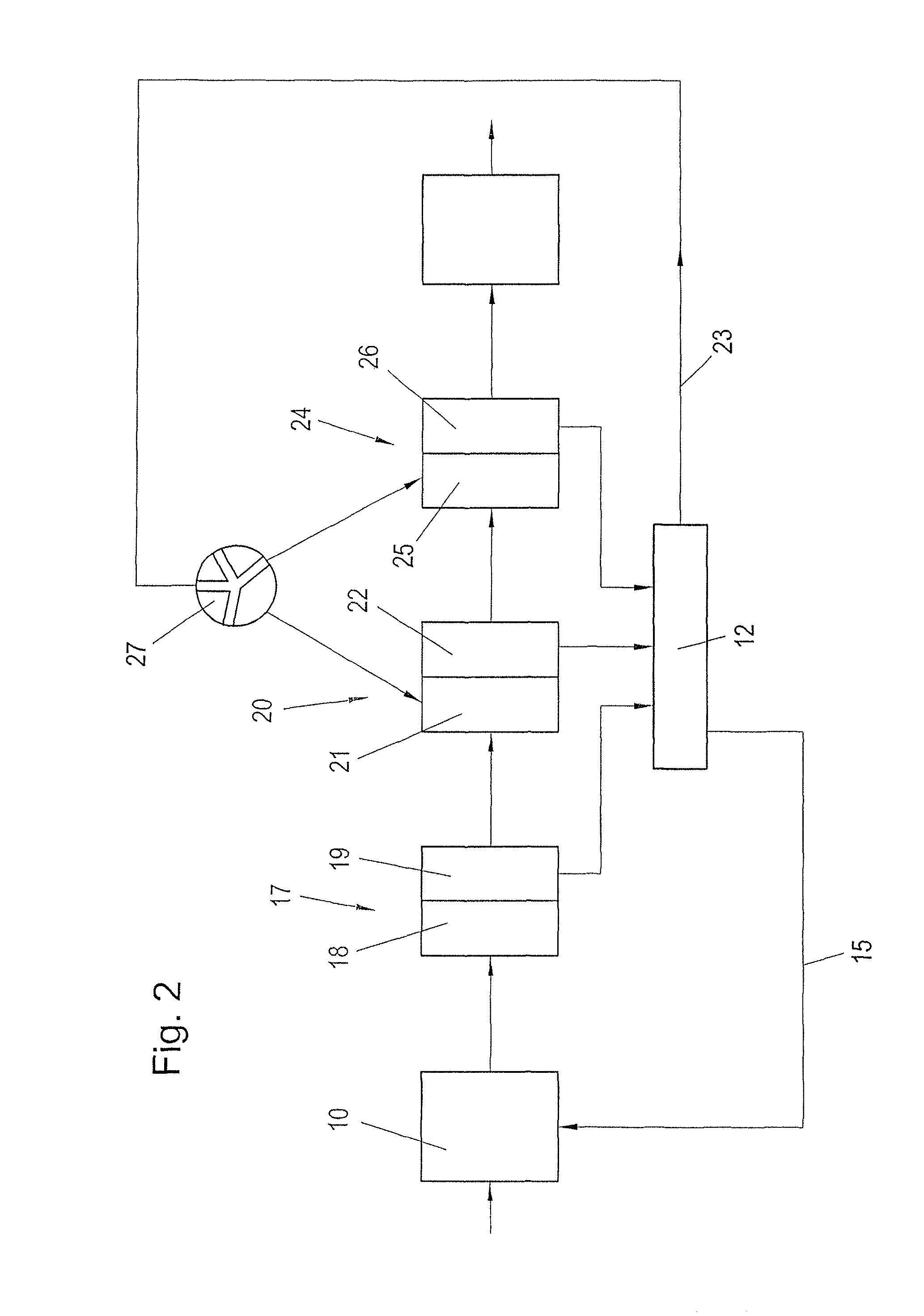

Recovery boiler combustion air system with intermediate air ports vertically aligned with multiple levels of tertiary air ports

ActiveUS20080236459A1Reduce particle residueQuick mixPulp liquors combustionCasings/liningsBlack liquorKraft process

A combustion air system particularly useful for Kraft process recovery boilers or soda process recovery boilers has a level of liquor air ports located above the black liquor guns, and multiple levels of tertiary air formed by substantially vertically aligned tertiary air ports located above the black liquor guns. The liquor air ports and the tertiary air ports are on the same opposing walls of the furnace and are substantially vertically aligned with air ports in the same wall at different levels. The liquor air ports are located just above the black liquor guns, within a range of about ½ foot to about four feet. The tertiary air ports are laterally offset with respect to the tertiary air ports on the opposing wall of the furnace. The first tertiary air level is located a vertical distance in the range of about four feet to twelve feet above the elevation of liquor air ports, and the second and any additional tertiary air levels are located and spaced from an adjacent tertiary air level at regular spaced vertical intervals in the range of about four feet to eight feet. The vertically aligned and laterally offset tertiary air ports form a combustion air pattern of vertical sheets which travel across the width of the furnace to the opposing wall to carry smaller liquor particles to the walls of the furnace and reduce carryover and improve combustion efficiency.

Owner:THE BABCOCK & WILCOX CO

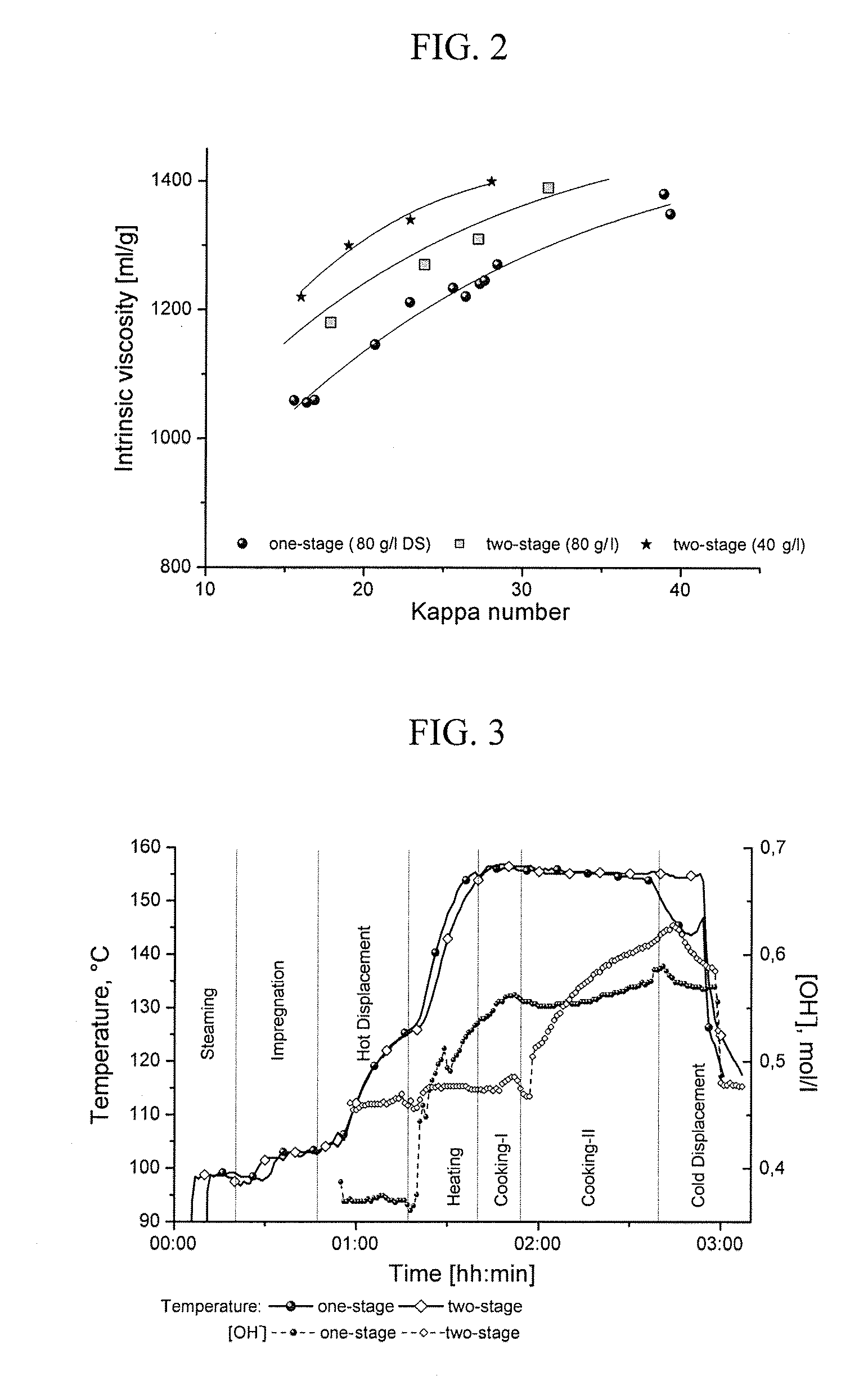

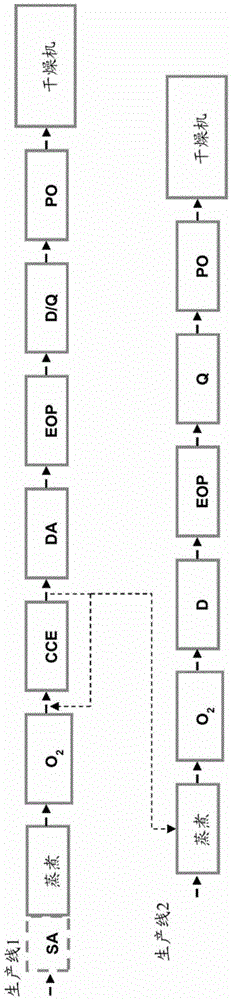

New process and a dissolving pulp manufactured by the process

ActiveCN104379833AIncrease win ratePulp properties modificationWashing/displacing pulp-treating liquorsSulfateKraft process

The present document relates to processes for manufacturing pulp and more specifically to improved processes for manufacturing dissolving pulp. The processes have primarily been developed to be used in connection with large scale kraft processes, i.e. they have been designed to be incorporated into a plant. A liquor derivable from the process and comprising xylan, lignin, alkali and water is also disclosed as well as a dissolving pulp produced by the process.

Owner:萨德拉森林业主复合经济公司 +1

Process for producing a pulp

ActiveUS8500956B2Easy to solvePretreatment with water/steamNon-fibrous pulp additionKraft processSulfate

The invention relates to a process for producing a dissolving pulp from a cellulosic starting material using the kraft process, comprising the step of cooking the starting material with a cooking liquor. The process according to the invention characterized in that the starting material is exposed to a steam treatment prior to cooking and that the pulp obtained by cooking is subjected to cold caustic extraction (CCE) in the course of further processing.

Owner:LENZING AG

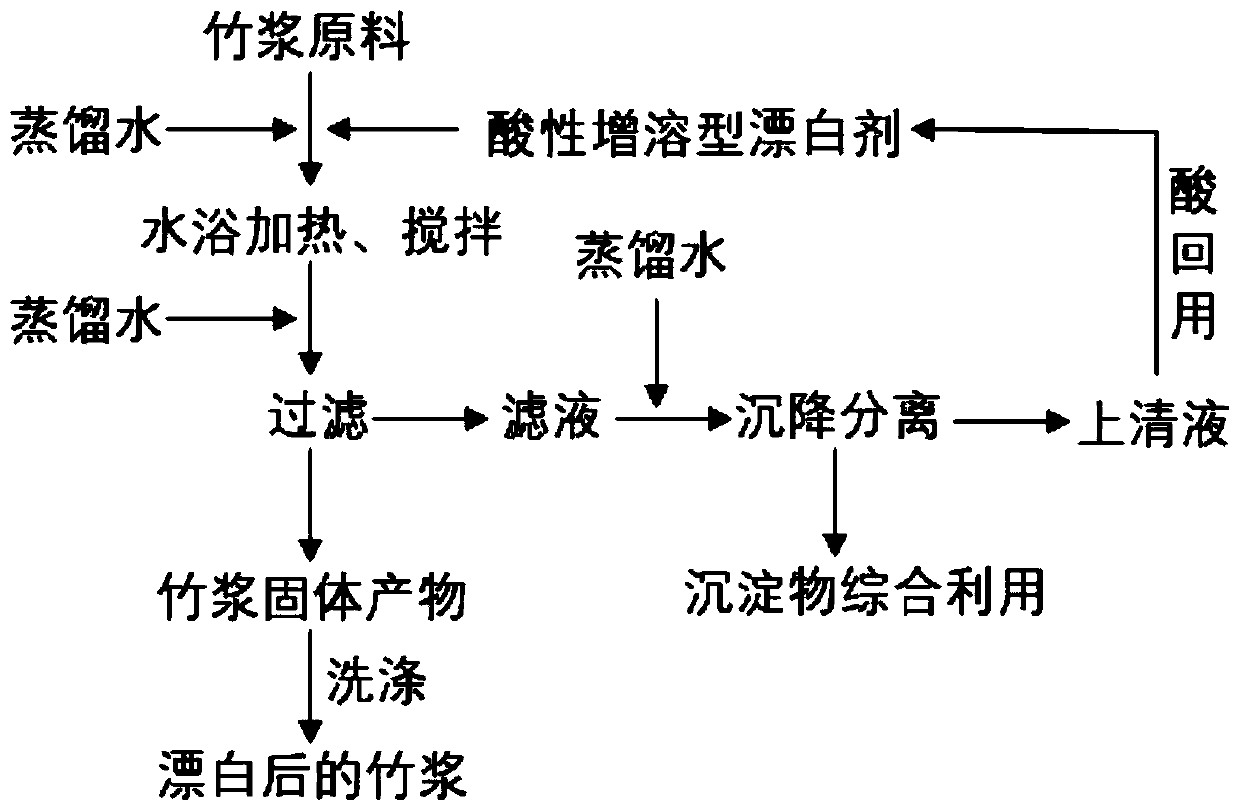

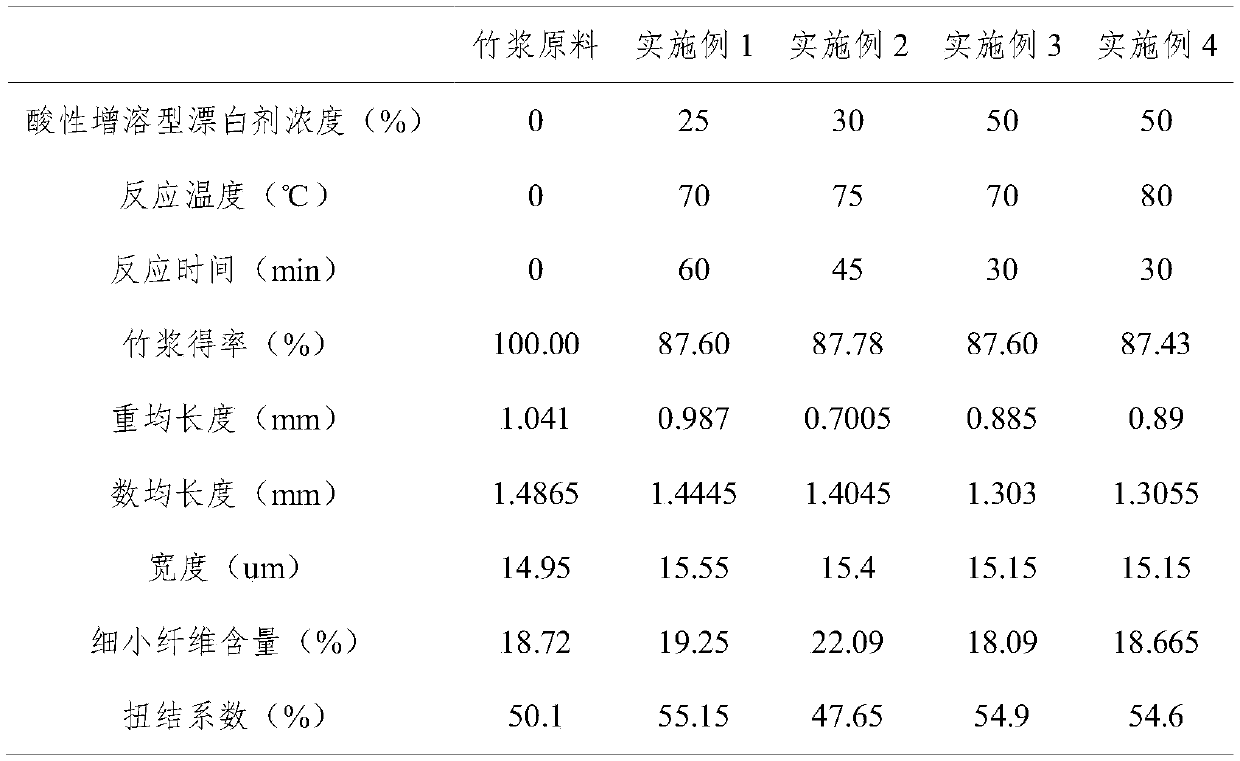

Method for bleaching bamboo pulp

InactiveCN110894696AHigh whitenessGet rid of the co-action dependency problemPulp bleachingChemical/chemomechanical pulpFiberKraft process

The invention provides a method for bleaching bamboo pulp. The method comprises the step of treating sulfate-process unbleached bamboo pulp used as a raw material by using an acidic solubilizing bleaching agent so as to obtain bleached bamboo pulp. As the treated bamboo pulp is subjected to a papermaking process, it is found that when the acidic solubilizing bleaching agent has a medium or low concentration, paper with good performance can be obtained. The method is free of chlorine addition, does not need a high-pressure environment, is good in bleaching selectivity and little in fiber damage; the acidic solubilizing bleaching agent adopted in experiments can be efficiently recycled and repeatedly used through a crystallization technology, so production cost is further reduced; and the method has good application prospects in the field of bamboo pulp bleaching.

Owner:NANJING FORESTRY UNIV

Preparation method of industrial hemp full stalk bleaching chemical pulp

ActiveCN102644211AReduce wasteImprove the shortagePulp bleachingPulping with inorganic basesKraft processWater chlorination

The invention provides a preparation method of industrial hemp full stalk bleaching chemical pulp, comprising the following steps of: cutting hemp stalk into small sections, pulping by a sulfate cooking method, sequentially washing, beating, screening pulp, dehydrating and chloridizing, carting out hydrogen peroxide-enhanced alkali treatment on chloridized pulp, carrying out medium / thick pypocholoride bleaching on the alkali-treated pulp by pypocholoride bleaching liquor, and carrying out medium / thick hydrogen peroxide complementary bleaching on the obtained bleaching pulp by hydrogen peroxide bleaching liquor, to finally obtain the hemp full stalk pulp bleaching chemical pulp. The invention provides a method for preparing the bleaching chemical pulp by directly using the industrial hemp full stalk, so that t the pulp is directly prepared from the hemp full stalk, the foundation for realizing the large-scale development of the preparation of the industrial hemp pulp can be laid, and the improvement of the ecological environment can be further importantly pushed and promoted.

Owner:YUNNAN JUHENG TECH

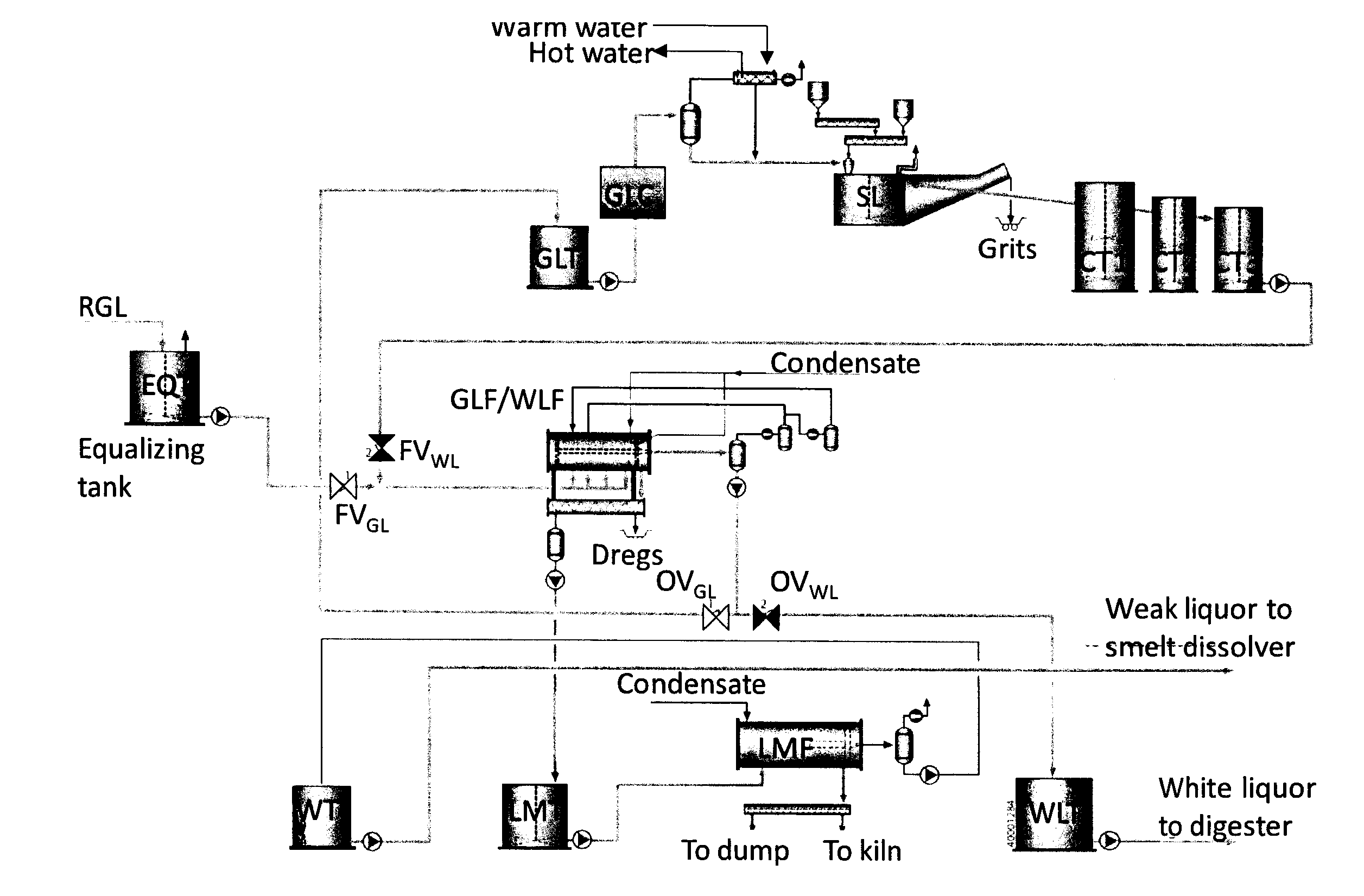

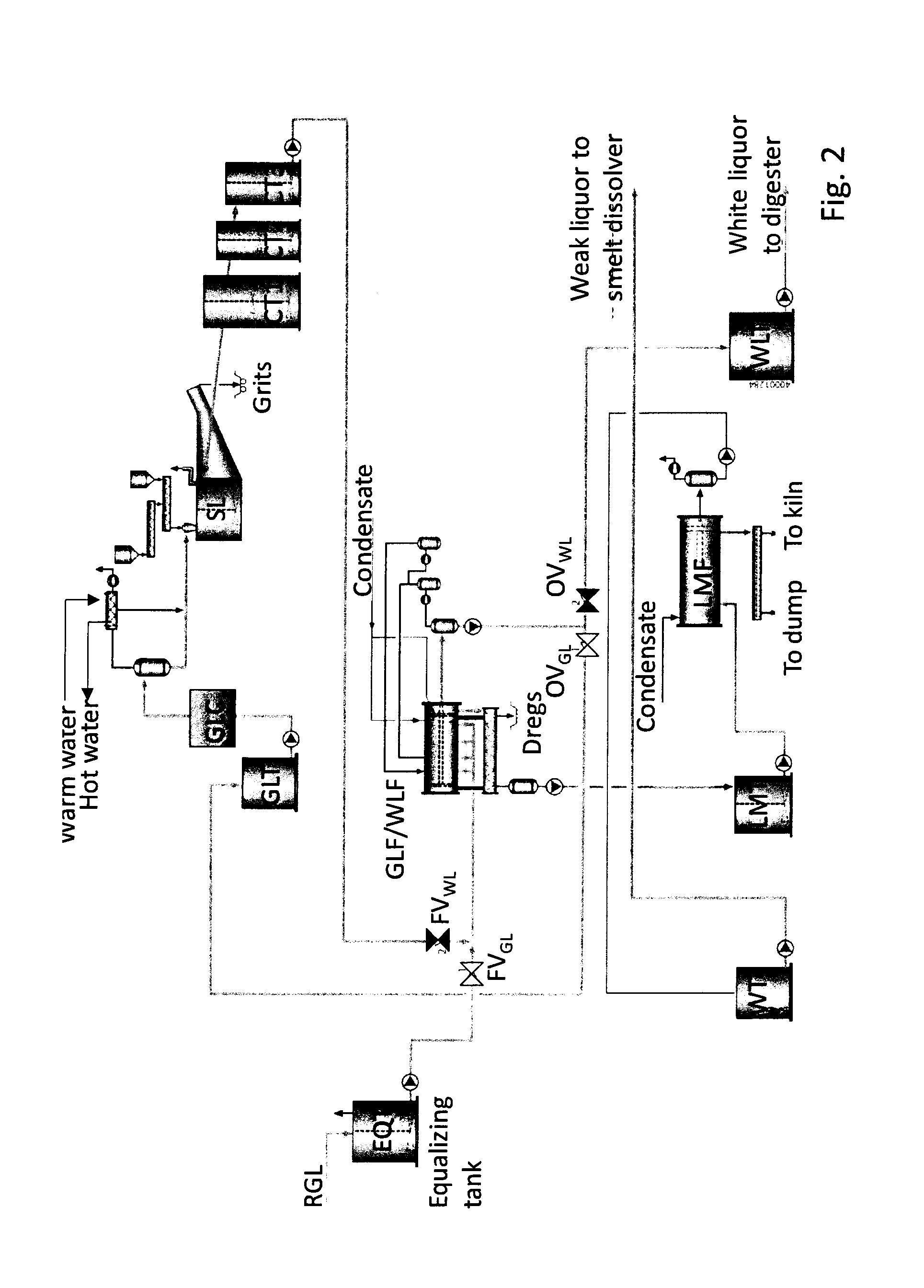

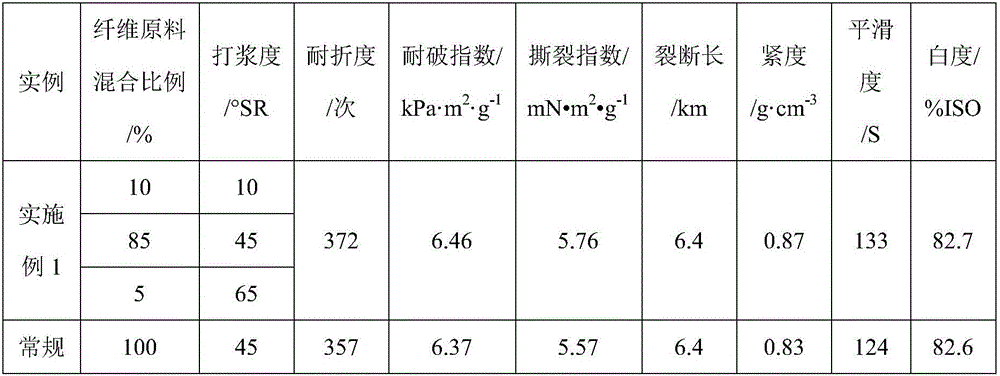

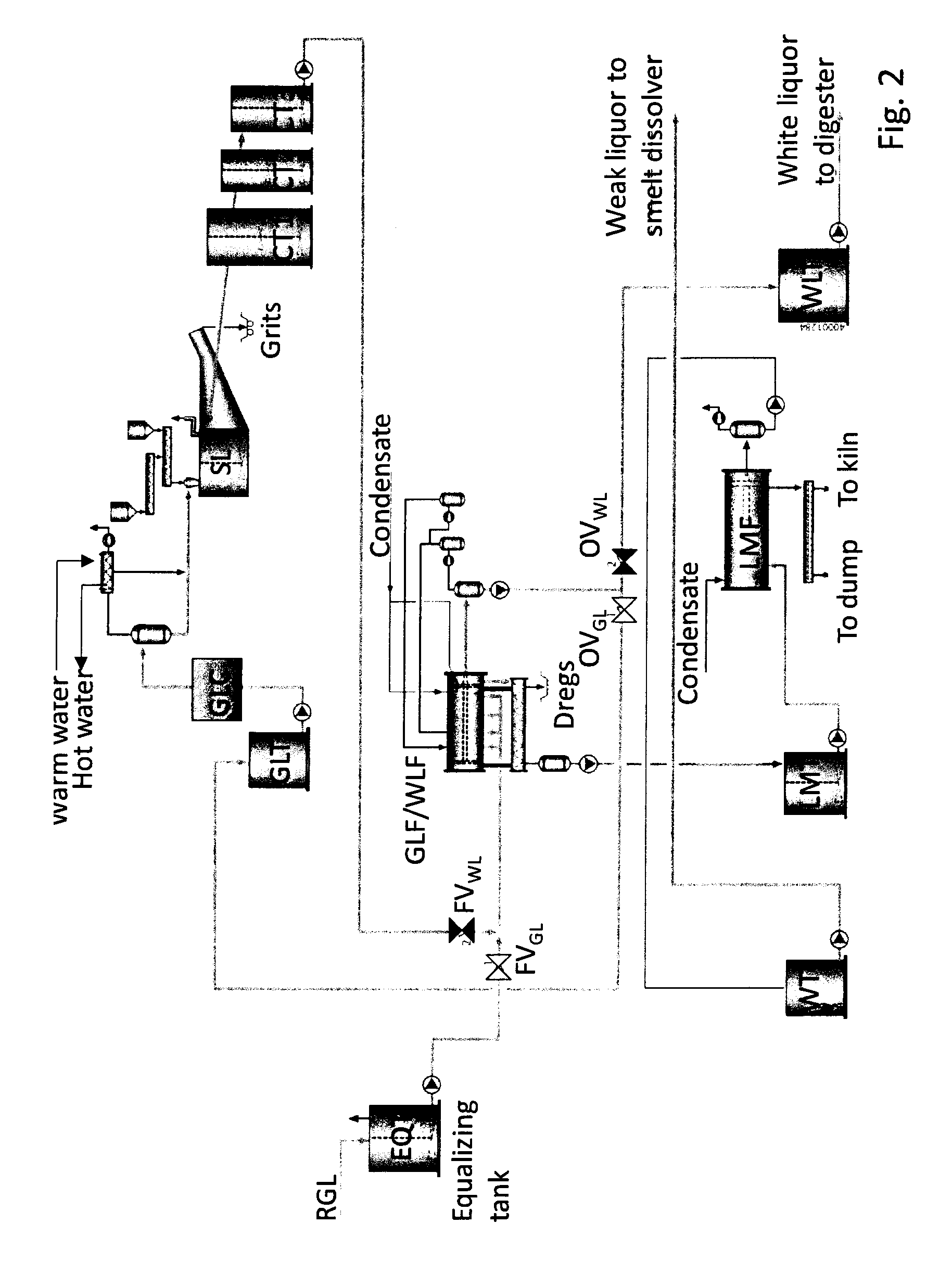

Method for the causticizing process for producing white liquor

ActiveUS20140374039A1Efficient processReduce contentPulp liquors combustionPulp by-products recoveryWhite liquorKraft process

The method is for preparation of white liquor in a chemical recovery process of the kraft process. The green liquor separation process and the white liquor separation process are taking place in the same common filter apparatus with no dedicated green liquor separation apparatus or any dedicated white liquor separation apparatus. The white liquor separation process and the green liquor separation process are conducted in sequence in the same filter apparatus. The white liquor separation process has a part of the cycle time in the range 20-50% of the total cycle time in the same filter apparatus.

Owner:VALMET AB

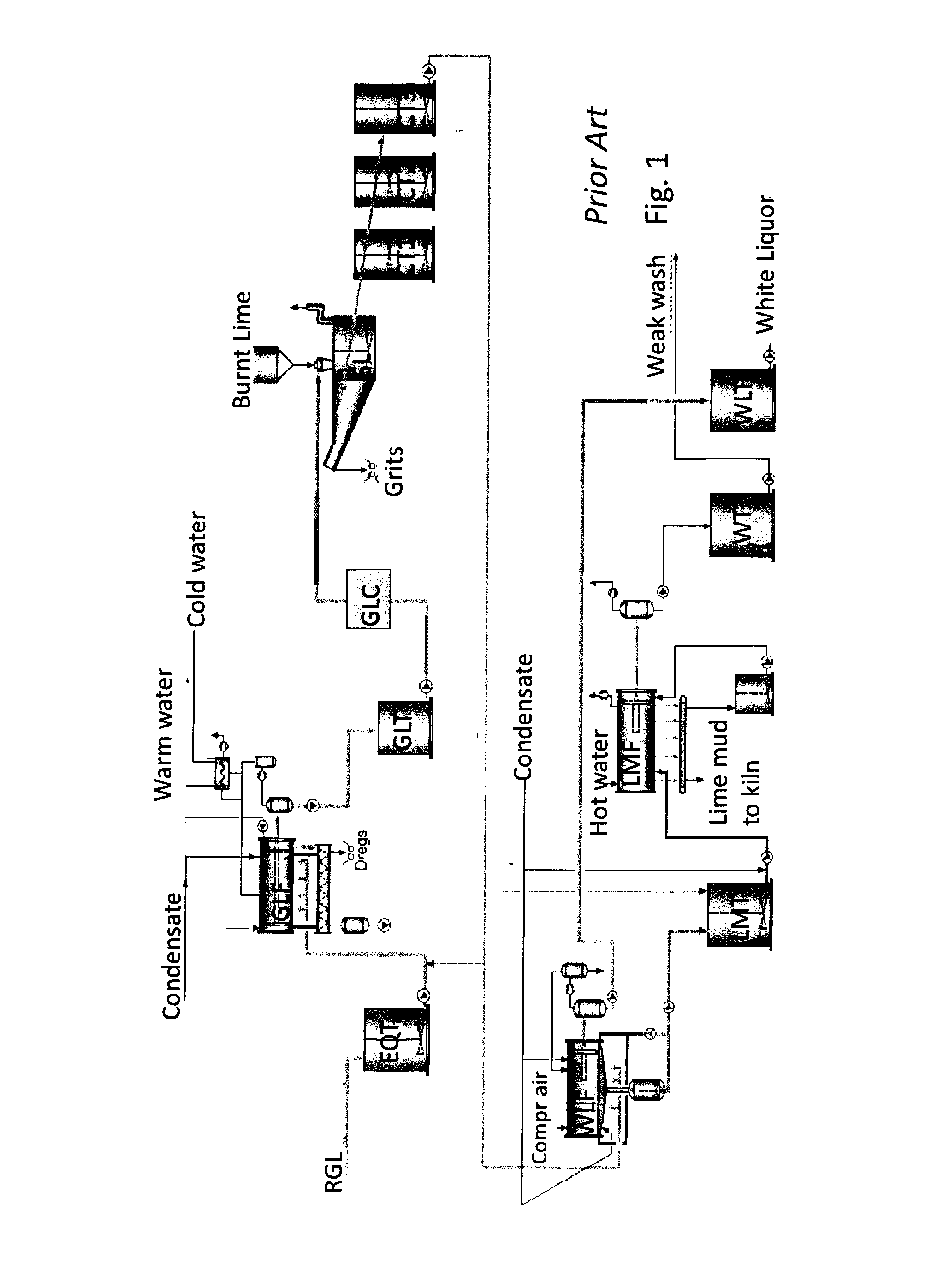

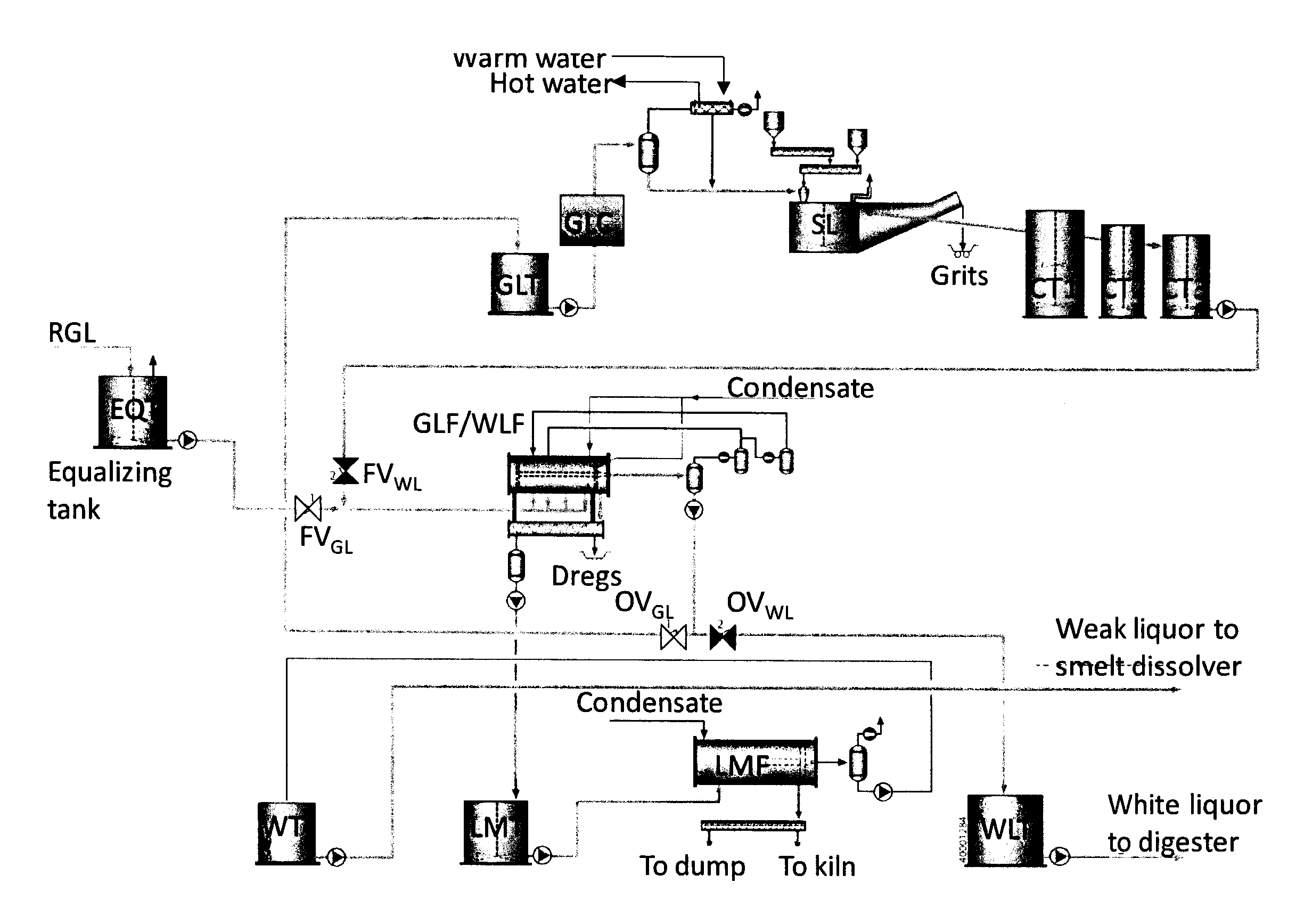

Process for recausticizing green liquor

ActiveUS10011948B2Improve filtering effectHigh crystallinityPulp liquor regenerationLime productionKraft processSulfate

A process for recausticizing green liquor in a sulphate or Kraft process for wood pulp production, in which a green liquor consisting of an aqueous solution of sodium carbonate as the major component and sodium sulphide is admixed with calcium oxide in a slaker and undergoes a reaction in a recausticizer to form an aqueous suspension containing sodium hydroxide and calcium carbonate as the major components, which suspension is filtered on a first filter and subsequently, after dilution with water in a dilution vessel, is fed over further filters two or three times and filtered to separate solids suspended therein, characterized in that after a first separation of calcium carbonate as the major component and calcium oxide as the minor component, carbon dioxide is added to the aqueous suspension at least during dilution in a dilution vessel and in particular in the dilution vessel (s) upstream of a second and / or a third filter.

Owner:MONDI GROUP

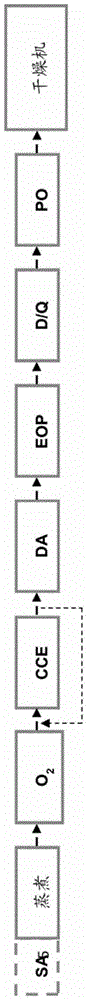

Method for preparing dissolving pulp by tcf bleaching of poplar kp

ActiveUS20210062420A1Quality improvementSolve the real problemPretreatment with water/steamPulp bleachingKraft processPulp and paper industry

The present application relates to a method for preparing dissolving pulp by TCF bleaching of poplar KP, including: preparing poplar KP by pre-hydrolysis kraft process with poplar as a raw material, and OZQP bleaching of the poplar KP to obtain dissolving pulp, wherein O denotes oxygen delignification, Z denotes ozone bleaching, Q denotes chelating treatment, and P denotes hydrogen peroxide bleaching. The dissolving pulp prepared by the same exhibits that all indexes can meet the requirements of excellent products in dissolving pulp industry standard (QB / T4898-2015), and most of the indexes are far superior to those of excellent products, and thus it can completely replace imported dissolving pulp.

Owner:QILU UNIV OF TECH

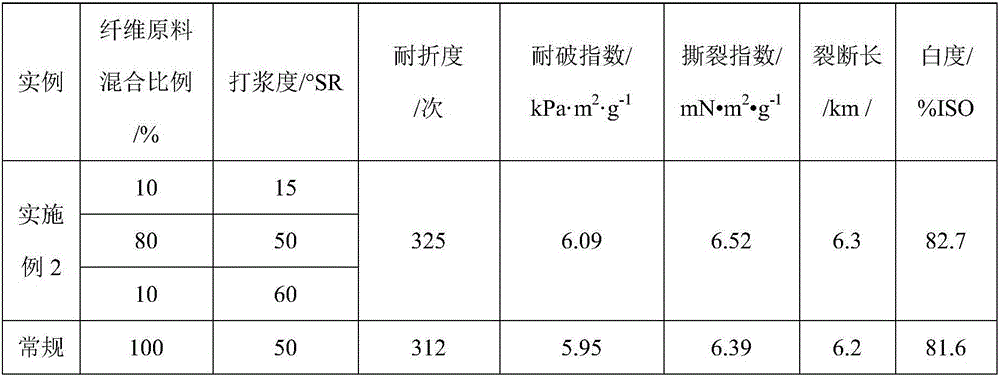

Method for preparing paper base by using needle and broad leaf-mixed sulfate elemental chlorine-free bleached chemical pulp

ActiveCN106676928AHigh tensile strengthImprove tightnessWashing/displacing pulp-treating liquorsPulp bleachingSulfatePaper based

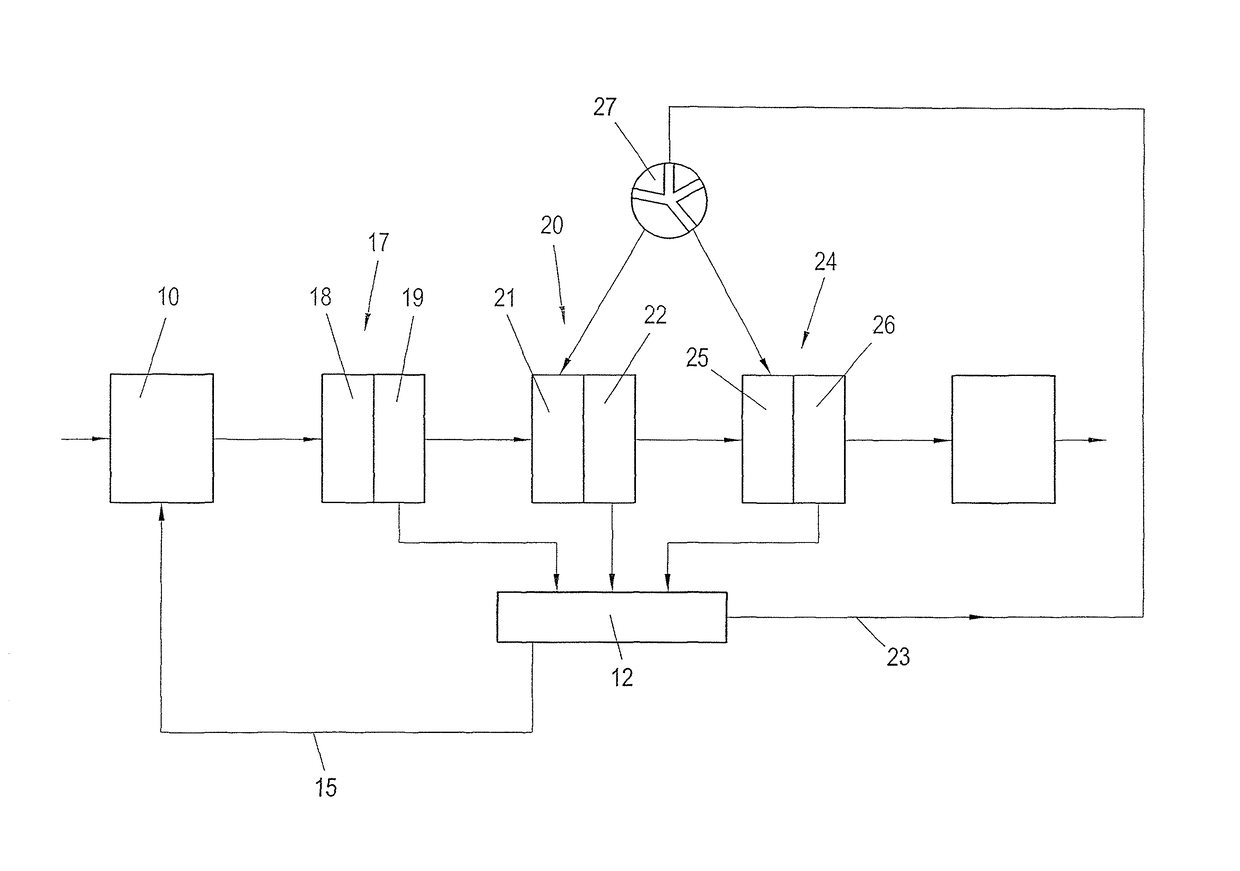

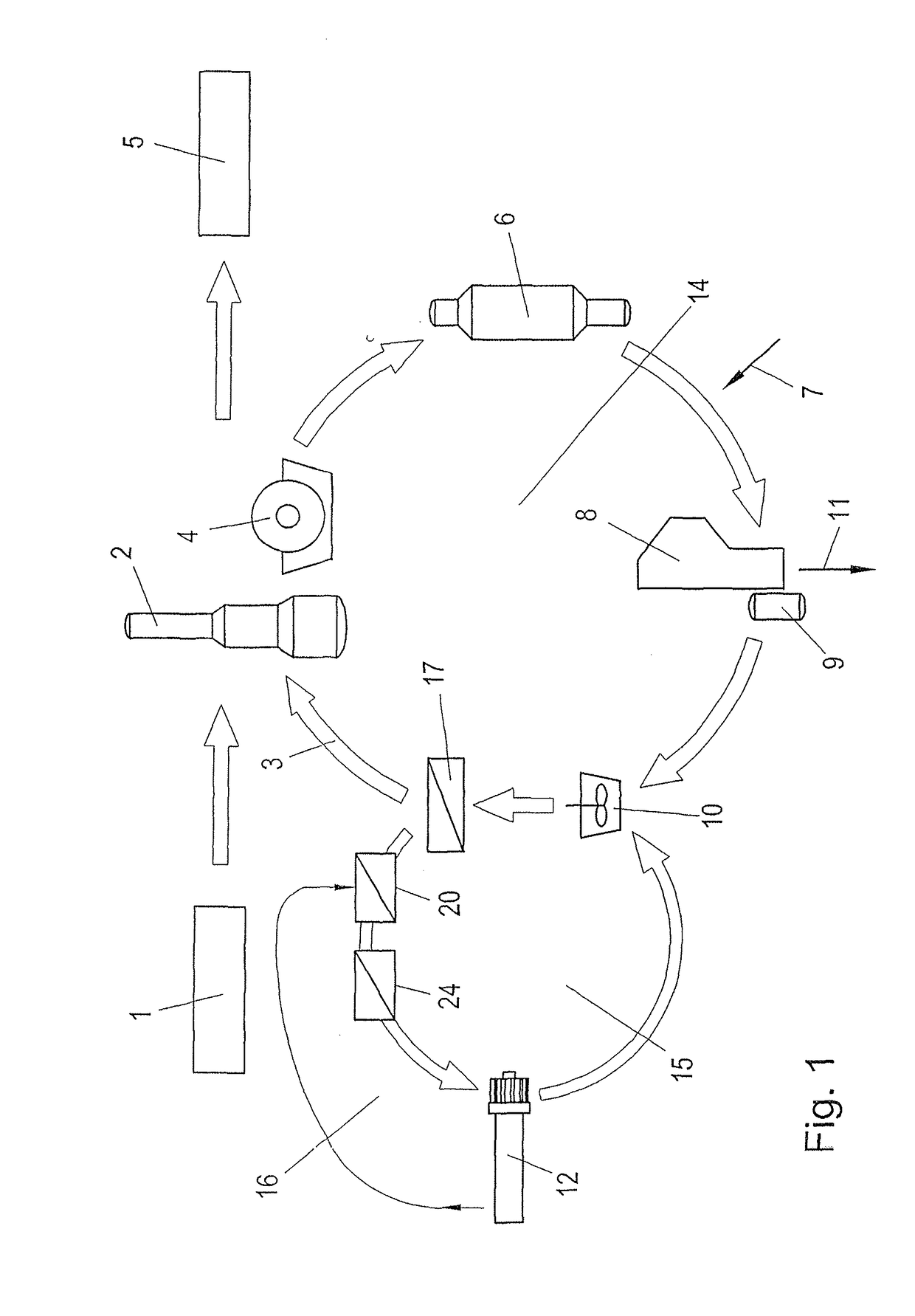

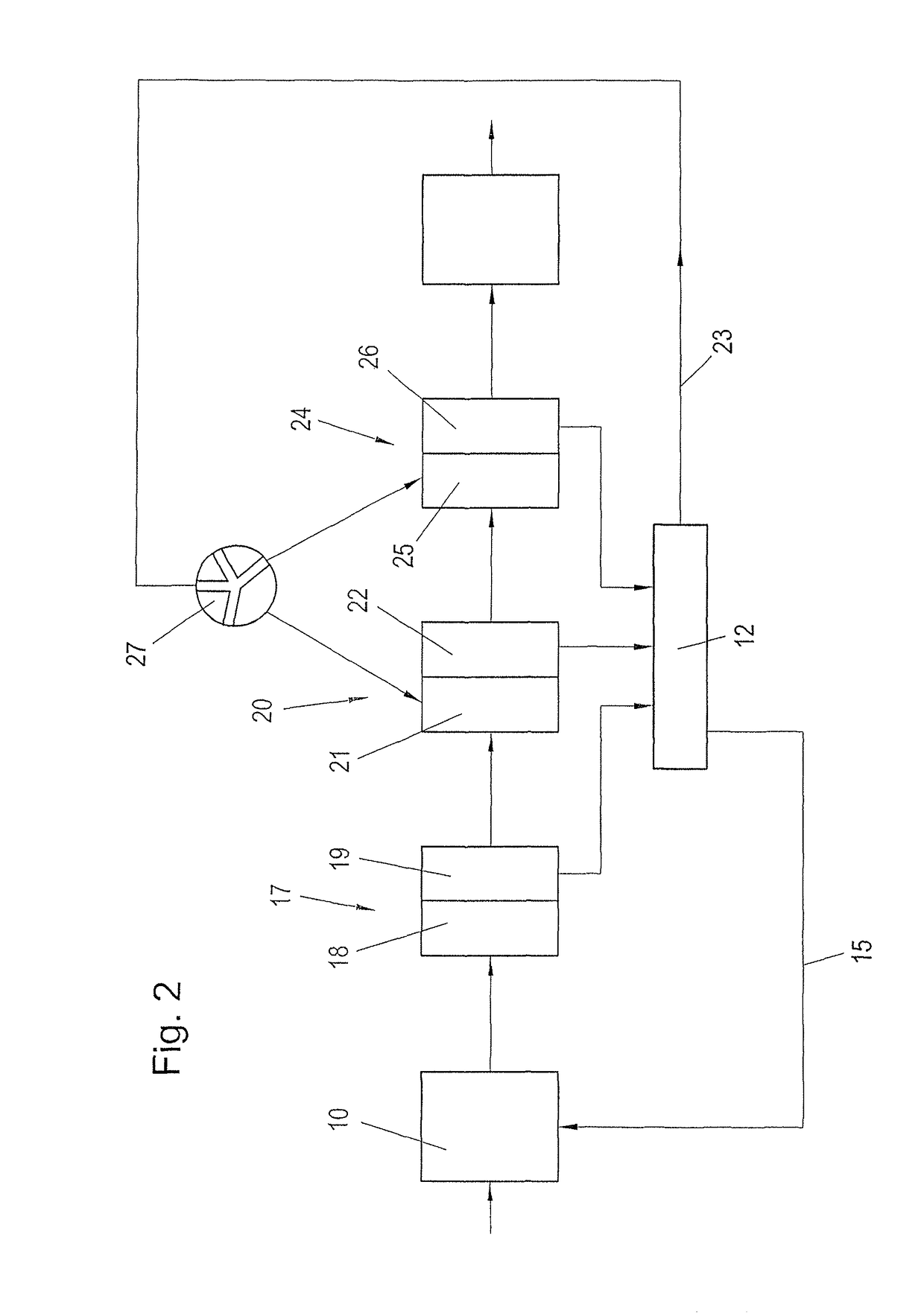

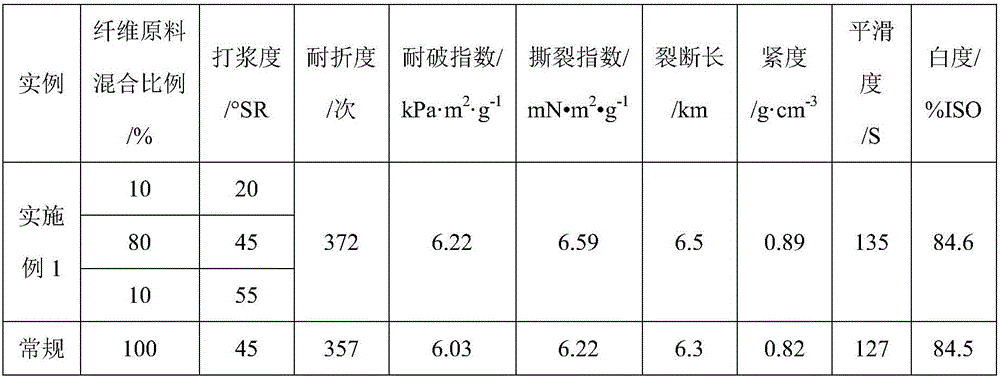

The invention discloses a method for preparing paper base by using needle and broad leaf-mixed sulfate elemental chlorine-free bleached chemical pulp. The method comprises the following steps: (1) cooking by using a sulfate digestion method to obtain needle and broad leaf-mixed pulp as a pulp raw material, dividing the obtained needle and broad leaf-mixed pulp into three parts, and respectively pulping the three parts of pulp, wherein the beating degree of the first part of pulp is 10-20 degrees SR, the beating degree of the second part of pulp is 45-50 degrees SR, and the beating degree of the third part of pulp is 55-65 degrees SR; (2) mixing the three parts of pulp prepared in the step (1) together according to a certain proportion to obtain mixed pulp, wherein the mass ratio of the first part of pulp to the second part of pulp to the third part of pulp in the mixed pulp is equal to (10-20) to (60-85) to (5-10); (3) molding the mixed pulp obtained in the step (2) by lifting or pressing to obtain a paper base material.

Owner:QILU UNIV OF TECH

Method for the causticizing process for producing white liquor

ActiveUS9187863B2Reduce contentImprove drynessPulp by-products recoveryPulping with inorganic basesWhite liquorKraft process

Owner:VALMET AB

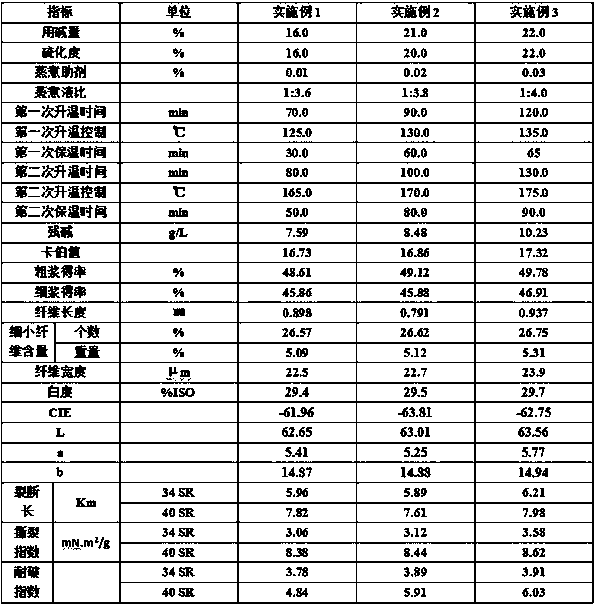

Method for preparing unbleached pulp from sugarcane bagasse

ActiveCN105297515AHigh pulping yieldQuality improvementPulp beating/refining methodsAnthraquinonesFiber

The invention discloses a method for preparing unbleached pulp from sugarcane bagasse. The method comprises the following steps of firstly, feeding the sugarcane bagasse subjected to impurity removal into a digester, and counted by oven dry weight of the sugarcane bagasse, adding 0.8 to 1 percent of Na5P3O, 10.2 to 2.5 percent of Na2SO3, 1.5 to 2 percent of KOH and 0.2 to 0.3 percent of anthraquinone, and cooking at the temperature of 130 to 135DEG C for 55 to 60 minutes; secondly, feeding the cooked raw materials into a twin screw refining extruder for performing rubbing and spreading to obtain coarse pulp; thirdly, washing the coarse pulp to obtain sugarcane bagasse unbleached pulp. Compared with traditional alkaline method and sulfate method, the method disclosed by the invention has the advantages that the pulping yield can reach 65 to 70 percent, the average length of fibers is 1.26 micrometers, the length-width ratio is greater, the ratio of BOD (Biochemical Oxygen Demand) / COD (Chemical Oxygen Demand) in sludge can reach about 0.5, a biochemical process is extremely-easily generated, and the pulping cost can be saved by about one third.

Owner:石河子市国力源环保制浆有限公司

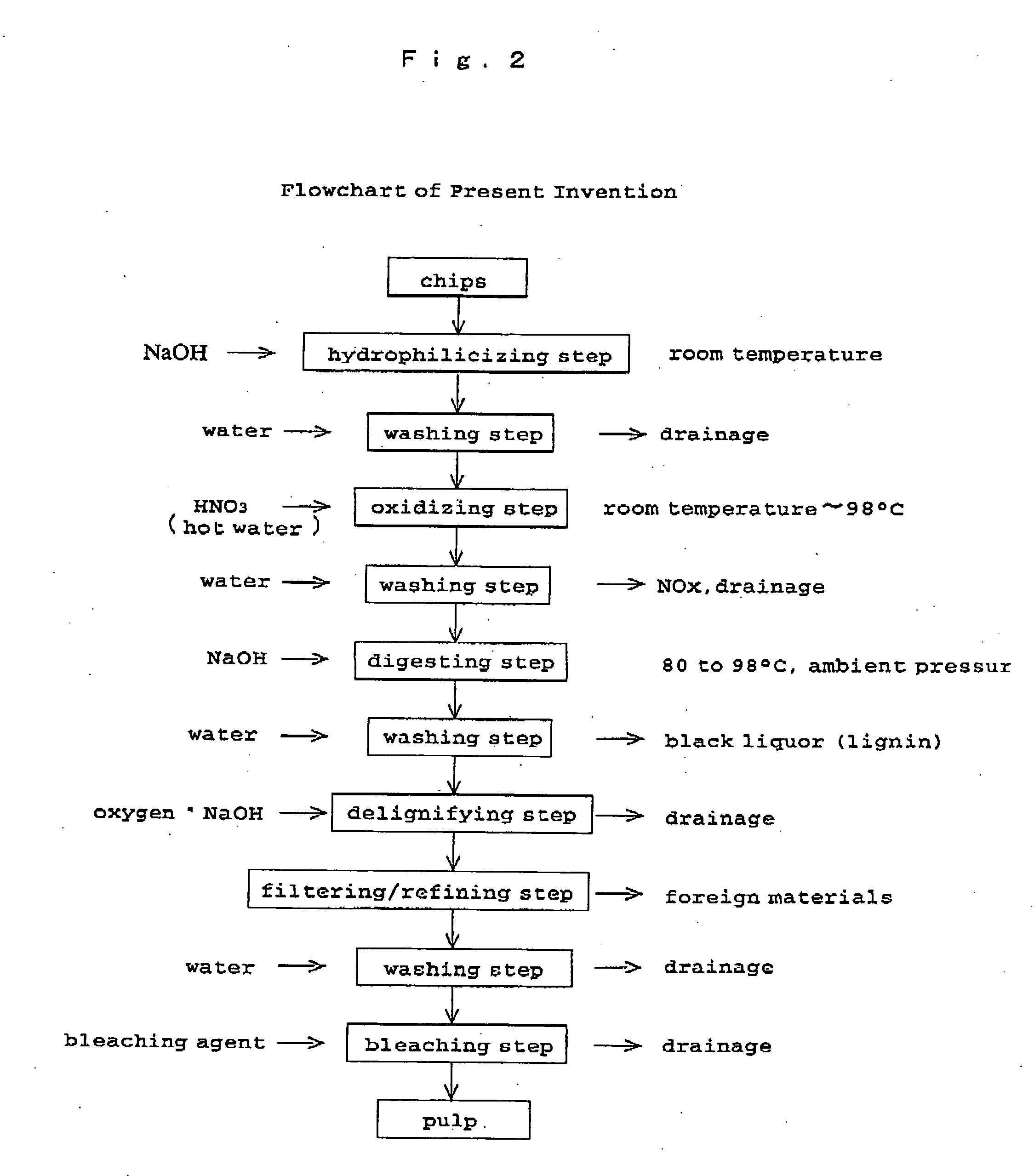

Method for production of pulp

InactiveUS20100175841A1Reduce water consumptionHigh yieldPretreatment with alkaline reacting compoundsWashing/displacing pulp-treating liquorsBlack liquorKraft process

A pulp production process can produce pulp at high yield without using sodium sulfide and high-temperature / high-pressure conditions if compared with the Kraft process and also collect lignin. Pulp is produced by processing wood chips for hydrophlicization at room temperature, using a dilute caustic soda aqueous solution, selectively partially modifying lignin in dilute nitric acid and digesting the wood chips by means of a dilute caustic soda aqueous solution under the atmospheric pressure. Lignin is agglomerated and sorted out from the isolated black liquor.

Owner:NIHON CELLULOSE CO LTD +1

Method for preparing fluff pulp from bamboos and fluff pulp prepared by method

ActiveCN114687234ASolve the current situation of dependence on importsIncrease added valuePaper recyclingPulp bleachingBlack liquorKraft process

The invention discloses a method for preparing fluff pulp from bamboos and the fluff pulp prepared by the method. The method comprises the following steps: treating bamboos with concentrated alkali at a relatively mild temperature for a certain period of time, replacing a treating fluid with dilute black liquor, separating hemicelluloses by using the treating fluid, cooking the treated bamboos by using a sulfate process to obtain unbleached bamboo pulp, screening coarse residues from the unbleached bamboo pulp by using a slotted screen, screening impurity cells from the unbleached bamboo pulp by using a microporous screen, and drying the unbleached bamboo pulp to obtain the bamboo pulp. And carrying out two-stage oxygen delignification on the screened pulp, and then carrying out ECF bleaching treatment with the flow of D0EpD1P to finally obtain the bamboo fluff pulp which is high in whiteness, low in DCM extract content, low in ash content, longer in fiber length, 4.2-4.6 million in fiber number per gram of paper pulp and higher in bulk.

Owner:SOUTH CHINA UNIV OF TECH

A kind of method that utilizes bamboo pulp to produce high penetrability paper sack paper

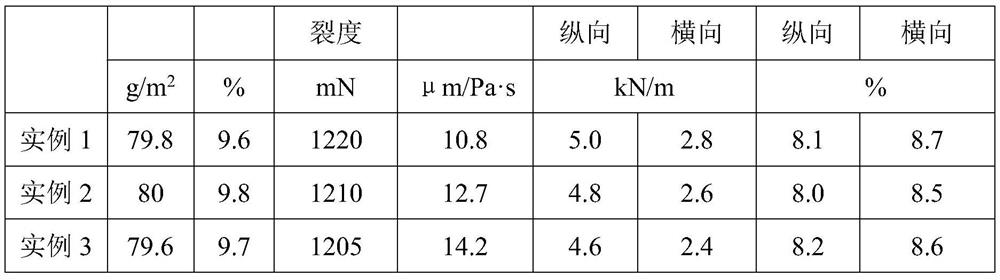

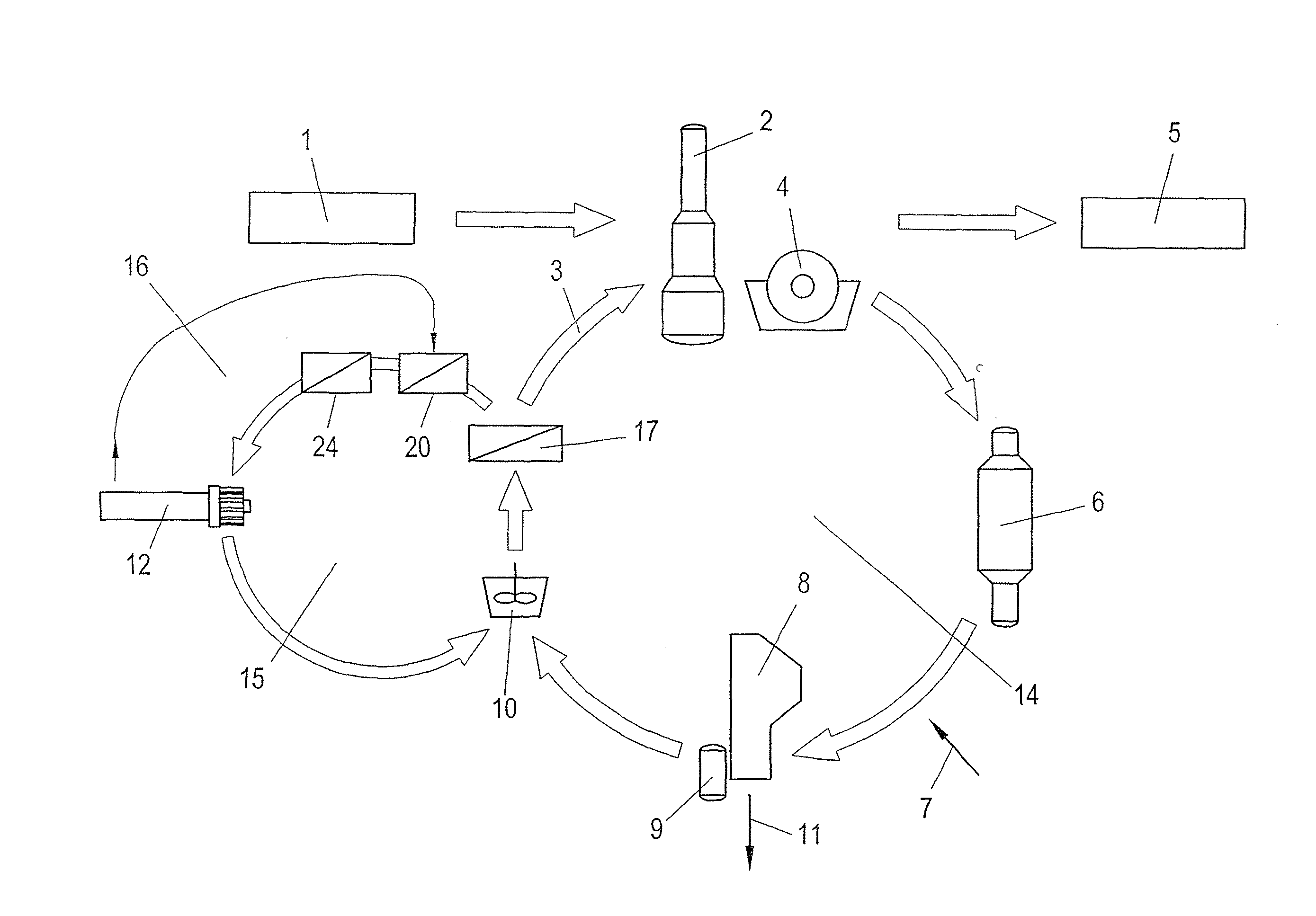

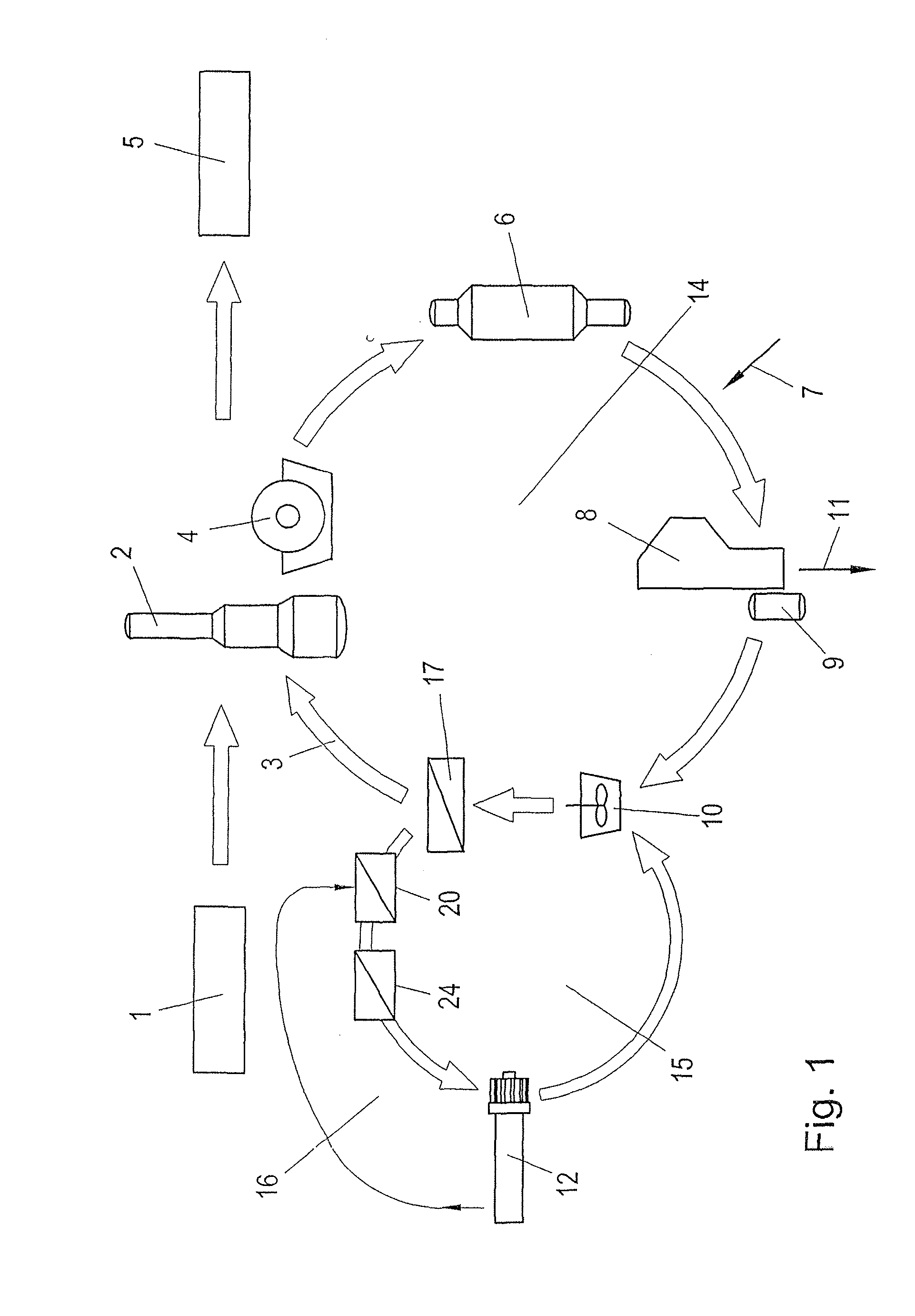

The invention discloses a method for producing high-stretch paper bag paper by using bamboo pulp, which is concentrated by a vacuum concentrator for pulp, high-consistency refining, low-consistency disc refiner, sand removal by flow, and pulp screening by pressure sieve. Floating sheet type headbox is formed on the Internet, pressed by four rollers and three nips, dried, coiled, rewinded, and packaged. Specifically, bamboo chips and coniferous wood chips are mixed, and then pulped by kraft method. The pulp obtained after washing and screening is subjected to high-consistency beating to maintain the length of the fiber, and then subjected to low-consistency beating, then adding auxiliary materials, pressure sieve pulp, netting, and forming on the net, pressing through four-rollers and three-press zones, and then drying Partial drying and extensibility device treatment to obtain paper bag paper. The method of the invention can produce stretchable sack paper with low cost, high physical strength and high air permeability.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

Process for recausticizing green liquor

ActiveUS20160002852A1Improve filtering effectHigh crystallinityPulp liquors combustionLime productionKraft processSulfate

A process for recausticizing green liquor in a sulphate or Kraft process for wood pulp production, in which a green liquor consisting of an aqueous solution of sodium carbonate as the major component and sodium sulphide is admixed with calcium oxide in a slaker and undergoes a reaction in a recausticizer to form an aqueous suspension containing sodium hydroxide and calcium carbonate as the major components, which suspension is filtered on a first filter and subsequently, after dilution with water in a dilution vessel, is fed over further filters two or three times and filtered to separate solids suspended therein, characterized in that after a first separation of calcium carbonate as the major component and calcium oxide as the minor component, carbon dioxide is added to the aqueous suspension at least during dilution in a dilution vessel and in particular in the dilution vessel (s) upstream of a second and / or a third filter.

Owner:MONDI GROUP

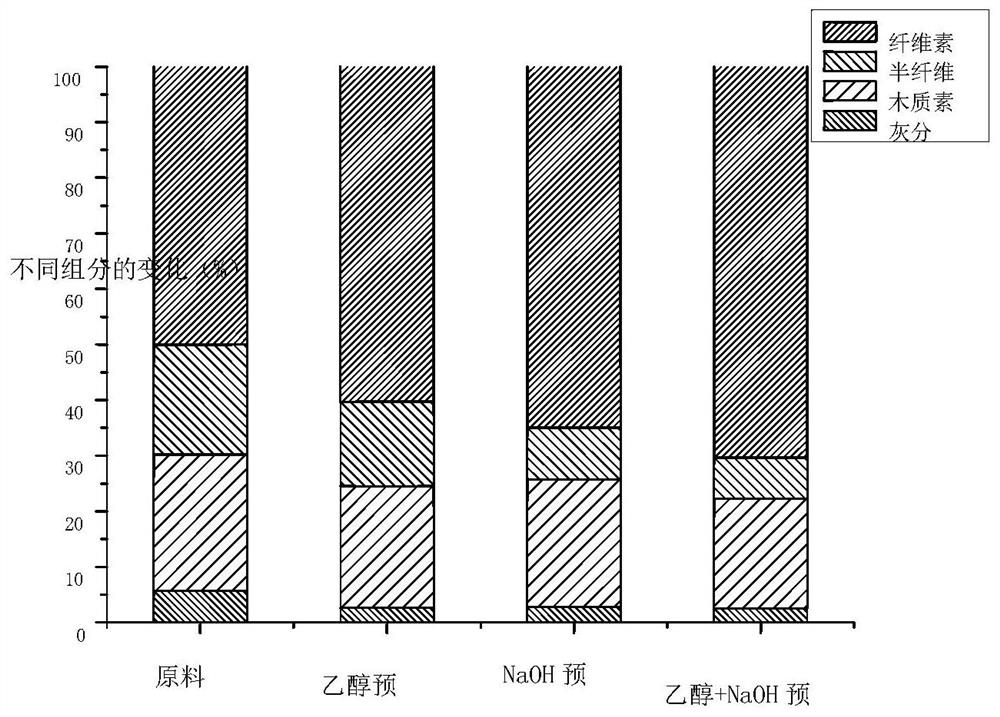

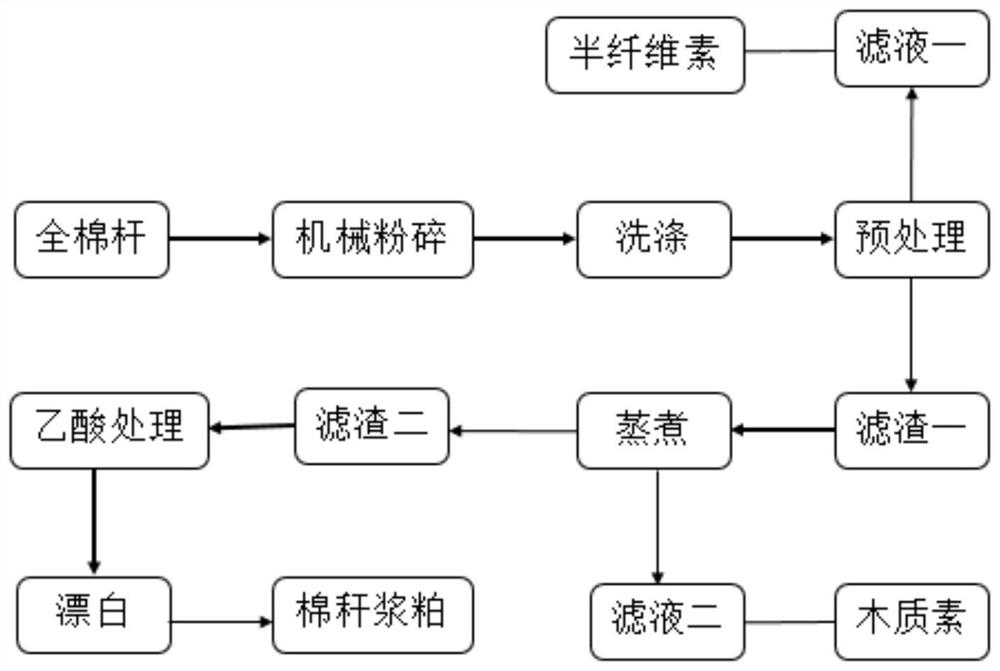

A method for preparing dissolving pulp from whole cotton stalks

ActiveCN108797176BTightly boundIncrease penetration rateWashing/displacing pulp-treating liquorsPulping with inorganic basesInorganic saltsOrganic acid

The invention discloses a method for preparing dissolving pulp from whole cotton stalks. The method comprises the steps of extracting hemicellulose and removing fat and waxy substances through pretreatment with organic alcohol and alkali; removing lignin and pulping through an organic alcohol assisted sulphate cooking method; and carrying out organic acid post-treatment to remove residual ash inorganic salt and the like. The method comprises the following steps: A, pretreating cotton stalks prepared before; B, stewing pretreated cotton stalk pulp by an ethanol-assisted sulfate method; C, carrying out organic acid post-treatment to remove residual ash; D, carrying out chelation treatment and bleaching. The method has the beneficial effects that with the organic alcohol assisted alkali pretreatment, organic alcohol improved sulfate stewing method and organic acid post-treatment process, the reaction conditions are mild, the temperature is low, the time is short and the production efficiency is high; the cotton stalk dissolving pulp has good performance, and the quality requirements of the dissolving pulp for viscose fiber are met; the content of alpha-cellulose is higher than 90%, the content of pentosan is less than 1.39%, and the ash content is less than 0.06%.

Owner:SOUTH CHINA UNIV OF TECH

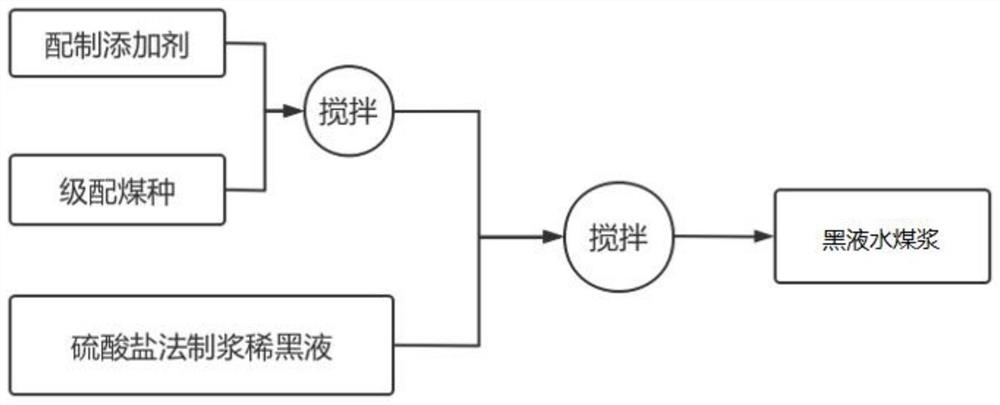

Method for treating sulfate pulping black liquor by using black liquor coal water slurry prepared from dilute black liquor

PendingCN114000370AReduce loadReduce energy consumptionSolid fuelsLiquid carbonaceous fuelsCoal waterBlack liquor

The invention relates to a method for treating sulfate pulping black liquor by using black liquor coal water slurry prepared from dilute black liquor. The method comprises the following steps: preparing black liquor coal water slurry by taking thin black liquor generated by a paper mill as a main raw material, wherein the sulfate-process papermaking black liquor is treated by a coal water slurry process for eliminating high-load organic matter pollution in the black liquor through burning the black liquor coal water slurry; then mixing pulverized coal and an additive, mixing the mixture with papermaking black liquor with the solid content concentration of 10%-20% generated by pulping by a sulfate process according to a mixing ratio (mass ratio) of 1:0.6 to 1:1.7 to prepare the coal water slurry, and burning the black liquor coal water slurry to eliminate high-load organic matter pollution of papermaking wastewater. The method has the characteristics of low investment, high economic practicability, safety in use, energy conservation, emission reduction, simplicity and feasibility in operation and the like, and can be popularized to sulfate-process papermaking enterprises.

Owner:GUANGXI UNIV

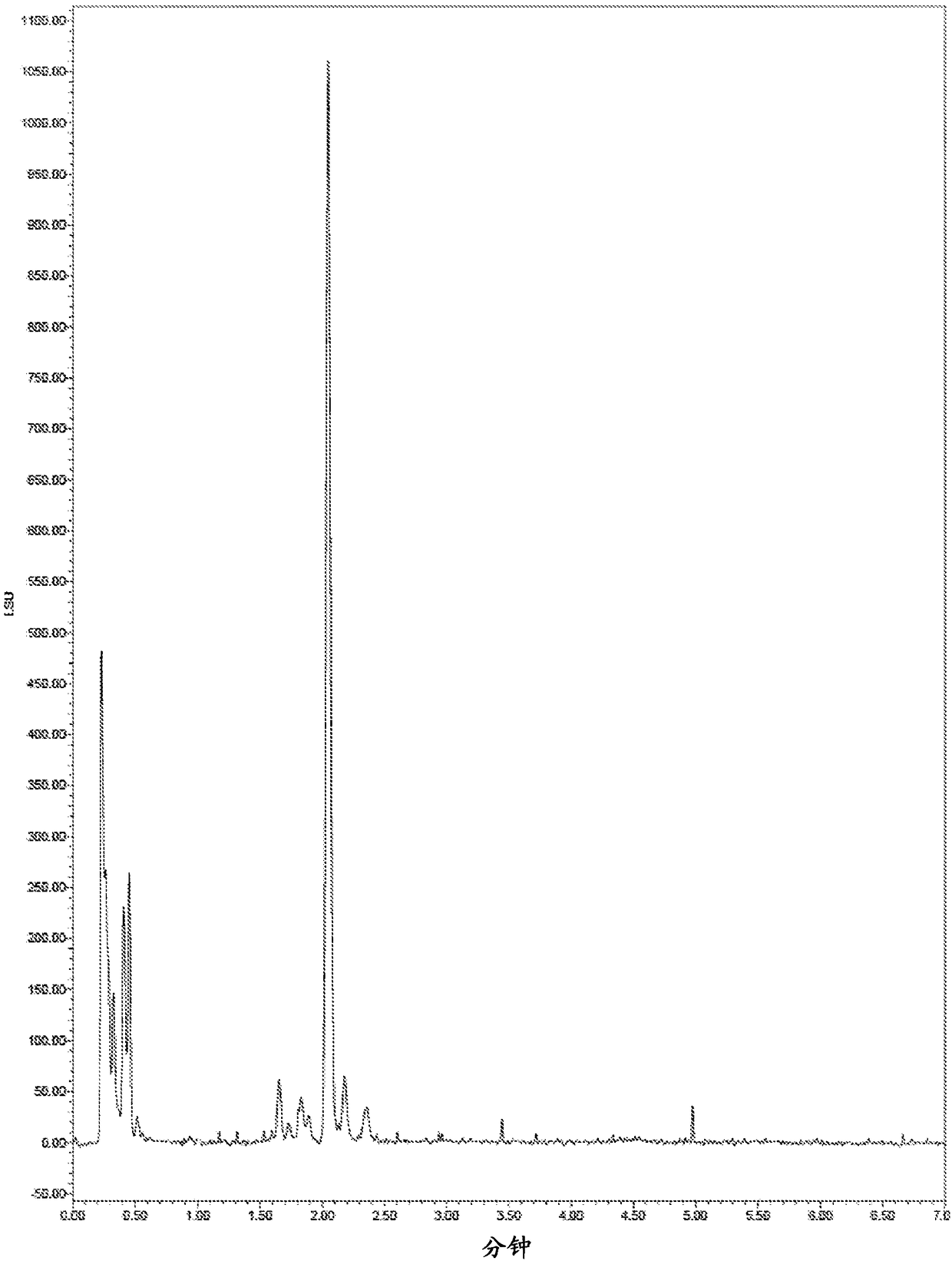

Extraction of phytosterols from tall oil soap using a solvent selected from dibromomethane, bromoform, tetrabromomethane or a combination thereof

The present invention relates to extraction of phytosterolsfrom alkaline tall oil soap which is obtained from the Kraft process black liquor by skimming.In the method according to the present invention, phytosterols are extracted using dibromomethane, bromoform, tetrabromomethaneor a combination thereof.

Owner:STORA ENSO OYJ

Production method of high-yield bamboo pulp

InactiveCN111074661AHigh yieldReduce energy consumptionPulp beating/refining methodsCellulose material pulpingChemical treatmentKraft process

The invention discloses a production method of high-yield bamboo pulp, and relates to the technical field of pulping and papermaking production. In order to solve the technical problems of low yields,high energy consumption, heavy pollution and high costs in the existing sulfate method bamboo pulp production processes, the method comprises the steps of bamboo slicing, bamboo chip screening, bamboo chip washing, bamboo chip dipping, extrusion treatment, chemical treatment, high-concentration pulping and latency elimination treatment. By adopting the method for pulping, high-temperature and high-pressure conditions are not needed, so that the production process is low in energy consumption and light in pollution, and meanwhile, the method has the advantages of high paper pulp yield and lowcost.

Owner:SICHUAN TECH & BUSINESS COLLEGE

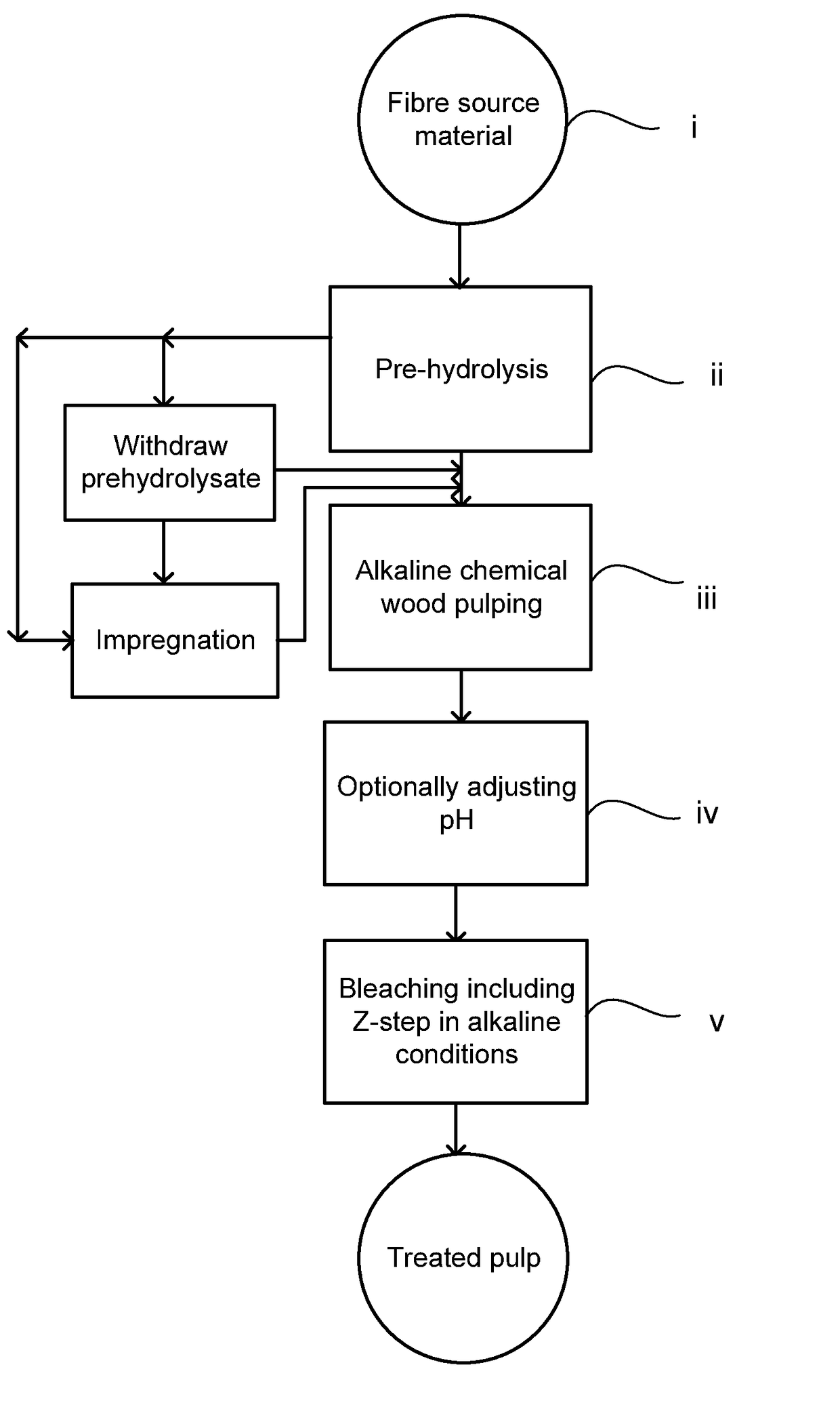

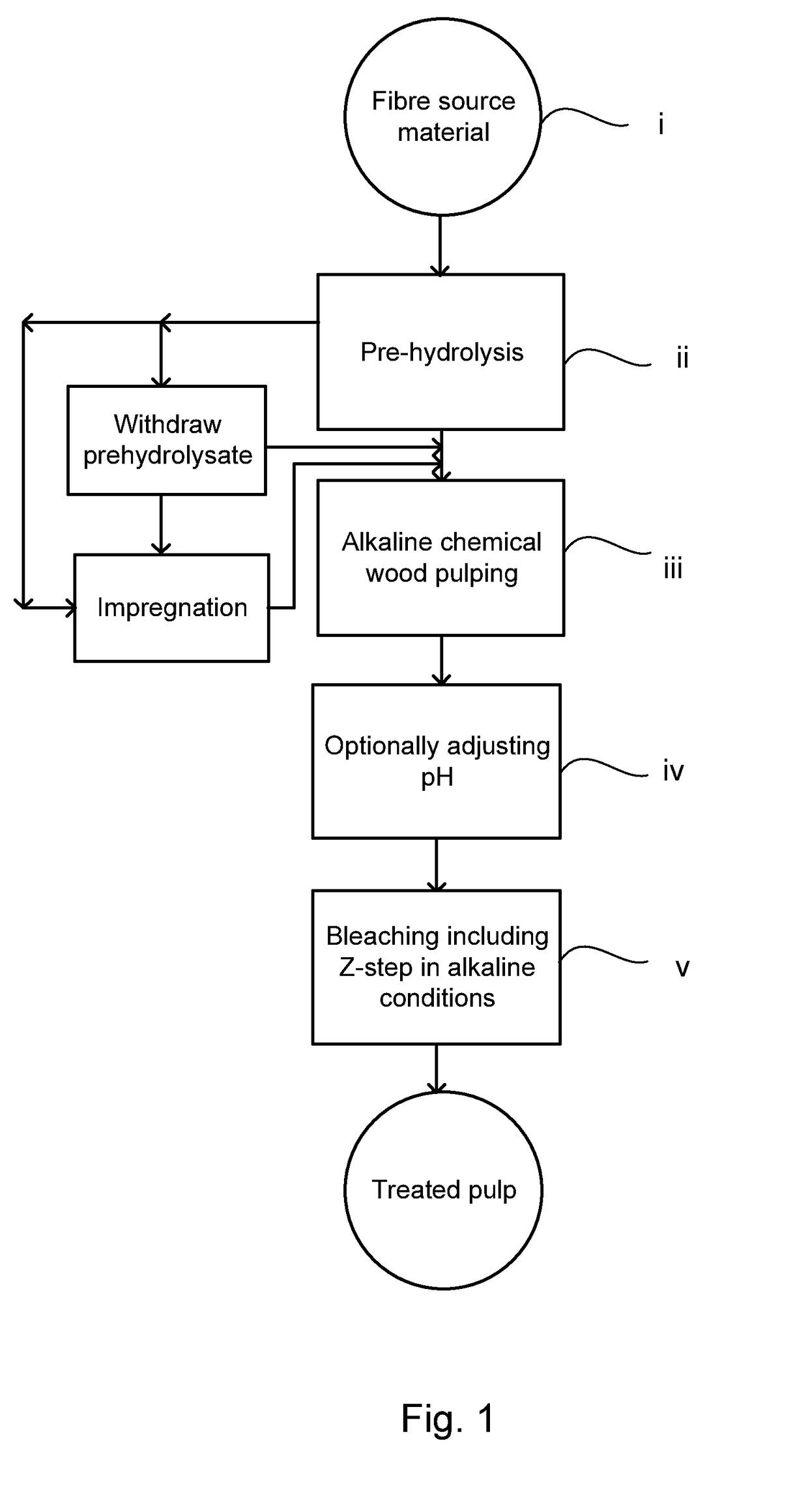

Process for the production of a treated pulp, treated pulp, and textile fibres produced from the treated pulp

InactiveUS20170314197A1Reduce riskImprove processing yieldPretreatment with water/steamArtificial filaments from cellulose solutionsFiberSource material

The present invention relates to a process for the production of treated pulp comprising the steps of: i. providing a fibre source material; ii. subjecting the fibre source material to pre-hydrolysis; iii. subjecting the pre-hydrolysed fibre source material to alkaline chemical pulping process, preferably kraft pulping, to obtain an alkaline pulp; iv. optionally adjusting the pH of the obtained pulp to above pH 9; v. subjecting the alkaline pulp to a bleaching sequence comprising contacting the pulp with ozone (Z) in alkaline conditions to obtain a treated pulp. The invention also relates to a treated pulp obtained, textile fibres produced from the treated pulp, textile products comprising the textile fibres and to the use of the treated pulp.

Owner:INNVENTIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com